Sirman Sinfonia 2 User manual

20

AUTHORIZED

RESELLER

1

English

Fresh pasta machine

INSTRUCTIONS, USE AND MAINTENANCE MANUAL

2

Ed. 001 11/2015

2

19

English

18 3

English

CONTENTS

1. Delivery and warranty 5

1.1 Foreword

1.2 Preserving and using the manual

1.3 Warranty

1.4 Description of the machine

1.5 Permitted use

1.6 Improper use - not permitted use

1.7 Identification of the equipment

1.7.1 Warning plates

1.8 Safety devices and protections

1.9 Operating station

2. Technical features 9

2.1 Main components

2.2 Technical specifications

2.3 Dimensions and weight of the machine

2.4 Noise level

2.5 Electrical diagrams

2.5.1 Single-phase wiring diagram

3. Controls and indicator lights 11

3.1 List of controls and indicator lights

4. Inspection, shipping, delivery and installation 11

4.1 Inspection

4.2 Shipping and handling the machine

4.3 Installation

4.3.1 Disposing of the packaging

4.3.2 Handling the machine

4.4 Electrical connections

4.4.1 Single-phase machine 220 Volt 50 hz

5. Start up and shut down 12

5.1 Checking the electrical connections

5.2 Checking the presence and effectiveness of safety

devices and guards

5.3 Checking the effectiveness of the emergency button

5.4 Machine start up

5.5 Machine shut down

6. Using the machine 13

6.1 Instructions

6.2

Dough preparation

6.3 Extrusion

6.4 Using the dough cutter

4

7. Maintenance 14

7.1 Lubrication

7.2 Cleaning the machine

7.2.1 How to remove tools

7.3 Waste Electrical and Electronic Equipment WEEE

8. Trouble-shooting 15

8.1 Trouble-shooting

17

English

8 - Trouble-Shooting

8.1 - Trouble-shooting

Problem

1 - The machine does not start up

2 - The fun is nor working

3 - The dough does not flow out

Cause

1.1 The differential switch is positioned to “0”.

1.2 The main switch is positioned to “0”

1.3 The start up button is faulty

1.4 Ensure all safety devices are enabled and working properly

2.1 - The light switch is not lit

2.2 - The fun got burnt out

3.1 - The extruder is dirty

3.2 - The machine is running in mixing mode

Solutions

1.1 - Bring the switch to “I” position

1.2 - Bring the switch to “I” position

1.3 - Contact the Technical Assistance

1.4 - Check the safety devices and protections

2.1 - Start the fun up by means of the light switch

2.2 - Contact the Technical Assistance

3.1 - Clean the extruder

3.2 - Shut the machine down and push the extruding mode button

7.5 Waste Electrical and Electronic Equipment WEEE

INFORMATION INTENDED FOR USERS

Pursuant to article 13 of the Legislative Decree n. 151, July 25

th

, 2005 "implementation of Di-

rective 2002/95/EC, 2002/96/EC and 2003/108/EC, related to the restrictions on the use of hazard-

ous substances in electrical and electronic equipment, as well as waste disposal”

The crossed bin symbol on the device or its packaging

indicates that , at the end of their life, the product must be collected separately from other

waste.

The separate collection at the end of this machinery life is organized and managed by the

manufacturer. The user who wishes to dispose of this equipment must contact the manufac-

turer and follow the procedure adopted to allow separate collection at the end of life.

Appropriate separate collection and subsequent decommissioning for recycling, treatment

and environmentally compatible disposal helps prevent negative impact on the environment

and health, and promotes the reuse and / or recycling of materials the equipment is made of.

Illegal disposal of the product involves

application of administrative sanctions provided by law.

16

7.4 - Disassembling the shovel and the

tank

- Unlock the fixing paddle rod by lifting

the lever (fig. 7.4.1)

- Grab the knob fixing rod and pull

until it is out and has freed the paddle

- Open the cover and remove the paddle by

pulling it out of its seat.

- Clean and wash the paddle

- Clean and wash the inside of the basin

by removing the product residues

7.4.1 Assembling the paddle

- With the cover open, insert the paddle in the basin;

make sure it is firmly fitted in its housing.

- Grab the knob fixing rod and push it down to lock the paddle

- Lower the lever and lock the paddle fixing rod

- Close the cover.

Fig. 7.4.2

Fig. 7.4.2

Fig. 7.4.1

5

English

1 - Delivery and warranty

1.1 - Foreword

WARNING!

The symbols used in this manual are intended to draw the reader's attention to

points and dangerous operations as regards personnel and operators safety as

well as the risks to damage the machine.

