Siqura UTF 4200 TX-MSA /Bilinx User manual

UTF 42xx /Bilinx Series

Optical Video/Data Transmitters/Receivers

USER MANUAL

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference, in which case the user

may be required to take adequate measures. Please read section 6 of this Manual

1. General description

This user manual is valid for the following models:

Model

Description

Housing

UTF 4200 TX-MSA /Bilinx

Transmitter

2 x mm

Stand-alone

UTF 4200 RX /Bilinx

Receiver

2 x mm

Rack-mount

UTF 4200 RX-2 /Bilinx

Receiver

2 x mm

Rack-mount

UTF 4210 TX-MSA /Bilinx

Transmitter

1 x mm

Stand-alone

UTF 4210 RX /Bilinx

Receiver

1 x mm

Rack-mount

UTF 4210 RX-2 /Bilinx

Receiver

1 x mm

Rack-mount

UTF 4250 TX-MSA /Bilinx

Transmitter

1 x sm

Stand-alone

UTF 4250 RX /Bilinx

Receiver

1 x sm

Rack-mount

UTF 4250 RX-2 /Bilinx

Receiver

1 x sm

Rack-mount

UTF 42xx /Bilinx /SA

Stand-alone

Table 1. Models described in this user manual

mm = multimode fiber sm = single-mode fiber

A UTF (Up the FiberTM) transmitter (TX) converts a

composite video signal into a high-quality, 9-bit

digitised optical equivalent and transmits this over

single-mode or multimode optical fiber. All UTF

Bilinx units support the Bilinx protocol. The data

signal is to be put on the coax cable, using suitable

equipment. The bidirectional data link enables camera

control over the same, extended distances as can be

bridged with standard UTF 42xx equipment.

Additionally, the transmitter provides an independent,

voltage-free alarm contact (normally open) for door

contacts and anti-tamper contacts, for example.

Complementary UTF receivers (RX) receive and

convert the optical signal to video/contact closure.

UTF 4200 models use one transmission wavelength

(1300 nm), whereas UTF 4210 and 4250 models use

two (1310 nm and 1550 nm). RX-2 models are dual

units, each subunit capable of communicating with a

separate transmitter.

A wide range of operating temperatures makes the

stand-alone transmit ter suitable for use within outdoor

camera housings and camera connection boxes (see

datasheet).

The TX MSA miniature, stand-alone transmitter can be

powered by the camera power supply (12-24 Vdc or

24 Vac) or by a PSA/PSR 12 DC.

If 24 VAC is used, read section 3 first.

For operation under extreme environmental conditions,

the PSR 12 DC is recommended.

The UTF receivers (RX, RX-2) are designed for use in

a TKH Security MC power supply rack. The UTF

42xx/SA are the stand-alone versions of the rack-

mounted models. UTF 42xx systems are SNM

compatible.

The general connection layout is given in figure 1.

