SJE Optima EST series User manual

Manufactured by

SJE Corporation, Ltd.

User’s Manual

Operating and Maintenance Instructions

Model: OPTIMA EST Series

<For EST (05K, 12K, 18K, 27K)>

Ver. G2.1.00

Distributor’s Contact Information:

7

Published by SJE Corporation, Ltd.

Copyright © 2013 by SJE Corporation, Ltd.

78-21, Sandan 7-Ro, Jeonggwan-Myeon, Gijang-gun

Busan, Republic of Korea

Tel: +82 51-521-3200

Fax: +82 51-521-3305

Website: http://www.sjecorp.com

E-mail: [email protected]

All rights reserved. No part of this publication may be reproduced, stored

in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior permission of SJE Corporation, Ltd.

Printed in Republic of Korea

SJE20160101

TableofContents

Introduction ------------------------------------------------------------------------------------------------------ 1

Intended Applications------------------------------------------------------------------------------------------ 1

Safety Precautions--------------------------------------------------------------------------------------------- 1

Symbols Key----------------------------------------------------------------------------------------------------- 3

Product Specifications----------------------------------------------------------------------------------------- 4

Exterior Descriptions------------------------------------------------------------------------------------------- 5

Pre-start Procedures------------------------------------------------------------------------------------------- 6

Initial Operation ------------------------------------------------------------------------------------------------- 8

Standard Operating Procedures---------------------------------------------------------------------------- 9

Moisture Control -----------------------------------------------------------------------------------------------10

Pause Operations ---------------------------------------------------------------------------------------------11

Shutdown Procedures----------------------------------------------------------------------------------------11

Freeze Prevention---------------------------------------------------------------------------------------------12

Maintenance----------------------------------------------------------------------------------------------------14

Safety Features------------------------------------------------------------------------------------------------19

Troubleshooting guide----------------------------------------------------------------------------------------21

Optional Items--------------------------------------------------------------------------------------------------25

1

Introduction

The Optima Steamer represents the future of environmentally friendly and effective cleaning. Safe,

durable and easy to use, the Optima will support your cleaning operations for many years to come.

IntendedApplications

.

The Optima Steamer is designed for cleaning surfaces capable of handling steam jet pressure of up

to 7~8.5 bar (101~123 psi) and maximum temperatures reaching at 135℃(275℉).

The Optima Steamer is capable of cleaning various surfaces including, but not limited to machinery /

parts, vehicle exteriors and interiors, engine compartment, glass, metal surfaces, windows, wheel

wells, vents, kitchenware, remove weeds and much more while simultaneously sanitizing and

deodorizing with very little water consumption.

SafetyPrecautions

Before operating the Optima for the first time, read the manual completely.

The manufacturer and distributors are not liable for the mechanical troubles, property

damage, or personal injury caused by the operator(s) unfamiliarity with the manual’s

instructions.

•With regards to the steam vessel, use only water and the manufacturer’s recommended steam

vessel cleansing solution. Do not put any other chemicals or detergents into the water tank or

steam vessel.

•Do not use distilled water or filtered water under 15 ppm

•“Soft” water is recommended. Otherwise, use only clean tap water with anti-scaling solution.

•The electric supply connection should be done by a qualified electrician and complied with IEC

60364-1.

•Make sure that all the switches on the machine are off before plugging the machine into an

electrical outlet.

•If an extension cord is used, insure that it is constructed waterproof and of proper diameter

based on the cord length and required the electrical specifications.

•Turn off and unplug the machine from its power source and allow the Optima Steamer to cool

down before carrying out any maintenance.

•Use only hoses, steam-guns and all other accessories recommended by the manufacturer. Use

manufacturer approved parts only.

•Use and store the Optima on a leveled up surface only.

•Do not use the machine in rain or snow outdoors. The Optima Steamer is not weather-proof or

water-proof.

•Never leave the machine unattended while in use.

•Never store the machine below 0℃(32℉) or extremely cold weather condition.

•In cold climates, do not allow water to sit when the Optima is not in use. Do not operate the

machine if any parts are frozen or suspected of being frozen. (See “Freeze Prevention on

page12)

2

•Do not use the Optima if any part, power cord, safety device, hose or spray gun is visually

damaged or suspected of being damaged.

•Use proper ear, eye and hand protection when operating the Optima. Noise can be generated

from steam pressure and it can be reach 95 decibels (dB).

•Do not use the machine within the reach of people who are not wearing any protective gears.

•Do not direct the steam jet spray, aim or discharge at itself, live electricity, people or animals.

•The machine is not to be used by children or persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction.

•Keep the Optima away from children and animals at all times.

•Children should be supervised to ensure that they do not play with the machine.

•Never disable a sensor in order to bypass an alarm.

•To provide continual protection against risk of the electric shock, connect properly to grounded

outlets only.