Do not operate the machine unless you are not certain to have understood proper-

ly the meaning of these indications.

WARNING!

For clarity, some illustrations in this Manual show the equipment or parts of it with

the panels or casings removed.

Do not use the machine in such conditions. The machine has to be used only

when all guards are in place.

This manual cannot be reproduced, even partially, without the consent of the man-

ufacturer and its contents can not be used for purposes not permitted by the manu-

facturer.

Any violation of the copyright mentioned above could lead to prosecution under law.

1.2 Preserving and using the manual

The purpose of this manual is to give the users by means of texts and images the

recommendations and essential criteria related to transport, handling, use and

maintenance of the machine. Read this manual carefully prior to using the machine.

The Manual must be preserved in a known easily accessible place, available for

consultation whenever required. If the Manual is lost, damaged or becomes illegible,

contact your reseller or directly manufacturer for a copy.

If the equipment concerned changes ownership, the Manual has to be handed over to

the new owner.

This manual reflects the state of the techniques at the moment the machine has been

placed on the market and it doesn't has to be considered obsolete just because not yet

updated according to the new expertise. The manufacturer reserves the right to update

the production and related manuals without updating the production and the previous

manuals, except for special cases. In case of doubts, please contact the nearest

Customer Assistance Service of the manufacturer.

The manufacturer aims to continuously improve its products.

For this reason, the manufacturer is keen to receive any report or proposal aimed at

improving the machine and / or the manual. The equipment has been delivered to the

user under warranty conditions at the moment of the purchase.

Please contact the manufacturer for further details.

1.3 Warranty

Under no circumstances the user is allowed to tamper with the machine. In case of

fault refer to your supplier.

Any attempt of the user or unauthorized personnel to disassemble, modify or more

generally tamper with any part of the machine will cause the Declaration of Con-

formity drawn up in accordance with EEC Directives 2006/42 to lapse, it shall void

the warranty and will relieved the Manufacturer from damages caused by such

behaviour.

6

The Manufacturer shall be relieved of all liability in the following situations:

- incorrect installation;.

- improper use of the equipment by inadequately trained personnel;

- use contrary to regulations in force in the country where the equipment is used;

- omitted or poor maintenance;

- use of non-original spares or not specific for the model;

- total or partial non-compliance with these instructions- with spare parts that are

not original or are not specific for the model.

1.4 Description of the machine

The machine in your possession is a simple, compact, highly efficient and powerful

equipment.

Since it must be used in food applications, the components were

carefully chosen to provide maximum hygiene.

• The basin is made of electropolished stainless steel.

• The tools are made of stainless steel to ensure durability

and maximum hygiene.

• Cast stainless steel spout

• Copper extruders.

- Ventilated single-phase motors offering the following advantages:

• consistency, high performance and durability of the motor;

• increases the real operation time due to fewer interruptions;

- It provides two operation modes: mixing and extruding.

- Maximum mixing capacity 2,5 kg

- Pre-arranged for dough-cutter installation.

The version represented in this manual have been built in compliance with EC

Directive 2006/42 and further modifications.

In case of accident, no responsibility can be charged to the manufacturer if the

machine has been modified, tampered with, if it has been used with the safety

guards removed or for purposes not permitted by the manufacturer.

1.5 Permitted use

The machine was designed and built for fresh pasta production.

It is to be used in professional environments; the machine operator has to be spe-

cialize din the field and have read and understood this manual. Do not use the

machine unless safely fixed to a solid workbench.

1.6 Improper use not permitted

The machine must be used exclusively for the purposes intended by the manufac-

turer; in particular:

- do not

use the machine for food products other than those indicated by the manufacturer.

- do not

use the machine unless it has been properly installed with all the protections

intact and properly assembled to avoid the risk of severe injury.

- do not access the electrical components without having previously disconnected

the machine from the mains: ones risks electrocution.

- Follow

the indicated flour / liquid quantities. Wrong quantities of ingredients

can

generate permanent damage to the machine.

- Do not wear clothing which do not follow the safety regulations.

Check with your employer as regards the safety regulations and safety equipment

to be provided with.

