PURPOSE

The CRT-06 controller is multi-function, programmable electronic

devices which enable control of heating or cooling devices in

order to maintain a stable room temperature, as well as to control

ambient and substance temperatures in industrial conditions,

with the option of supervising technological processes.

CRT-06CRT-06

www.fif.com.pl

ul. Konstantynowska 79/81

tel/fax 48 42 2270971 POLAND

95-200 Pabianice

F&F products are covered by an 24 months warranty from date of purchase

DIGITAL TEMPERATURE

REGULATOR

DESCRIPTION OF CONTROL PANEL:

To work and programming of regulator CRT-06 is use control

panel. It include two line with eight sign on alfanumerical display

and keyboard with five buttons, which is situated under the

display.

In standard work mode on display are present values of

temperaturer which are measure by sensors C1 and C2. If is

connect only one sensors- C1, then at place on display for reprts

from C2 anything is diplaied.

Signs on the left side of display, signalize work mode of regulator

in position of output relay. This sign present:

In programming mode button Return make possible to

return main menu. If button will be push at edition mode,

then program return to main menu without save all

registry. Button Return enable to delete information

abaut errors.

BUTTONS FUNCTIONS:

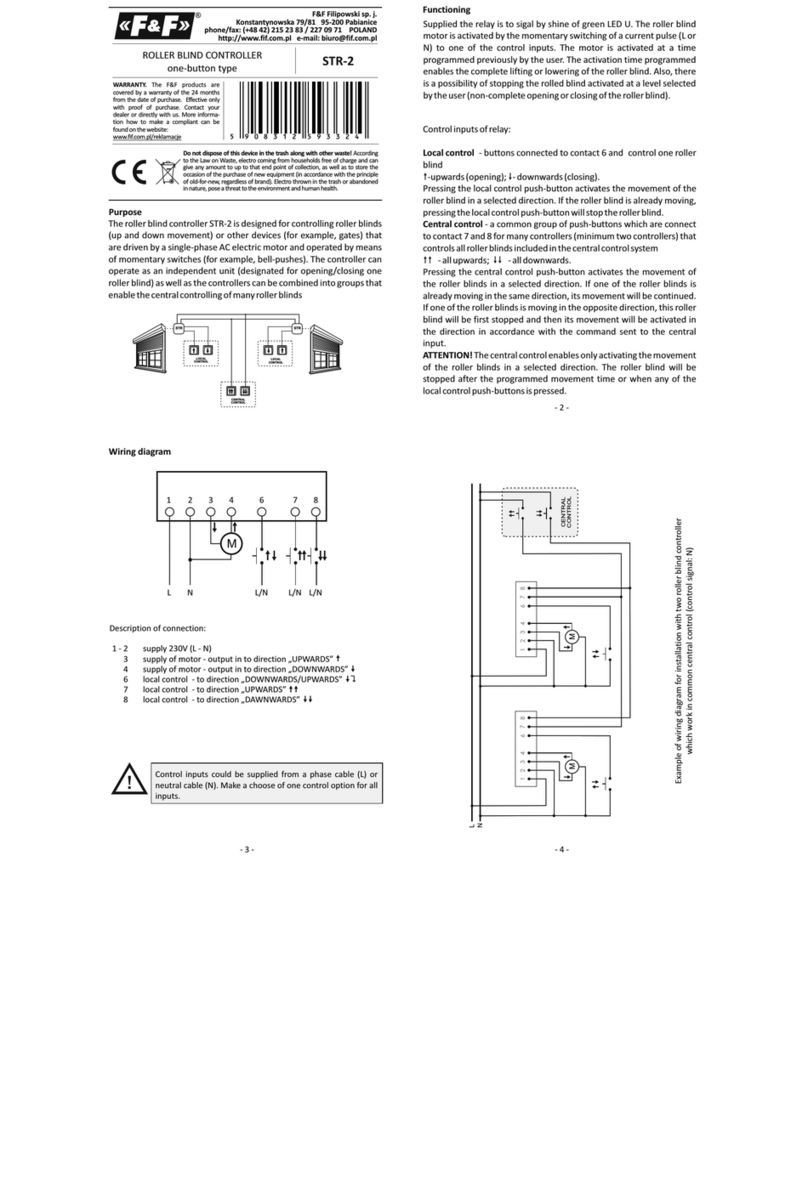

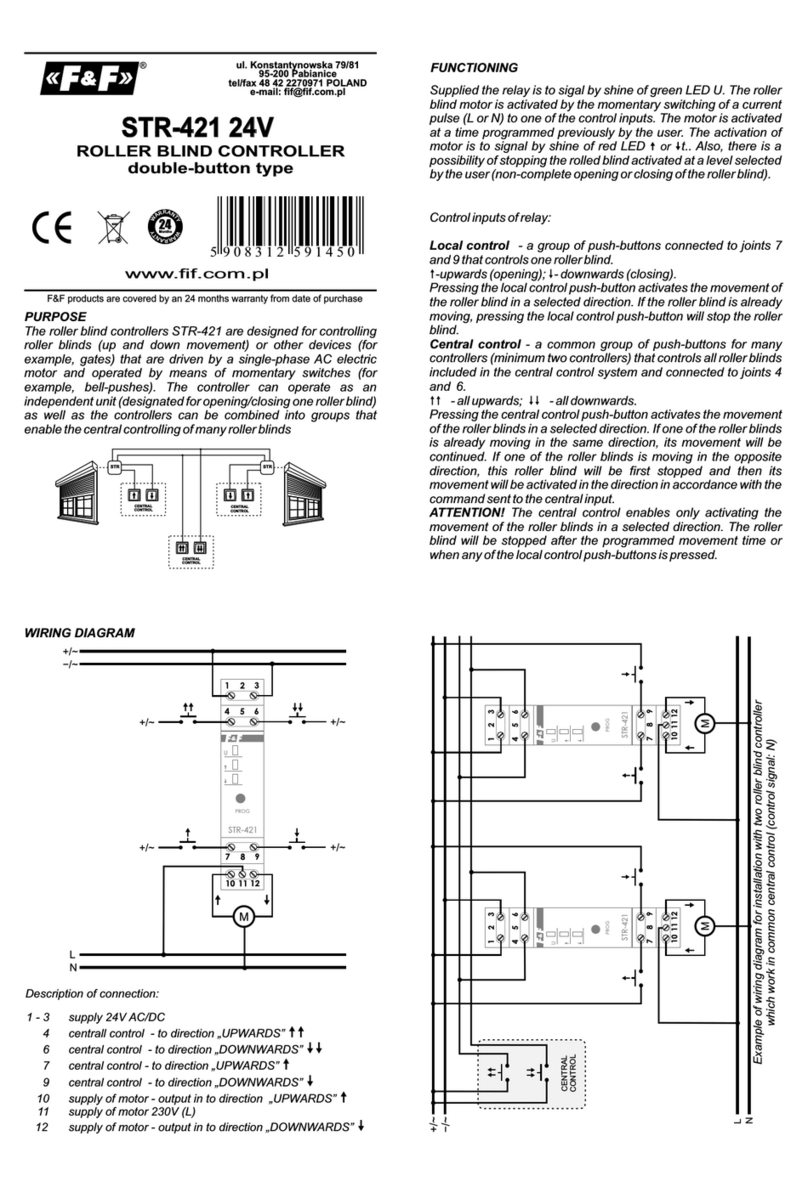

L1

L2

L3

CRT

N

N

L

N

N

CONTROLLERS FEATURES:

- controlling panel use for programming and monitor to work of

regulator

- possibilty of connection two independent temperature probes

PT-100

- two outputs of relay 1P which were attribute to sensors

- control panel for programming and monitoring;

- 10 operation functions;

- 2 independent temperature sensors;

