Sirona DAC PROFESSIONAL User manual

båÖäáëÜ

a^`=PROFESSIONAL

pÉêîáÅÉ=j~åì~ä =

Sirona Dental Systems GmbH

Operating Instructions DAC Professional

59 57 928 D 3370

2D 3370.201.01.11.02

Content Page

Installation of the Dac Professional…………………………………………… 2

Maintenance…………………………………………………………………... 9

Fault 1: Vacuum system………………………………………………………. 15

Fault 2: Steam generator……………………………………………………… 20

Fault 4: Pressure Release……………………………………………………… 21

Fault 6: Ventilation……………………………………………………………. 22

Fault 8: Time base…………………………………………………………... 23

Fault 9: Door open…………………………………………………………….. 24

Fault 10: Overheating of the Steam generator………………………………… 25

Fault 12: Door locking………………………………………………………... 27

Fault 14: No feed water……………………………………………………….. 28

Fault 18: Sensor “nr” Input “ nr”……………………………………………... 32

Fault 21: Preheating…………………………………………………………… 34

Fault 22: Overheating of preheating…………………………………………... 35

Fault 26: A/D-converter………………………………………………………. 36

Fault 27: Temp.Sens.def 1,2…………………………………………………... 37

Fault 29: Battery RAM………………………………………………………... 38

Fault 31: System leak…………………………………………………………. 39

Fault 32: Power loss / Sterilize sterile filter…………………………………... 41

Fault 33: Pressure loss………………………………………………………… 42

Fault 34: Sterilization TU……………………………………………………... 43

Fault 35: Sterilization TO……………………………………………………... 46

Fault 36: Sterilization PU……………………………………………………... 48

Fault 37: Sterilization PO……………………………………………………... 49

Fault 38: Sterilisation TD……………………………………………………... 50

Fault 48: Parameters…………………………………………………………... 51

Possible solutions for drying problems……………………………………….. 52

Cycle printout…………………………………………………………………. 53

Cycle process………………………………………………………………….. 54

Saturated steam table………………………………………………………….. 55

Helix test………………………………………………………………………. 56

Bowie & Dick test…………………………………………………………….. 57

Valve diagram………………………………………………………………… 58

Diagnosis program……………………………………………………………. 59

Service program………………………………………………………………. 60

Revision history……………………………………………………………….. 61

Installation of the DAC Professional

Figure 1 General features

1 Water storage tank 11Power cable

2 Emergency overflow (OUT) 12Front adjustable feet of the unit

3 One-way drain (OUT) 13 Serial data and printer interface (RS 232).

In combination with NitraWin use serial modem cable

4 Spring-operated safety valve –

release betw. 2.9 – 3 bar 14Fuses for the unit: 2 ×16 A / FF

5 Connection for demineralised /

distilled water (OUT) 15 Power switch

6 Sterile filter 16Sliding-lock handle

7 Connection for pressure release

for water storage tank (IN) 17Hinged door (opens to the left)

8 Cooler/Blower 18Operator’s control and monitoring panel

19Cover to water tank9 Connection for demineralised /

distilled water (IN) (quick-fitted

threaded connection for 6 x 1

hose)

20Drain hose for water tank, drain side (OUT)

10Connection for 8 x 1 pressure

release (OUT) 21 Drain hose for water tank, demineralised-water side (OUT)

12

13

14

15

16

17

19

18

20 21

Rear view

1

6

7

8

10

11

2

3

4

5

9

Side view

175 150 250

370

460

70

55

09/21/2006 2/61 Servicemanual DAC Professional

Required Space:

Before setting up the autoclave you should make sure that the following requirements are met:

The DAC Professional is not designed to be installed in a cupboard or enclosed space. In order to

ensure adequate ventilation, there should be at least 10 cm clearance to the sides (for dimensions

see Figure1), and 10 cm clearance at the rear for connections.

Above the autoclave there must be sufficient space to allow access to the built-in water storage tank

(1) and for a good circulation of air.

The DAC Professional operates with a blower (8) on the rear of the unit, as part of the cooling

system.

The functioning and the service life of the unit can be impaired if the blower (8) is not allowed to

freely remove the heat from the unit.

Important: Before installing the unit, make sure that there is sufficient free circulation of air

around the unit.

A plane, horizontal surface is required which is sufficiently stable to support the autoclave

(unloaded weight 43 kg).