15

English

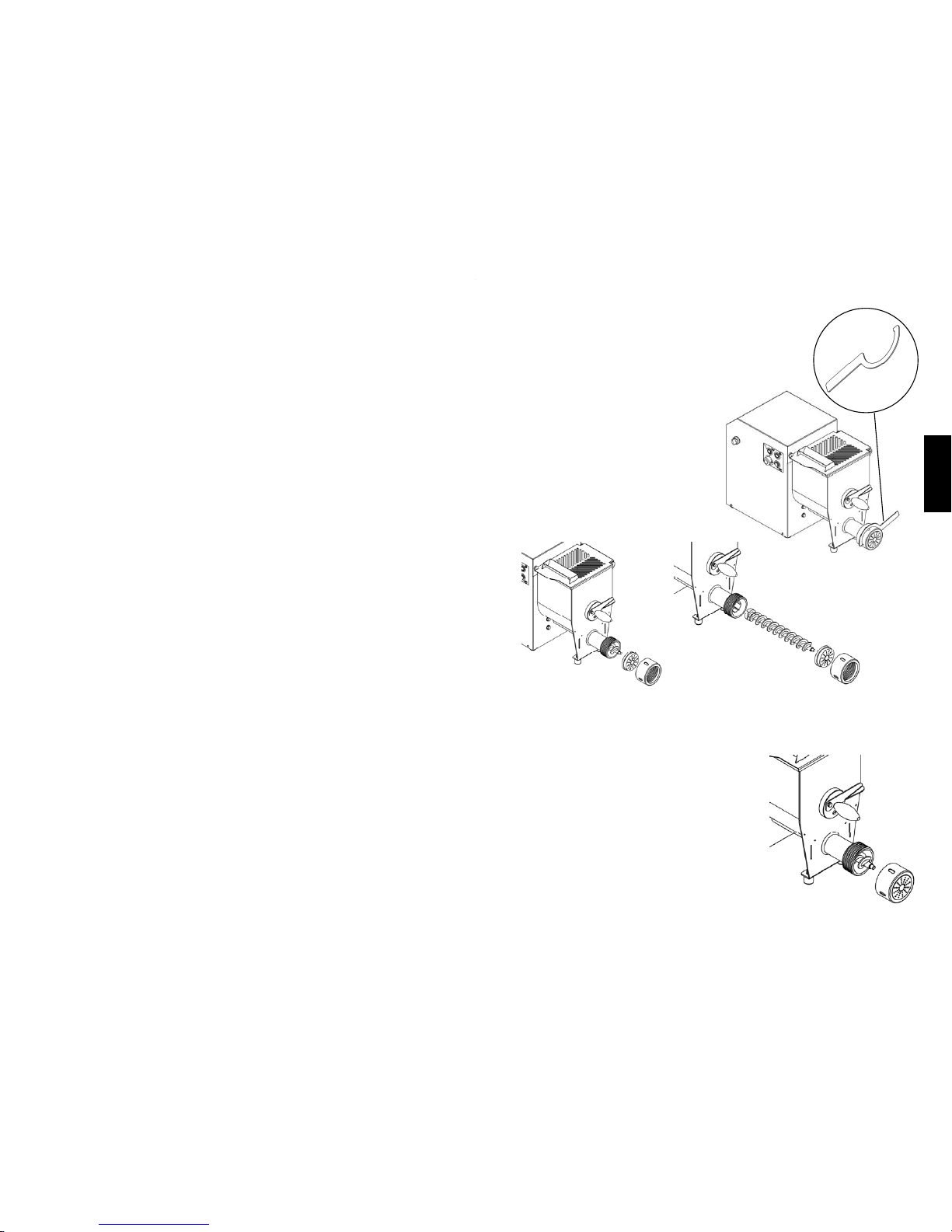

7.3 - Removing the locking ring, extruder, spiral and

cleaning the spout

- Loosen the nut by means of the special spanner (supplied)

unscrew it manually completely and then remove it.

- Pull out the extruder and wash it thoroughly.

Dip it in a bowl containing

water and vinegar

- Remove the spiral from the spout, clean

it and wash it thoroughly

- Remove from the inside of the overflow

spout all dough residues.

7.3.1 - Extruder maintenance

When not in use, it is recommended to keep the extruders soaked in a vessel con-

taining water and vinegar to prevent any pasta residues from drying out and block

the extruded pasta outlet.

7.3.2 - Assembling the spiral, the extruder and

the locking ring

- Insert the propeller in the spout

- Fit the extruder to the locking ring (fig. 7.3.4)

- Fasten the locking ring to the spout

- Loosen the locking ring by means of the special

spanner

Fig. 7.3.1

Fig. 7.3.2 Fig. 7.3.3

Fig. 7.3.4

14

7 - Maintenance

7.1 Prescriptions

WARNING! All maintenance and cleaning intervention must only be carried out with

the machine shut down and disconnected from the mains.

The area where maintenance is performed must always be clean and dry.

Do not allow unauthorized personnel to operate on the machine.