3

SymbolsKey

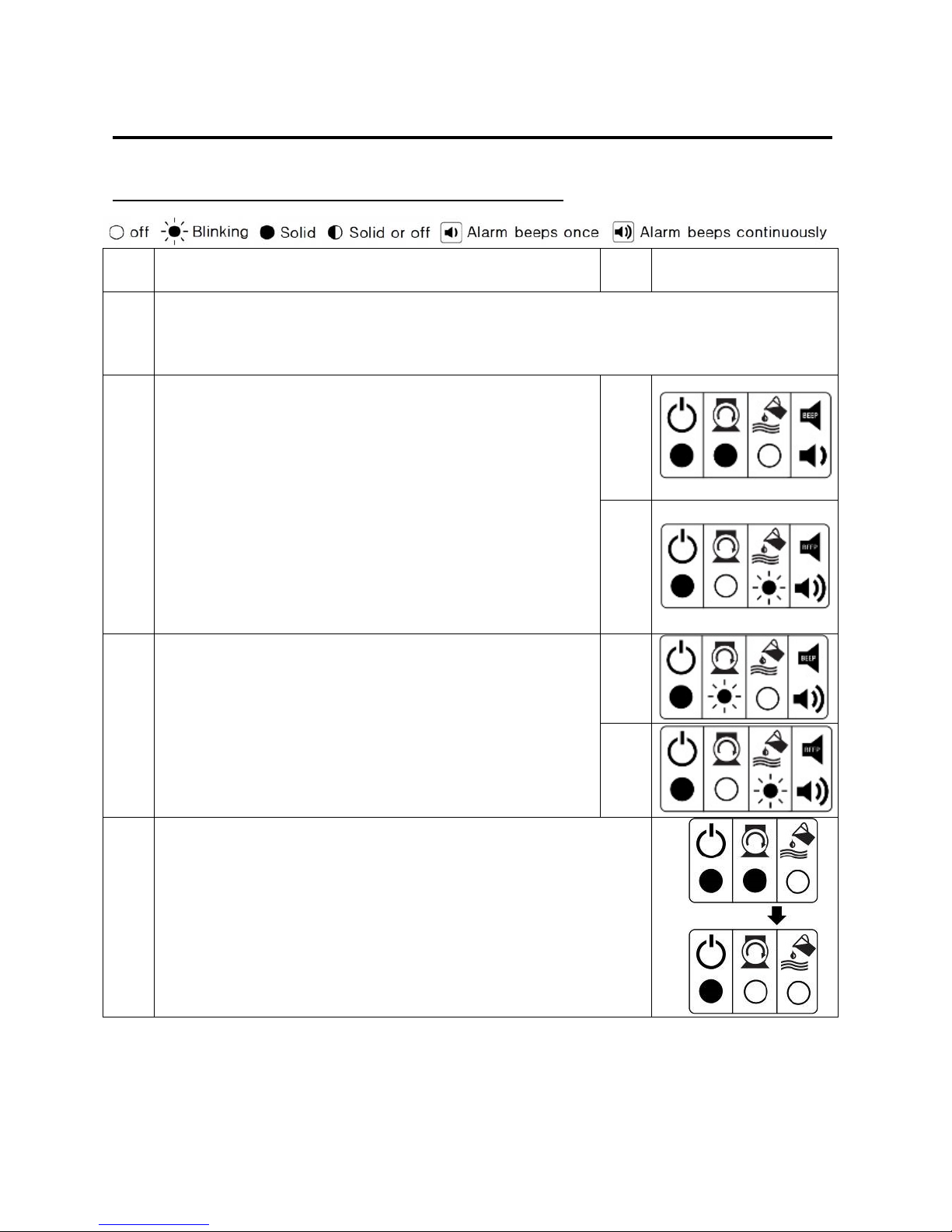

LED Light Indication

Main Power on.

Water pump run on. Water pump over-run

flashing.

Low water level detection

error on.

Water tank level low

flashing.

Alarm beeps once.

Alarm beeps continuously.

Do not direct the steam jet

at people, live electricity,

animals, etc.

Read the manual.

Warning: risk of burns. Water pump run

Feed-Water

Warning:

risk of electric shock.

Water supply connection. Caution.

Pressure gauge Ground

Thermistor Main power

Electric Heater Steam jet

TS

TS

4

ProductSpecifications

Model Name Optima EST (05K, 12K, 18K, 27K)

Capacity Display 05K 12K 18K 27K

Working Pressure 7~8.5 bar / max 9.5 bar (101~123 psi / Max 137.7 psi)

Spraying Temperature < 135℃(< 275℉)

Boiler / Steam

Temperature 174℃/ max. 180℃(346℉/ Max 356℉)

Preheating Time

(in minutes) 20~21 8~9 6~7 6~7

Rated Electric Power

(KW) 5.2 12.2 18.2 27.2

Voltage / Hertz

(Customization available

in the specified range)

200 ~ 240V, 1Ph

50/60 Hz

200 ~ 480V, 3Ph,

50/60 Hz

Water Tank Capacity 40 ℓ(10.6 gals)

Water Consumption

Rate (Max) 300 ~ 1200cc/min (0.08~0.32gpm)

Net Weight (kgs / lbs) 74 kgs

(163 lbs )

83 kgs

(183 lbs)

Product Dimensions

[L] x [W] x [H] 1090 x 700 x 900 mm (43 x 28.3 x 35.4 inch)

Note!

*To ensure safety and machine effectiveness, do not modify factory settings for steam pressure

and temperature.

* Water consumption rate may vary based on the use of the moisture valve and business

applications. (See page 10, “Moisture Control”).

5

Exterior Descriptions Model Name: EST(05K, 12K, 18K, 27K)