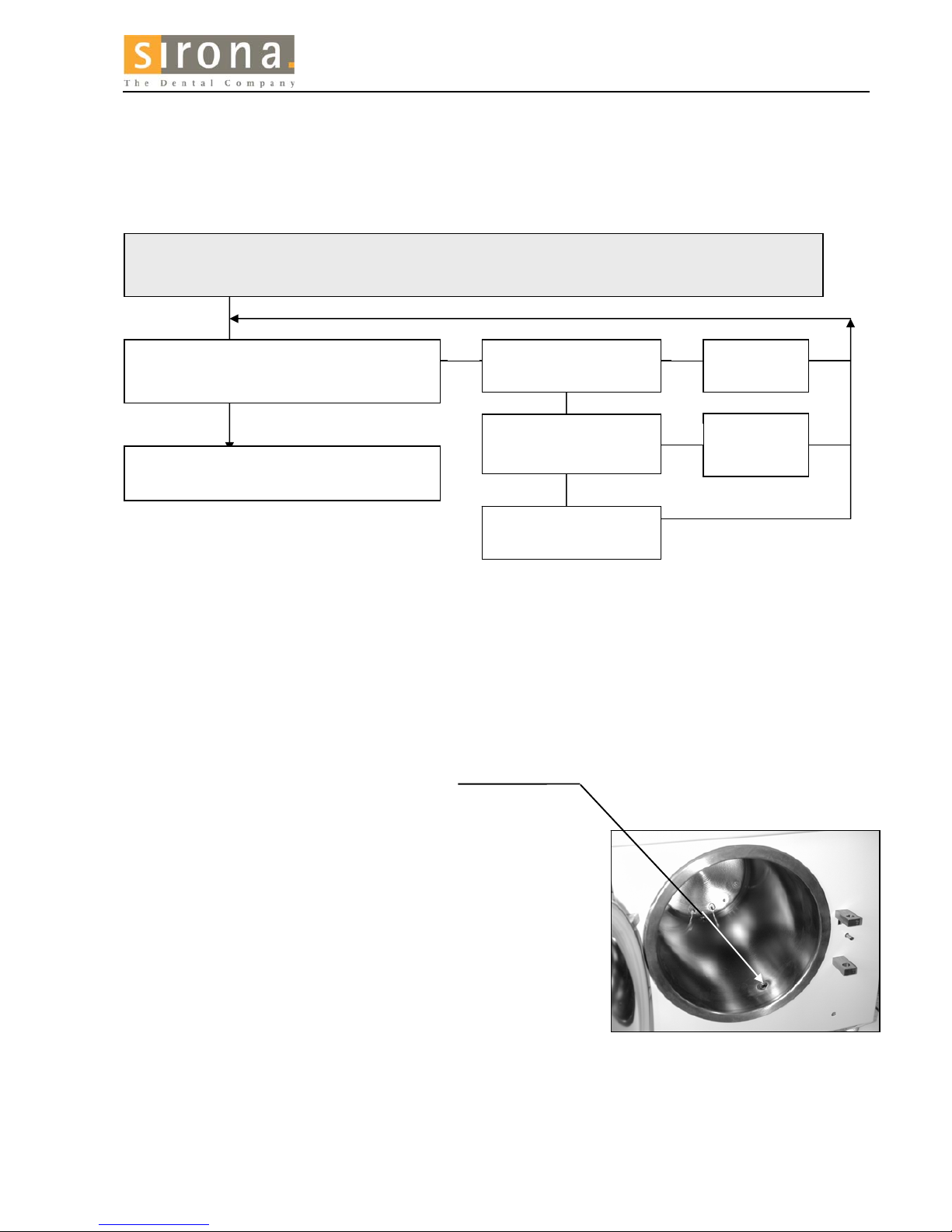

Make sure that the inside of the chamber is in level and then turn the front feet 3 times down (see

figure 2).

Figure 2

The inside of the chamber

should be in level and then

the front feet are turned 3

turns down.

09/21/2006 3/61 Servicemanual DAC Professional

Power supply

The power supply should be 230 V, 50 - 60 Hz, and 2500 W, with ground protection and a 16 A

fuse.

The power cable supplied is 1.35 m long.

If the NITRAprint®is used, then an additional power socket will be required.

One-way-outlet

The wastewater outlet should be at least 30 cm lower than the autoclave and the connection pipe

should not sag or be twisted, so that all water can drain away.

The supply with feed water (distilled or demineralised)

If an autoclave has a closed-loop water system, impurities in the water regularly lead to damage.

Therefore, the DAC Professional has a one-way system.

The autoclave automatically withdraws the feed water it needs, from the internal water storage tank

(1) which has to be refilled with purified water.

The quality of the feed water (for steam generation) must be below 15µS to comply with EN13060.