Any possible replacement of components, including the replacement tools, must be

carried out with original spare parts by authorized workshops or directly by the man-

ufacturer.

7.1 - Lubrication

The machine does not require lubrication.

7.2 Cleaning the machine

WARNING! Unplug the machine from the mains before cleaning.

Do not wash the machine with pressurized water jet.

Use non toxic detergents and expressly intended for the cleaning of food compo-

nents.

7.2.1 – How to remove the tools

At the end of each work cycle, in order to clean the machine you must remove the

work tools

How to remove the mixer blade:

1 – Put blade “1” in position as shown in fig. 7.2.1

2 – Lift lever “2” and pull out rod “3”

3 – Remove blade “1” by pulling it upwards.

WARNING! If the blade is not locked in position

as shown in fig. 7.2.1 it cannot be removed.

How to remove the propeller

1 – unscrew nut 4

2 – remove draw-plate 5

3 – remove propeller 6

WARNING!

After each kneading, ensure the propelling pivots are thor-

oughly cleaned so the blade and Archimedean screw can be

properly assembled (fig 7.2.2)

Fig. 7.2.2

1

Fig. 7.2.1

2

3

5

4

6

7

English

- Do not use the equipment if damaged.

- Before using the machine make sure that any dangerous condition

has been

appropriately cleared. In case of abnormal operation, stop the machine and warn the

persons in charge with maintenance.

- Do not allow unauthorized persons to operate on the equipment.

The emergency treatment in case of an accident caused by electrical shock

implies to first remove the contact between the injured person from the conductor

(since usually the person faints). This is dangerous operation. The victim in this

case is a conductor: touch him/her could imply being electrocuted.

It should therefore first be remove contacts directly from the supply valve,

otherwise move the victim using insulating materials (wood or PVC stick, cloth,

leather, etc.). It is recommended to call for medical staff, the patient has to be

transferred to a hospital.

1.7 - Identification of the equipment

Providing an exact description of the "Version", the "Serial Number" and the '' Year

of manufacture" of the machine will allow rapid and effective answer from our cus-

tomer service. It is recommended to indicate the machine version and serial num-

ber whenever you call for service.

Collect these data from the plate shown in Fig. 1.7.1. It is suggested to insert the ma-

chine identification data in the following table:

WARNING!

Do not alter the data on the identification plate under

any any circumstances.

Machine version…………………………..

Serial No.…………………………………..

Year of manufacture……………………...

Type………………………………………...

A = machine version

B = Voltage

C = motor power

D = motor frequency Hz

E = Weight

F = Amperage

G = Year of manufacture

H = Serial No.