1. Top Cover

2. Lateral/Side panel

3. Tank cap

4. Water tank

5. Throttle door

6. Front wheel

7. Y-strainer

8. Non-return valve

9. Quick Plug for feed-water

10. Drain valve

11. Moisture control valve

12. Turning wheel with brake

13. Steam outlet

14. Warning sticker

15. Specification sticker

16. Handle

17. Control box

18. Operating instruction sticker

19. LED signal information

6

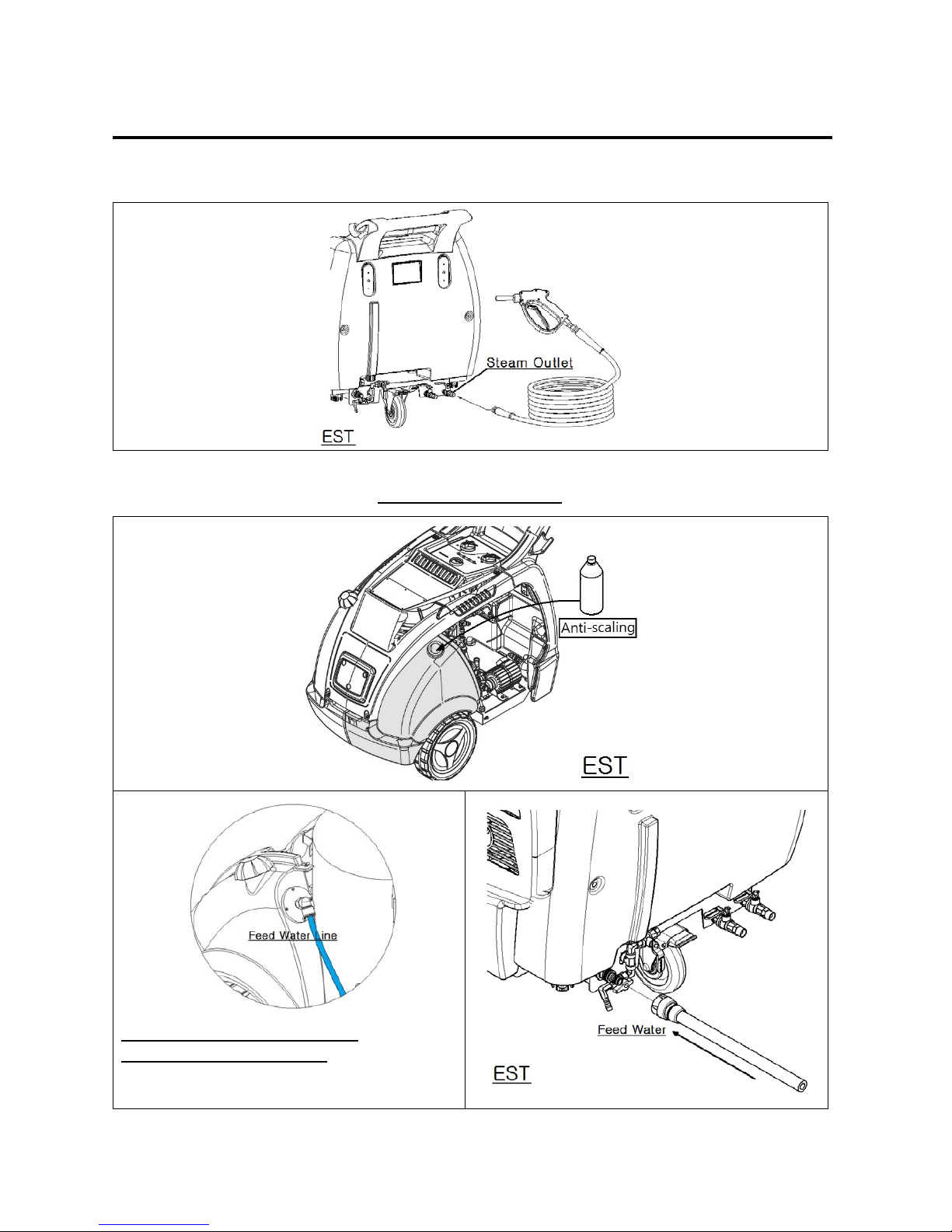

Pre-start Procedures

Steps:

1. Connect the steam hose and gun to the steam outlet valve. Ensure a tight connection (use tools).

2. Fill the water tank with soft water. When tap water is used, add anti-scaling solution to the water

tank as instructed by the supplier. Do not use distilled water.

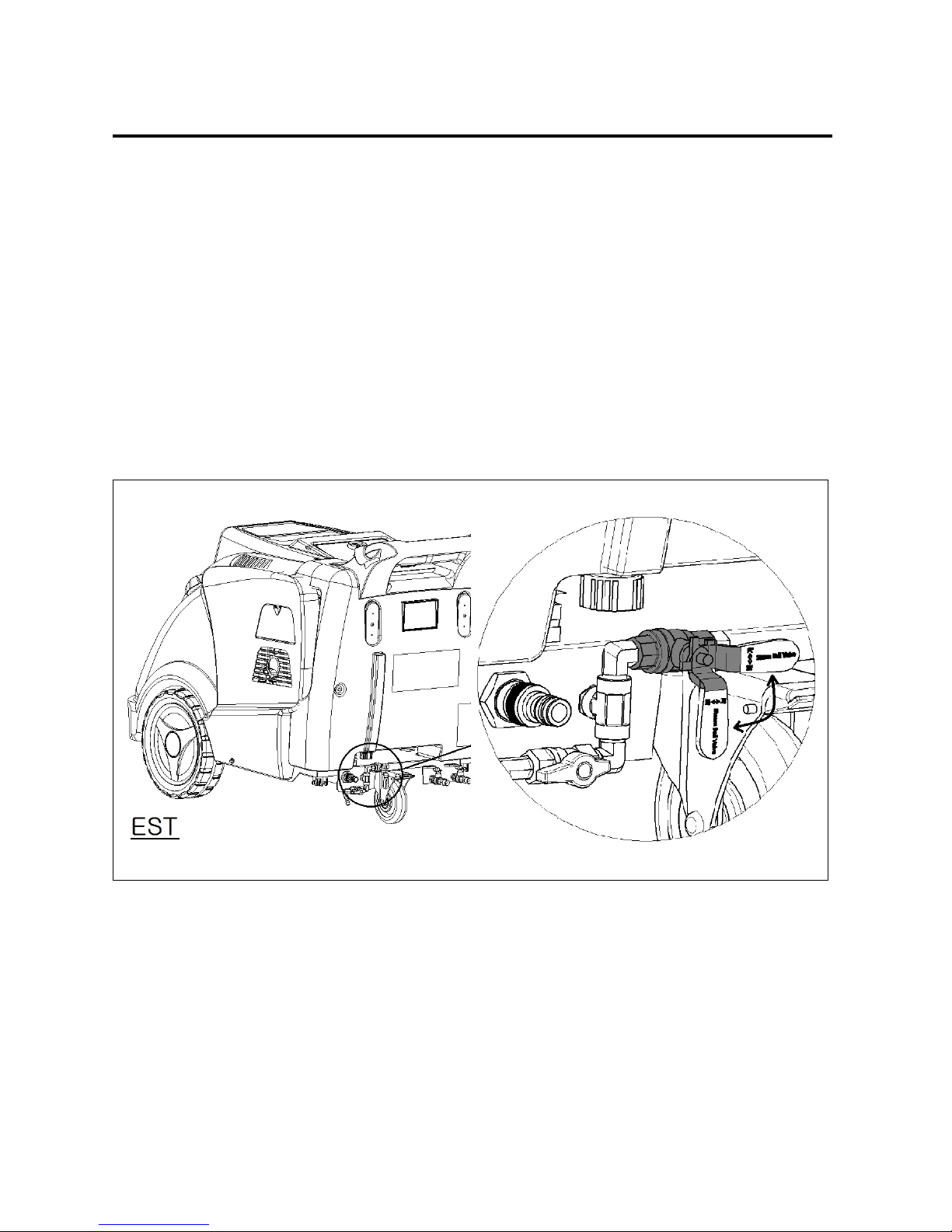

Automatic Water-filling System

[Standard for Optima EST ]

You may connect water hose directly to the

machine using the provided quick-coupler.

7

Anti-scaling water treatment

If water other than treated soft water is used, scale will build up on steam vessel walls, probe

sensors and pipes. This will adversely affect the performance and lifespan of the machine. In order to

prevent this, we recommend operators to use anti-scaling solution. Simply add anti-scaling solution

every day and ensure that the steam vessel is drained at the end of the day. This procedure will

prevent scale build-up inside steam vessel and increase the thermal efficiency of the machine.