The DAC Professional is directly supplied with demineralised / distilled water through a hose from

the built-in water storage tank (right side of the tank (front side)). The advantage of this system is

that only electric power is required, and no water from the mains. A sensor measures the water level

in the water storage tank. If the water level is too low, the system will warn the user that the tank

must be filled before the program can start. The drain water (used feed water) is collected in the

waste-water tank (left side of tank (front side)) and must be manually drained. When the waste-

water tank becomes full, the system will warn the user that the tank must be drained before a

program can start. This is the standard condition of the equipment as delivered. See figure 4.

Clean and empty the wasted water tank and the clean water tank every 2nd week (see operating

manual)

Destilled or demineralised water below 15µS.

Waste-water tank

09/21/2006 4/61 Servicemanual DAC Professional

Figure 4

Back view

09/21/2006 5/61 Servicemanual DAC Professional

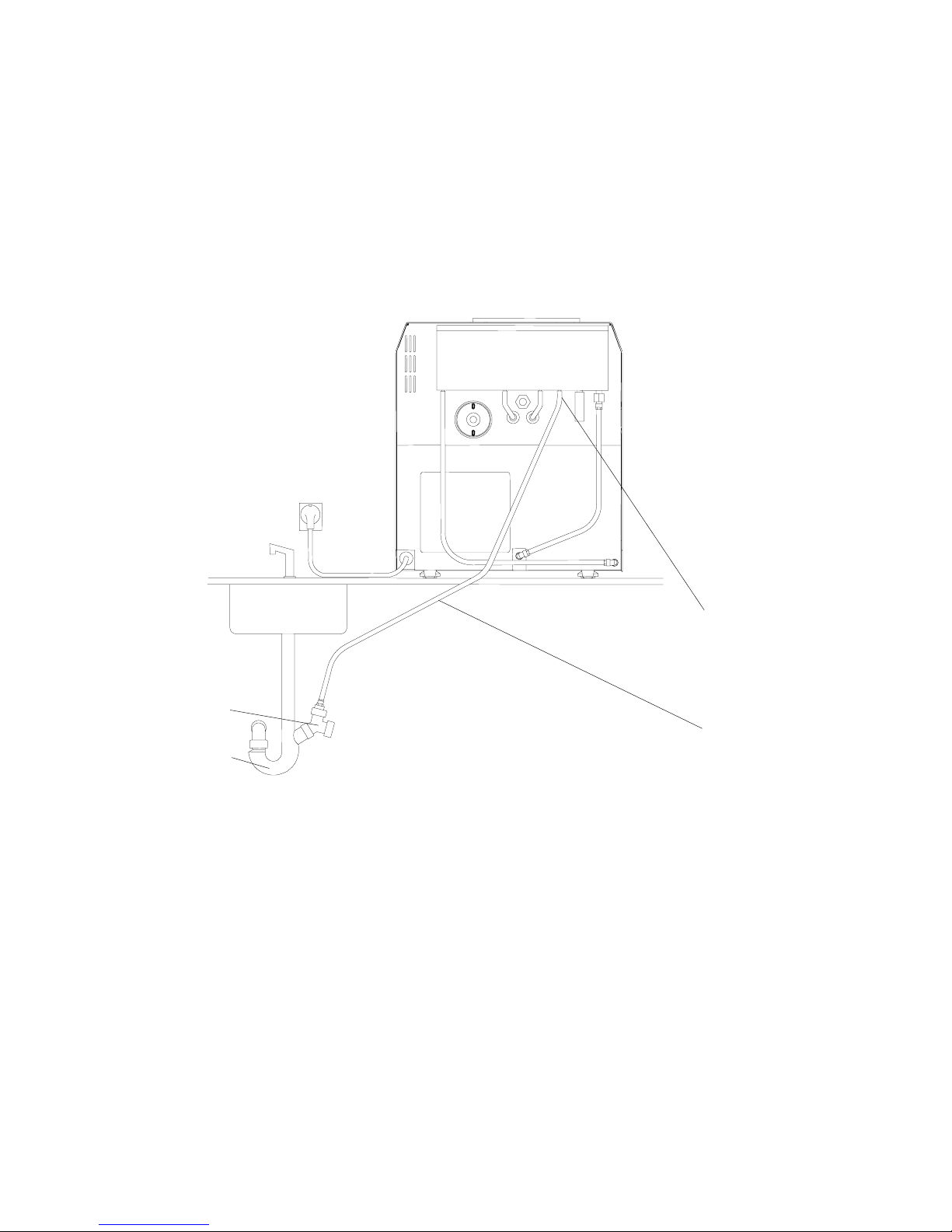

One-way-outlet

Wastewater outflow is possible via a wall-mounted trap or a double-chamber trap under a sink.