I = Manufacturer

L = Barcode

A

B C

D E

F G

H

I

L

Fig. 1.7.1

8

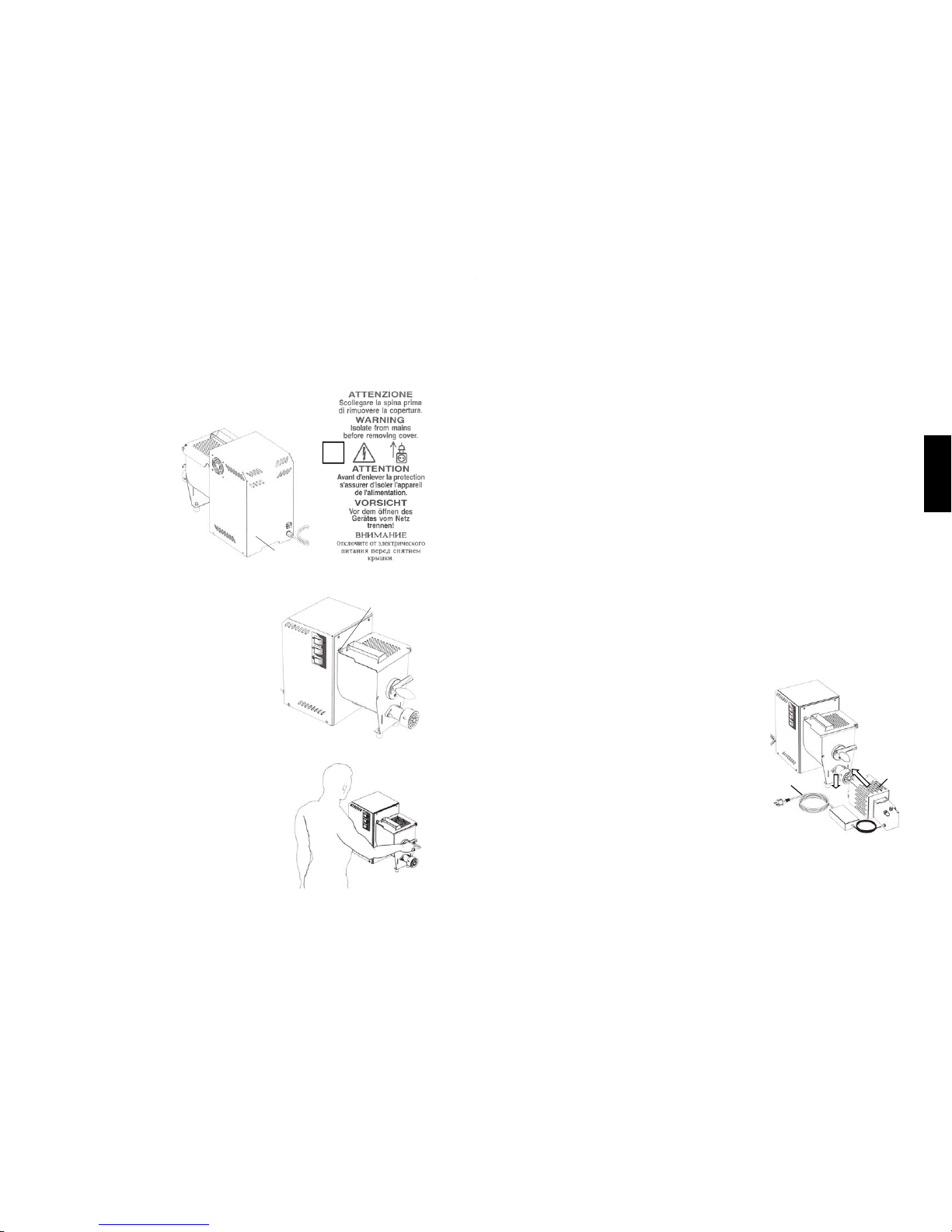

1.7.1 - Warning plates (fig. 1.7.2)

WARNING!

Do not intervene on electrical components when the machine is connected to the

mains. Ones risks electrocution. Follow the indications on the plates.

Failure to comply to the recommendations could result in

personal injury. Make sure the plates are always in place

and readable. Otherwise apply or replace them.

1.8 - Safety devices and protections

WARNING!

Before use ensure that all the safety devices are

installed and working properly.

Before each working shift ensure that all the safe-

ty devices are installed and that they are working

properly. Otherwise contact the person in charge

with maintenance activity.

1 - The sensor prevents the mixer from starting, if

the lid is lifted. If you open the interlocked lid

during operation, the mixer stops: close the lid,

press the OFF switch and then ON to start the

mixer again.

WARNING!

Do not tamper with the safety devices.

1.9 - Operating station

The correct position that the operator must occupy

to optimize the working with the machine is shown

in fig. 1.9.1.

Fig. 1.7.2 A

A

1

Fig. 1.8.1

Fig. 1.9.1

13

English

6 Description of the machine

6.1 Prescriptions

WARNING!

Only authorized personnel can operate on the machine.

Priori to the start up the operator must first ensure all the guards are in place and

all the safety devices are present and effective.

Otherwise, shut the machine down

and contact the operator in charge with maintenance.

Ensure that the of flour / egg ratio is always 1kg of flour / 400 g of egg.

Prior to start up, arrange the machine with the suitable extruder, spiral and mixing

paddle

6.2 - Dough preparation

1 - Pour the flour mix in the mixing basin

2 - Close the top cover and insert the funnel on the feeder cap

3 - Select mixer mode by means of the selector button “2” (fig 3.1.1)

4 - Start the machine in mixer mode by means of the button "1" (Fig. 3.1.1)

5 - Start the motor fan by means of the air vent switch "1" (Fig 3.1.1)

6 - Start pouring the eggs already beaten in the feeder funnel

7 - After the eggs where poured, wait for the dough to be ready (about 15 min)

8 - Shut down the machine

6.3 - Extrusion

1 - Ensure the proper extruder is fitted on the locking ring

2 - Select extruding mode by means of the selector button “2” (fig 3.1.1)

3 - Start the machine in extruding mode by means of the button 1 (fig 3.1.1)

4 - The spiral will process the dough. Once the pasta will reach an adequate

pressure the extruding will begin.

5 - Cut with a knife the dough that comes out of the extruder to the necessary

length

6 - When the basin is empty, shut off the machine.

6.4 - Using the dough cutter

1 - Fit the dough cutter "1" (fig 6.4.1) to the machine

by inserting it in the slits at the sides of the

product outlet.

