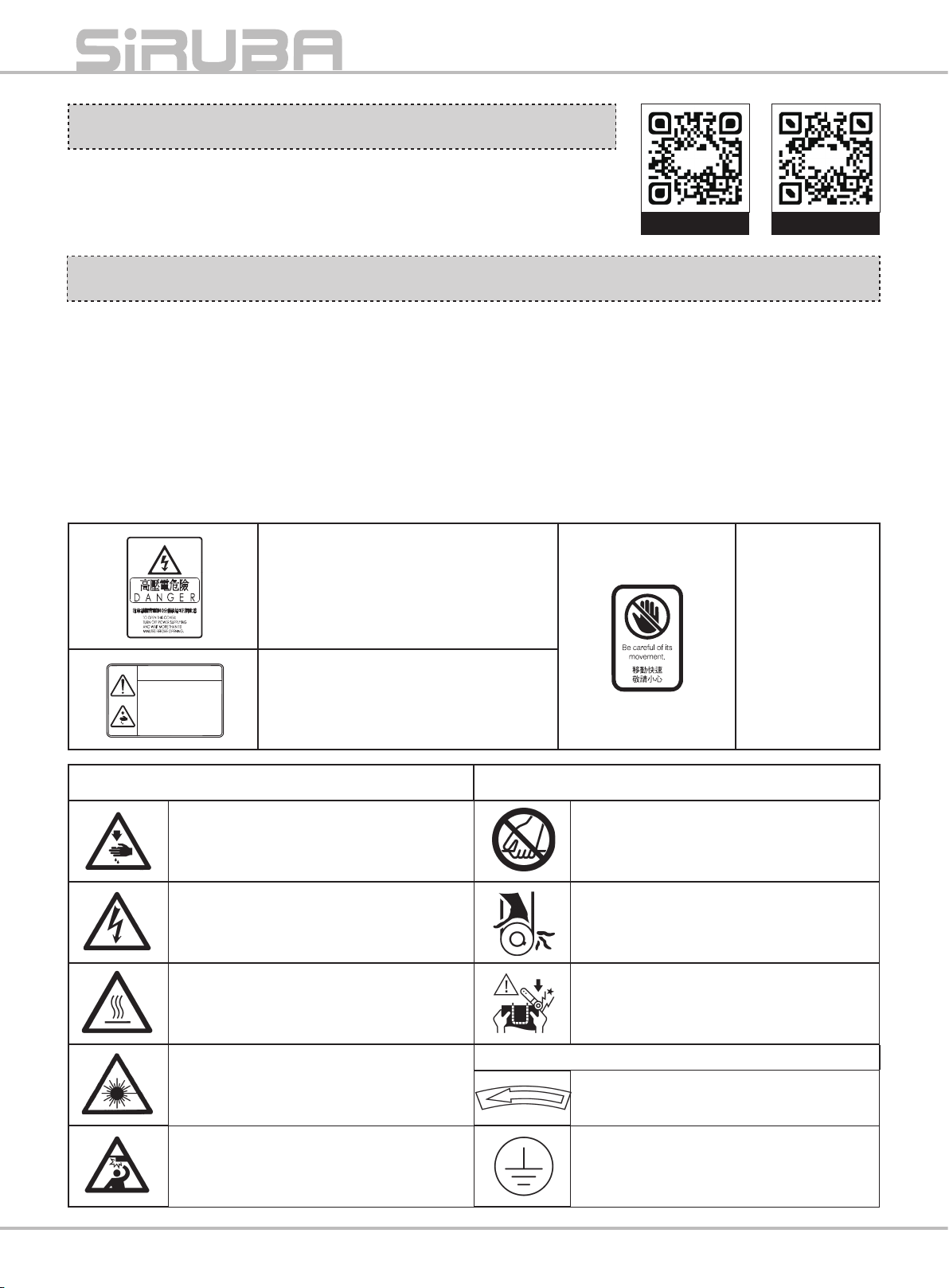

(1) 注意手,頭髮,衣服不在機件移動範圍。不要將個人物品

置放於機器上。

(2) 機器會高速運作。保持雙手遠離移動機件範圍。機器完全

停止前不要靠近。

(3) 在移動物件或重新設定機器時,注意不要被機器或零件撞

擊。

(4) 避免突然起動造成意外,在檢查或維修馬達或皮帶時,務

必關閉電源並確認機器完全停止。

(5) 機器停止時,伺服馬達是無聲的。注意要關閉電源以免突

然起動。

(6) 永遠保持電控箱的風扇與氣道淨空。

6. 潤滑

(1) 請依照說明書指示,選用合格的油脂來潤滑機件。

(2) 如果油品接觸到眼睛或身體,立即以清水沖洗。如有不適,

立即尋求醫護人員協助。

(3) 如果油品不慎進入身體,立即尋求最近的醫療協助。

7. 維修保養

(1) 只有合格的技師或工程師能夠進行維修服務,包含機器調

整與修理。只採用原廠的零件進行更換。如果採用非原廠

零件,或是因不當維修/調整所造成的傷害,本公司將不

負任何責任。

(2) 只有合格的技師或認證的工程師才能對電控系統進行維修

或保養。

(3) 當對氣動原件(如氣缸)進行維修保養時,務必先拔除風

源,並將氣體完全洩除,以避免突然啟動。

(4) 在調整或更換部件後,檢查所有螺絲是否銷固。

(5) 定期清潔是必需的。在清潔前務必先關閉電源,並確認機

台完全停止。

(6) 如果運作異常或不良,立即停止操作並關閉電源。聯絡授

權經銷商或我們公司以尋求技術協助。

(7) 當保險絲故障,立即關閉電源,找出故障原因並予以排除

後,更換同規格的新的保險絲。

(8) 定期檢查與清潔風道,電線與管路。

8. 工作環境

(1) 機器必需不用電磁波干擾。.

(2) 電源供應必需良好且穩定。電壓波動不得超過 10%。

(3) 隨時檢查空壓的壓力與品質。如果氣源不穩定,請安裝合

適器材以改善。

(4) 機器操作環境,室溫 5°C ~ 35°C, 相對濕度 35%~85%.

(5) 為了保護電子元件與安全起見,當有劇烈氣溫變化而導致

凝水時,立即關閉並拔除電源,並靜候至完全乾燥為止。

(6) 為了安全起見,當有打電或閃電時,請停止操作,關閉並

拔除電源。

(7) 勿在機器週遭使用電視或收音機,以避免干擾。

(8) 依當地法令規範,在操作中採取必要的防護。

(9) 關於包裝材料,潤滑油品,以及機器(含零配件)的丟棄,

請依各地政府法規的規範執行。

(2) The machine is designed to run at high speed. Always keep

your hands away from the moving area. Do not resume the

work cycle until the machine stops completely.

(3) Be careful not to be caught by the machine or components

when removing or resetting the machine.

(4) To avoid accident caused by abrupt start, when performing

service on the motor or belt, make sure the power is off and

the machine stops completely.

(5) A servo motor is silent as the machine stops. Be sure to

turn off the power to avoid an abrupt start. (6) Always keep

the fan and airway of the power cabinet clean from any

obstacle.

6. Lubrication

(1) Apply only qualified oil and grease onto the parts as

instructed in the manual.

(2) If the lubricant contacts your eye or body, wash it off

immediately. Consult a medical care if necessary.

(3) If the lubricant goes into your body accidentally, go to the

nearby medical care immediately.

7. Service

(1) Only a certified engineer/technician is allowed to perform

service to the machine, including adjusting and repairing.