Example is shown on figure 5. A 1 meter outlet connection pipe can be supplied on request.

The wastewater outlet should be at least 30 cm lower than the autoclave and the connection pipe

should not sag or be twisted, so that all water can drain away.

Figure 5

31 29

3

30

Back view

09/21/2006 6/61 Servicemanual DAC Professional

fåëí~ää~íáçåëéêçíçâçää=L=

d~ê~åíáÉé~ëë

fåëí~ää~íáçå=oÉéçêí=L=t~êê~åíó=

m~ëëéçêí

mêçíçÅçäÉ=ÇÛáåëí~ää~íáçå=L=

ÑáÅÜÉ=ÇÉ=Ö~ê~åíáÉ

mêçíçÅçäç=ÇÉ=ãçåí~àÉ=L=

m~ë~éçêíÉ=ÇÉ=Ö~ê~åí∞~

eóÖáÉåÉ

Kunde / Customer /

Client

/

Cliente

Händler /Dealer /

Depositaire

/

Depositante

Adresse, Tel.:

Address, tel.:

Adresse, tel.

:

Dirección, tel.:

Adresse, Tel.:

Address, tel.:

Adresse, tel.:

Dirección, tel.:

Kundennummer / Customer No.

No. du client / No. de cliente

Auftragsnummer / Order No.

No. de commande/No.de pedido

Seriennummern / Serial numbers /

Numéros de série

/

Numéros de serie

Pos. Serial-No. Modell

DAC Universal

SIROCLAVE B

VS

S

SIROPRINT

SIROSEAL

SIROCLEAN

SIROMINI B

Bowie

&Di ck

vacuum

Time Alarm

Press. bar psi

Temp °C °F

Progra m

Sterilization

134° C 5 min .

3va cuu m

Sterilization

121° C 20 mi n.

3va cuu m

Faststerilization

134° C 4 min .

1va cuu m

Special

Vacuum

Sterilize

Drying

Ready

H2O ma x.

H2O mi n.

H2O ma x.

Test Set Power

START

STOP

Rückseite

rear

verso

dorso

T

Vacuum

Sterilize

Drying

Ready

Time Alarm Press.bar psi Temp. C° F°

min.

max.

Bowie& Dick

Vacuumtest Set Power

Sterilize1

134 °C

5m in

3v acuu m

Steri liz e 2

121°C

20min

3vacuum

Fast cycle

134°C

4min

2vacuum

Special

121-13 5 °C

3-60 min

2-3-4 vacuum

SIROMINI B

Rückseite

rear

verso

dorso

Inbetriebnahme gemäß bauseitiger Installationsanleitung und Montageanleitung sowie bedarfsweise länderspezifische sicher-

heitstechnische Kontrollen fehlerfrei durchgeführt.

Commissioning performed error-free according to the pre-installation instructions and installation instructions, as well as country-specific

safety controls where required.

Mise en service exécutée conformément aux instructions d’installation et aux instructions de préinstallation et éventuels contrô-

les de sécurité spécifiques au pays exécutés sans détection de défauts.

Puesta en funcionamiento según las instrucciones de instalación y de montaje en la obra así como, si es necesario, de haber efectuado

controles técnicos de seguridad específicos del país exentos de defectos.

Äußerer Gerätezustand einwandfrei / Visual inspection of unit shows no defects /

Etat extérieur correct de l’appareil

/

Estado externo de la unidad en perfectas condiciones

Betreiber bzw. autorisierte Person unterwiesen / Operator or authorized person trained /

Exploitant ou personne autorisée a été avisé(e) / Usuario y/o persona autorizada instruidos

Name / Name /

Nom

/

Apellido

Kunde / Customer

Client

/

Cliente

Unterwiesene Person / Trained person /

Personne initiée

/

Persona instruida

Verkäufer / Sales rep.

Vendeur

/

Vendedor

Techniker / Technician

Technicien

/

Tecnico

Unterschrift / Signature /

Signature

/

Firma

Datum / Date

Date

/

Fecha:

Datum / Date

Date

/

Fecha:

Datum / Date

Date

/

Fecha:

Datum / Date

Date

/

Fecha:

FÜR DEN HÄNDLER FOR THE DEALER

POUR LE DEPOSITAIRE PARA EL DEPOSITANTE

Bemerkungen /Remarks /

Remarques

/

Observaciones

Fehlende Teile

Missing parts

Pièces manquantes

Piezas faltantes

Beschädigte Teile

Damaged parts

Pièces endommagées

Piezas dañadas

Fehlerhafte Funktion

Nonconforming functions

Funcions défectueuses

Funciones defectuosas

09/21/2006 7/61 Servicemanual DAC Professional

fåëí~ää~íáçåëéêçíçâçää=L=

d~ê~åíáÉé~ëë=

fåëí~ää~íáçå=oÉéçêí=L=t~êê~åíó=

m~ëëéçêí

mêçíçÅçäÉ=ÇÛáåëí~ää~íáçå=L=

ÑáÅÜÉ=ÇÉ=Ö~ê~åíáÉ

mêçíçÅçäç=ÇÉ=ãçåí~àÉ=L=m~ë~J

éçêíÉ=ÇÉ=Ö~ê~åí∞~

Das vorliegende Protokoll wird

durch den für die Installation

verantwortlichen Techniker und

dem Betreiber bzw. einer von

ihm benannten Person ausge-

füllt.

Das Ausfüllen und Versenden

des Installationsprotokolls /

Garantiepasses kann elektro-

nisch über die Serviceangebote

im Händlerbereich der Sirona-

Internet-Seiten oder konventio-

nell per Fax erfolgen. Anhand

dieses Dokumentes wird das

installierte Gerät bei Sirona

erfasst und stellt somit die

Grundlage zur Erfüllung etwai-

ger Garantieansprüche, insbe-

sondere der erweiterten

Garantie, dar.

The present document is written

by the engineer responsible for the

installation and the operator or a

person authorized by the operator.

The Installation Report / Warranty

Pass can be completed and

forwarded electronically via the

service offers located in the Dealer

domain of our Internet home page

or printed, filled out and faxed to

us. Based on this document, the

installed unit is registered by

Sirona and is the basis for

fulfillment of any warranty claims,

especially regarding extension of

the warranty period.

Le présent document est établi

conjointement par le technicien

responsable de l’installation et

par l’exploitant ou une personne

nommée par lui.

Vous pouvez nous renvoyer le

protocole d'installation / fiche

de garantie dûment rempli par

fax ou par voie électronique

dans l'ESPACE REVENDEURS

(onglet SERVICE ) du site

internet Sirona. Ce document

permettra à Sirona de gérer

l'appareil installé et servira de

base pour répondre aux

éventuelles revendications de

garantie, notamment de

garantie étendue.

El presente documento es

confeccionado por el técnico

responsable de la instalación y el

usuario y/o una persona por él

nombrada.

El protocolo de montaje y el

pasaporte de garantía se pueden

rellenar y enviar utilizando las

ofertas de servicio de la zona de

distribuidores de la página Internet

de Sirona, o bien por fax. Este

documento, con el que Sirona

registra el equipo instalado, es la

base para dictaminar sobre los

derechos de garantía,

especialmente de las garantías

prorrogadas.

Diese Unterlage ist keine Bestellunterlage für Ersatzteile!

This document does not constitute an order form for spare parts!

Ce document n’est pas un formulaire de commande pur pièce de rechange!

¡Este no es un documento para pedir piezas de repuesto!

FAX:

++49(0)6251/16-1808

In USA please send to:

(704) 587-9394

ïïïKëáêçå~KÇÉ

ïïïKëáêçå~KÅçã=

oder:

or:

ou:

o

Bitte senden an:

Please send to:

À envoyer à:

Enviare a:

09/21/2006 8/61 Servicemanual DAC Professional

Maintenance instruction and protocol

DAC Professional

1 Maintenance is to be performed every 2nd. Year or 2000 cycles.

2 Important before maintenance:

2.1 Safety instructions:

•The autoclave is still under power also it is switched off (Mains switch, Fuse

holders)!

•For every work that leads to let raise the pressure in the chamber, the door must be

closed safe. Check that the autoclave has locked the door (Tappet of the door lock

prevents to open the door)!

⇒Please have the user perform a vacuum test the morning you will perform the

maintenance to shorten the time of work for the technician!

⇒If the autoclave is connected to a water treatment system (aqua dem) e. g. SiroDem

please perform the maintenance for this device also!

3 After the maintenance

⇒Please make two extra copies of this service record.

⇒The original will be kept in the doctor’s office, or in the clinic or hospital. The first copy will

remain with the person who performs the service.

4 Data of Device

Serial-No:

___________________________________________

Year of production:

___________________________________________

Reading on the total-cycle counter:

___________________________________________

Number of successful cycles:

___________________________________________

Technician:

___________________________________________

Date: Time:

______________ from: ______ to: _______

Serviced by (company, depot, or specialized Sirona

dealer):

___________________________________________

Name and address of doctor’s office, clinic, or hospital::

___________________________________________

The above-stated person has performed the maintenance work according to the following

service checklist:

The person performing the maintenance will make a check in the circle to show that he has

performed the step of work O :

!