2 - Plug the connector "2" (fig. 6.4.1) into the

connector "3" (fig 6.4.1)

3 - Start the machine in extruding mode

4 - Use the potentiometer "4" (fig 6.4.1) to vary the

rotation speed of the cutter so as to cut the dough

to the desired length

1

2

Fig. 6.4.1

12

4.3.2 - Handling the machine

WARNING! Handle the machine with care and attention, avoid accidental falls that

could damage it. To avoid muscle strain, when lifting the machine, use the force of

the legs.

4.4 - Electrical connections

WARNING!

Ensure the mains match the voltage given on the equipment’s ID plate. All interventions

must be carried out exclusively by specialized and expressly authorized personnel. Carrie

out the electrical connection to properly earthed mains.

4.4.1 - Single phase machine 220 V / 50 Hz

In this version the machine is supplied with a power

cable having 3 x 1.5 mm cross section. The cable

is connected to a three-poles single-phased plug.

Connect the cable to single phase 220 Volt-50 Hz

mains; interpose a differential circuit breaker of 16 amps.

In installations with voltages other than those mentioned, please

consult the manufacturer. Should it be necessary to lengthen the

power cable, use a cable having the a cross section that matches

the one installed by the manufacturer.

5 Starting-up and shutting-down

5.1 - Checking the electrical connections

Connect the plug to the mains and press the start button (3 Fig. 3.1.1). The ma-

chine gets enable din extruding mode; ensure the spiral direction of rotation is

counter-clockwise.

Otherwise, disconnect the machine from the mains and contact your supplier.

Note:

In the machines connected to a single phase line, manufactured for this specific power sup-

ply, the correct direction of rotation is determined directly by the manufacturer.

5.2 - Checking the efficiency of safety guards and devices

1 - Top lid

When the lid is lifted, the machine must stop.

The machine must not start, when the lid is open.

5.3 Checking the efficiency of the OFF switch (fig.3.1.1)

When machine is plugged and tools are in movement, press the OFF switch (1)

Fig.3.1.1. The machine must stop.

5.4 - Starting the machine (fig. 3.1.1)

Connect the plug to the electric mains, select the operation mode (mixing/extruding)

with the selector (2), press the ON switch (1) Fig. 3.1.1, the mixer will start.