- two independent temperature values may be set;

- 2 x 1P contacts applied to the temperature sensors;

- 2 hysteresis set values, one for each sensor;

- AUTOMATIC mode - operation with one selected function;

- MANUAL mode permanent closing or opening of the contact

without a temperature measurement. Separate temperature

drops for the P1 and P2 contacts.

- memory feature for maximum and minimum temperature values

registered, independent for the C1 and C2 sensors;

- CORRECTION related to the temperature read-out error

against the model thermometer;

- WARNING - visual signalisation of the temperature sensor

failure, range exceed and speed riasing or falling temperature

exceed

- limiting access to program menu using PIN code

- LIGHT selection of display illumination mode.

- LANGUAGE program menu in three languages: Polish, English

or Russian

CRT-05 is equipped to:

CRT-05

OKOK MenuMenu

+125şC

+97şC

Two liness,

with eight sign

alfanumeric

display

Controll

buttons

At programming mode buttons UP and DOWN make to

possibility to select position of menu and to increase or

reduce value of edited parameter.

In programming system mode button OK enable to pass

to selected position from menu and enter the changes.

In standard work button OK is use to change order

temparature T1 and T2 .

Button Menu enable to pass to programming mode of

regulator.

In change order value mode use it cause reconnection

between setting for first and secon sensor.

OKOK

MenuMenu

5 9 0 8 3 1 2 5 9 2 7 1 6

+125º

+97º

Reprts from

sensor C1

Reprts from

sensor C1

Position of output

realy P1

Position of output

realy P2

Open joint - automatic work mode

Open joint - manual work mode

Close joint - automatic work mode

Close joint - manula work mode