Use manufacturer recommended steam vessel anti-scaling solution only.

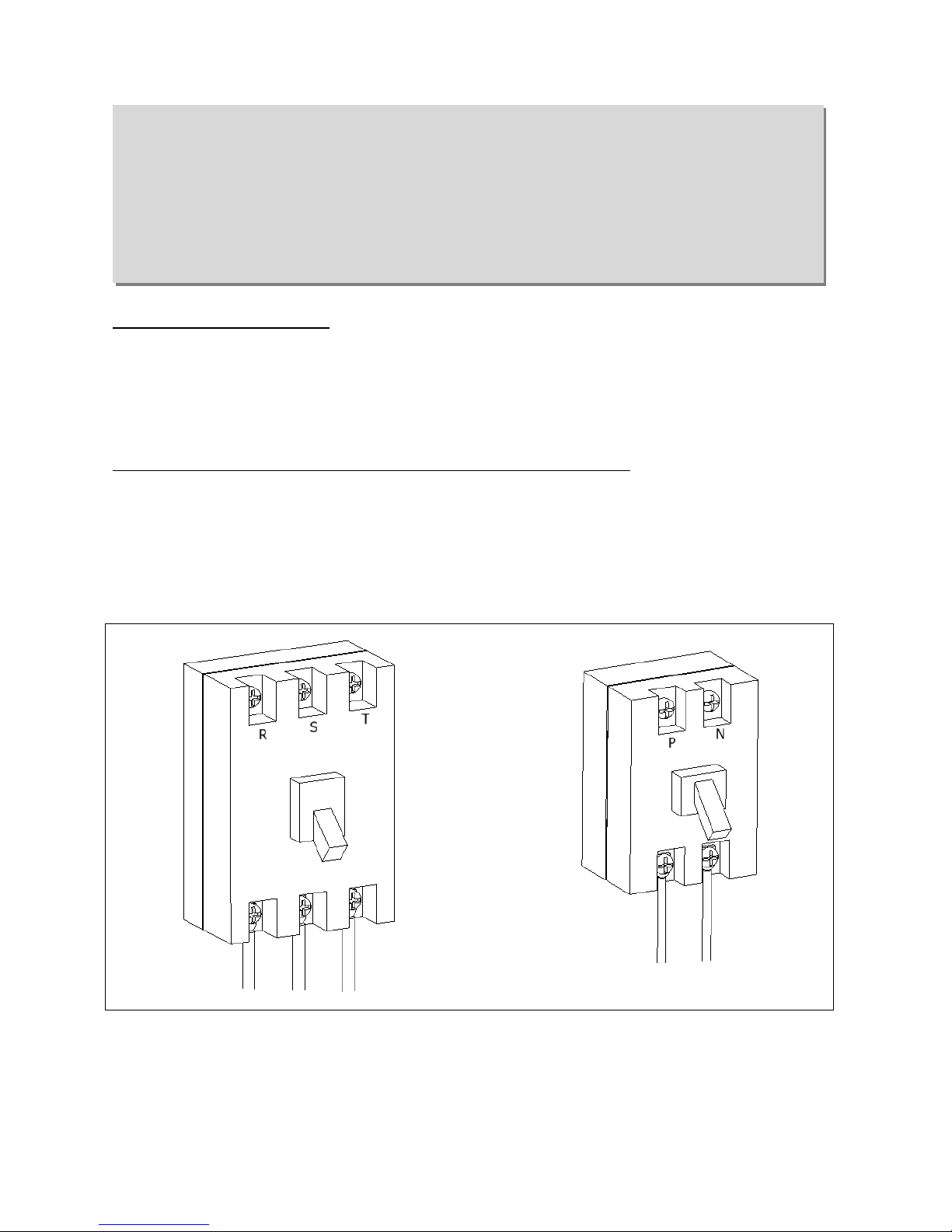

3. Connect the machine to required power source.

Make sure that machine switches and breaker switches are off before connecting the machine to a

breaker. Connect the power cable, R, S, and T for 3 phase models EST(12K, 18K, 27K) and P and N

for the single phase model [EST (05K)] to the breaker. Connect the grounding cable to grounding

point and turn on the breaker switch.

