SixThreeZero REACH YOUR DESTINATION User manual

ASSEMBLY GUIDE

REACH YOUR DESTINATION - 1, 3, & 7 SPEED

sixthreezero

We want you to love your bike as much as we do.

If you run into any issues, no matter how small,

let us know and we’ll take care of it.

OUR COMMITMENT

SIXTHREEZERO

310.982.2877

Need assembly, repair, or installation assistance? He’s your guy!

Want live help? Call or email to schedule an appointment.

MEET JACOB,

OUR MECHANIC

310.982.2877

Welcome to the sixthreezero experience. Now for the fun

part... the assembly.

I know, I know, we’ve all had to assemble something we’ve

bought before - a tv stand, coffee table, possibly a grill or

even a bike a time or two before. It’s never fun, it never goes

well, you always lose a nut or a screw and by the time you’re

done, you’d rather destroy whatever it is you’ve bought

than actually use it. Well, I’m here to make sure that doesn’t

happen.

Assembly of a bike can be a fun, engaging, learning

experience. Call up a friend, ask your spouse or child, don’t

rush, and enjoy the process. Part of the fun in building your

bike is telling people “I built it all by myself.” I build bikes

almost everyday and I always learn something new. I enjoy

the process of building something from the ground up, and

I hope you will too.

The instructions were written and designed by me, so if you

have any suggestions please let me know!

Good luck,

MECHANIC / SIXTHREEZERO

A NOTE FROM

OUR MECHANIC

4, 5, AND 6MM

ALLEN KEY

Creating something wonderful with your own hands is basically the

best feeling ever. We want you to have fun building your new bike,

so there’s only a few things you need to get started.

TOOLS

YOU’LL NEED

PHILLIPS HEAD

SCREWDRIVER

SCISSORS

(Use to cut zip ties)

SCHRADER VALVE

BICYCLE PUMP

8, 10, 13, AND 15MM

CRESCENT WRENCHES

Or use the multi-tool

provided

BICYCLE OR

AUTO GREASE

Recommended

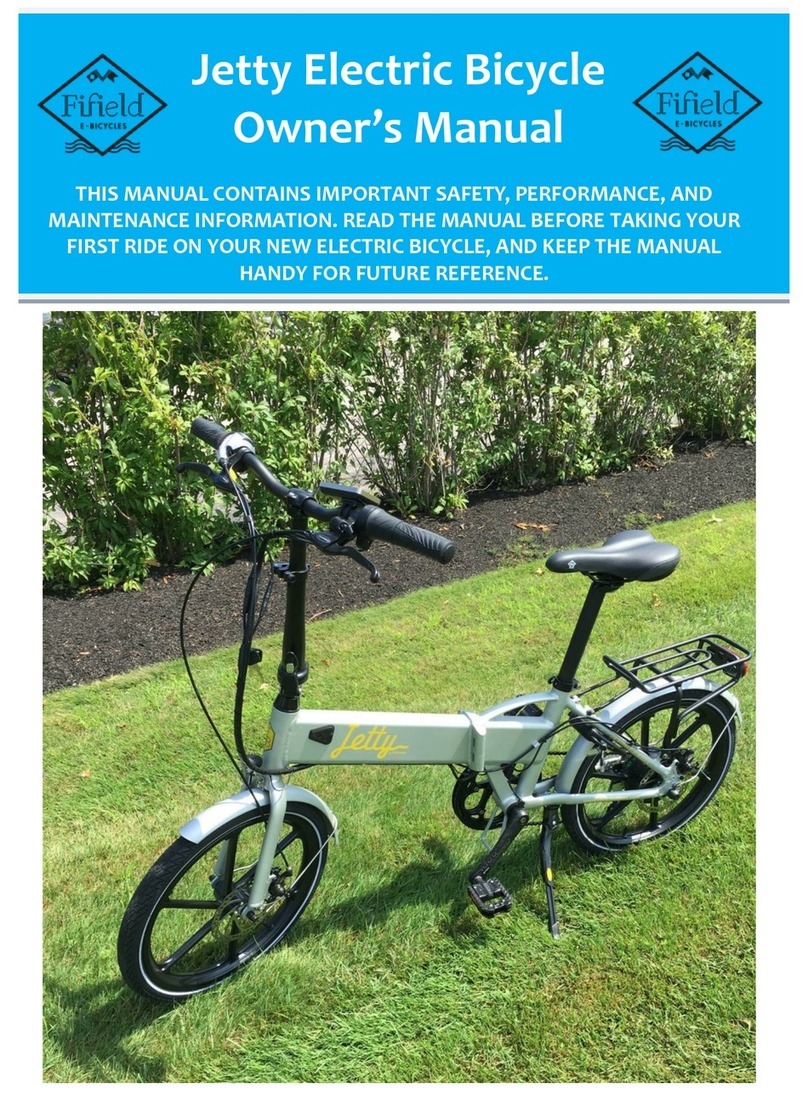

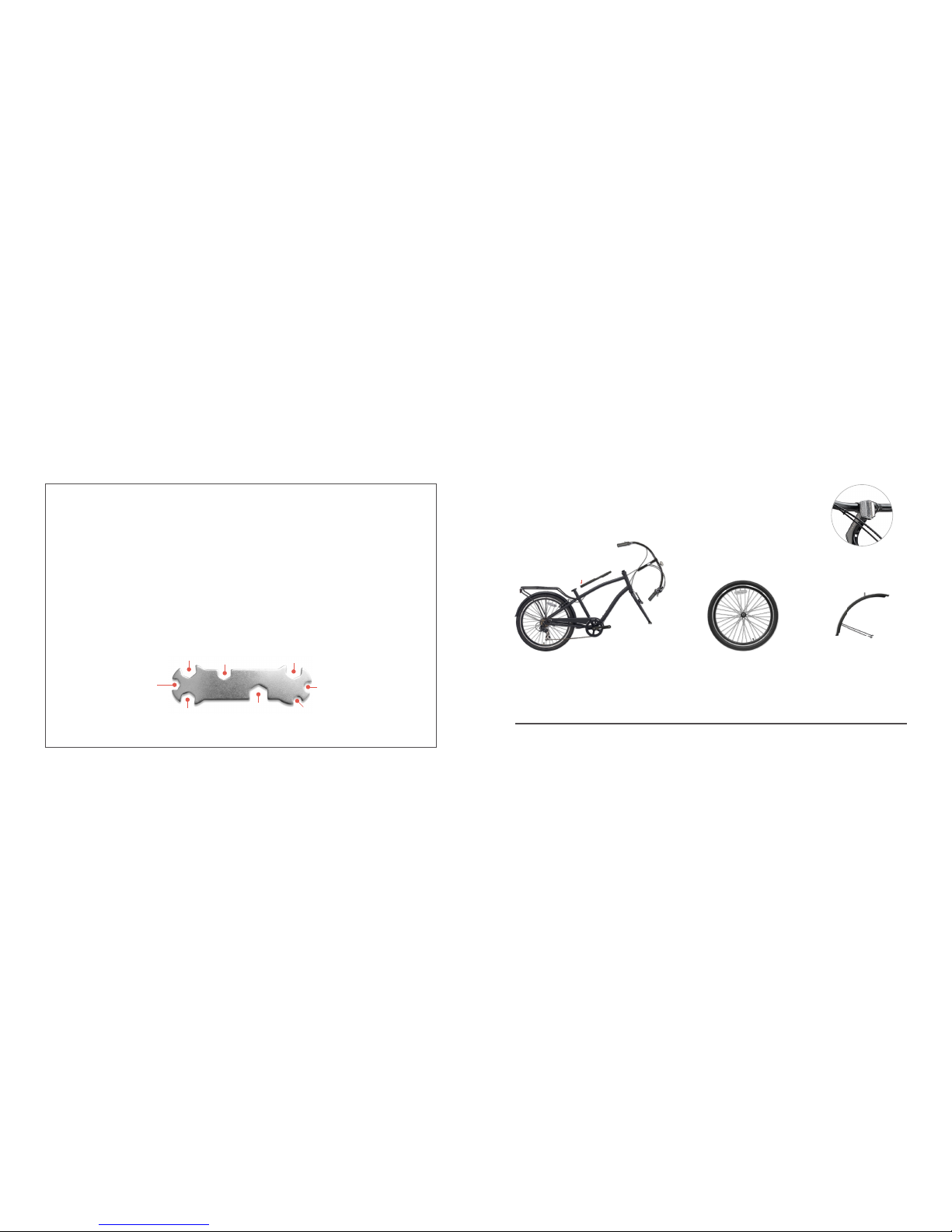

Lay out all the parts in front of you.

Make sure you have all the parts before getting started.

WHAT’S IN

EACH BOX?

12MM

14MM

17MM

FRONT

FENDER BOLT

10MM

FRONT + REAR

EYELET BOLTS

8MM

PEDALS + REAR AXEL

15MM

13MM

9MM

pre-installed

FRONT REFLECTOR

fender strut usually

comes pre-installed

FRONT FENDER

+ STRUT

QUICK RELEASE

FRONT WHEEL

Seat post is zip-tied to frame

HANDLE BAR / FRAME / REAR

WHEEL AND REAR RACK SET-UP

Seat Post

BOX 1

PEDALS

QUICK RELEASE

SKEWER

HARDWARE

In the box or

attached the frame

SEAT

BOX 3 BOX 4

ASSEMBLY

GUIDE

4, 5, AND 6MM

ALLEN KEYS

EXPERIENCE

BOOKLET

MULTI-TOOL

BOX 2

LOCK NUT CAP

All the names of all the parts for your bike, all in one place.

Keep this handy during assembly, and everything will go just fine.

Note:

The bicycle in the diagram may not be the model you purchased.

Use diagram for bicycle part reference only.

BIKE PARTS

REFERENCE

LOCK NUT CAP

LOCK NUT

SEATPOST

SEATPOST CLAMP

REFLECTOR

FENDER

REAR BRAKE

CASSETTE

DERAILLEUR

WHEEL

REAR RACK

HANDLEBAR

GRIPS

HANDLEBARS

HANDLEBAR STEM

BRAKE LEVER

FRONT FENDER

REFLECTOR

SHIFTER

FRONT BRAKE ARMS

CHAIN GUARD

CRANK

CHAIN

CRANK WHEEL

CRANK ARMS

EYELET SCREWS

FORK

FENDER STRUT

PEDALS

QUICK RELEASE

SKEWER

SEAT

SPOKE

RIM

TIRE

AXLE

TIRE VALVE

Tools you’ll need:Parts required:

10MM

MULTI-TOOL

(2) WASHERS, NUT

AND LONG BOLT

(pre-installed)

FRONT FENDER

+ STRUT

PHILLIPS

SCREWDRIVER

4MM

ALLEN KEY

QUICK RELEASE

FRONT WHEEL

QUICK

RELEASE SKEWER

FRAME, REAR RACK

+ REAR WHEEL

(6) 4MM ALLEN

KEY SCREWS

(pre-installed)

BRAKE ARMS

METAL TUBE

METAL TUBING

The front brake is facing away

from the bike body.

CORRECT

The brakes are behind the fork.

INCORRECT

01

Spin the front fork so that the the handlebars are

pointing inwards.

02

Pinch front brake arms, pulling the metal tubing up and

out until it is disengaged and the brake arms are open.

FRONT WHEEL,

FENDER + REAR RACK

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

FORK

DROPOUTS

AXLE NUTS

Locate the arrow on the wall of the tire and position the

tire like the image below. With the arrow pointing

forward, insert the wheel into the fork dropouts.

The axle nuts will fall inside the fork entry.

DO NOT untighten axle

nuts on the front wheel.

CAUTION

03 04

Reattach the brake arms by connecting the metal

tube as shown.

05

All of the components for the quick release skewer are

attached out of the box.

Unscrew QR5 and remove QR4. Do not remove QR2 and

QR3 from the quick release handle QR1.

- QR1

QR4QR2 QR3 QR5

----

----

-

----

Quick release skewer must be installed correctly to avoid bicycle damage

and/or injuries.

NOTE

06

Insert the quick release skewer through the hub opening

on either side of the wheel, as shown below.

Slide quick release skewer completely through the hub.

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

08

Making sure the wheel is straight, attach QR5 to QR1

by compressing the spring completely. Hold the quick

release lever in place and tighten QR5 lightly.

07

Place QR4 on the open side of the quick skewer, with the

smaller end pointing inward.

- QR1

QR4 QR5

----

----

The lever should be tight enough to feel resistance at a 90º angle.

Make sure the front wheel is securely tightened and properly aligned so

there are no issues when you assemble the brakes.

NOTE

09

Lift the lever up towards the fork. If the lever does not

lock in place smoothly, loosen QR5 slightly and try again.

It will take a small amount of strength, but that is normal.

QR5

----

10

Once the front wheel is secured, lower the kickstand

and locate the front fender.

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

(2) WASHERS, NUT

AND LONG BOLT

(pre-installed)

FRONT FENDER

+ STRUT

Order from front to back:

LONG BOLT, WASHER, FORK, FENDER TAB, WASHER, NUT.

Remove the screws from the fork eyelets.

NOTE

PHILLIPS

SCREWDRIVER

10MM

MULTI-TOOL

11

Align the fender struts with the eyelets on the fork, so that

the fender tab is pointing upwards. Slide the fender up

through the back of the front tire.

Use a Phillips head screwdriver and the 10mm multi-tool

to remove then install the fender tab screw and nut.

FENDER TAB

FENDER

STRUTS

FORK

EYELETS

Align the front rear rack arms to the eyelets on the frame

below the seat. Use a 4mm allen key to tighten the screws

and attach the rear rack to the frame.

13 4MM

ALLEN KEY

4MM

ALLEN KEY

REAR

RACK

(2) 4MM ALLEN

KEY SCREWS

(pre-installed)

12

Attach the screws into the struts and eyelets. Use a

4mm allen key to tighten the screws and attach the-

fender strut to the fork eyelet.

(2) 4MM ALLEN

KEY SCREWS

(pre-installed)

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

Install the angled rear fender strut to the frame in this

order (from the frame out): Frame, fender strut, and

phillips head screws. Tighten with a 4mm allen key.

14 4MM

ALLEN KEY

4MM

ALLEN KEY

(2) 4MM ALLEN

KEY SCREWS

(pre-installed)

(2) 4MM ALLEN

KEY SCREWS

(pre-installed)

Install the bottom rear rack arms to the frame in this order

(from the frame out): Frame, fender strut, rear rack arms,

and 4mm allen screws. Tighten with a 4mm allen key.

15

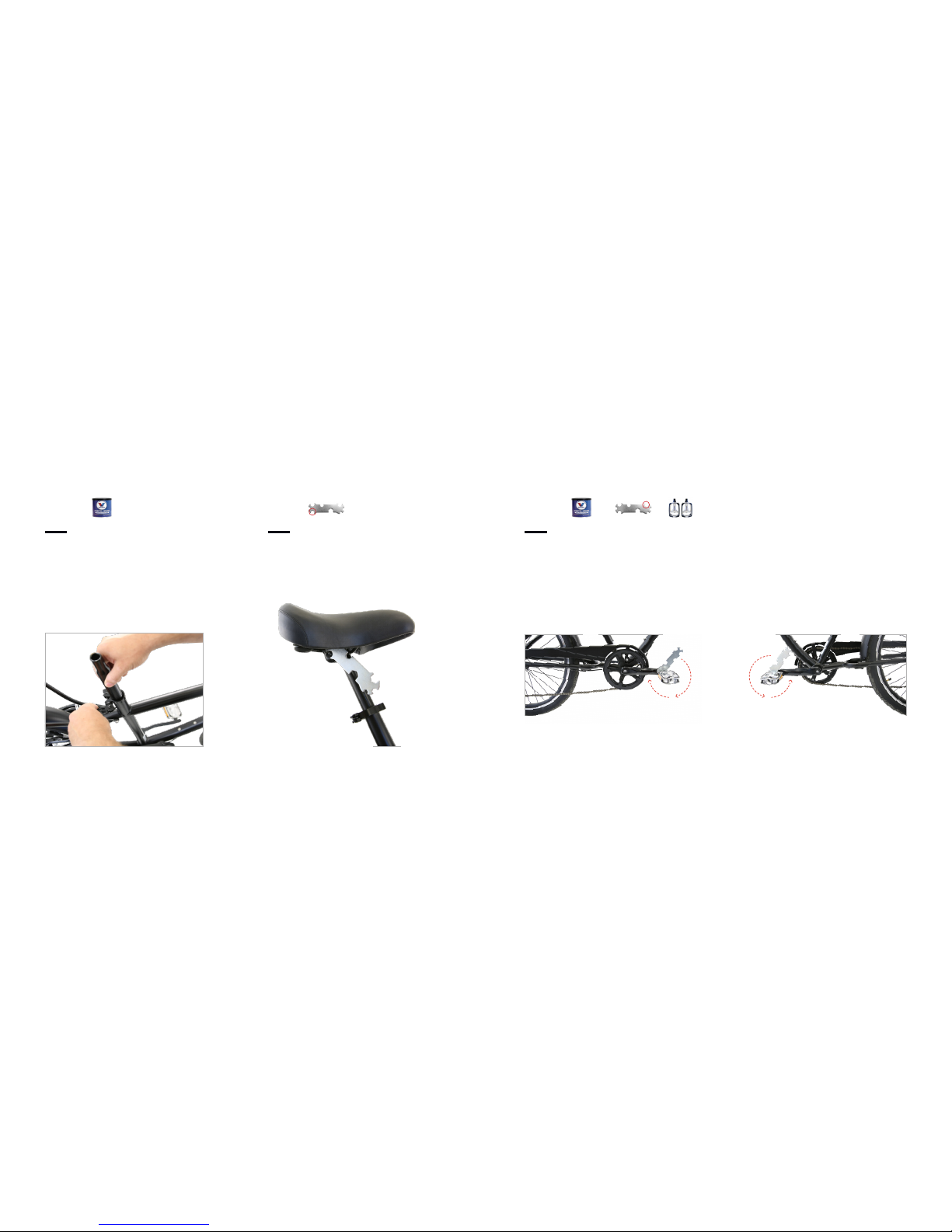

SeatPost

HANDLEBAR,

SEAT + PEDALS

HANDLEBAR

LOCK

NUT CAP

SEAT

6MM

ALLEN KEY

PHILLIPS

SCREWDRIVER

13MM + 15MM

MULTI-TOOL

BICYCLE OR

AUTO GREASE

PEDALS BICYCLE

PUMP

2 .

FENDER

STRUT

1 .

FENDER

STRUT

3.

REAR

RACK

ARM

2.

4MM

ALLEN

KEY

SCREW

4.

4MM

ALLEN

KEY SCREW

1 .

FRAME

ORDER: ORDER:

23

1

1

2

4

Repeat on both sides. Repeat on both sides.

NOTE NOTE

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

HANDLEBAR

STEM BOLT

Line up the stem, frame, and front wheel, then tighten the handlebar

stem bolt.

SeatPost

LOCK NUT CAP

ST1 STEM

ST2 LOCK NUT/

HEAD TUBE

15

Place the lock nut cap in between ST1 and ST2.

HANDLEBARLOCK NUT CAP

Straightening the stem, frame, and front

wheel will ensure that your handlebars

and wheel are properly aligned.

NOTE

ADJUSTMENT BOLT

16

Loosen handlebar adjustment bolt using the 6mm Allen

key. Change the angle of the handlebars to your liking.

Riders typically prefer their grips parallel to the ground.

6MM

ALLEN KEY

Straighten the reflector so that it points forward.

Adjust the position of the

front reflector by loosening

the screw on the bracket.

17 PHILLIPS

SCREWDRIVER

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

18

Apply great to seat lever, then open seat post clamp.

Holding the seat post firmly, insert into seat post tube

until the top is level with your waist.

Close the seat post clamp lever.

Make sure not to drop seat post into the frame.

CAUTION

BICYCLE OR

AUTO GREASE

Place the seat onto the seat post, using the 13mm multi-

tool to tighten the nuts under the seat.

19 13MM

MULTI-TOOL

LEFT PEDALRIGHT PEDAL

20

Apply grease to threading on both pedals.

Select the pedal stamped R and locate the right side of the

bike (with the chain and chain guard). Align threading with

the right crank arm, turning the pedal clockwise to tighten it.

BICYCLE OR

AUTO GREASE

15MM

MULTI-TOOL

PEDALS

Locate the pedal stamped L and align with the left crank

arm. The left side pedal is reverse-threaded, tightening in

a counterclockwise direction.

Hand tighten accordingly, then follow up by tightening

both pedals with the 15mm multi-tool or crescent

wrench.

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

21

Pump air into the tires to the recommended PSI on the

sidewall of the tire.

BICYCLE PUMP

Sit on the bike and check the angle formed by your knee.

If your knee forms the incorrect angle, use the seat post

clamp lever to raise the seat until you have a subtle bend

or achieve a comfortable height.

22

CORRECT INCORRECT

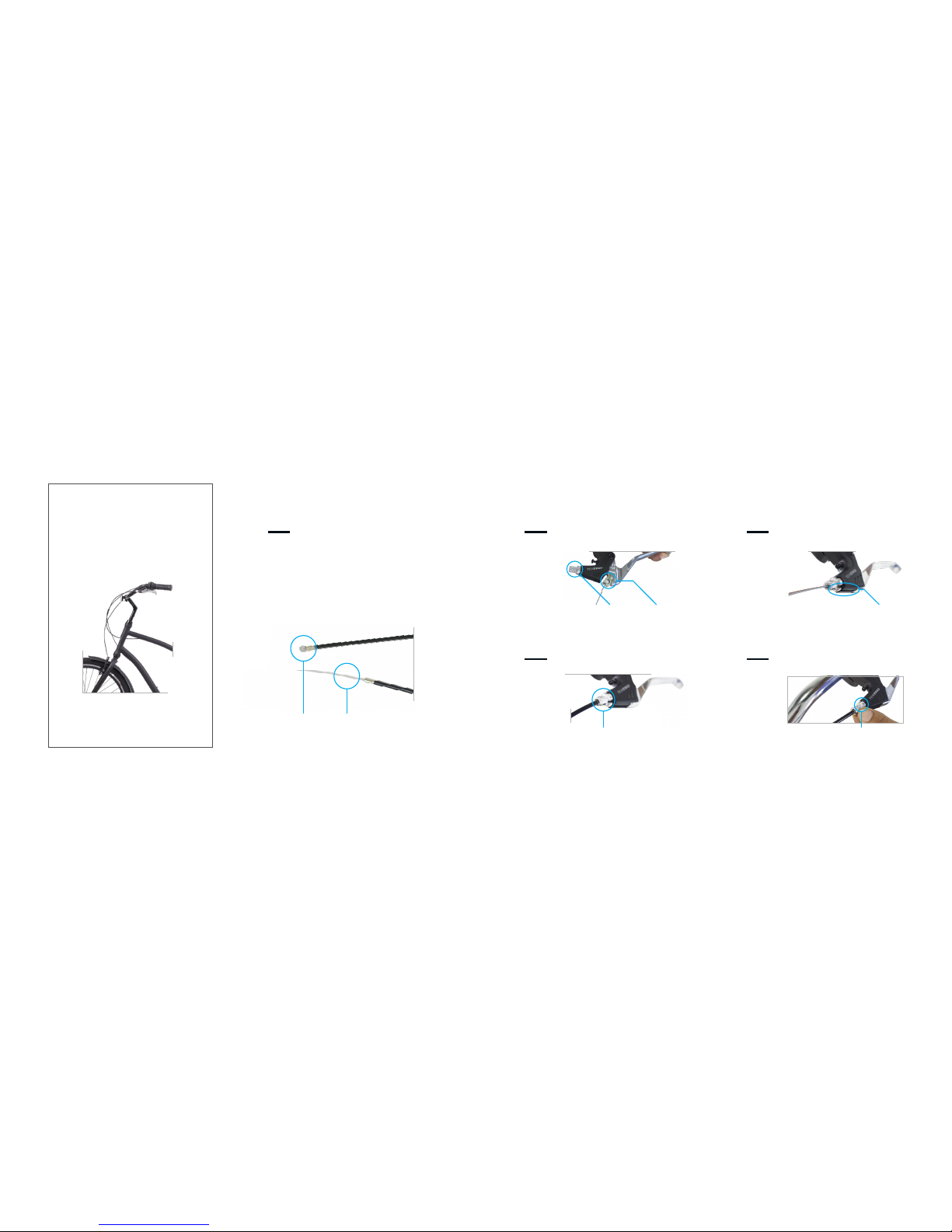

BRAKE

ASSEMBLY

FRONT BRAKE

ARMS + PADS

BRAKE

LEVERS

METAL TUBE

CABLE

HOUSING

BRAKE

ADJUSTMENT

SCREW BRAKE LEVER

BARREL

HANGER

CABLE

BRAKE

HOUSING

BARREL

ADJUSTER

BRAKE

LEVER

CREVICE

SPRING

TENSION

SCREWS

BRAKE PAD

SCREW

BRAKE ARMS

PADS

PHILLIPS

SCREWDRIVER

TOOLS REQUIRED

5MM

ALLEN KEY

DIAGRAM

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

ATTACHED

BRAKE CABLE

Only follow steps 1-9 if your brake cable is not

attached to the bicycle.

If your brake cable is attached, skip to step 10.

NOTE

BARREL CABLE

01

There are two ends to the brake cable.

One end has a barrel attached, while the other end has an

open piece of cable.

02

04 Slide the cable housing up toward the

brake lever until it fits snug inside the barrel

adjuster.

05 Turn the lock ring on the barrel adjuster

clockwise, tightening the barrel to prevent

any loose movement.

LOCK RING

03 Pull on the cable and slide it through the

narrow crevice that runs along the brake

lever.

BRAKE

LEVER CREVICE

BARREL

HANGER

BARREL

ADJUSTER

BARREL ADJUSTER

Attach the brake cable to the brake lever

by squeezing the lever and inserting the

barrel into the barrel hanger.

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

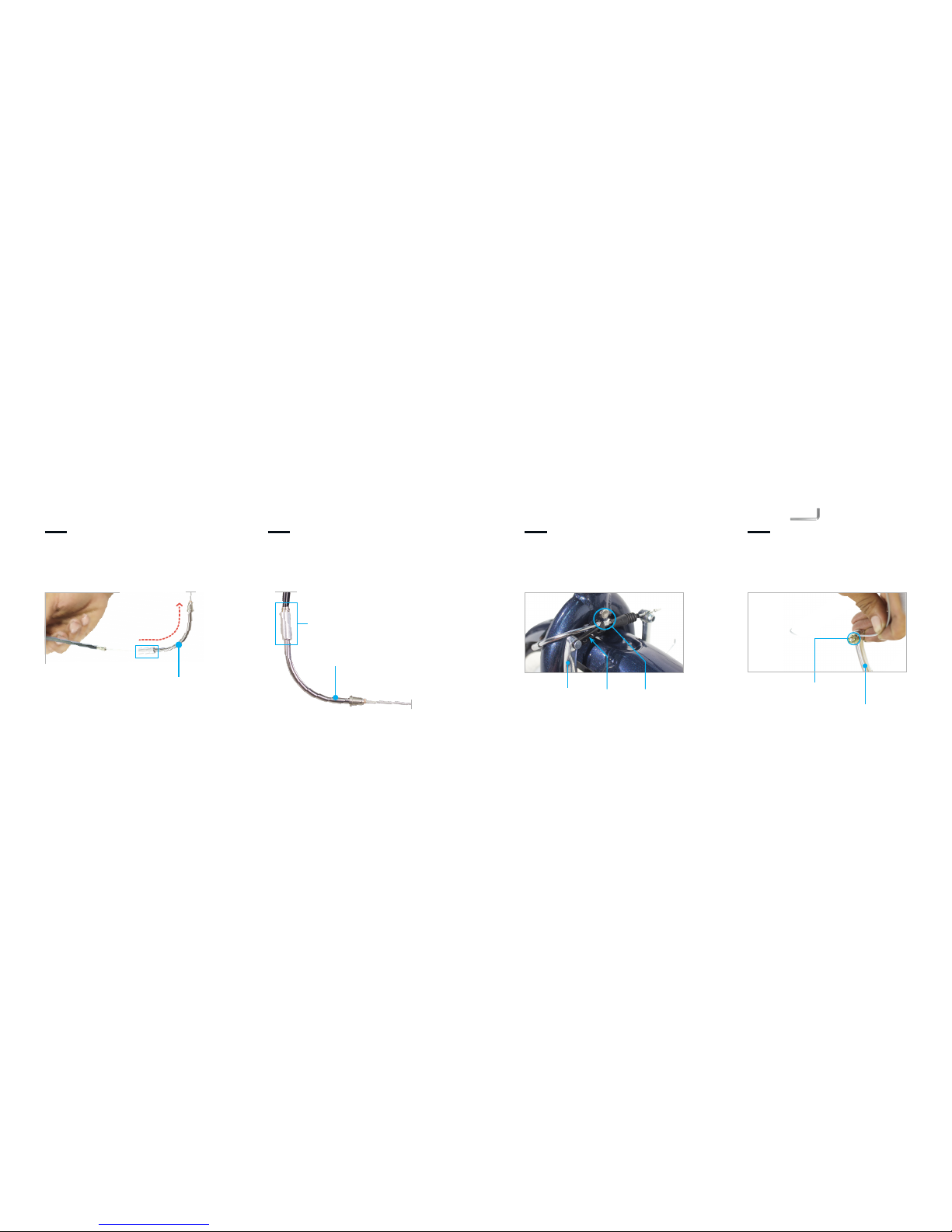

07

Slide the metal tube up the brake cable until the housing

fits snugly into the cable housing.

CABLE GUIDE

METAL TUBE

METAL TUBE

06

Insert the open end of the brake cable into the larger end

of the metal tube.

08

Slide the exposed end of the metal into the metal tube

hanger, located on the left brake arm. Make sure the

metal tube is hooked securely inside the hanger.

LEFT

BRAKE ARM

METAL TUBE

HANGER

END OF

METAL TUBE

Using a 5mm Allen key, loosen the brake cable adjustment

screw. Slide remaining brake cable between the right

brake arm and the adjustment screw.

BRAKE ADJUSTMENT SCREW

RIGHT BRAKE ARM

09

5MM ALLEN KEY

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

10

Pull the cable outward, reducing the distance between

the brake pads and the rim by about 1/4 inch on both

sides. Retighten the adjustment screw.

CABLE

11

Make sure the pads are evenly lined up with the rim. If

the pads rub against the tire, they are too high; if they

don’t make full contact with the rim when braking, they

are too low.

Adjust the positions by holding the brake pad with one

hand and loosening the nut on the back with a 5mm

Allen key.

5MM

ALLEN KEY

ADJUST WITH

5MM ALLEN KEY

12

If one pad seems to run against the rim while the other

still has plenty of space, you will need to center the

brakes. To do this, adjust the spring tensioner screws

located at the base of each brake arm.

Tightening the screw on the right brake arm pushes the

right brake pad away from the rim, and the left brake pad

towards the rim.

Loosening the right screw allows the right brake pad to

move closer to the rim, and the left brake pad away from

the rim.

SPRING

TENSIONER SCREW

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

3 SPEED

DERAILLEUR TUNING

10MM

MULTI-TOOL

PHILLIPS

SCREWDRIVER

DIAGRAM TOOLS REQUIRED

01

Check and adjust gears. Shift into 2nd gear by twisting

the shifting unit. The shifter has an outer exterior that

resembles a gold ball, that us the part that turns.

02

Look through the window in the back of the rear hub.

If the yellow dot is within the parallel lines and arrows,

your bike is properly adjusted.

LOCK NUT

BARREL CABLE

ADJUSTER

CABLE

SHIFTER

HAVING TROUBLE? CALL 310.982.2877 OR EMAIL [email protected].WE STRIVE FOR PERFECT, ALTHOUGH IT’S NOT ALWAYS POSSIBLE, WE NEVER LEAVE A RIDER BEHIND.

03 06

If not adjusted correctly, loosen the lock nut with a

10mm cresent wrench, and turn the adjustment barrel in

either direction. The yellow dot will start to move.

04

Tightening the adjustment barrel in, moves the yellow

dot away from the rear wheel.

10MM

MULTI-TOOL

10MM

MULTI-TOOL

05

Untightening the adjustment barrel out moves the yellow

dot in towards the rear wheel.

Center the yellow dot within the parallel lines. Once the

yellow dot is within range, tighten down the nut using

the 10mm crescent wrench.

Table of contents

Other SixThreeZero Bicycle manuals