5.5 Stopping the machine (fig.3.1.1)

To stop the mixer, press the OFF switch (1) Fig. 3.1.1

9

English

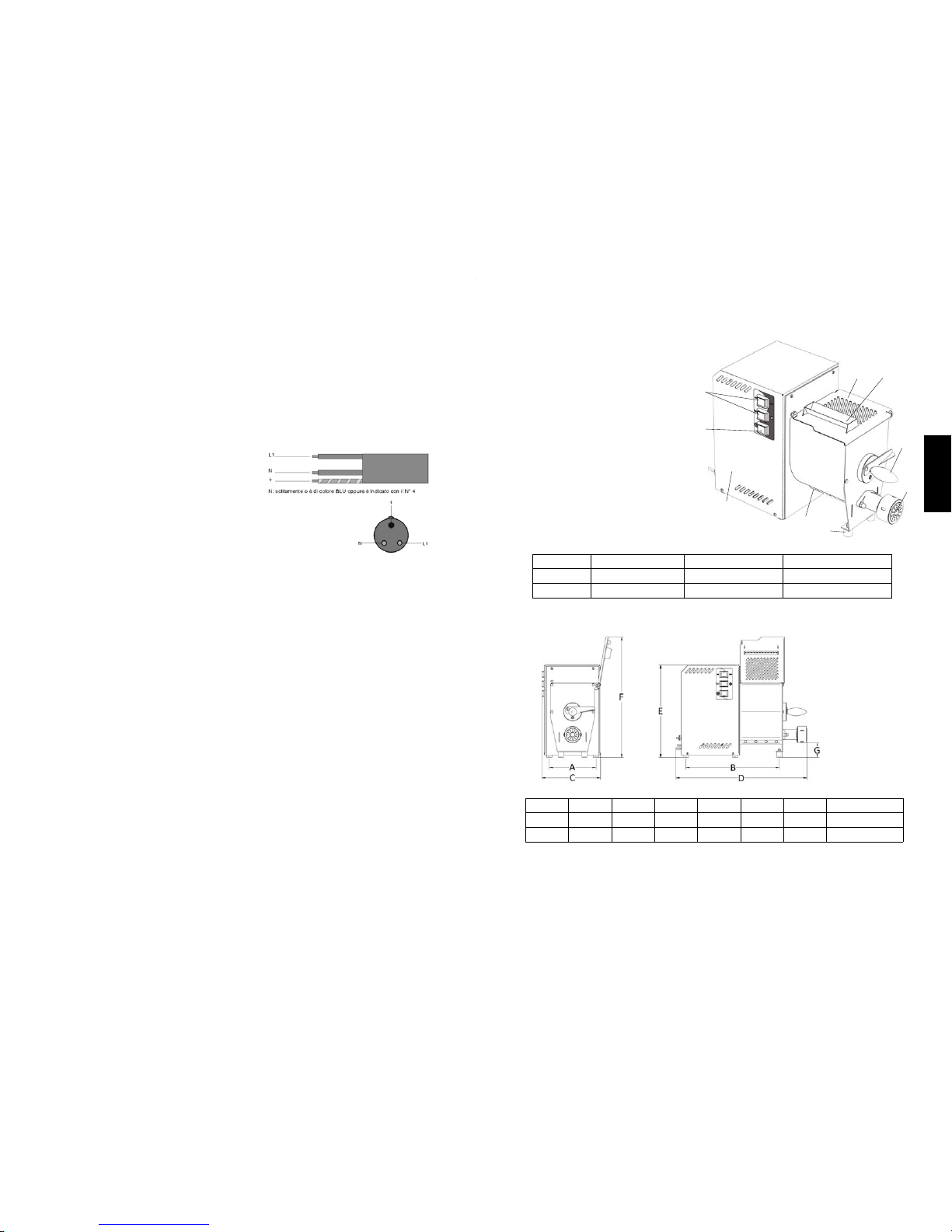

2 -Technical features

2.1 - Main components

To facilitate the understanding of the

manual, hereafter there are listed

below and shown in fig. 2.1.1. the

main parts of the machine

1 - Feet

2 - Dough basin

3 - Copper extruders

4 - Feeder funnel

5 - Commands

6 - Fan switch

7 - Casing

8 - Interlocked cover

9 - Paddle release

2.2 - Technical features

2.3 - Dimensions and weight of the machine

2.4- Noise level

The measured machine equivalent noise level does not exceed 70 dB.