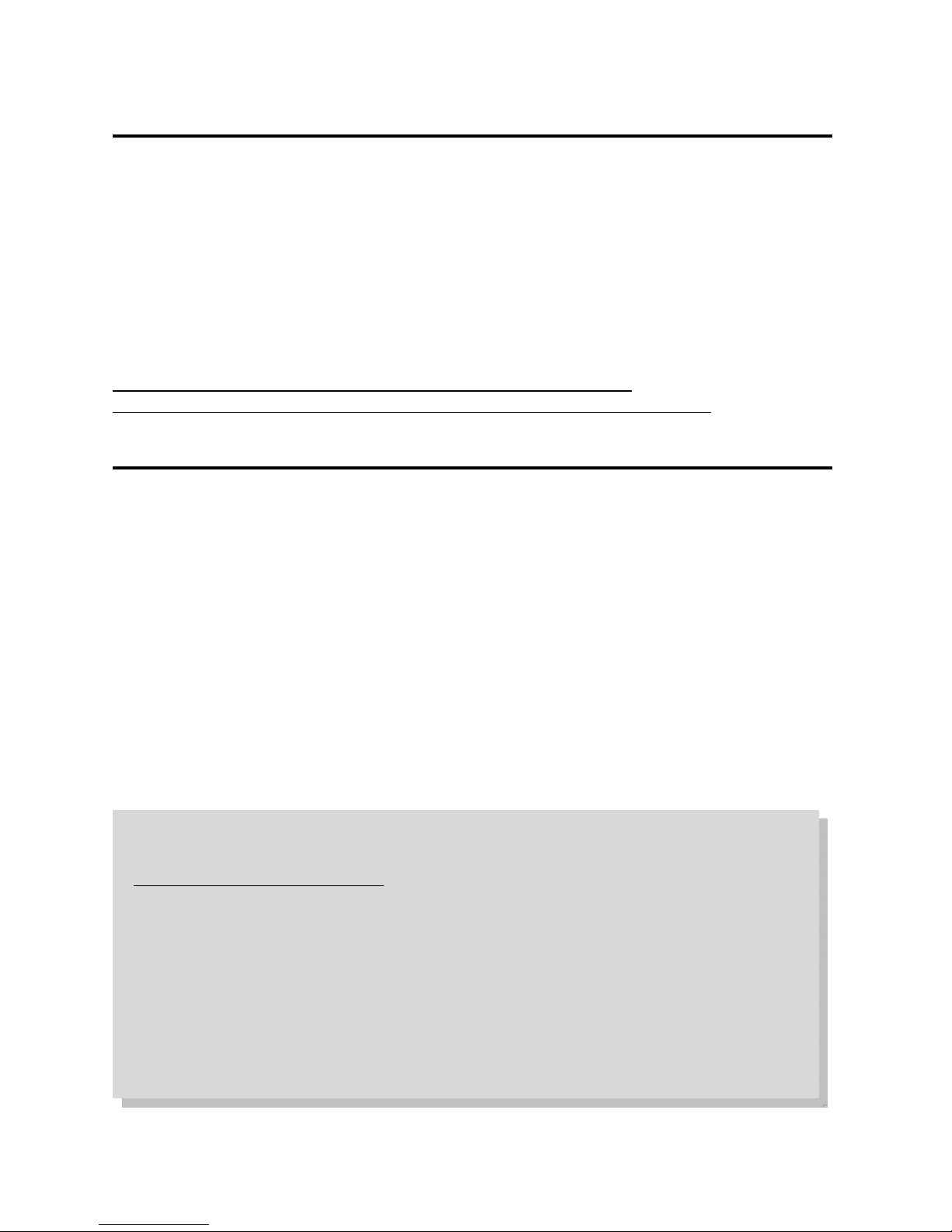

Water Quality Matters!

Water quality can greatly affect the Optima’s life span/time and performance. It is important to

use SOFT WATER. If tap water is used, daily use of water treatment (water softening liquid) and

regular sediment removal will help ensure efficient operations (see page 14 “Maintenance A & B”

for more information).

Do not use distilled water. Do not put any other chemicals or detergents into the water

tank or steam vessel.The feed water temperature should be above 5℃(40℉).

8

Initial Operation

“Initial operation” means operating the machine after draining all water from the steam vessel.

After completing the pre-start procedure, follow the steps below.

Steps Instructions / Corrective action Type Signal indications

1

Make sure the water tank is full. (If using the auto water filling system, connect water hose to

water supply source, i.e. faucet and open the valve)

Connect the power cord to the outlet. (Double-check the breaker capacity)

2

Turn on the POWER (EMERGENCY STOP) switch and

then turn on the STEAM switch. You will see one of the

following signal indications.

A: POWER and WATER PUMP RUN light are on. The

water pump supplies water to the steam vessel for about

120 seconds

B: The POWER light is on and the WATER TANK light is

flashing, and the alarm is going off. This means the float

switch in the water tank does not detect water. Add water to

the water tank.

A

B

3

If the alarm beeps continuously for more than 120 seconds,

you will see either A or B signal indications.

A: If water pump runs over 120 seconds at initial operation,

check the condition for the pump and water filter then reset

the STEAM switch.

B: Insufficient water. Refill the water tank.

A

B

4

When water supply reaches the low water probe sensor,

programmed normal Operation will begin. You will see 2 lights

(POWER & WATER PUMP RUN) on, and then WATER PUMP

RUN light will turn off when water reaches the high water probe

sensor.

Note!

When using the Optima after draining the steam vessel, the above procedure must be repeated.

9

StandardOperatingProcedures

Steps:

1. Turn on the POWER (EMERGENCY STOP) switch, and then turn on the STEAM switch. If the

alarm beeps once, and the POWER light is on, the machine is ready to operate.

(If you are starting the Optima for the first time or using after draining the steam vessel, refer to

“Initial Operation” on the previous page.)

2. Once heating starts, it will reach the operating pressure within 6~21 minutes.

(Pre-heating time varies per model).

3. After the steam pressure reaches 8.5 bar (123.2 psi), open the steam outlet valve(s) and begin

to operate.

Review all safety precautions on page 1~2. Never leave the machine unattended.

The exhaust is very hot. Take precautions when operating the machine in a

confined space.