09/21/2006 9/61 Servicemanual DAC Professional

Maintenance instruction and protocol

DAC Professional

5 Static Check

5.1 General instructions / Safety instructions

⇒For the following service work, it is recommended to remove the lower part of the rear

wall of the device, in addition to the housing. The DAC Professional will remain fully

functional after these parts are removed. Warning: Be sure to observe the relevant

safety precautions that must be observed for operating the device without the rear wall

and the housing.

5.2 Check the levelling of the autoclave

⇒Check to make sure the autoclave has been set up and positioned properly to slope to

the rear. Starting from a level position, the front feet of the autoclave must be screwed

three (3) turns for the DAC Professional. The autoclave must slope to the rear to ensure

that the residual water and condensate will properly flow out toward the rear.

O Levelling was o.k. O Levelling corrected

5.3 Check of the chamber and the tray rack

⇒Check the chamber and the tray rack for dirt / rust.

The chamber should be checked at every use by the practice personnel.

Cleaning the chamber is not a part of the maintenance!

O Chamber / Tray rack were clean

O Chamber / Tray rack must be cleaned

O Chamber / Tray rack have been cleaned

5.4 Check the door gasket

⇒Check the door gasket (rubber seal) to make sure that it is not damaged. Clean if

required with a mild commercial liquid cleaning agent (pH = 5 … 8; the agent must NOT

contain vinegar), or with spirits (alcohol).

O Gasket was clean

O Gasket was cleaned

O Gasket has been exchanged

______________________________________________________________________

______________________________________________________________________

5.5 Adjustment of the door locking mechanism

⇒See Instructions in the Service manual“

O Adjustment performed

5.6 Check / grease the door lock

⇒Check the door lock for wear or defects. Lubricate with plain silicone grease.

O Door lock greased

O Following parts were exchanged: ________________________________________

09/21/2006 10/61 Servicemanual DAC Professional

Maintenance instruction and protocol

DAC Professional

5.7 Check the door hinges for correct play

⇒The play is too excessive when the door knocks against the door latch when closed and

the door must be lifted to be closed.

O Slight play

O Following parts exchanged because of excessive play: ________________________

5.8 Check the retaining rings of the bolts of the door hinge

⇒Both of the hinge bolts must be secured against sliding out of place, by the use of

retaining rings on the top and lower sides of each bolt.

O Retaining rings OK

O Retaining rings / bolts were exchanged

5.9 Check / Adjustment of the door contact switch

⇒Check and adjust the door contact (there should be 1 ... 2 mm from the display “Door

closed” to the lower limit).

O Adjustment is o.k.

O Adjustment corrected

5.10Cleaning the cooler / fan / cooler ribs

⇒To do this, completely disassemble the cooler and the fan, and clean the cooler ribs and

the fan on both sides with a vacuum hoover. Here it is necessary to disconnect the hose

connections, the tightening clamps of the cooler, the mounts of the blower, and the

electrical connections to the solenoid valves and fan. Then dust and clean the cooler ribs.

O Done.

5.11Exchange the sterile filter

⇒During every maintenance the sterile filter order no: 6126093 must be exchanged.

O Done

5.12Check the pressure-release filter

⇒Remove the sieve inserts for both pressure-release filters and clean them. Exchange if

necessary. The cap nuts must be unscrewed to remove the filter inserts. These nuts are

freely accessible without further disassembly of the autoclave. Helpful hint: place the

autoclave between two tables for your work.

O Cleaned

O Exchanged

09/21/2006 11/61 Servicemanual DAC Professional

Maintenance instruction and protocol

DAC Professional

5.13Check of the electrical connections

⇒Check to make sure that the cables are tightly connected. Make sure to carefully check

the power-conducting tab connectors (tab-and-receptacle connections) that are listed

below:

CHECKED:

O Mains switch

O Mains fuses / holders

O The proper power-supply voltage on the main board of the electronic control system

O Output of steam generator (ACOUT1) and power-voltage feed (LL, N) on the CPU-

board.

O Overheating protection for the steam generator

O Overheating protection for the Preheating

O Tighten the screw connections for all rectifier plugs

5.14Check all hoses inside the autoclave

⇒Check all hoses on the inside of the device to make sure that they are not damaged, and

that they are in correct position.

⇒Tighten to finger tightness, and then use an engineer's wrench to turn one-half turn more

(½).

O Hoses and connections are o.k.

O Connections tighened

6 Functional check

6.1 Run a program "Vacuum-Test"

⇒Carry out the Vacuum Test program with a cold autoclave (if possible by the practice

before the maintenance).