Motor Supply Hourly capacity Extruders

watt/hp V/Hz kg/h. ø mm

370/1 230/50 559

ABCDEFGNet weight

mm mm mm mm mm mm mm kg

206 411 258 580 406 530 64 28

1

2

3

4

5

6

7

8

9

Fig. 2.1.1

Fig. 2.3.1

10

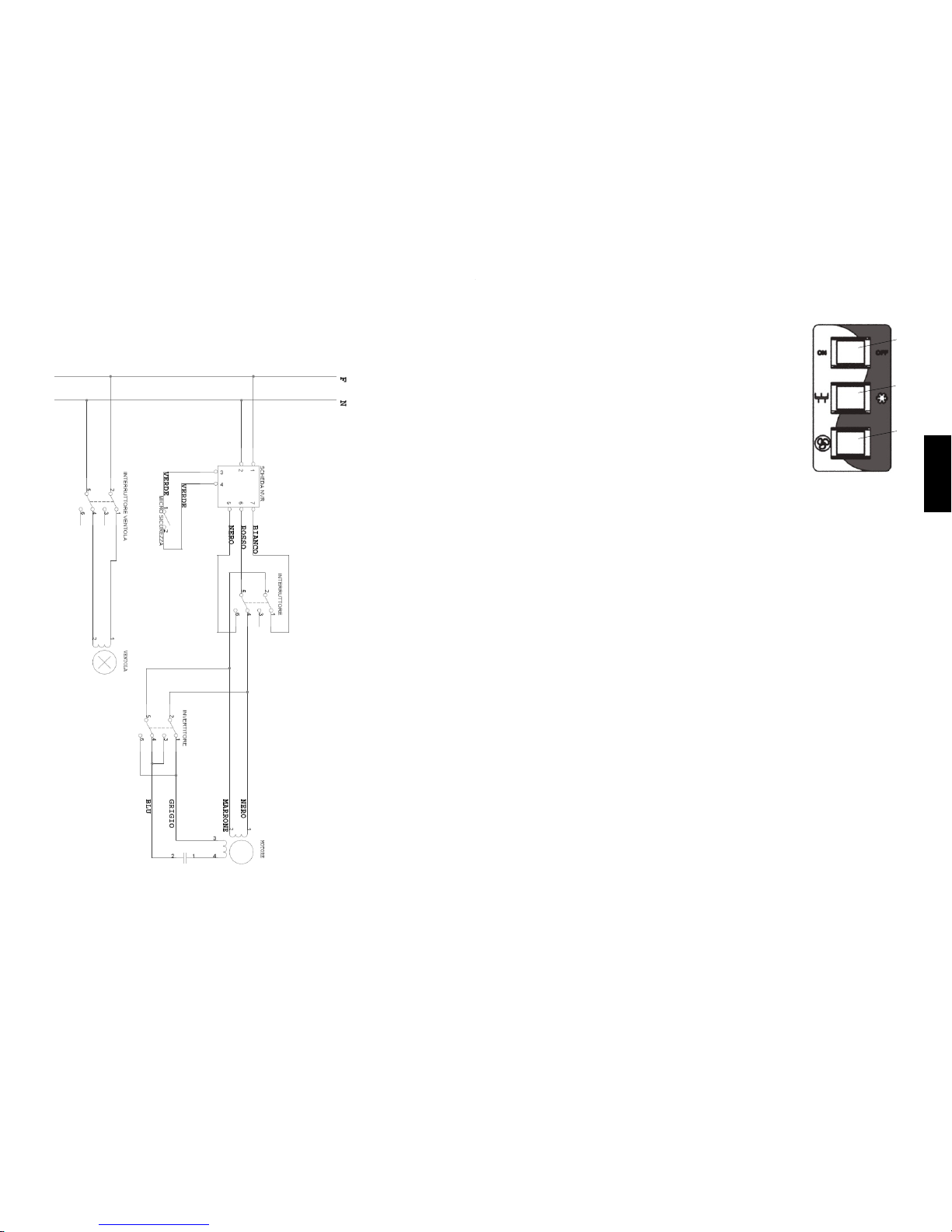

2.5 - Electrical diagrams

2.5.1 - Single phase electrical diagram

11

English

3 - List of controls and indicator lights

3.1 - List of controls and indicator lights

1 - Start switch

It starts the mixer in the selected operation mode.

2 - Extruding/mixing mode selector

It allows to select the operation mode: mixing mode (the spiral

moves the product inside the bowl) or extruding mode (the

spiral pushes the product towards the die). To shift mode,

stop the mixer, select the mode and start the machine.

3 - Fan indicator switch

It starts the fan for internal ventilation and to cool the motor. The LED inside the

switch is lit, when you switch on the fan.

4 - Inspection, shipping, delivery and installation

4.1 Inspection

The equipment in your possession has been tested at our factory to verify that all moving

parts work properly and it is properly adjusted. The tests are carried out with materials simi-

lar to those processed by the user.

4.2 - Shipping and handling the machine

All materials shipped have been thoroughly checked before delivery to the shipping compa-

ny. Unless otherwise agreed upon with the customer, the machine is wrapped with nylon

and fixed with steel straps on the bench, cover by a box which is also fixed with steel straps

to the pallet. On receiving the machine, check the integrity of the packaging. In case of dam-

age to the packaging, the carrier shall sign the notice of receipt for instance which should

sound like this: "I tentatively accept..." and the reason.

ON opening the packaging, in case of badly damaged components of the machine, file a

complaint to the shipping company within three days from the date indicated on the docu-

ments.

4.3 - Installation

WARNING!

The machine installation area has to be sturdy and the surface has to ensure a safe sup-

port. When positioning the machine keep extensive space around it. This allows greater

manoeuvrability during operation and ensures access for maintenance. Prepare suitable

lighting around the machine to ensure proper visibility to the machine operator.

- Remove the cellophane wrapping off the machine and other packaging present on the

inside.

4.3.1 - Disposing the packaging

The components such as cardboard, nylon, wood products are comparable to municipal

solid wastes. They can therefore be freely disposed off. The Nylon is a pollutant material

that produces toxic fumes when burned. Do not burn it; dispose it off in accordance with the

laws in force regarding the matter. If the machine is delivered in countries where special

rules are implemented, the packaging must be disposed off according to such regulations.

Fig. 3.1.1

1

2

3

Table of contents

Popular Pasta Maker manuals by other brands

Ernesto

Ernesto 331467 1907 Operation and safety notes

Marcato

Marcato AtlasMotor Wellness Instructions for use and maintenance

Imperia

Imperia Chef-in-Casa 750 instruction manual

IMPERIA & MONFERRINA S.p.A.

IMPERIA & MONFERRINA S.p.A. P6 User and maintenance manual

amzchef

amzchef DT-A-0 instruction manual

Imperia

Imperia PASTA PRESTO NSP Instruction handbook