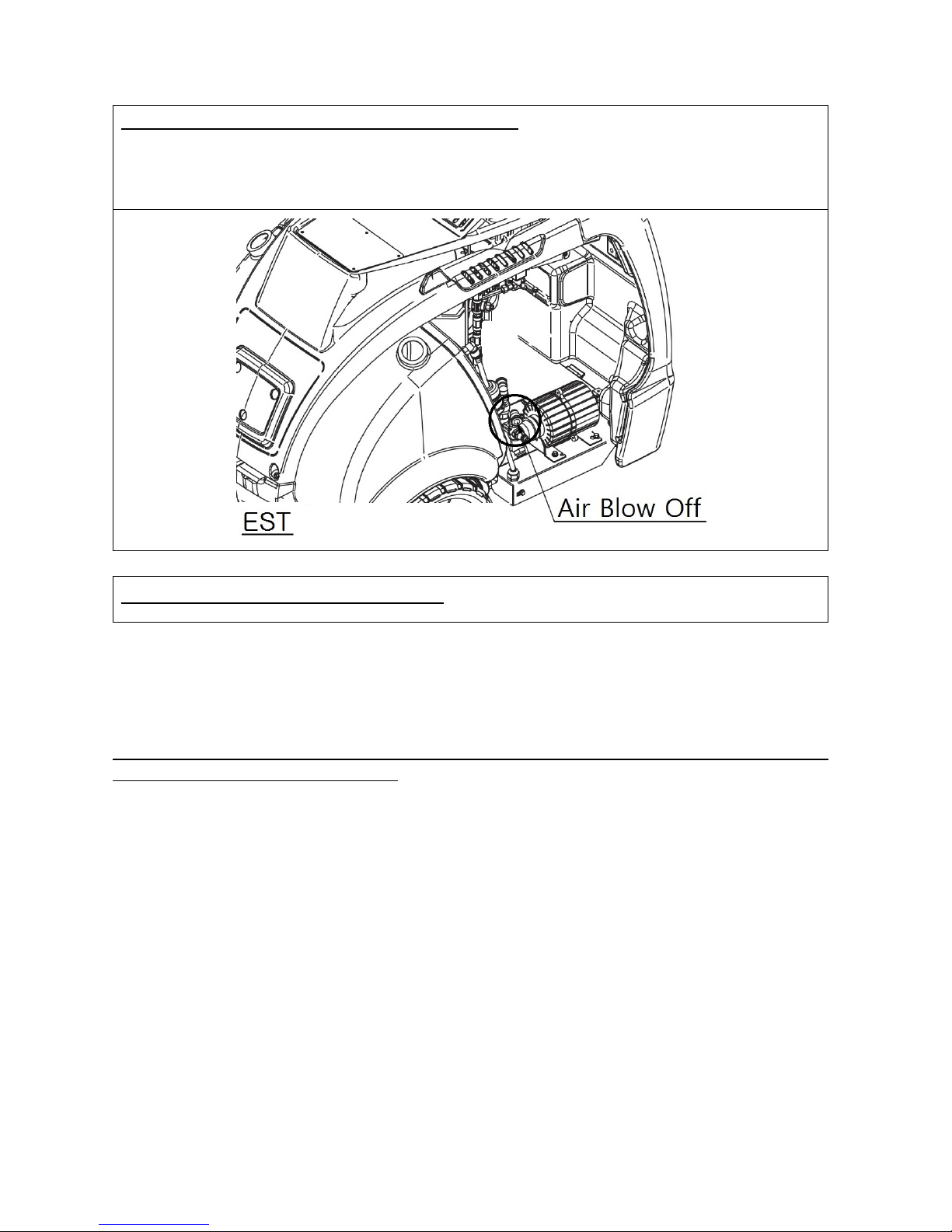

[Automatic air purge system]

Optima Steamer is equipped with an electronic

valve that purges air to avoid false pressure

reading of the system. Whenever the Thermistor

reading is below 100℃ (212°F), the system

assumes that the high pressure in the steam

vessel is due to internal air and will open the

electronic valve to remove internal air.

10

Moisture Control

You can increase the moisture content in the steam by opening the moisture control valve.

Increasing the moisture content in the steam increases water consumption and may produce water

run-off.

Dry steam may persist due to extremely hot weather; adjust the moisture control valve accordingly.

When cleaning and/or sterilizing interior surfaces, ensure that the moisture control valve is closed to

minimize surface moisture. Wet steam may persist in extremely humid or cold weather.

Note!

In extremely hot or dry weather conditions, using two spray guns continuously with the moisture

control valve open all the way may consume steam faster than what can be replenished. In this case,

the alarm will sound. Close the moisture control valve by 1/3 and allow pressure to build.

11

PauseOperations

(Follow these steps if you intend to stop using steam for more than 5 minutes temporarily.)

Steps:

1. Turn the STEAM switch off.

2. Close the steam outlet valves and pull the steam gun trigger to release any remaining steam in

the hoses. This will prevent the release of water (condensed steam) and increase the life span

of the steam hoses and guns.

Note!

When manually refilling the water tank, must turn off the STEAM switch.

After refilling the water tank, turn the STEAM switch back on then resume operation.

Shutdown Procedures

Steps:

1. Turn off the STEAM switch.

2. Turn off the POWER (EMERGENCY STOP) switch

3. Use up existing steam in the steam vessel until the pressure drops to 1~2 bar (15~29 psi). Then

train out all water from steam vessel by opening the drain valve. If the water from the steam

vessel is milky, open the Y-strainer drain valve (cap) and clean the filter of Y-strainer

4. Close the steam outlet valve and pull the spray gun trigger to release the remaining steam in the

hoses. This will prevent the release of water (condensed steam) at next use and increase the

life span of the steam hoses and spray guns.

5. In cold climates or cold weather condition, additional steps are required to prevent damages.

(See "Freeze Prevention" on page 12).

Tips!

