SiMUaA

®

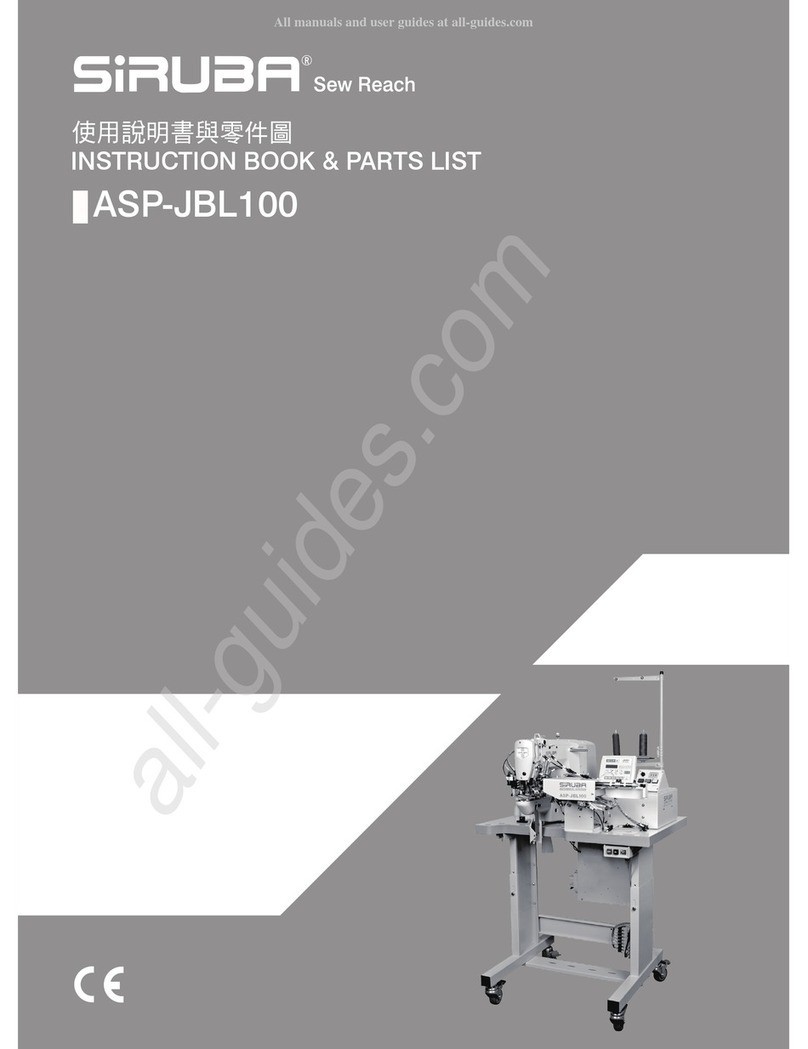

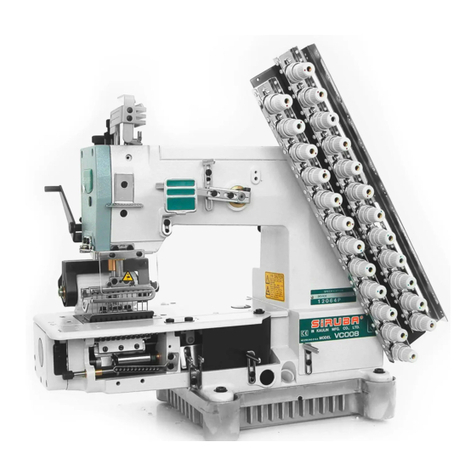

Sew Reach Introduction

CONTENTS

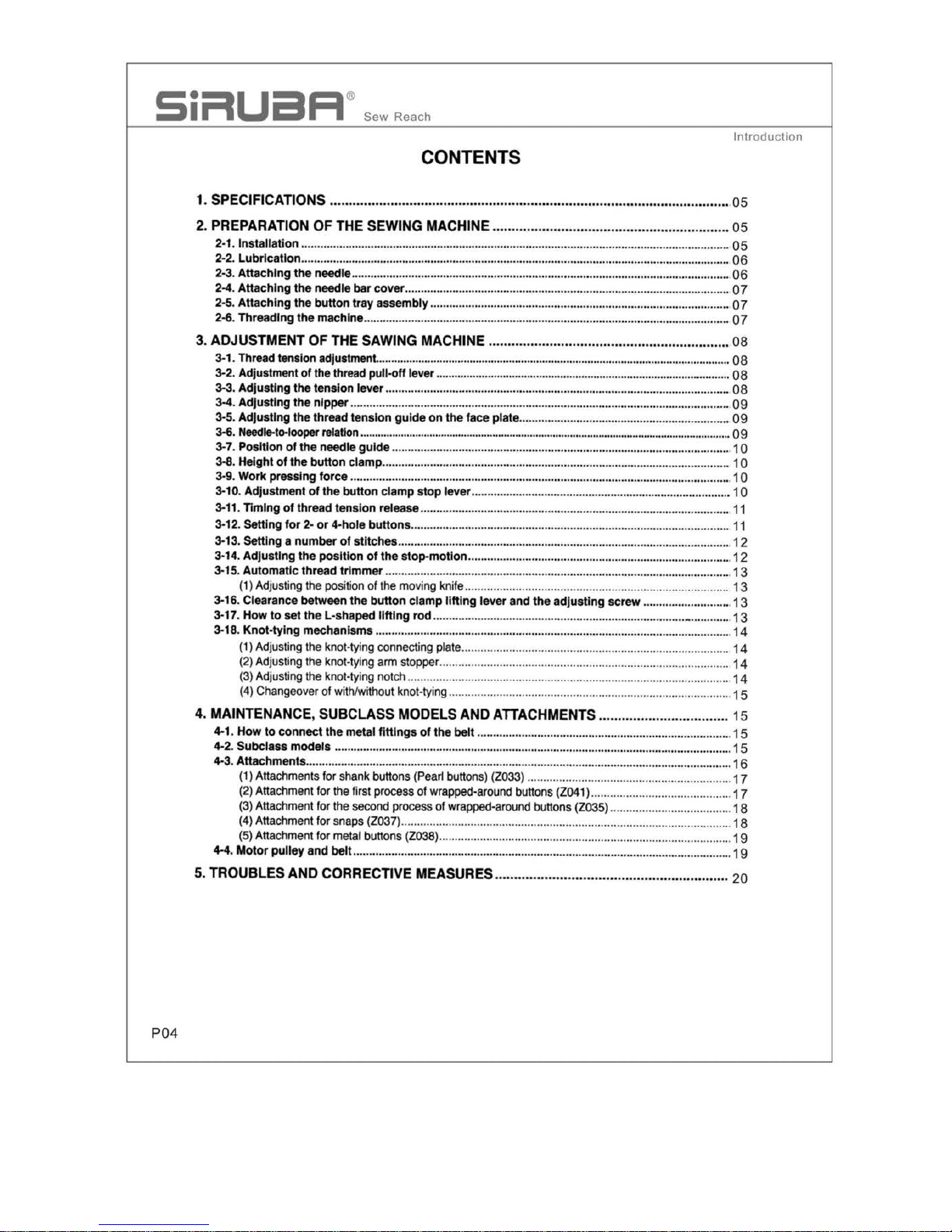

1. SPECIFICATIONS .........................................................................................................

05

2.

PREPARATION

OF

THE

SEWING

MACHINE

......................

..

.............................

..

.......

05

2·1

. Installation.......................................................................................................................................

