SITETEC M250D User manual

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

Unit Manual

M250D Mixing unit

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

SiteTec M250D mixing unit

First of all we like to thank you for purchasing this mixing unit and hope it will be of complete satisfaction to you. This

product is built to perform, easy to maintain and is user friendly. To insure a long lifetime of this quality product we would

like your attention for this maintenance- and operating manual. Please keep it near the mixing unit at all times so it can be

of help at all times.

------------------------------------------------------------------------------------------------------------------------------

OPERATING MANUAL

1.1 MOBILISATION

1.2 PLACING THE MIXING UNIT ON-SITE

1.3 OVERALL CHECK OF THE MIXING UNIT

1.4 CAPACITY PARAMETERS

2.1 CHECK BEFORE STARTING THE MIXING UNIT

2.2 STARTING THE MIXING UNIT

2.3 OPERATING THE MIXING UNIT WITHOUT RECYCLING SYSTEM

2.4 OPERATING THE MIXING UNIT IN GENERAL

2.5 SERVICING ON THE MIXING UNIT AND EXCHANGING PARTS

3.1 12 HOUR SHIFT MAINTENANCE

3.2 24 HOUR SHIFT MAINTENANCE

3.3 WEEKLY MAINTENANCE

3.4 MONTHLY MAINTENANCE

3.5 3 MONTH MAINTENANCE

4.1 DEMOBILISATION

4.2 LONG-TERM STORAGE

5.1 PARTS SUPPLY AND RECOMMENDED PARTS STOCKLIST

5.2 PARTS & SERVICE

5.3 VALVE SCHEDULE

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

1.1 MOBILISATION

In most cases a 10 ton/meter crane will be enough to mobilize this mixing unit.

Prior to lifting the mixing unit a few checks must be made:

1. check if all stored articles on the mixing unit are securely tied down

2. take the ignition key out of the control panel

3. make sure the mixing tank, pump and piping is drained and cleaned

4. open all valves

When all this is done you can hook up the lifting chain.

Use a rope, tied to the unit to steer and/or turn the unit when it is lifted.

NEVER:

1. stand or walk underneath the load

2. use chains that are to short, to light, or have uneven lengths

3. use uncertified lifting equipment

NOTE:

WHEN PLACING A RECYCLING SYSTEM ON THE MIX UNIT ALWAYS USE TWIST LOCKS BETWEEN THE CORNER BLOCKS

TO CONNECT THE CONTAINERS.

1.2 PLACING THE MIXING UNIT ON SITE

Before you place your mixing unit on its site location, there are a few preparations you can do:

1. place a sheet of 4x4 meters of oil resistant plastic foil on the location of the unit

2. place 3 drag line boards each at least 3 meter long horizontally, well supported by solid soil, on top of the plastic

foil.

3. if you decide not to use the plastic foil: always use drag line boards or something similar placed horizontally to give

the mixing unit its full support and to create a non slippery working floor

When all this is done you can unhook up the lifting chain.

Now the connections have to be made:

1. Water : 2’’ id BSP thread

2. Mud discharge : 2’’ victaulic with banjo female

The installed power is:

1x 11 kW hatz diesel

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

1.3 OVERALL CHECK OF THE MIXING UNIT

Before you can start mixing there are a several checks to be made:

1. Check for debris in the mixing tank

2. Put 2 pump strokes of high quality bearing grease in all nipples on the GORMAN RUPP pumps.

3. Check if all electrical cables and wires are still in good condition, repair if necessary.

4. Check, overall, for any damaged or loose parts and repair if needed.

5. Check all guards.

6. Check the tank for cracks.

1.4 CAPACITY PARAMETERS

This unit is capable of mixing 250 ltr/min with normal fresh water, 7 ph and up to 60 sec of viscosity.

2.1 CHECK BEFORE STARTING THE MIXING UNIT

Before starting the unit you must do a quick check of all components of the unit:

1. Check the pump: - fluid levels

- debris plugging suction

2. Open suction valve and close drain valve

2.2 STARTING THE MIXING UNIT

First make your self acquainted with the valve schedule in 5.3.

1. To start the mixing unit, fill the complete unit for 3/4 with water.

2. Open suction valve mix pump from mix tank nr.1.

3. Close the air bleed valve on the impeller housing of the mixing pump when all air is out of the pump.

4. Open the discharge valve from pump to venturi nr.2

5. Start diesel engine

6. Now you can start mixing bentonite with the unit: open the valve of the hopper approx. half way.

7. Now suction noise will be heard out of the hopper funnel. Slowly add bentonite.

8. Add bentonite until required mud-viscosity is reached.

9. Open discharge valve to nozzles.

10. Run the unit for a few minutes: keep in mind that the viscosity of the mud will increase in this time as the mud is

being sheared

As mud is being used the fluid level inside the mixing tank must be maintained: add water and bentonite on time and, if a

mud recycling system is used, keep a eye on the mud level of the mud pit, with a SiteTec recycling system, mud will be

transferred from the recycling unit to the mixing unit. This means you have to add very little bentonite and/or water, just to

keep the mud level in the mixing tank to its maximum and in the right condition.

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

2.3 OPERATING THE MIXING UNIT WITHOUT RECYCLING SYSTEM

To maintain a continuous mixing process add water and bentonite in the correct ratio. And a minimum of 250ltr water per

min.

2.4 OPERATING THE MIXING UNIT IN GENERAL

When the mixing unit is in service the responsible mud man has to keep checking all items discussed in chapter 1.3 and 2.1

on a regular basis. Extra to that is checking mud level in the mixing tank and keeping the right viscosity of the mud.

Fill the tank with water for at least ¾ open venturie valve and slowly the hopper valve, make sure that al the other valves are

closed. Start adding dry product at the right ratio. When you have a right mixture close hopper valve.

When mixing only open venturie valve and hopper valve, when circulating and using outlet always close hopper valve.

Only open max 2 valves at the same time, the operator has a choice between nozzles with venturie for max circulation or

nozzles with outlet to HP pump.

If no mud is used you can close the valve of the hopper and stop the mixing pump.

This reduces wear of the unit. Do start-up before mud is needed!

If no mud is used you can close the valve of the hopper and stop the mixing pump.

This reduces wear of the unit. Do start-up before mud is needed!

Never start the pump without de-aerating the pump or without fluid.

In case of use of recycled fluid, mount stainless eductors/tank nozzles in the tank.

2.5 SERVICING ON THE MIXING UNIT AND EXCHANGING PARTS

1. Before you start working on the unit, stop all functions and switch off the main switch.

2. Disconnect main power cable.

3. Before you start working on the pump close all valves and drain the pump.

READ GR INSTRUCTION MANUAL TO REPLACE PARTS ON THE GR PUMP

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

3.1 12 HOUR SHIFT MAINTENANCE

The maintenance on the mixing unit for a 12 hour shift is running through all the points discussed in chapter 1.3

Notice only the time intervals for different oil changes that have to be made on time.

3.2 24 HOUR SHIFT MAINTENANCE

The maintenance on the mixing unit for a 24 hour shift is running through all the points discussed in chapter 1.3 at every

change of shifts (2x in 24 hours).

3.3 WEEKLY MAINTENANCE

For weekly maintenance on the mixing unit the following activities are recommended:

1. Check the unit overall as described in chapter 1.3

2. Clean the unit also the tank

3. Grease the all nipples on the GORMAN RUPP pump: see GORMAN RUPP instruction manual before working on the

pump

for grease use Shell RHODINA EP2

3.4 MONTHLY MAINTENANCE

For monthly maintenance on the mixing unit the following activities are recommended:

1. Follow all the points described in weekly maintenance

2. Remove guard from Flex tire drive and tire mount guard if the condition of the drive is o.k.

3. Check impeller, seal plate and impeller housing for wear: see GORMAN RUPP instruction manual before working

on the pump

3.5 3 MONTH MAINTENANCE

For 3 month maintenance on the mixing unit the following activities are recommended:

1. follow all the points described in monthly maintenance

2. check mixing tank for cracks or loose welds inside the tank

NEVER WORK INSIDE THE TANK WHEN ANY MUD IS PRESENT INSIDE THE TANK!!

READ THE INSTRUCTION MANUAL OF THE GR PUMP

READ THE MAINTENANCE MANUAL OF THE GR PUMP

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

4.1 DEMOBILISATION

In most cases a 10 ton/meter crane will be enough to demobilize this mixing unit.

Prior to lifting the mixing unit a few handlings must be made:

1. Drain the unit by opening the drain valve on the pump and bottom of tanks

2. Undo all hoses and open all (drain) valves

3. Clean the whole unit including the inside of the tank

When all this is done you can hook up the lifting chain.

Use a rope, tied to the unit to steer and/or turn the unit while it is lifted.

NEVER:

1. stand or walk underneath the load

2. use chains that are to short, to light or have uneven lengths

3. use uncertified lifting equipment

4.2 LONG-TERM STORAGE

Long-term storage is when the mixing unit is out of use (on or off site) for more than 3-4 weeks.

If this is so, there are a few preparations to be made to make sure the unit can be in operation as soon as it is needed.

Preparations on the pump:

1. drain all the mud out of the unit

2. drain mud from the tank and GORMAN RUPP pump

3. flush the GORMAN RUPP pump with clean water, open all valves

4. check to see if oil changes have to be made

CLEAN YOUR ENTIRE UNIT

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

5.1 PARTS SUPPLY AND RECOMMENDED PARTS STOCKLIST

To make sure all your wear parts are available you have to stock your parts on-site.

We therefore made a list of the parts and quantities of all wear parts for a 12 month period.

When ordering parts always mention unit type and serial number

USE GENIUNE PARTS SUPPLIED BY SiteTec ONLY!!!

Parts list:

WEAR PARTS MIXING UNIT

articlenumber

GR 82H52

200255

Venturi system

100135

Victaulic clamp 2" and 3"

501236/501237

Victaulic clamp 2" and 3" rubber

501270/501271

Waterfilter

503002

Waterfilter cup

503012

Oilfilter

303205

Fuel filter

303208/303206

Airfilter

303203

Manometer 0-6 bar

504002

PE Tank manhole cover

705010

Tire coupling

300126

Butterfly valve 3"

502053

Eductor Nozzle 1,5"

502053

5.2 PARTS & SERVICE phone numbers:

Call SiteTec +31 343 595 400 for service, parts, rental and technical support.

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

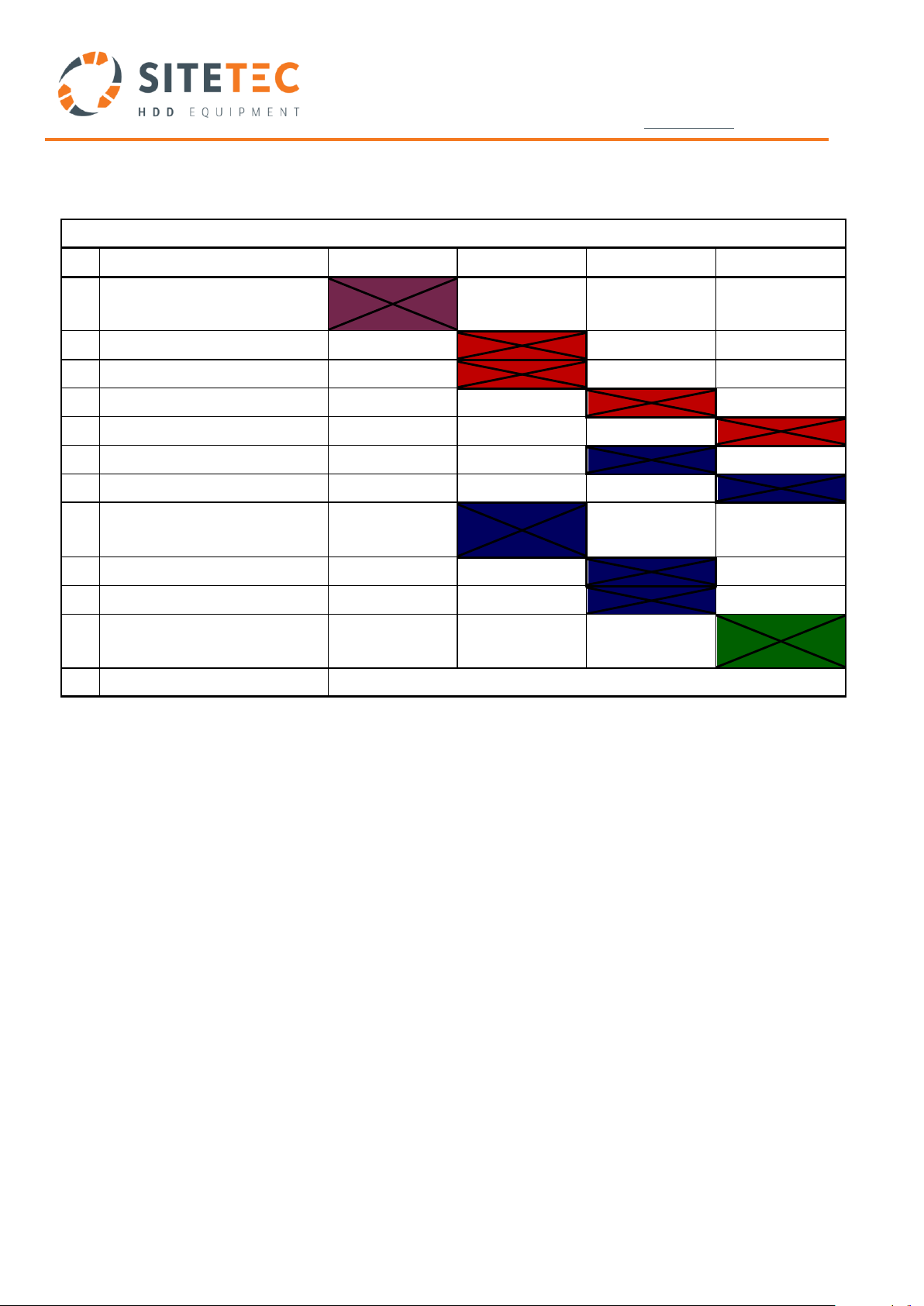

5.3 valve schedule:

1. Suction valve mix tank to pump.

2. Discharge from pump to venturi.

3. Discharge from pump to tank nozzles.

4. Discharge from pump to outlet.

5. Outlet to drain tank.

6. Hopper inlet valve dry bentonite.

7. Water inlet valve.

8. Bleed valve

Photo

1

2

3

4

5

6

7

8

Molenvliet 28

3961 MV Wijk bij Duurstede

+31 343 595 400

In all cases in which we act as offerer or supplier, our offers, assignments given to us and agreements concluded with us are subject to the METAALUNIE

TERMS AND CONDITIONS. These terms and conditions have been filed at the Registry of the Rotterdam District Court. The Dutch law is applicable on all

our agreements. KVK nr. 34043947 | VAT/BTW nr. NL.0034.76.443.B01 | IBAN NL94ABNA 0565320300

General Maintenance schedule SiteTec units

Weekly

250 Hour

500 Hour

1000 Hour

1

Grease nipple’s 5

pumpstrokes

2

Engine oil

3

Pump powerend oil

4

Gearbox oil

5

Hydraulic oil

6

Engine and fuel filter

7

Engine air filter

8

Pump powerend oil

filter

9

Gearbox oil filter

10

Hydraulic oil filter

11

coolfluid and coolfluid

filter

12

Silica filter

Check daily replace when colour changes (see filter)

Table of contents