Extend the life span of the Optima

1. Use soft water or clean tap water.

2. Use water treatment daily if tap water is used.

3. Always remove steam from hoses, spray guns, and the steam vessel after use.

4. Store the Optima at room temperature.

5. Remove sediments from the steam vessel regularly. (See “Maintenance” on page 14)

6. Remove hardened scale from the vessel regularly. (See “Maintenance” on page 14).

12

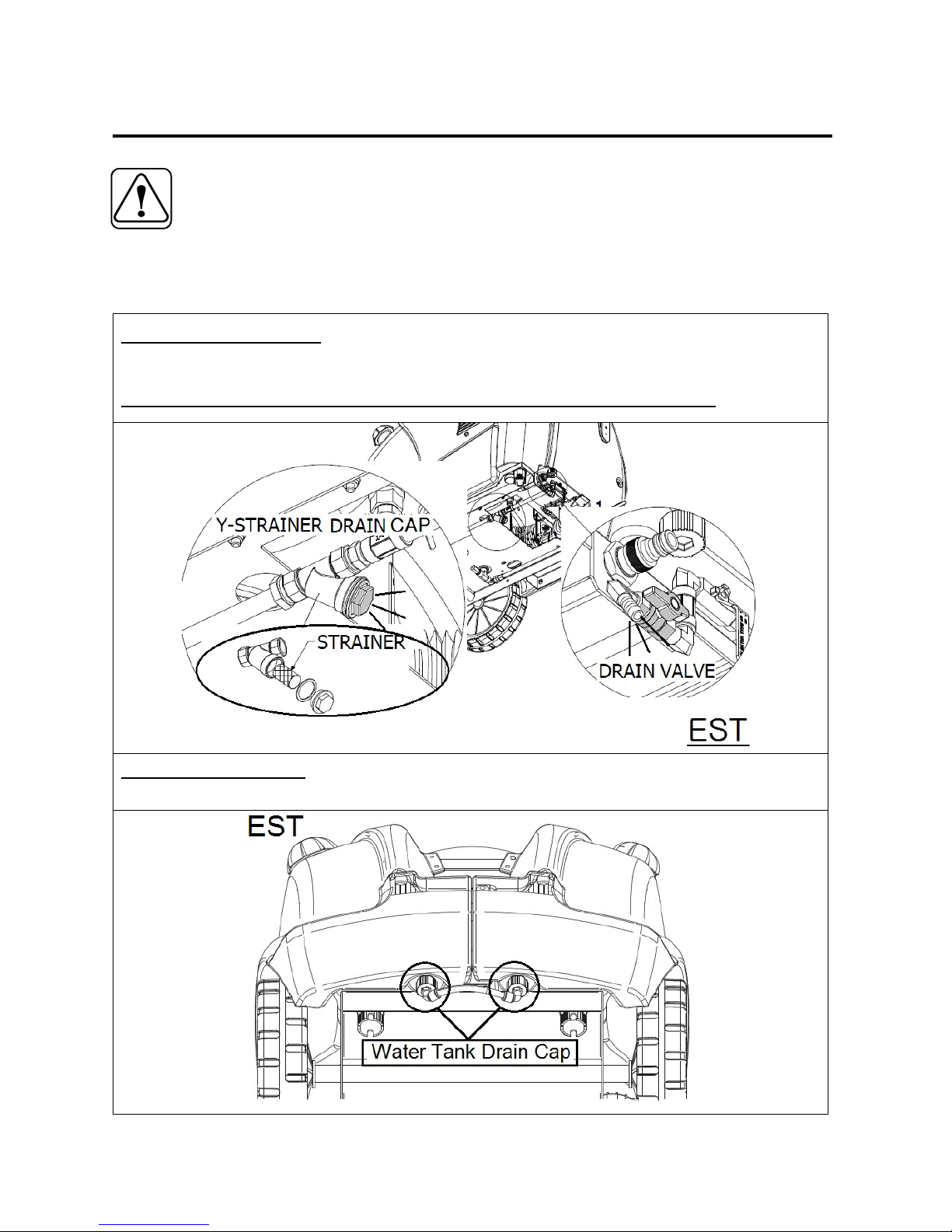

Freeze Prevention

The Optima Steamer can perform in the sub-zero weather. However, it takes

precautions for storage. In cold climates it is necessary to store the Optima in an area

where the temperature is above freezing. Unplug the machine from electrical source and

follow steps below to protect the Optima against ruptured lines and damage caused

during cold climates.

Steps:

1. Empty the steam vessel

Slowly open the drain valve cap once the pressure is below 2 bar (29 psi).

Keep drain valve and Y-strainer drain cap open until next use.

Warning! : Steam is extremely hot. Wear appropriate hand and eye protection.

2. Empty the water tank.

Open the water tank drain cap at bottom side.

13

3. Drain the water suction lines and the water pump.

Open the drain valve or Y-strainer drain cap, then disassemble / detach water suction line from

top of water pump and drain all remaining water using compressed air. Keep drain valve open

until next use.

4. Store the machine at room temperature.

Note!

Doing freeze prevention maintenance can prevent costly repairs. Frozen water can rupture lines,

cause malfunctions and destroy parts. Never operate the machine if any part is frozen or suspected

of being frozen. Thaw the machine at room temperature overnight. Carefully inspect the machine.

If the machine is visually damaged or performs abnormally, immediately turn off the machine and

contact your distributor or manufacturer.

14

Maintenance

Warning!

Unplug the machine from electrical source and allow it to cool off before conducting maintenance.

Wear appropriate safety protection.

Note: To avoid unexpected downtime, keep up with maintenance schedule.

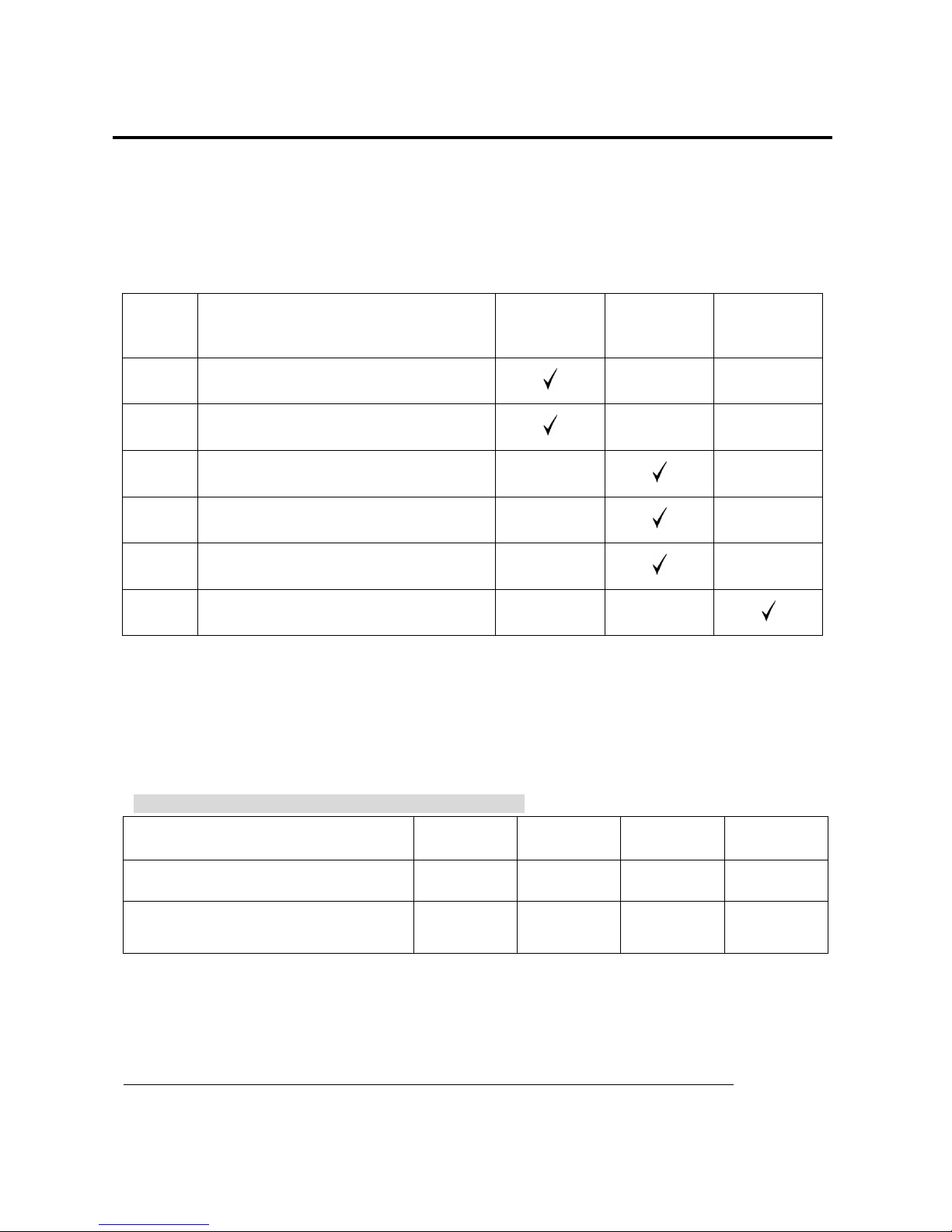

Maintenance Schedule

Maintenance Items Daily

Monthly or

as needed

Every year

or as

needed

A Add water treatment. (Softener)

B Check for/drain sediments from steam

vessel

C Drain water tank

D Check/replace water filter

E *Check/clean water probe sensors

F *Perform steam vessel de-scaling

*The frequency of these maintenance items may vary based on the hardness of water in your area.