05

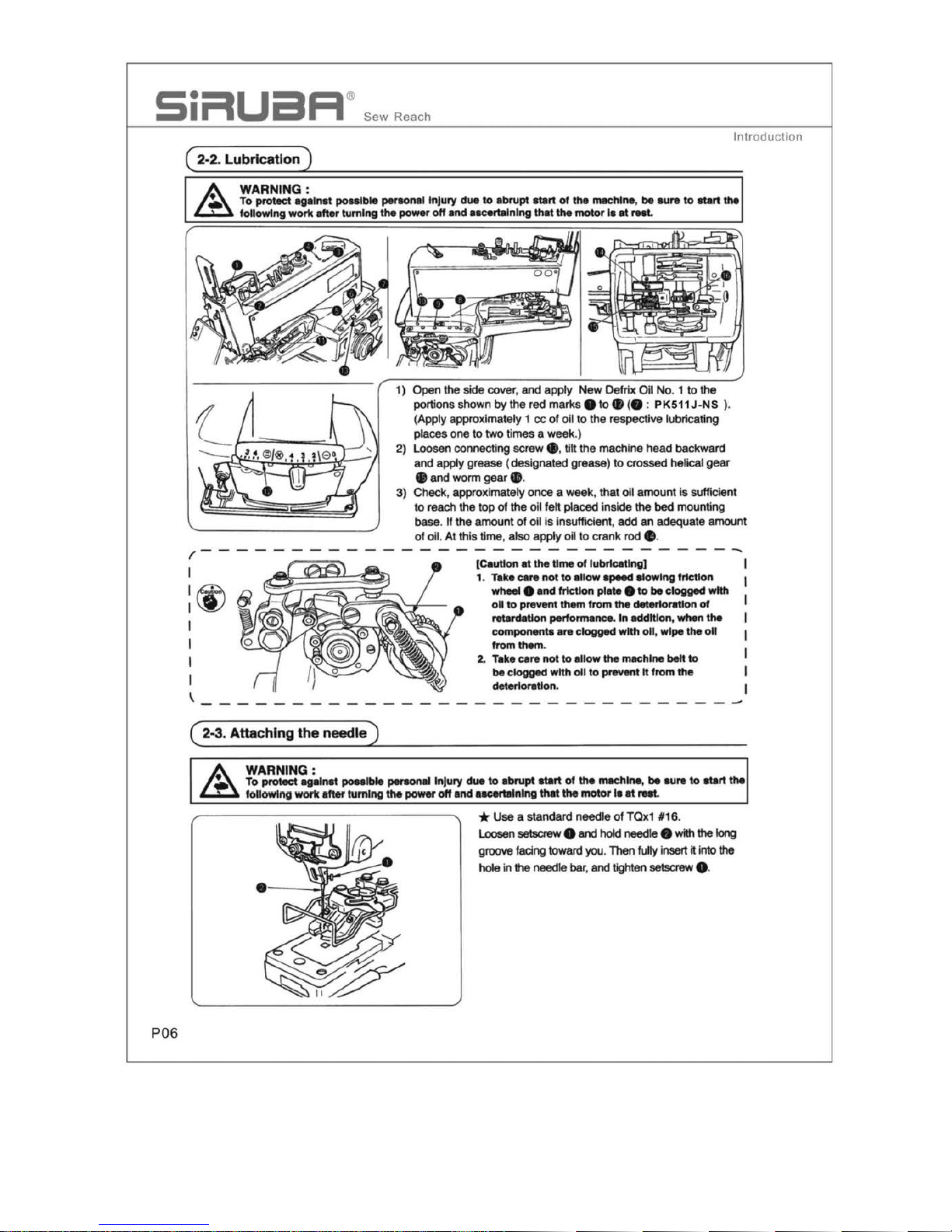

2·2. Lubrication.......................................................................................................................................

06

2-3. Attaching

the

needle.......................................................................................................................

06

2-4. Attaching

the

needle

bar

cover

......................................................................................................

07

2-5. Attaching the button

tray

assembly..............................................................................................

07

2-6. Threading

the

machine...................................................................................................................

07

3. ADJUSTMENT

OF

THE

SAWING

MACHINE ..............

..

...............................................

