6

SAFETY….cont

INTRODUCTION:

WE LEARN BY EXPERIENCE Learning safety through personal experience, like a child

touching a hot stove is harmful. wasteful. and unwise. Let the experience of others teach

you.

SAFE PRACTICES DEVELOPED FROM EXPERIENCE

in the use of welding and cutting are described in this manual. Research, development, and

field experience have evolved reliable equipment and safe installation, operation, and servic-

ing practices. Accidents occur when equipment is improperly used or maintained The reason

for these sole practices may not always be given. Some are based on common sense, others

may require technical volumes to explain, it is wiser to follow the rules.

READ AND UNDERSTAND THESE SAFE PRACTICES

before attempting to install, operate or service the equipment. Comply with these procedures

as applicable to the particular equipment used and their instruction manuals, for personal

safety and for the safety of others.

FAILURE TO OBSERVE THESE SAFE PRACTICES

may cause serious injury or death. When safety becomes a habit, the equipment can be used

with confidence.

GENERAL:

The plasma cutting machine is simple and safe to operate under normal circumstances. If the

unit is to be used under unusual circumstances, e.g. in wet or damp conditions, on boats or

oil rigs, or in an elevated position. Then extra thought must be given to any possible hazard

introduced by the situation.

ELECTRICAL:

A. DO NOT operate the machine with any of the panels removed.

B. DO NOT attempt any repairs unless you are a competent electrician.

C. Ensure that the machine is connected to the correct supply voltage through the recom-

mended fuse.

NB: This unit must be earthed.

D. DO NOT dismantle the protection nozzle from the torch without first switching off the

machine.

ELECTRIC SHOCK

Either AC or’ DC voltages associated with the cutting environment can cause severe

burns to the body or fatal shock. Severity of electrical shock is determined by the path

and amount of current through the body.

VENTILATION:

Ventilation must be adequate to remove the smoke and fumes during cutting. See

the relevant safety standard for acceptable levels.

FUMES:

Toxic gases may be given off when cutting, especially if zinc or cadmium coated

materials are involved. Cutting should be carried out in a well ventilated area, and

the operator should always be alert to fume build-up.

In small or confined places use a fume extractor.

VAPORS:

Vapors of chlorinated solvents can form the toxic gas phosgene when exposed to

U.V radiation from an electric arc. All solvents, degreasers and potential sources of

these vapors must be removed from the arc area.

NB: IF IN DOUBT SEEK PROFESSIONAL ADVICE.

GENERAL PRECAUTIONS:

BURN PREVENTION

1. Wear Protective Clothing leather gauntlet gloves, hat, and high safety toe

shoes. Button shirt collar and pocket flaps, and wear cuff less trousers to avoid entry

of sparks and slag.

2. Wear Helmet with Safety Goggles or glasses with side shields underneath, appro-

priate filter lenses or plates (protected by clear cover glass). This is a MUST for weld-

ing or cutting (and chipping) to protect the eyes from radiant energy and flying

metal. Replace cover glass when broken. pitted, or spattered.

3. Avoid oily or greasy clothing. A spark may ignite them.

4. Hot metal such as electrode stubs and work pieces should never be handled

without gloves.

5. Medical first aid and eye treatment. First aid facilities and a qualified first aid

person should be available for each shift unless medical facilities ore close by

for immediate treatment of flash burns to the eyes and skin.

Flammable hair preparations should not be used by persons intending to weld or

cut.