Use only genuine parts for replacement. Our company

assumes no responsibility/liability for any accident caused

by improper repair or adjustment, or the use of any parts

other than genuine one.

(2) Only a certified technician or authorized engineer is allowed

to repair or maintenance the electric system.

(3) When performing service to air-driven parts, like an air

cylinder, first disconnect the air supply and expel the air

completely to avoid abrupt start.

(4) Check all screws and nut are fixed well after adjusting and

replacement.

(5) A periodical cleaning is necessary. Make sure the power is

off and the machine stops completely before cleaning.

(6) If the machine functions poorly or abnormally, stop the

operation and turn off the power. Contact the authorized

dealers or us to request for a technical service support.

(7) When there is a fuse failure, turn off the power, find out the

cause of the failure and apply solution to it, then replace

with a new one with the same spec.

(8) Periodically check and clean the fan airway and the cable/

wiring.

8. Working Environment

(1) The machine should be free from the affection of electro-

magnetic wave.

(2) The power supply should be in good and reliable condition,

the fluctuation of rated voltage should be less than 10%.

(3) Always check the air pressure and quality. Some extra

device might be needed if the supply is not reliable.

(4) The machine is designed to be used with ambient

temperature 5°C ~ 35°C, relative humidity 35%~85%.

(5) To protect the electronic components and for safety cause,

when there is a frost resulting from a dramatic temperature

rise, disconnect the power and wait until it dry completely.

(6) For safety cause, when there is a thundering or lightening,

stop the operation and disconnect the power supply.

(7) Do not use TV or radio nearby the machine as to avoid

interference.

(8) Apply necessary protection during operation. Follow

applicable regulations set by local administration.

(9) For disposal of packages, lubricant, and product, please

follow the applicable regulations set by local administration.