08

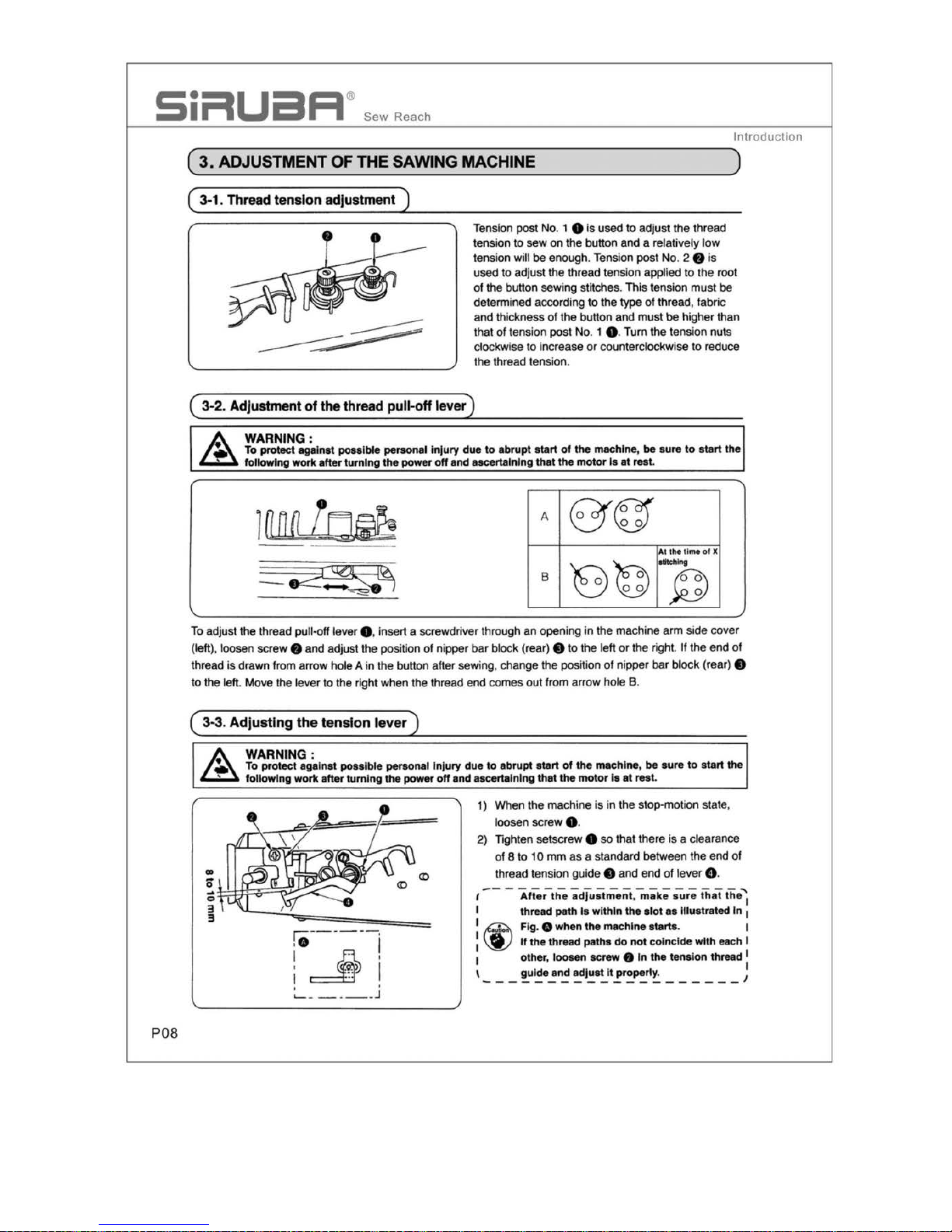

3·1. Thread tension adjustment.....................................................................................................................

08

3-2. Adjustment

of

thethread pull-offlever.................................

..

.................................................._..........

08

3-3. Adjusting

the

tension lever............................................................................................................