15

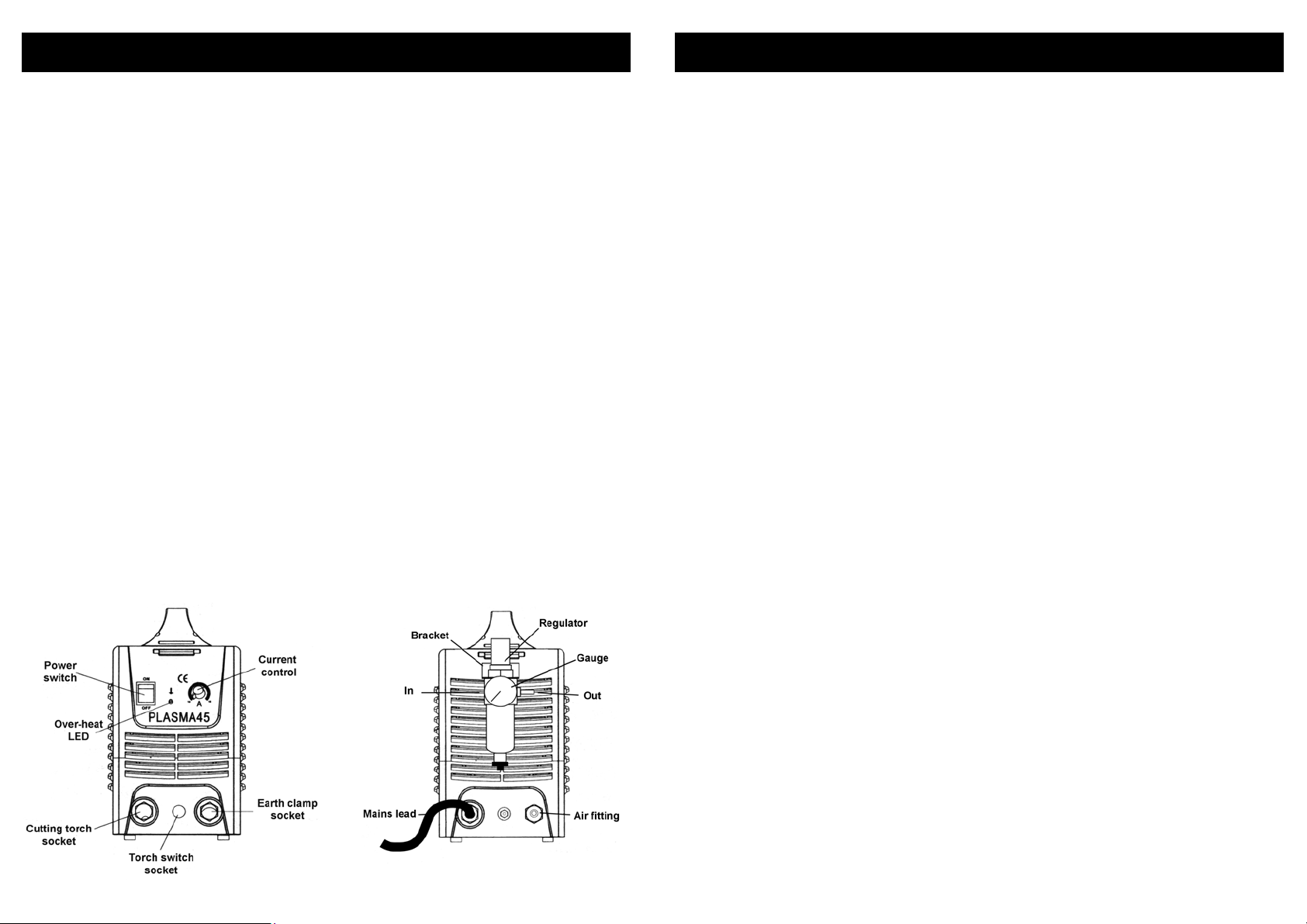

TORCH ASSEMBLY

Under no circumstances must the plasma nozzle be removed or any other work be

carried out on the torch with the machine switched on. Ignoring this precaution

could lead to serious burns or contact with high DC voltages.

If the machine has just been used for cutting, allow the cooling air to stop before

switching the machine off for torch servicing.

The torch should be kept free of slag at all times to ensure the free passage of air.

To assemble / dismantle the torch:

1. Invert the torch so the tip points upwards.

2. Unscrew and remove the shield cup.

3. Remove the Tip ,swirl baffle and electrode.

4. Ensure the torch head thread is upper most.

5. Fit electrode into end of torch head.

6. Fit swirl baffle onto electrode, ensure is it seated fully onto the electrode.

7. Fit tip onto the swirl baffle.

8. Fit shield cup and screw on.

The Tip and electrode need replacing when worn.

Indication of wear are a loss off cutting capacity or that the cut is no longer 90 de-

grees.

When inspecting the Tip look for erosion of the hole in the centre of the tip or a

build up of metal residue.

When inspecting the electrode look for erosion in centre of the electrode

MAINTENANCE

1. Clear dust from machine at regular intervals use clean dry compressed air,

if use in a dirty environment the machine should be cleaned once a

month.

2. Check all connections are clean and tight, if there is any oxidization clean

the connection with a mild abrasive or wire brush.

3. If the machine is not to be used for a long time, store it in the original pack-

ing a dry place.