CONTENTS

1. Important note on safety.......................................................................... 4

2. General ...................................................................................................... 5

2.1 Range and main functions...................................................................................................5

2.2 Storage and Shipment ........................................................................................................6

2.3 Warranty............................................................................................................................6

3. Nomenclatures and technical information................................................ 7

3.1 Nomenclatures ...................................................................................................................7

3.1.1 - BWT MANAGER CONNECT DUO PH / Redox (family pools and spas) .............................7

3.1.2 - BWT MANAGER CONNECT DUO PH / Redox Panel (family pools and spas) ....................8

3.1.3 - BWT MANAGER CONNECT DUO PH / Redox / Free chlorine in an "open" cell (public

pools) ..................................................................................................................................9

3.1.4 - BWT MANAGER CONNECT DUO PH / Redox / Free chlorine in a "closed" cell (public

pools) ................................................................................................................................10

3.2 Nameplate .......................................................................................................................11

3.3 Technical features ............................................................................................................12

Main functions: ...................................................................................................................13

4. Installation and connections .................................................................. 14

4.1 Choice of installation site ..................................................................................................14

4.2 Wall-mounting of the cabinet ............................................................................................14

4.3 Installation of tapping saddles for probes ("free-standing" version) and product injections....16

Recommended for installation as a "free-standing" version:...................................................16

Recommended for installation as a "pre-mounted panel" version: ..........................................17

Mounting the tapping saddles:.............................................................................................18

Mounting the pH and redox probe holders:...........................................................................18

Mounting the injection kit ....................................................................................................19

Mounting the suction kit ......................................................................................................20

Mounting the pH and/or redox probes ..................................................................................20

4.4 Commissioning / Electrical connections ..............................................................................21

Changing the internal protection fuses .................................................................................23

4.4 Filling of chemical containers.............................................................................................23

5. Setting up and using the BWT Manager Connect Duo............................ 24

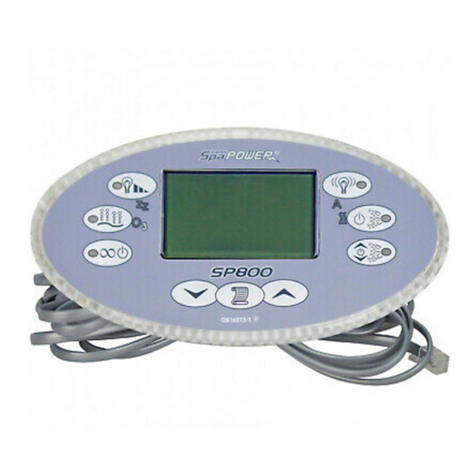

5.1 Keyboard .........................................................................................................................25

5.2 Main display .....................................................................................................................25

5.3 "Info"menu ......................................................................................................................25

5.4 Help menu .......................................................................................................................26

5.5 "Calibration" menu ...........................................................................................................26

5.6 Setup menu .....................................................................................................................27

5.7 Advanced settings menu ...................................................................................................29

6. pH probe calibration................................................................................ 34

7. Redox probe calibration.......................................................................... 35

8. Calibration of the free chlorine probe of the open amperometric cell .............. 36

9. Free Chlorine calibration of Amperometric closed cell.................................. 37

10. Temperature probe calibration ........................................................ 37

11. Proportional dosage (TWM): Time with modulation) with or without

overdose alarm ........................................................................................... 38