2

Warnings on the device

Fig�: Danger of crushing

EU Declaration of conformity

Explanation Applied standards and directives

SIPOS Aktorik GmbH as manufacturer declares

herewith that the 2SA7 and 2SQ7 actuators

meet the basic requirements of the following

Directives:

2014/30/EU (EMC Directive)

2006/42/EC (Machinery Directive)

The following harmonized standards in terms of the

specied directives have been applied:

Directive 2014/30/EU: EN 61800 -3: 2004 /A1: 2012

Directive 2006/42/EC: EN ISO 12100:2010,

EN ISO 5210:1996; EN ISO 5211:2001,

DIN 3358:1982

SIPOS actuators are designed for the operation of industrial valves. Putting into service is prohibited

until the nal machinery has been declared in conformity with the provisions of Directive 2006/42/EC.

The following basic requirements in compliance with Annex I of the Directive are respected:

Annex I, articles 1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.6, 1.3.1, 1.3.7, 1.5.1, 1.6.3, 1.7.1, 1.7.3, 1.7.4

The manufacturer shall be obligated to electronically submit the documents for the partly completed

machinery to national authorities on request. The relevant technical documentation pertaining to the

machinery described in Annex VII, part B has been prepared.

Authorized person for documentation: Dr. Thomas Suckut, Im Erlet 2, 90518 Altdorf, Germany

The latest versions are available for download at http://www.sipos.de.

2 Assembly and connection

If the devices are used in non-industrial applications with increased safety requirements, they

have to be ensured by additional safety measures during assembly.

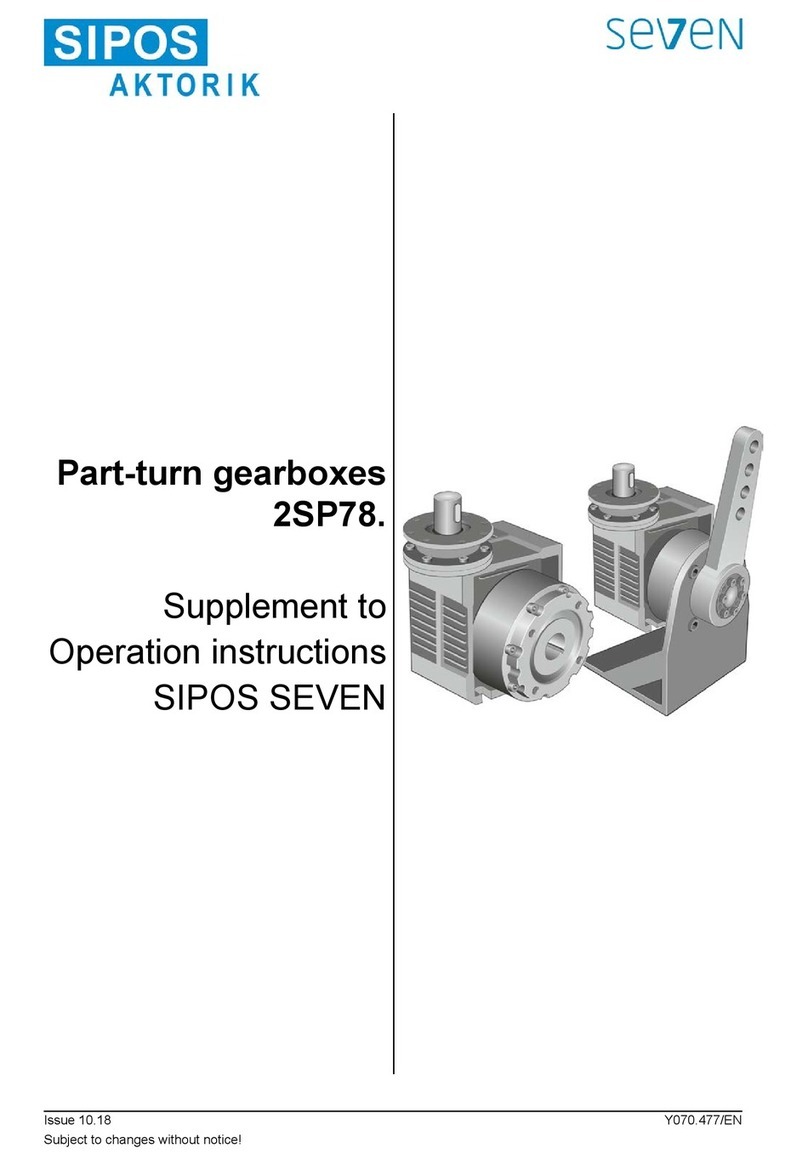

2�1 Mount to valve/gear

2�1�1 General assembly instructions for all output shaft types

■Mounting and operation is possible in any position. Heed the local ambient conditions, in

particular the vibration load, which can be caused when mounting an actuator to a vibrating

valve.

■Do not apply force and avoid shocks!

■Check that the end connection ange and the output shaft type match the valve/gear.

■Thoroughly clean mounting faces of output mounting anges at actuator and valve/gear.

■Slightly grease the connection points.

■The bolts used upon delivery are not greased. Use bolts with at least 8.8 quality. If similar

stainless steel bolts are used, they should be greased slightly using petroleum jelly.

Use screws with a depth of engagement of at least 1.25 x the thread diameter.

■The housing of the SIPOS SEVEN actuator consists of an aluminum alloy which is corrosion

resistant under normal environmental conditions. If the paint was damaged during assembly,

it can be touched up with original paint supplied in small quantity units by SIPOS Aktorik.

1�3 Disposal and recycling

1�3�1 Packaging

The packaging of our products consists of environmentally friendly materials which can easily be

separated and recycled. We use the following packaging materials: Wood-based panels (MSB/

OSB), cardboard, paper, PE foil. For the disposal of the packaging material, we recommend

recycling and collection centers.

1�3�2 Actuator

Our actuators have a modular design and may therefore be easily disassembled, separated and

sorted according to materials, i.e.: electronic parts, different metals, plastics, greases and oils.

The following generally applies:

■Collect greases and oils during disassembly. As a rule, these are substances hazardous to

water and must not be released into the environment.

■Arrange for controlled waste disposal of the disassembled material or for separate recycling

according to materials.

■Observe the national/local regulations for waste disposal.

Fig�: Transport

Danger of crushing. When pressing in the crank

handle or the hand wheel ensure that neither the

hand nor the ngers are crushed, refer to gure.

Applicable for devices of the 2SA7.5/6/7/8 series

(size 4): Indicates which type of lubricant was used,

refer to also to “Lubricant assignment and quantity”

section in these operation instructions.

Hot surface. Risk of hot surface temperatures

(caused by high ambient temperature and frequent

operation as well as long activation times).

1�2 Transport and storage

■The device must be supplied in sturdy packaging.

■For transport, loop the rope around the hand wheel housing,

refer to illustration. Only use the eyes (1) on the electronics

unit to lift the actuator's own weight, without neither addi-

tional gear nor valve.

■Do not attach the ropes and hooks at the crank handle or

hand wheel for the purpose of lifting.

■Store in well-ventilated, dry room

at -30 °C – +80 °C.

■Protection against damp oors: Either store actuator in a

shelf or pallet.

■Keep connection hood/cover and cable glands as well as the

cover of the electronics unit and position recording closed.