A. Add anti-scaling water treatment.

Add the recommended dosage of anti-scaling water treatment into the water tank. Use a TDS

meter to determine the hardness of water in your area.

(See “Pre-start Procedure” Step #2 Page 6)

[Recommended Anti-scaling Water Treatment Dosage]

TDS Meter Reading (ppm) 0 - 40 40 – 120 120 - 425 425 - 1000

Hardness description Very Soft Soft Hard Very Hard

Dosage per every

100L (27gal) of water No dose 25ml 50ml 100ml

Scale is caused by dissolved mineral in water settling on internal surfaces. Scale build-up can

greatly impact steam vessel longevity and operating efficiency. Adding anti-scaling water

treatment will help prevent scale from forming on the inside wall of the steam vessel and protect

against sensor malfunction.

Only add water and the manufacturer approved anti-scaling solution to the water tank.

15

B. Check for/drain sediments from steam vessel

Open the drain valve and check the color of the water. If the water is milky, drain all remaining

water & sediment from the steam vessel by opening the Y-strainer drain valve or cap.

C. Drain water tank

Drain out all sediment of water tanks by removing the drain cap from bottom of the tank. This will

flush out sediments which may have settled to the bottom of water tanks.

D. Check/replace water filter.

Check the water filter routinely and replace as needed.

16

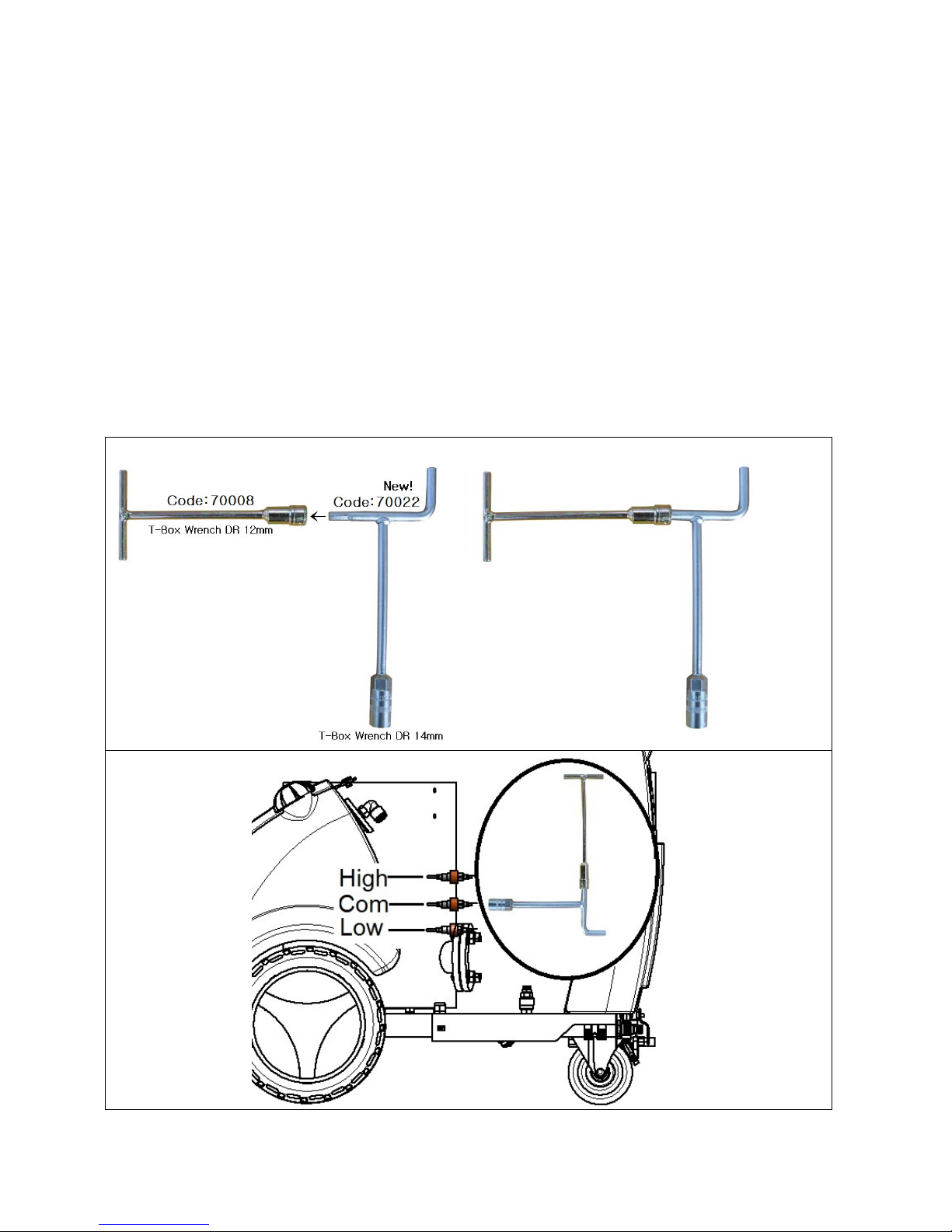

E. Check/clean water probe sensors.

The Optima has three water probe sensors (High, Com, Low). Scale build-up on the water probe

sensors can affect sensor accuracy and will prevent the machine from operating abnormally.

What you will need: screw driver (+), 14mm deep socket wrench, breaker bar (DO NOT USE A

POWERED/TORQUED WRENCH!!!), sandpaper, and Teflon tape.

Steps:

1. Unplug the electric cord and let the steam pressure drop to “0.”

2. Cool down and drain the steam vessel by opening the drain valve.

3. Remove the top cover or open the lateral door and disconnect the sensors from wiring.

4. Remove the sensors from the vessel using 14mm deep socket wrench.

5. Using sandpaper, scrub the tip of sensors clean. Replace them if necessary.

6. Wrap the threads of the sensors with Teflon tape at least 6 times and insert the sensors by using

tools.

Table of contents