Siro ERB35LE User manual

Battery Motor – Radio Drive

ERB35LE

03-2020

1

1. General safety guidelines

Notes on the product

Check the drive for intactness. Do not use the product if you discover any damage.

In this case, contact the point of sale.

Only use the drive to open and close suitable hangings.

Read this manual completely before starting the installation.

Make sure that the roller blind’s tube, in which you intend to use the drive, is

undamaged.

Check that the blind can be opened and closed smoothly.

Replace damaged parts if you find any defects.

Inform all persons in safe use of the controls and the drive.

Observe the blind during the operation and keep people away until the blind is

fully opened or closed.

Do not allow children to play with the control unit.

2. Electrical connection

The distance between the drive and the transmitter should be at least 300 mm.

The distance between the two radio receivers should be at least 500 mm.

Strong, local transmitters (e.g. radio headphones) whose transmission frequency is identical

to the control (433MHz) can influence the function.

It is recommended to fully charge the drive with the CH264 charger before the first

commissioning. Only then will the motor reach full power. The charger is equipped with a

control display that allows you to check the charge level at any time. During charging, the

indicator lamp lights up red. Green when the engine is fully charged.

The engine can also be operated and programmed during charging.

2

3. Programming of the remote control (radio) transmitters

3.1 Check the connection between the engine and transmitter

1. up button

2. stop button

3. down button

4. set button (P2)

1. Test the connection between the handheld transmitter (remote controller) and the motor by

pressing the up or down button to move the drive up or down. If the connection exists,

please go directly to point 3.3.

2. If the motor does not move, you must first establish the connection between the motor and

the transmitter.

Important: For all programming, please only use the left P2 button as shown.

3.2 Establishing and deleting the connection between the motor and the remote

controller

Establish connection:

The connection from the drive to the remote controller is thus established. You can now control

the drive by pressing the up and down buttons on the remote controller.