2. Indicators and connectors

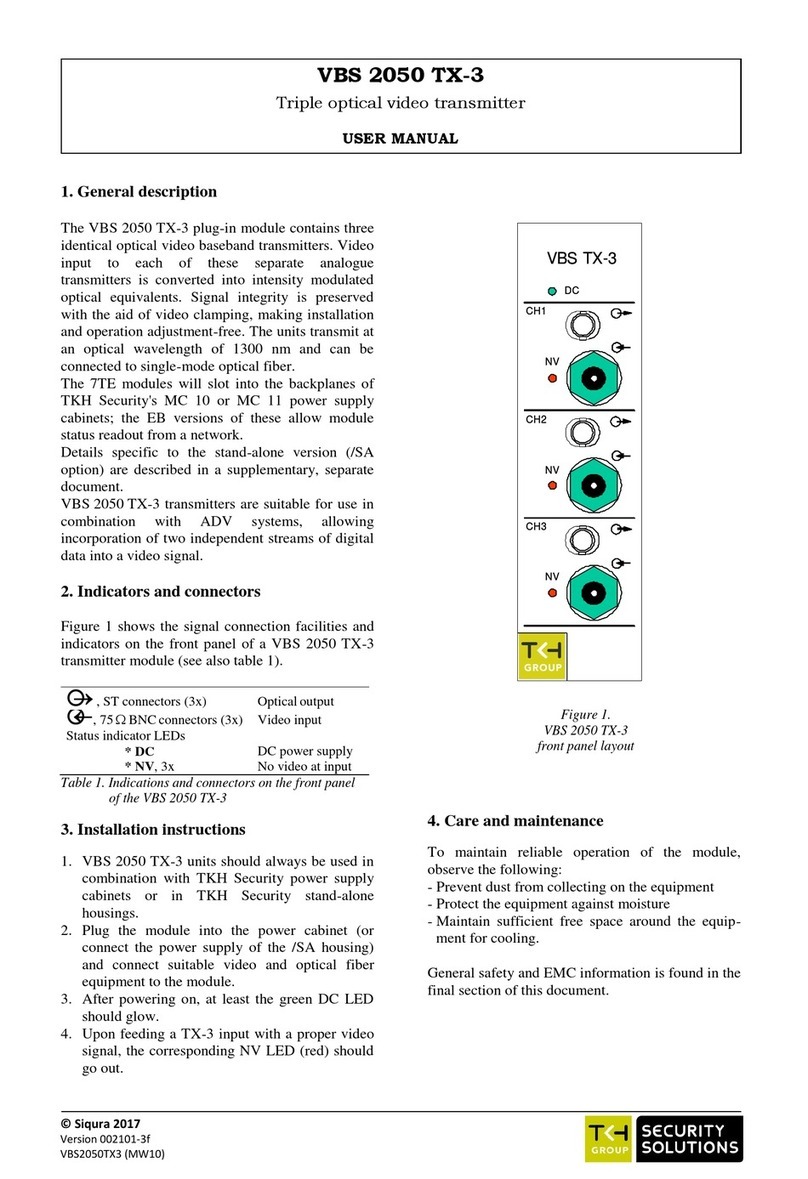

Transmitters

The miniature stand-alone UTF transmitter has the

following parts, indications, and connectors (figure 2a):

1: TX: Primary optical fiber connection

2: RX (unmarked): Secondary optical fiber connec-

tion (not used in 4210 and 4250 models)

3: BNC 75 Ω connector: Composite video input

4: DC: shows SYNC: This indicator can show:

Green: Operational link

Red: Local synchronisation error

Yellow: Remote synchronisation error.

5: Mounting bracket

6: CC/GND: 2-Pin Combicon connector for alarm

contacts

7: DC 12-24 V / AC 24 V: 2-Pin power supply

connector (Combicon)

49,7

49,6

47,5

TX

VIDEO IN

DC

GND

CC

DC 12-24V

AC 24V

Up-the-Fiber™

D I G I T A L

1

2

3

5

6

7

5

4

24,5 20,5

Figure 2b. Miniature UTF transmitter (TX-MSA),

side view. Sizes in millimetres.

Figure 1. UTF general connection; data may come from camera

fiber

video

contact closure

UTF

TX cc

UTF

RX

data

video

coax coax

Figure 2a. Indicators and connectors on the miniature

UTF transmitter (TX-MSA). Sizes in millimetres.

© Siqura 2017

Version 052706-2g

UTF 42xx BX(Bilinx) (MW10)