08

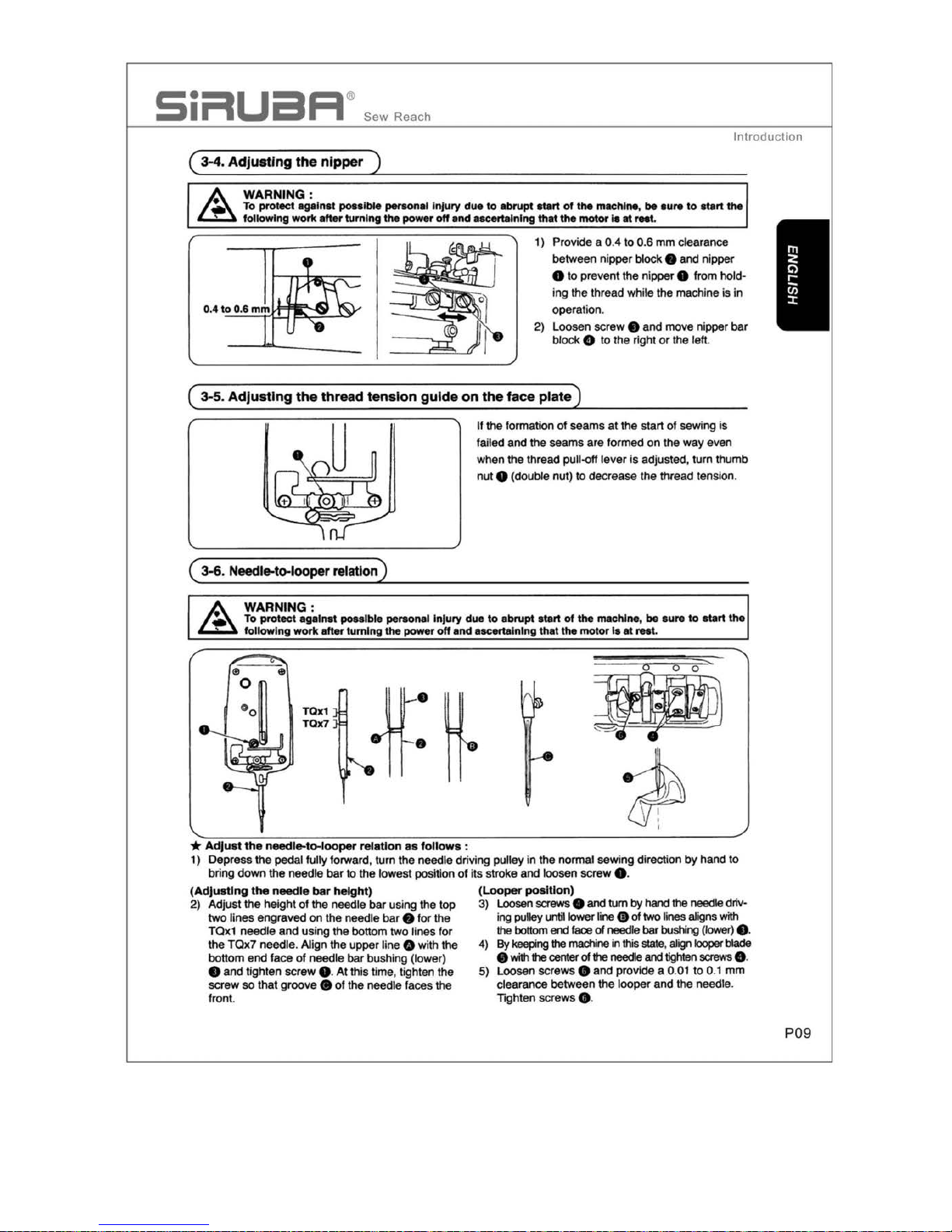

3-4. Adjusting

the

nipper.......................................................................................................................

09

3-5. Adjusting

the

thread tension

guide

on

the

face

plate

..................................................................

09

3-6.

Needle-to-looper

relation............................................................................................

..

...................................O9

3-7. Po

sition

of

the needle

guide

.........................................................................................................

..

10

3-8. Height

of

the button

clamp

............................................................................................................. 10

3·9. Work pressing force........................................................................................................................10

3-10. Adjustment

of

the

button clamp

stop

lever..................................................................................1O

3-11.

Timing

of

thread tension release..............................................................................................

...

11

3-12.Setting

for

2-or 4-hole

buttons

............................................................................

...

..................... 11

3-13. Settinga

number

of

stitches

.......................................................................................................

..

12

3-14.

Adjusting

the

position

of

the stop-motlon.................................................................................

..

12

3-15. Automatic thread

trimmer

...........................................................................................................

..

13

(

1)

Adjusting the position of

the

moving knife

....

............................................................................... 13

3-16. Clearance

between

the

button clamp

lifting

lever

and

the

adjusting screw ............................

13

3-17. How

to

set

the

L-shaped

lifting

rod

...............

..

..............................................................-.............

13

3-18.

Knot-tying

mechanisms

..............................................................................

..

................................

14

(1)

Adjusting the knot•tying connecting plate....................................................................................

14

(2)

Adjusting

the

knot-t

ying

arm

stopper...................................................................

....

..

......

..

..........

14

(3)

Adjusting

the

knot-tying notch...........................................

..

............................

..

....

..

...

.......

..

.........

14

(

4)

Changeover

of

with

/without knot-ty

ing

..................

..

...

....................

....

.

....

....

..

...............................

15

4.

MAINTENANCE

, SUBCLASS

MODELS

AND

ATTACHMENTS

.......

..

.....................

..

..

15

4-1.

How

to

connect

the

metal

fittings ofthe belt ...........................

..

...................................................

15

4-2

. Subclass models ..........................................................................................................................

..

.15

4-3.

Attachments

..........................................................................

..

..........................................................

16

(1)

Attachments for shank buttons

(Pearl

buttons)

(2033) .............................

..

.................................

17

(2)Attachment for the first process of

wrapped-around

buttons (2041)......

....

..

.........

....

...................17

(3)

Attachment for the

second

process of

wrapped-around

buttons (2035)....................................

..

18

(4)

Attachment for snaps (2037).............

..

.........................................................................................

18

(5)

Attachment for metal buttons (2038)................................................................

..

..........................

19

4-4

. Motorpulley

and

belt

............................................................................................................

..

.........

19

5.

TROUBLES

AND

CORRECTIVE

MEASURES

...................................

..

......

..

..........

......

20

P04