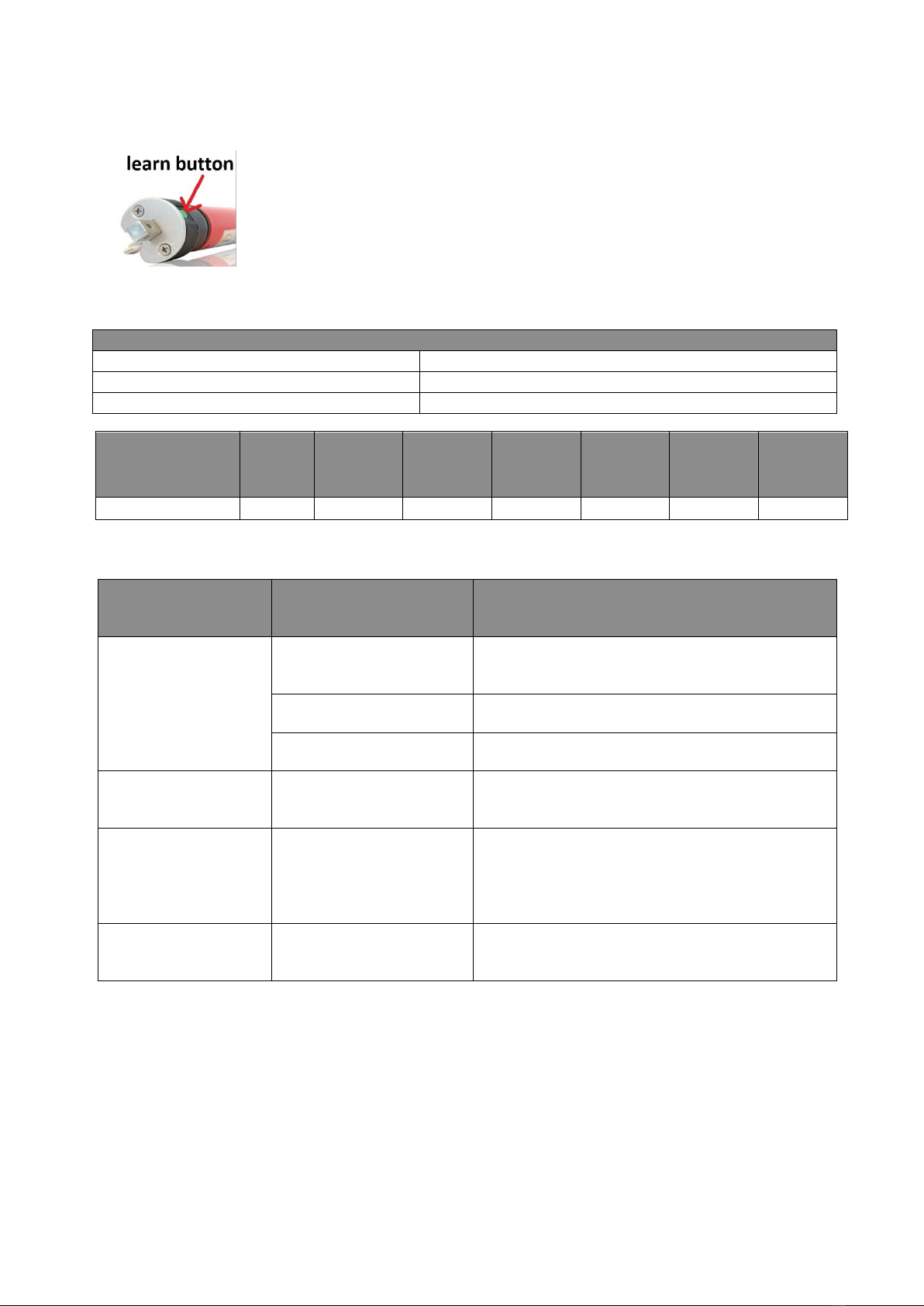

1. Press and hold the learn

button on the motor head

until the drive reacts

(usually after 3 seconds)

with a beep and an up/down

movement. Release the

learn button immediately.

2. Press the P2 button

twice. When pressed for

the first time, the drive

responds with a beep and

an up/down movement.

When pressed twice, the

drive responds with only

one beep.

3. Press the up

button once. The

drive confirms with

several beeps and an

up/down movement.

3

Delete connection:

3.3 Check and change the direction of rotation of the drive

Important: Please ensure the direction of rotation before starting to input the motor. We are

not liable for product damage caused by negligence during installation.

If the direction of rotation is reversed, you must repeat all the steps in section 3.2 under

Establish connection. Only in step 3 press the down button instead of the up button on the

remote control.

The direction of rotation is now changed.

4. Installation of the motor

Do not hit the motor with hard objects – not even to push it into the winding shaft.

This can cause damage to the drive and roller blind’s shaft.

Avoid installing the tubular motor in damp places or places where it comes into

contact with water

Installation

Place the tubular motor into the roller blind’s shaft.

The driver and adapter must be completely recessed into the winding shaft. The adapter must

be first pushed into the groove provided for this purpose on the crown of the motor head.

The drive head of the motor can be installed on the right or left side.

During installation, make sure that the drive head can be reached at any time after installation

in order to charge the drive via the external power supply.

1. Press the P2 button

once. The drive confirms

with a beep and an

up/down movement.

3. Press the P2 button

once. The drive confirms

with several beeps and an

up/down movement.

2. Press the stop button

once. The drive confirms

with a beep and an

up/down movement.

4

5. Setting the end positions

You need to define the upper and lower end positions, when reaching these, the

drive switches off automatically. To do this, the drive system must be fully inserted.

You can choose whether to set the lower or upper end position first.

The time between each button combination should not exceed 6 seconds.

Otherwise, the setting status is aborted.

After each command, the drive reacts with an up/down movement. This indicates

that the drive has recognised the respective command.

With some roller blind fabrics, enormous temperature fluctuations cause the fabric

length to change. Depending on the fabric and overall length, in extreme cases, there

can be a shortening in cold weathers and a lengthening at high temperatures, which

can even be in the centimetre range. Especially for cassette systems it is absolutely

necessary not to parameterize the upper end position up to the stop but to leave at

least 1 cm clearance!