2

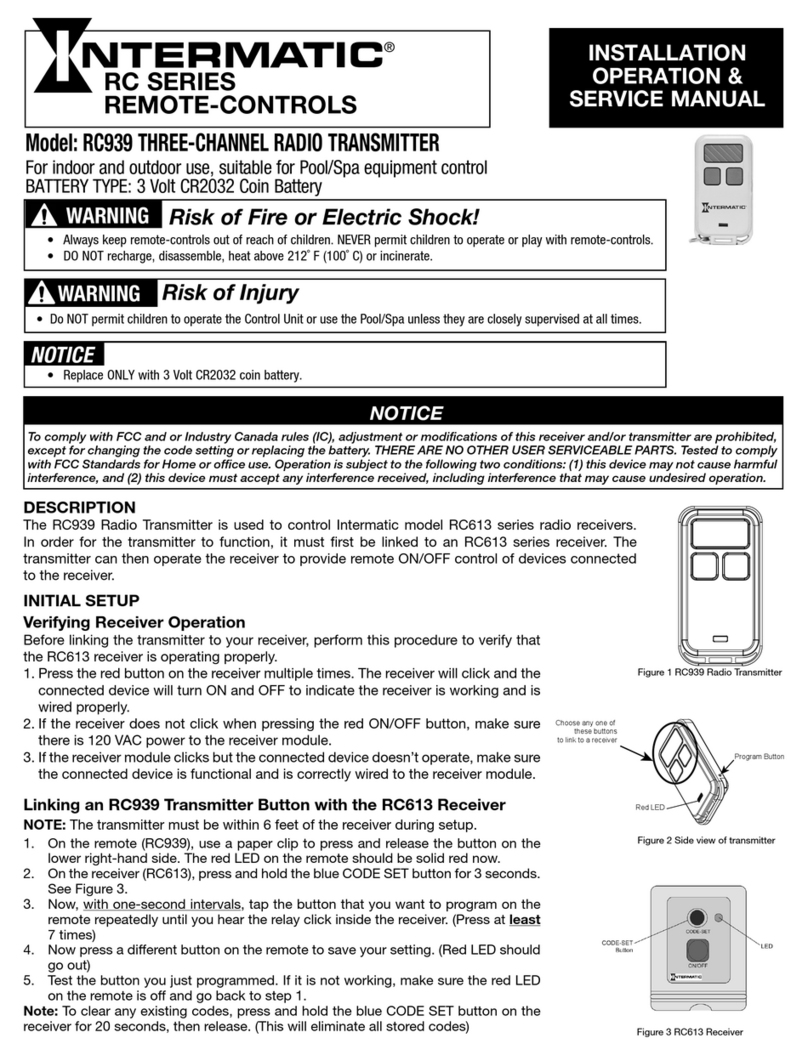

Receivers

The UTF Bilinx receivers (figures 3 and 4) have the

following indications and connectors:

1. SYNC: This LED can show:

Green: Operational link

Orange: Remote synchronisation error

Red: Local synchronisation error

2. NV: This LED can show:

Red: No video on in- or output

Off: Video signal present

3. Connector for potential-free alarm contacts:

RX model : 2-pin connector (channel CC1)

RX-2 model : 4-pin connector (channel CC1

and channel CC2)

4. BNC 75 Ω connector: Composite video output

5. TX: Connection for optical fiber

6. RX : Connection for optical fiber

In one-fiber units only TX is used.

3. Configuration and installation

!Note on powering of a UTF TX-MSA with 24 Vac

from the camera !

The miniature stand-alone transmitter can convert

24 Vac power through an internal full rectifier bridge;

the "-" of its internal DC voltage is connected to the

metal housing. If the camera uses the same Vac power

supply in parallel, but with a single-sided rectifier

circuit, the UTF power supply diodes may suffer, since

there always will be a connection between the housings

through the coax cable shielding. To prevent the

occurrence of such problems, proper measures must be

taken to separate the two loads of the 24 Vac supply;

this might be preferable in any case, as a precaution.

If in doubt, please contact your distributor.

Mounting

Before mounting the miniature transmitter, the

mounting bracket has to be installed in a suitable place.

After securing the bracket, the transmitter can be

clicked into it. Make sure the transmitter is positioned

and fixed correctly.

A stand-alone receiver can be easily installed; prevent

undue bending of cabling. In case more than one

receiver is needed, use TKH Security MC 10 or MC 11

cabinets.

Powering up a system

When powering up an appropriately connected system,

the "DC” indicator on the transmitter (if suitably

powered) should show green and the "SYNC" indicator

on the receiver should also light up green. If no video

signal is present, the corresponding "NV" indicator

shows red. DC and SYNC indicators on systems not

connected will light red.

Figure 3. Indications and connectors

on a UTF Bilinx RX receiver

Figure 4. Indications and connectors

on a UTF Bilinx RX-2 receiver

RX VIDEO

RX

NV

CCI

SYNC

1

2

3

4

6

TX

5

RX-2 VIDEO

VIDEO

CH2

RX

RX

CHI

NV

NV

CCI

CC2

SYNC

1

2

3

2

4

6

6

4

SYNC

1

TX

5

5

TX

3

4. Care and maintenance

The modules are designed to be maintenance free. To

guarantee reliable operation of the units, take the

following precautions:

prevent dust from collecting on or in the

equipment;

protect the equipment against moisture;

maintain cooling space around the equipment.

5. Technical specifications

For technical specifications, please refer to the data

sheet of the relevant model.

6. Safety, EMC, ESD

General

The safety information contained in this section, and on other

pages of this manual, must be observed whenever this unit is

operated, serviced, or repaired. Failure to comply with any

precaution, warning, or instruction noted in the manual is in

violation of the standards of design, manufacture, and intended

use of the unit.