⇒Attach the test printout at the end of this report.

⇒Read the leak rate from the printout and the time that was used for the evacuation or

note it below.

⇒Check and evaluate the vacuum-pump performance on the basis of the evacuation time

required for the vacuum test. Maximum time for vacuum evacuation tmax = 2 min. Actual

time required: ……….. min. If the time is exceeded check the autoclave for leakages,

function of the solenoid valves and the performance of the vacuum pump.

Leak rate = __________________ mbar/min

Time for evacuation= ___________ min

O O.K.

O Works done: ________________________________________________________

09/21/2006 12/61 Servicemanual DAC Professional

Maintenance instruction and protocol

DAC Professional

6.2 Run a test cycle "Quick-Program"

⇒Carry out the Fast Program with unwrapped objects. You can stop the drying phase after

2 minutes to save time. Print out the test results and enclose with this service report.

⇒Check all connections for leakages during the sterilization cycle when the chamber has

built up a pressure.

⇒Make an acoustic check during the test run for unusual noises (e. g. Clattering of lose

parts when autoclave vibrates.) If there are unusual noises caused by the vacuum pump

e. g. from the cavitation jet, exchange it. Add a protocol print-out and the indicator strip of

the helix-test in the below mentioned field at the end of this report.

⇒Add the protocol print-outs (stick them in the fields at the end of this protocol)

O Leakages checked

O Acoustic check performed

O Works done: _________________________________________________________

7 Reset the maintenance counter

⇒Resetting as described in the separate Instruction.

O Done

09/21/2006 13/61 Servicemanual DAC Professional

Maintenance instruction and protocol

DAC Professional

8 Confirmation

O The maintenance was successfully performed

O The maintenance was not successfully because of the following:

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

Additional notes:

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

We confirm that the maintenance has been performed in accordance to the above mentioned

instruction.

__________________________________________

Signature of the service technicians

___________________________________________

Signature / Stamp of the practice / clinic

9 Protocol Print-outs

9.1 Vacuum-Test:

9.2 Quick-Program:

09/21/2006 14/61 Servicemanual DAC Professional

Fault diagnosis for DAC Professional

Fault 1: Vacuum system

CONFIGURATION OFCOMPONENT GROUPS IN THE AUTOCLAVE

ERROR 1 VACUUM UNIT

K

C

VV1

F

PV

VV2

VDA2

VQ

SLW

SQ1

PQ

VB

VDA1

H1

F

F

DAC Professional Configuration of the component

groups in the autoclave (TOP VIEW) FRONT

K

Item Bezeichnung Description State of valve

when no

current is

applied (dead)

ACOUT

(power

output)

C Kühler cooler 4

F Filter filter

H1 Dampferzeuger steam generator 1

K Kessel vessel

PQ Pumpe aqua dest pump for distilled water 5

PV Vakuumpumpe vacuum pump 3

SLW Sensor Leitwert sensor for conductivity

SQ1 Strömungswächter flow sensor for dist. water

V Ventil (Magnet~) valve (solenoid)

V

V

VB

B

B

Belüftung ventilation open 8

V DA1 Druckablaß 1 pressure release 1 closed 7

V DA2 Druckablaß 2 pressure release 2 closed 9

V

V

VQ

Q

Q

Speisewasser aqua dest feed water (distilled) closed 5

V

V

VV

V

V1

1

1

Vakuum 1 vacuum 1 closed 6

V

V

VV

V

V2

2

2

Vakuum 2 vacuum 2 closed 6

This overview shows a rough schematic of the spatial configuration of the

component groups, pipes, and hoses, in the DAC Professional. The following error

descriptions will refer to this overview to help you find the component groups to be

checked.

09/21/2006 15/61 Servicemanual DAC Professional

Fault diagnosis for DAC Professional

Fault 1: Vacuum system

Tripping conditions:

Fault conditions may occur if the monitoring time Uet1 was exceeded for achievement of the following:

•The required evacuation pressures for the individual sub-atmospheric pulses

–P37, P38, P40, P41 for cold starts

–P1, P2, P21, P22 for hot starts

•The required evacuation pressure (P17) for the vacuum test

•The required evacuation pressure (P12) for evacuation / pressure relief

•The required minimum pressure for drying (P3).

Causes of the problem / Correction of the problem

Action / checking by operating staff:

•Check for defects and for soiling of the door seal and the sealing surfaces of the sterilization chamber,

and on the round plate around the door of the sterilization chamber. Repair and clean if necessary.

•Check to make sure that the autoclave is properly set up (it must be installed with a tilt (at slope), as

described in the operating instructions).