In the following, the settings of the end positions are described, starting with the lower end

point.

5.1 Setting the desired end positions:

Thus, both end positions are set. The drive will automatically stop at the respective end

positions during operations.

Please note that saving the setting is only effective if both end positions are set.

5.2 Delete the end positions

1. Press the P2 button on

the remote controller, then

the up button and again the

P2 button. Each time it is

pressed, the drive responds

with a beep and an up/down

movement. At the end the

drive responds with several

beeps. You are now in the

setting mode.

2. Use the down button on

the remote controller to

move the motor to the

lower desired end position

and stop it there using the

stop button. Then press

and hold the stop button

again until the drive

confirms with several beeps

and a subsequent up/down

movement.

3. Use the up button on the

remote controller to move

the motor to the lower

desired end position and stop

it there using the stop

button. Then press and hold

the stop button again until

the drive confirms with

several beeps and a

subsequent up/down

movement.

Press 1x P2 button, 1x down button and 1x P2

button. The drive confirms as always with a beep

and an up/down movement. At the end, the drive

confirms with several beeps. Both end positions are

now deleted. You can set new end positions now.

5

6. Reset to factory settings

7. Technical data

Technical data

Power supply:

DC12V

Protection class:

IP44

Operating temperature:

0°C to +50°C

Definition

Diameter

D

(mm)

Length

L

(mm)

Torque

(Nm)

Rotational

speed

(U/min)

Voltage

(V)

Power

input

(mA)

Weight

(g)

ERB35LE

35

670

3,0

28

12

1660

1330

8. Bug fixing

Problem

Possible cause

Solution

Drive does not run

Battery weak

Charge the drive via the mains connection

on the motor head with the corresponding

charger.

Remote controller

without function

Change to a new battery.

Transmitter is not set

up

Establish the connection between the motor

and the transmitter (see 3.2).

Drive is very slow,

even with charged

battery

Incorrect installation

Make sure that the shaft, materials and

drive can move freely.

Drive stops in-

between both end

positions

Adapter or roller

capsule not positioned

correctly

Check that the adapter is correctly seated

on the groove provided in the crown and, if

necessary, screw the roller capsule into the

shaft with a locking screw.

The end position

changes marginally

Fabric changes due to

temperature

differences

Reset end position (see 5.1).

9. Warranty conditions

SIRO Antriebs- und Steuerungstechnik offers a 2-year warranty on new drives that have been

professionally installed and properly operated in accordance with the installation instructions.

The warranty covers all design faults, material defects and manufacturing faults.

Any defects occurring within the warranty period will be remedied by SIRO free of charge by

supplying an equivalent or new product. Replacement delivery for warranty reasons does not

result in general extensions of the original warranty period.

Any claims for compensation beyond this are excluded.

Press and hold the learn button on the motor head with

an object until the drive reacts only 3 times with a

up/down movement and 3 beeps. Release the learn

button again. The motor is now set to the factory

settings. All previous connections and settings are

deleted.

Table of contents

Other Siro DC Drive manuals

Popular DC Drive manuals by other brands

olympia electronics

olympia electronics BS-164 quick start guide

RGC

RGC 250E instructions

ZIEHL-ABEGG

ZIEHL-ABEGG ZETADYN 3C Original operating instructions

Digga

Digga PDD-PD50 Service & repair manual

Holex

Holex 83 4655 Instructions for use

Siemens

Siemens SINAMICS GM150 Operating instructions & installation instructions

elero

elero SunTop Operating and assembly instructions

Espa

Espa Evopool SilenPlus instruction manual

Piezoconcept

Piezoconcept HS1 Installation and operation manual

nord

nord NORDAC SK 200E troubleshooting guide

MAIMAN ELECTRONICS

MAIMAN ELECTRONICS SF6030 user manual

Danfoss

Danfoss AME 25 SU operating guide