Installation, adjustment, maintenance and repair of this

equipment are to be performed by trained personnel aware of the

hazards involved. For correct and safe use of the equipment and

in order to keep the equipment in a safe condition, it is essential

that both operating and servicing personnel follow standard safety

procedures in addition to the safety precautions and warnings

specified in this manual, and that this unit be installed in locations

accessible to trained service personnel only.

Siqura assumes no liability for the customer’s failure to comply

with any of these safety requirements.

UL/IEC/EN 60950-1: General safety requirements

The equipment described in this manual has been designed

and tested according to the UL/IEC/EN 60950-1 safety

requirements.

If there is any doubt regarding the safety of the equipment, do not

put it into operation. This might be the case when the equipment

shows physical damage or is stressed beyond tolerable limits (e.g.

during storage and transportation).

Before opening the equipment, disconnect it from all power

sources. The equipment must be powered by a SELV*) power

supply.

When this unit is operated in extremely elevated temperature

conditions, it is possible for internal and external metal surfaces

to become extremely hot.

Optical safety

This optical equipment contains Class 1M lasers or LEDs and

has been designed and tested to meet IEC 60825-

1:1993+A1+A2 and IEC 60825-2:2004 safety class 1M

requirements.

Optical equipment presents potential hazards to testing and

servicing personnel owing to high levels of optical radiation.

When using magnifying optical instruments, avoid looking

directly into the output of an operating transmitter or into the end

of a fiber connected to an operating transmitter, or there will be a

risk of permanent eye damage.Precautions should be taken to

prevent exposure to optical radiation when the unit is removed

from its enclosure or when the fiber is disconnected from the

unit. The optical radiation is invisible to the eye.

Use of controls or adjustments or procedures other than those

specified herein may result in hazardous radiation exposure.

The installer is responsible for ensuring that the label depicted

below (background: yellow; border and text: black) is present in

the restricted locations where this equipment is installed.

The locations of all optical connections are listed in the

Indications and Connectors section of this manual.

Optical outputs and wavelengths are listed in the Technical

Specifications section of this manual.

EMC

Warning: Operation of this equipment in a residential

environment could cause radio interference.

This device has been tested and found to meet the CE

regulations relating to EMC and complies with the limits for a

Class A device, pursuant to Part 15 of the FCC rules.

Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) This device

must accept any interference received, including interference that

may cause undesired operation. These limits are designed to

provide reasonable protection against interference to radio

communications in any installation. The equipment generates,

uses, and can radiate radio frequency energy; improper use or

special circumstances may cause interference to other equipment

or a performance decrease due to interference radiated by other

equipment. In such cases, the user will have to take appropriate

measures to reduce such interactions between this and other

equipment.

Note that the warning above does not apply to TKH Security

products which comply with the limits for a Class B device. For

product-specific details, refer to the EU Declaration of

Conformity.

Any interruption of the shielding inside or outside the equipment

could make the equipment more prone to fail EMC requirements.

To ensure EMC compliance of the equipment, use shielded cables

for all signal cables including Ethernet, such as CAT5E SF/UTP

or better, as defined in ISO IEC 11801. For power cables,

unshielded three wire cable (2p + PE) is acceptable Ensure that

all electrically connected components are carefully earthed and

protected against surges (high voltage transients caused by

switching or lightning).

ESD

Electrostatic discharge (ESD) can damage or destroy

electronic components. Proper precautions should be taken

against ESD when opening the equipment.

*) SELV: conforming to IEC 60950-1, <60 Vdc output, output voltage

galvanically isolated from mains. All power supplies or power supply

cabinets available from Siqura comply with these SELV requirements.

7. Product disposal

Recycling The unit contains valuable materials which

qualify for recycling. In the interest of protecting

the natural environment, properly recycling the

unit at the end of its service life is imperative.

8. EU Declaration of Conformity

The EU Declaration of Conformity for this product is available at

http://www.tkhsecurity.com/support-files.

Hazard Level 1M

This manual suits for next models

9

Table of contents

Other Siqura Transmitter manuals

Popular Transmitter manuals by other brands

Evikon

Evikon PluraSens E2638-SO2 user manual

Extron electronics

Extron electronics DTP T FB 332 user guide

Brähler Systems

Brähler Systems INFRACOM ICen IV operating instructions

R.V.R. Elettronica

R.V.R. Elettronica TEX1000LIGHT user manual

JTS

JTS PT-920B instruction manual

Kanardia

Kanardia Daqu installation manual