•Check to make sure that the condensate drain at the bottom of the sterilization chamber is not stopped.

It can be stopped if instruments, filter paper, etc. fall onto the bottom of the chamber.

•Check for the following:

–If you are using the internal system for supply of demineralised water, check to make sure that the

pressure-release pipe is not stopped.

–If you are using an external waste-water connection that empties into the building waste-water

system, check to make sure that this drain pipe does not have a kink (make sure the water can

flow freely out).

09/21/2006 16/61 Servicemanual DAC Professional

Fault diagnosis DAC Professional

Fault 1: Vacuum system

Faults in the autoclave / Correction of faults by technical service personnel

Yes

Yes

Yes

Note:

No

Start the vacuum test Important: All vacuum tests must be conducted with a cold, dry autoclave. Watch the

evacuation pressure achieved here and the pressure change over time (from the display).

Is the vacuum pump

running? No ÆFault Class: Control fault / faulty pump please check the following for faults: power

output ACOUT3; fuse F1; possibly defective vacuum pump. Correct the fault, and then go

to next.

ÆFault Class: Vacuum fault

Pump system too weak

Correct fault and go on with

normal program start.

Vacuum test OK

Leak rate OK

Pressure is stable

Leak rate is too great

(> 1.3 mbar) and permanent

pressure rise

"Fault 1: Vacuum

system"

The sub-atmospheric

pressure achieved is very

weak, or the pressure is

the same as in the room.

"Fault 31: System leaks"

Pressure rise over P3

(very large leaks)

Sub-atmospheric

pressure is within the

range of moderate to

just less than the

evacuation pressure

(P17)

In the Service Program, raise the evacuation pressure (P17) for the vacuum test by approx. 20 mbar more than

the evacuation pressure reached during the first test. Then repeat the test. (Important: When changing

P17, make sure that P13 is always greater than P17. If necessary, also raise 13 to ensure that P13 >

P17. If this is not done, you will receive the error message “System leak”.)

Special vacuum test OK?

(System flag F11 = 1)

(Pressure stable?)

Vacuum test OK?

(Leak rate < 1.3 mbar/min) No

Fault 1

Vacuum system

ÆFault Class: Leak fault

Repair the leak in the intake

line; then next

ÆFault Class: Leak fault

Stop the leaks and then next

09/21/2006 17/61 Servicemanual DAC Professional

Fault diagnosis for DAC Professional

Fault 1: Vacuum system

Fault 1: Vacuum system

ÆFault class: Fault in control system or function of the pump

You can check the input voltage for the vacuum pump, as well as the function of the pump, as follows:

ÆFault class: the vacuum performance of the pump system is too weak

►The vacuum solenoid valves 1 + 2 do not open (VV1, VV2)

•The solenoid valve, or coil, or rectifier plugs are defective.

•The activation for the solenoid valve (output 6) is defective.

Switch on output 6 in the Diagnosis program.

Check the electric control system and the switching behavior of the solenoid valve.

►The flow resistance in the intake line is too high

•Filter in the intake fitting on the sterilization

chamber is clogged up

►The pressure-sensor signal is defective, or the

processing of this signal is not correct

•The level of the pressure-sensor signal, or the signal processing,

is too high. See the section “Sensor Fault Group”.

►The suction of the vacuum pump is too weak

Check the vacuum performance of the membrane as follows:

1. Check to see if there are leaks.

2. Make sure that the chamber to be evacuated is empty and dry.

3. If there are no leaks, and if the chamber is empty and dry,

check the performance of the pump. It must be at least

800 mbar in 80 s, or 900 mbar in 180 s.

4. If there are no leaks, and if the chamber is empty and dry, and if the performance of the pump does not meet

the above level (800 mbar in 80 s, or 900 mbar in 180 s), then exchange the pump.

Yes

Make sure that the intake side is vented, since the pump will not start against a vacuum. In the Diagnosis

program, switch on the solenoid valves for vacuum 1 + 2 (VV1 + VV2) by switching on the power output

ACOUT 6 (the valves are open when the current is applied).

Yes

Yes

No

In the Diagnosis Program, switch on the pump

(PV) by switching the power output ACOUT 3.

Does the pump now run?

Check Fuse F1. Is it OK?

Test the power output

EP2-2 on the circuit board

with a meter. Out

p

ut OK?

No Exchange

fuse F1.

Exchange the

circuit board.

No

The pump is defective.

Exchange the pump.

Proceed to the next step in the higher-level

fault-analysis plan.

09/21/2006 18/61 Servicemanual DAC Professional

Other manuals for DAC PROFESSIONAL

2

Table of contents

Other Sirona Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual