SJ TWM30 User manual

Product Description

Product Specification

1/3

Model: TWM30

Differential Pressure Controller

Digital Pressure Gauge

Support multiple working modes

Buit-in buzzer with sound-light alarm,

field programmable alarm pressure value

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Accuracy

±1.0% F.S.

Process connection

Quick coupler

Air inler way: front panel, back

panel, side panel

Case/Ring

ABS

Pressure limitation

0 type: 10 kPa

2 type: 80 kPa

6 type: 5 kPa

Ambient temperature

-20℃ ... 70℃

Medium temperature

-10℃ ... 60℃

Display

LCD, switchable backlight button

Voltage supply

DC 16-30 V

Output signal

None, 4-20mA & 0-10V, RS485

Relay

2 SPDT RELAY 3A@250VAC/30VDC

Control signal

None, 2 SPDT RELAYS

Power consumption

≦ 2.5W

Protection level

IP 54

Weight

360 g

Electrical connections

Cable outlet (0.5 cm)

Nominal size

4.5"

Pressure medium

Gas

Scale ranges

0 type: -1000 ... 1000 Pa

2 type: -10000 ... 10000 Pa

6 type: -100 ... 100 Pa

Pressure units

Pa, kPa, mbar, mmHG, inWC, mmWC

Used to measure fan and blower pres-

sure, filter resistance, medical equip-

ment, etc

2/3

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Product Specification

Accuracy

±1.0% F.S.

Process connection

Quick coupler

Air inler way: front panel, back

panel, side panel

Case/Ring

ABS

Pressure limitation

0 type: 10 kPa

2 type: 80 kPa

6 type: 5 kPa

Ambient temperature

-20℃ ... 70℃

Medium temperature

-10℃ ... 60℃

Display

LCD, switchable backlight button

Voltage supply

DC 16-30 V

Output signal

None, 4-20mA & 0-10V, RS485

Relay

2 SPDT RELAY 3A@250VAC/30VDC

Control signal

None, 2 SPDT RELAYS

Power consumption

≦ 2.5W

Protection level

IP 54

Weight

360 g

Electrical connections

Cable outlet (0.5 cm)

Nominal size

4.5"

Pressure medium

Gas

Scale ranges

0 type: -1000 ... 1000 Pa

2 type: -10000 ... 10000 Pa

6 type: -100 ... 100 Pa

Pressure units

Pa, kPa, mbar, mmHG, inWC, mmWC

Dimensions

135

115

33

43

76

Unit: mm

3/3

※ Ordering information

Model / Scale range/Output signal / Control signal / Options

SIN JIA ENTERPRISE COMPANY LIMITED

TEL: +886-2-2550-4512

FAX: +886-2-2550-4510

www.sj-gauge.com

No.3, Ln. 71, Chifeng St., Datong Dist., Taipei City 103, Taiwan

For any changes to the specifications of this catalogue,the latest version shall prevail.

Operation Manual

Panel Display

Differential Pressure Controller

Model: TWM30

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

1/10

SET/SP

button

Button

Descriptor

Pressure unit

Pressure value

BACK/ZERO

button

Button

Bleeder vent

※ Note: Press and hold for 3 seconds.

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

2/10

Menu Instruction

■ Set point and alarm setting sort display:

Press and hold to enter the relay control point and alarm point setting menu. This

menu display is based on the control mode selection in the submenu. 3 control modes are

set separately:

(1) ISP: Control relay works alone

(2) 2SP: Control relay and alarm relay work independently

(3) SPAL: Control relay work and alarm relay is used as alarm function output

In the 2SP mode, the alarm relay works; in the control mode, SP2H and SP2L are the high

and low points of its control action respectively; for specific control logic, please refer to P6

"Out output". In the SPAL mode, the alarm relay works in the alarm state output mode, ALHI

and ALLO are respectively the high and low points of its alarm signal output.

Pressure Display Main Menu Sub-menu

Press to enter the

sub-menu

Scroll down the main

menu to switch the

sub-menu function

switch

X

Back to Main Menu

1. Press to enter the main

menu

2. Press and hold to enter

the control point setting

and alarm point setting

Eliminate the buzzer alarm

sound

Backlight switch

1. Press to cancel the alarm

status

2. Press and hold to reset

the setting

1. Enter the sub-menu

function setting

2. Save the parameter

setting (the parameter

flashes during setting)

1. Return to the previous

main menu

2. Press and hold to return

to the main menu

1. Decrease the value

2. Move the setting button

Increase the value

Operation Manual

SET

SP/AL

SET

SP/AL

BACK

ZERO

Differential Pressure Controller

Model: TWM30

3/10

■ Menu navigation:

control point setting and alarm pont setting

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Operation Manual

Differential Pressure Controller

Model: TWM30

SET

SP/AL

SET

SP/AL

BACK

ZERO

Pressure display

Press and hold

for 3 seconds

Flashing

Control mode

1SP

Visible when AL

mode=LD

Visible when AL

mode=LDHI

Visible when AL

mode=HI

Control mode

SPAL

Control mode

2SP

4/10

■ Menu navigation: main menu

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Operation Manual

Differential Pressure Controller

Model: TWM30

SET

SP/AL

BACK

ZERO

SET

SP/AL

BACK

ZERO

SET

SP/AL

BACK

ZERO

SET

SP/AL

BACK

ZERO

BACK

ZERO

Press and hold

for 3 seconds

Pressure display

(Continued)

Unit setting

Filter level

Output control

Alarm mode

setting

Working mode

Alarm relay status

when alarming

Alarm working

mode

Inhibition of alarm

signal at power-on

Alarm delay

time

Flashing

Flashing

5/10

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Operation Manual

Differential Pressure Controller

Model: TWM30

SET

SP/AL

BACK

ZERO

SET

SP/AL

BACK

ZERO

(Continued)

Pressure peakPressure valley

Analog signal ranges

setting high value

Output signal

selection

Analog signal ranges

setting low value

Baud rate

Reset

6/10

Instruction of Main Menu Functions

■ pressure unit

Used for pressure unit selection and setting.

Pascal (Pa), kilopascal (kPa), Millibar (mbar), millimeters of mercury (mmHG), inches of

water column (inWC), millimeters of water column (mmWC)

Among them, only Pa, mmWC, mbar three units can be selected when the range is -100 ...

100 Pa.

■ pressure filter level

A total of 0~7 filter levels can be used. Used to adjust the air pressure detection sensitivi-

ty.

■ output

Used to set the working mode setting, 1 control output, 2 control output or 2 control and

alarm output mode.

(1) MODE submenu (working mode setting):

1sp: 1 relay control output

2sp: 2 relay control output

Spal: 1 relay control output, alarm relay status output

(2) 1SP submenu (for 1 relay control direction):

(3) AL submenu (alarm mode setting):

HI-high pressure alarm, Lo-low pressure alarm, Hilo-high and low pressure alarm

(4) ALOS sub-menu (alarm relay status when alarming):

Clos-The alarm relay will act on when it alarms;

Open-When alarming, the alarm relay action is disconnected;

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Operation Manual

Relay do not operate

Relay operation

REV-Reverse control

Upper limit

Lower limit

DIR-Direct control

Differential Pressure Controller

Model: TWM30

7/10

Errl : Zero clearing failed

Err2: Failed to set the max limit (the max limit must be greater than the min limit)

Err3: Failed to set the min limit (the max limit must be greater than the min limit)

Err4: The password for restoring factory settings is entered incorrectly

Err5: Pressure sensor error

System Error Remark

(5) ALrE sub-menu (alarm working mode):

Onof-Alarm automatically turns on and off

Hold-Alarm status is maintained until the alarm is manually cancelled

(6) AL.H sub-menu (inhibition of alarm signal at power-on):

N-Turn on the power-on alarm signal suppression; eliminate the low-voltage alarm when

starting up

Off-Turn off the suppression of the power-on alarm signal; the low-voltage alarm is direct-

ly output when the power is turned on

(7) ALdL submenu (alarm delay time):

0-3600: The maximum delay is 3600 seconds

■ display

Peak: Pressure peak; valy: pressure valley

■ more settings

Output signal control and RS485 control parameter settings.

(1) RNGL: analog signal range setting low value;

(2) RNGH: analog signal range setting high value;

(3) Out: output signal selection

I: Single current signal output U: Single voltage signal output

I-u: current and voltage signal output 485: 485 signal output

(4) bAUd: RS485 communication baud rate setting

(5) Addr: RS485 communication address ID setting

■ reset

Enter the number 1234 to confirm the factory reset.

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Operation Manual

Differential Pressure Controller

Model: TWM30

8/10

Electrical Connections

■ Cable outlet type: connect according to the corresponding wire color.

■ Trachea connection

The back of the product supports side and back air intake; the back and the side vents are

connected; therefore, after using one of the vents, you need to plug the vent on the other

side with a plug; the + hole connects the trachea to the high pressure area to be measured;-

Connect the trachea to the low pressure area to be measured.

M10

M16

DC power cord interface

Current output port, connect to the positive end of the

multimeter, and the other end to Power-

Voltage output port, connect to the positive end of the

multimeter, and the other end to Power-

RS485 Communication interface

Power +

Power -

4~20mA Output

0~10V Output

RS485_A

RS485_B

SP1 RELAY N/O

SP1 RELAY COM

SP1 RELAY N/C

Normal open

Common

Normal close

Normal open

Common

Normal close

SP2 or Alarm RELAY N/O

SP2 or Alarm RELAY COM

SP2 or Alarm RELAY N/C

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Operation Manual

Description

Connection

Connection

Cable outlet

Cable outlet Cable description Cable descriptionCable outlet function

Differential Pressure Controller

Model: TWM30

9/10

Installation

Panel Screw Gague Plastic Wall

Hole diameter 106.6 mm

■ Panel installation

Open a 120mm diameter hole on the panel to be installed, insert the product from the

front of the panel, and finally install the lug on the back, and then fix it on the panel from

the back with ST3.5x30 screws. The pressure port and the air pipe are connected reliably,

pay attention to the difference between the high and low pressure ports.

■ Embedded installation

Panel

Gauge

3 lugs

■ Accessories

Static pressure tips, plastic lug, self-modified screw, wall head, expansion tube, PU tube

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Operation Manual

Differential Pressure Controller

Model: TWM30

Frequently Asked Questions

■ The pressure display or output value does not change after pressurization (mostly

displayed as 0 or FULL ) or the change is not accurate.

(1) Whether the loading pressure exceeds the burst pressure and directly breaks the

pressure core.

(2) Whether the medium used is corrosive or differs from the applicable medium of the

purchased product.

(3) Check whether the intake hose is blocked by foreign matter (particulate matter or

water column) or leaks.

(4) Whether the use environment temperature exceeds the compensation temperature

range.

(5) Whether there is a misoperation of clearing during pressurization, if any, clear again

after confirming that there is no input pressure.

■ A slight drift in the zero pressure value

After the drift is stable, perform the reset operation.

■ Attention

(1) The power supply should be disconnected during the installation process, and the

power interface should not be short-circuited, otherwise it will bring unpredictable conse-

quences and even damage the product.

(2) Please use within the rated voltage range.

(3) Do not make the pressure exceed the withstand pressure value, otherwise it may

damage the product and safety.

(4) Some unused output wires need to be wrapped with insulating tape to avoid possible

short circuits.

Operation Manual

10/10

Copyright © 07/2022 by SIN JIA ENTERPRISE COMPANY LIMITED. All rights reserved.

Differential Pressure Controller

Model: TWM30

Table of contents

Popular Controllers manuals by other brands

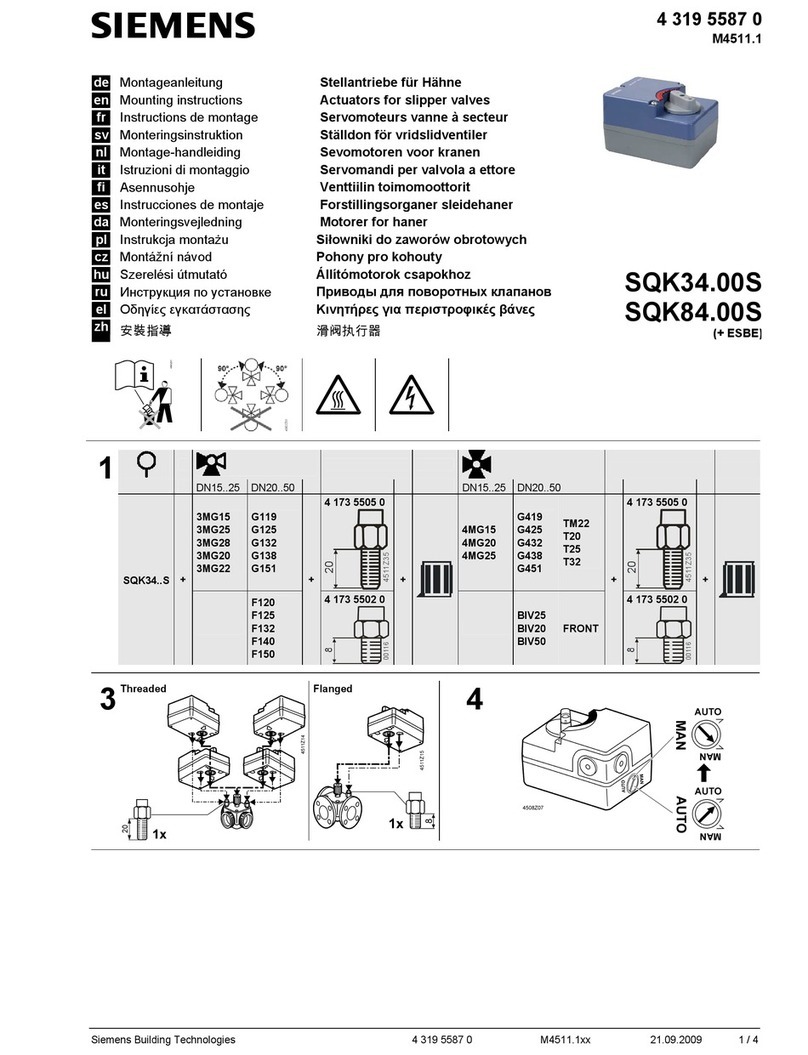

Siemens

Siemens SQK34.00S Mounting instructions

I2R Tech Lighting Solutions

I2R Tech Lighting Solutions Moving Head Controller 2.0 user manual

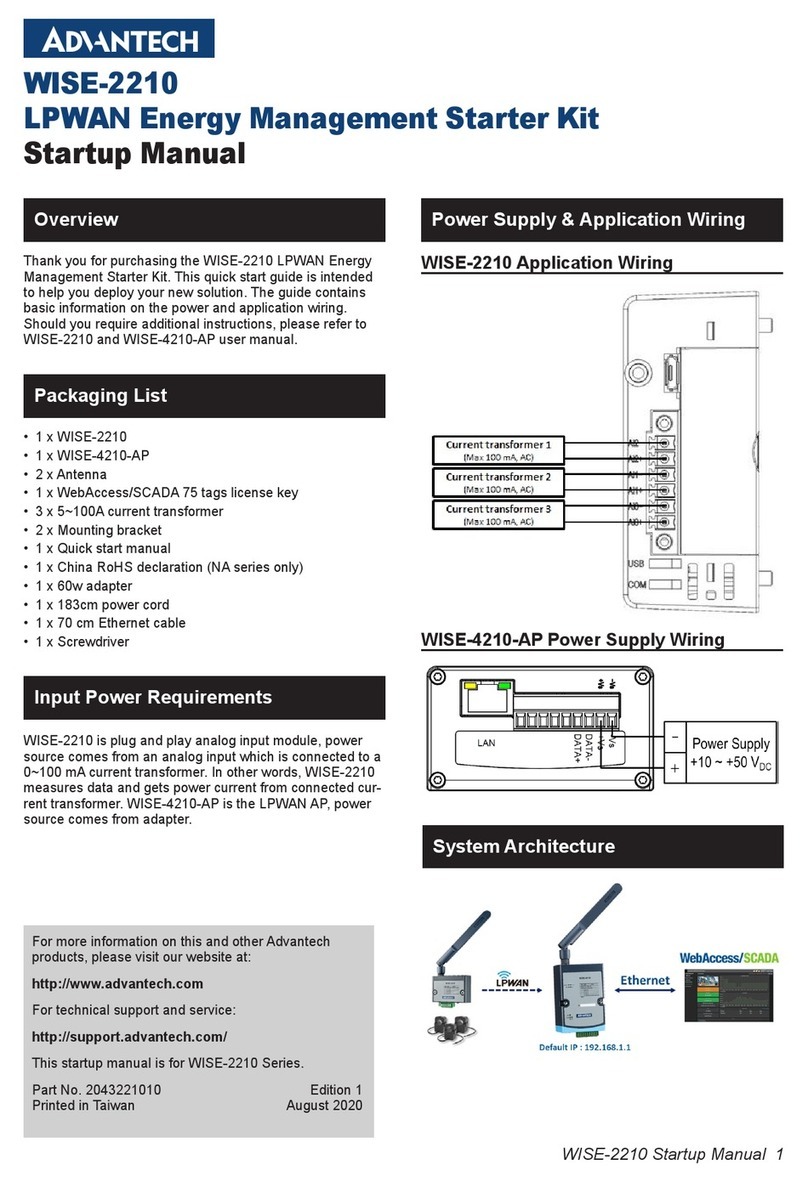

Advantech

Advantech WISE-2210 Startup manual

PowMr

PowMr Pstar-30A user manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R16MTCPU Programming manual

Martem

Martem TELEM-AGC-L user manual

kincrome

kincrome K13350 instruction manual

ABB

ABB Jocab Safety Vital 2 Operating instruction

Marshall Electronics

Marshall Electronics VS-PTC-50 user manual

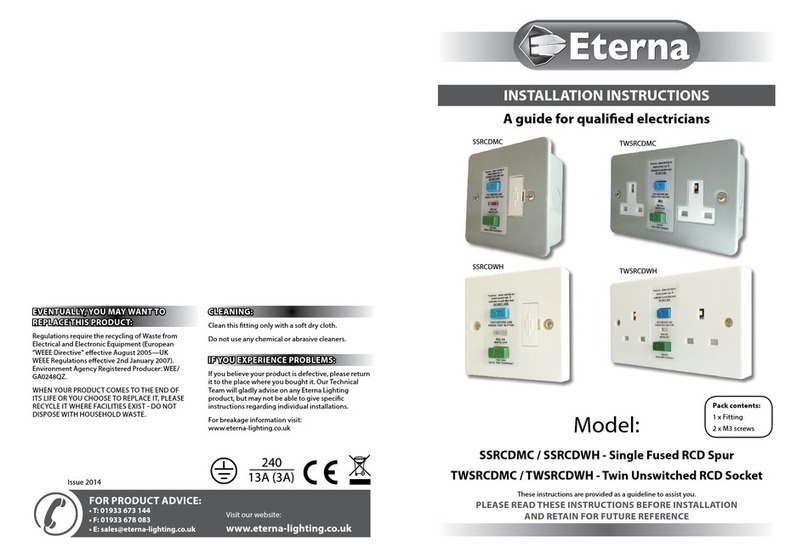

Eterna

Eterna SSRCDMC installation instructions

Siemens

Siemens Simatic S7-1500 Getting started

Comar Condensatori

Comar Condensatori BMR4 Installation and user manual