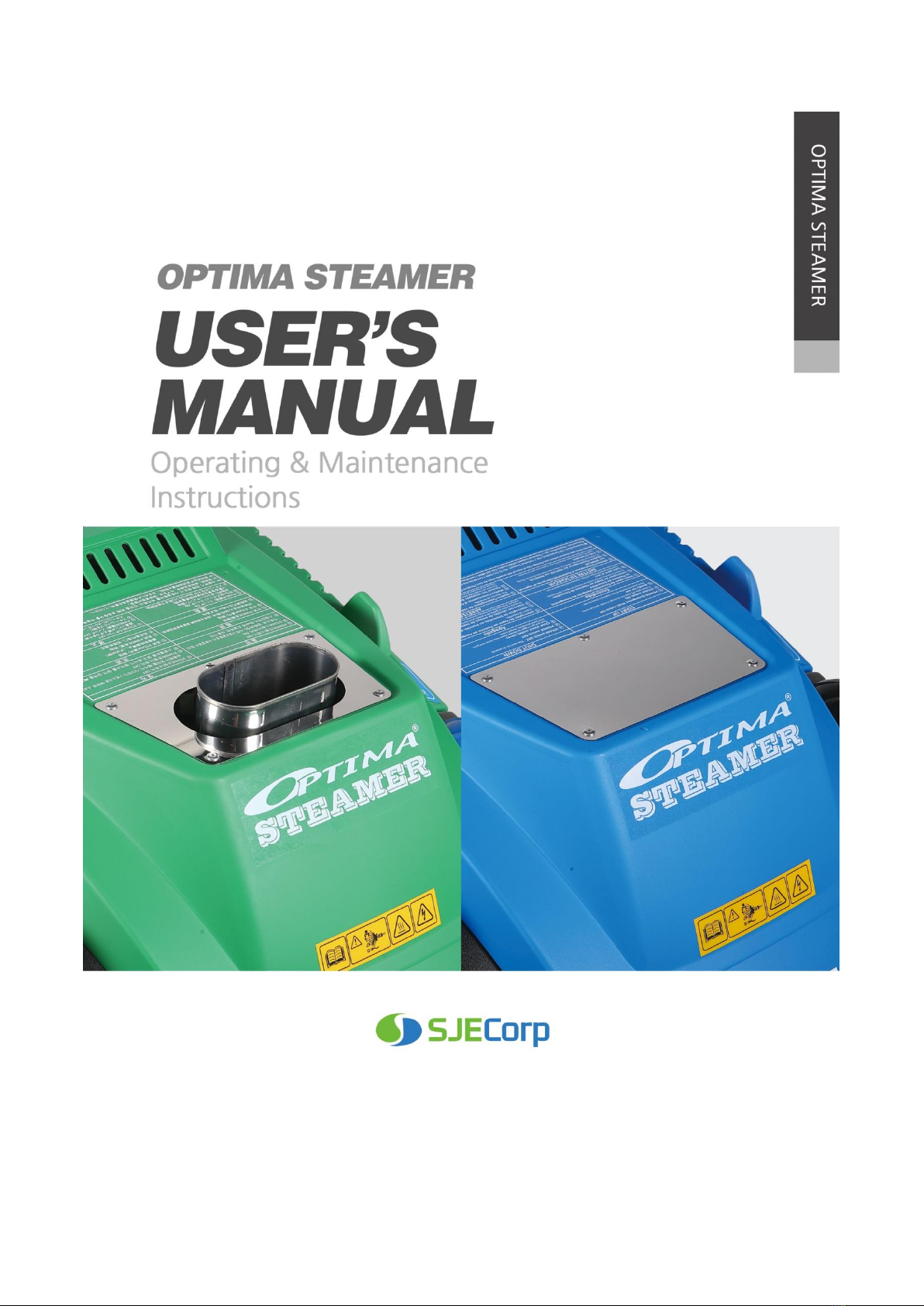

SJE OPTIMA DM Series User manual

Published by SJE Corporation, Ltd.

© 2022 by SJE Corporation, Ltd.

78-21 Sandan 7-ro, Jeonggwan-Eup, Gijang-Gun,

Busan, South Korea

Tel: +82 51-521-3200

Fax: +82 51-521-3305

Website: http://www.sjecorp.com

E-mail: [email protected]

All rights reserved. No part of this publication may be reproduced, stored

in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior permission of SJE Corporation, Ltd.

Manufactured by

SJE Corporation, Ltd.

User's Manual

Model: OPTIMA DM Series

Ver. G2.3 / G2.7

Distributor’s Contact Information:

1

Table of Contents

Introduction--------------------------------------------------------------------------------------------- 2

Applications -------------------------------------------------------------------------------------------- 2

Product Specifications --------------------------------------------------------------------------------- 2

Exterior Description ------------------------------------------------------------------------------------ 4

Safety Precautions------------------------------------------------------------------------------------- 6

Included Items and Accessories----------------------------------------------------------------------- 9

Pre-Start Procedure----------------------------------------------------------------------------------- 10

Standard Operating Procedure ----------------------------------------------------------------------- 12

Air Adjustment----------------------------------------------------------------------------------------- 14

Moisture Control--------------------------------------------------------------------------------------- 14

Pause Operation -------------------------------------------------------------------------------------- 15

Shutdown Operation ---------------------------------------------------------------------------------- 15

Maintenance ------------------------------------------------------------------------------------------ 16

Freeze Prevention ------------------------------------------------------------------------------------ 21

Troubleshooting Guide-------------------------------------------------------------------------------- 23

Service Request--------------------------------------------------------------------------------------- 28

OPTIMA STEAMER™ Limited Warranty ------------------------------------------------------------- 28

2

Introduction

The Optima Steamer represents the future of environmentally friendly and effective cleaning.

Optima Steamer is focused on supporting your cleaning operations with high-quality green

cleaning solutions.

Applications

The Optima Steamer is capable of providing ample amount of super-heated steam continuously in

perfect pressure and temperature.

The Optima Steamer is designed to clean a wide variety of surfaces including cleaning machinery

& components, washing vehicle exteriors, interiors, engine compartment, glass, metal surfaces,

windows, wheel wells, vents, deodorizing bad odors, sanitizing hazardous food-borne bacteria from

food processing equipment, removing weeds and more.

Product Specifications

Model Name

DM(DMF)

Working Pressure

7~8.5 kgf/㎠/ Max 9.0 kgf/㎠(99~120.8 psi / Max 128 psi)

Temp. at Gun Tip

< 135℃(< 275℉)

Steam Vessel Temp.

178℃/ Max 180℃(352.4℉/ Max 356℉)

Preheating Time

2 ~ 3 minutes

Voltage

100V~ / 110-120V~ / 220-240V~

50/60Hz

(Customer configuration available)

Electrical Power

100V~

110-120V~

220-230V~

450W

350W

300W

Water Tank Capacity

20 ℓ (5.3 gals)

Rated Flow

300 ~ 1,200cc/min. (0.08~0.32gpm)

Fuel Tank Capacity

20 ℓ (5.3 gals)

Fuel Nozzle

1.10 gallon/hour @ 10.0 bar

Net Weight (kgs / lbs)

83 kgs (182.9 lbs)

Product Dimensions

[L] x [W] x [H]

1090 x 700 x 900 mm

(42.9 x 27.5 x 35.4 inch)

*

Water consumption per car wash is subject to change depending on the use of the Moisture

Control Valve. (See page 14, “Moisture Control”)

For user's safety, DO NOT modify factory settings for steam pressure and temperature.

3

Product Specifications

Model Name

EST (05K, 12K, 18K, 27K)

Electrical Power Display

05K

12K

18K

27K

Working Pressure

7~8.5 kgf/㎠/ Max 9.0 kgf/㎠(99~120.8 psi / Max 128 psi)

Temp. at Gun Tip

< 135℃(< 275℉)

Steam Vessel Temp.

174℃/ max. 180℃(345.2℉/ Max 356℉)

Preheating Time

20~21 min.

8~9 min.

6~7 min.

6~7 min.

Max. Electrical Power

5kW

12kW

18kW

27kW

Voltage

200V / 208V /

230V 50/60Hz

(custom config.

available)

3-phase 200V / 208V / 230V /

380V / 415V / 440V / 460V / 480V

/ 600V 50/60Hz

(custom config. available)

3-phase 380V /

415V / 440V /

460V / 480V /

600V 50/60Hz

(custom config.

available)

Water Tank Capacity

40 ℓ (10.6 gals)

Rated Flow

300 ~ 1,200cc/min (0.08~0.32gpm)

Net Weight (kgs / lbs)

69.5 kgs

(153.2 lbs)

72.5 kgs

(159.8 lbs)

73.5 kgs

(162 lbs)

79.5 kgs

(175.2 lbs)

Product Dimensions

[L] x [W] x [H]

1090 x 700 x 900 mm (43 x 28.3 x 35.4 inch)

*

Water consumption per car wash is subject to change depending on the use of the Moisture

Control Valve. (See page 14, “Moisture Control”)

For user's safety, DO NOT modify factory settings for steam pressure and temperature.

4

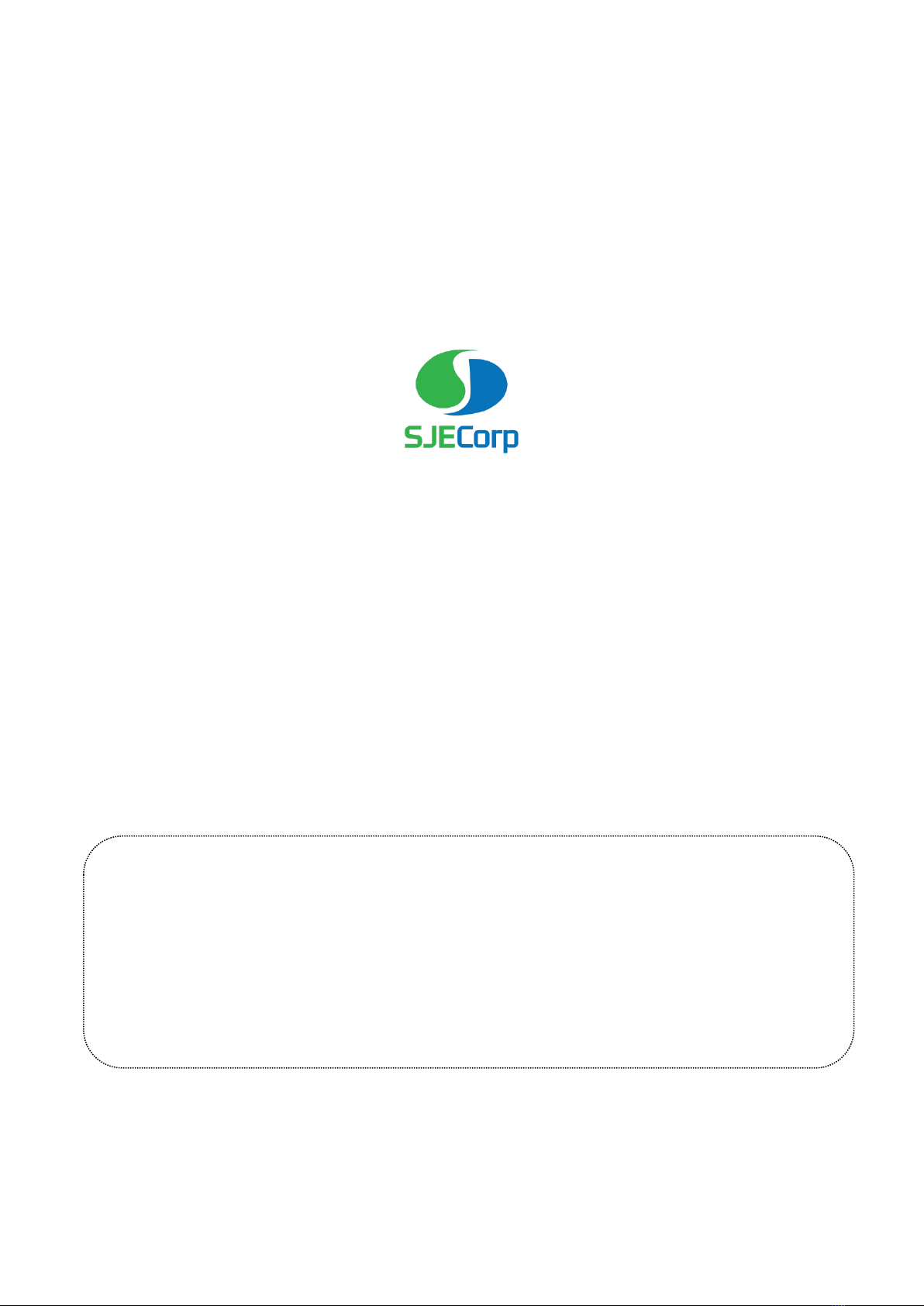

Exterior Description Model: DM(DMF)

1. Exhaust Flue

2. Top Cover

3. Lateral/Side Panel

4. Tank Cap

5. Water Tank

6. Throttle Door

7. 12" Rigid Wheel

8. Y-strainer

9. Non-Return Valve

10. Quick Plug for Feed-Water

11. Drain Valve

12. Moisture Control Valve

13. Swivel Caster

14. Steam Outlet Valve

15. Warning Sticker

16. Specification Sticker

17. Handle

18. Control Box

19. Operating Instruction Sticker

20. System Status LED Indicators

5

Exterior Description Model: EST(05K, 12K, 18K, 27K)

1. Top Cover

2. Lateral/Side Panel

3. Tank Cap

4. Water Tank

5. Throttle Door

6. 12" Rigid Wheel

7. Y-strainer

8. Non-Return Valve

9. Quick Plug for Feed-Water

10. Drain Valve

11. Moisture Control Valve

12. Swivel Caster

13. Steam Outlet Valve

14. Warning Sticker

15. Specification Sticker

16. Handle

17. Control Box

18. Operating Instruction Sticker

19. System Status LED Indicators

6

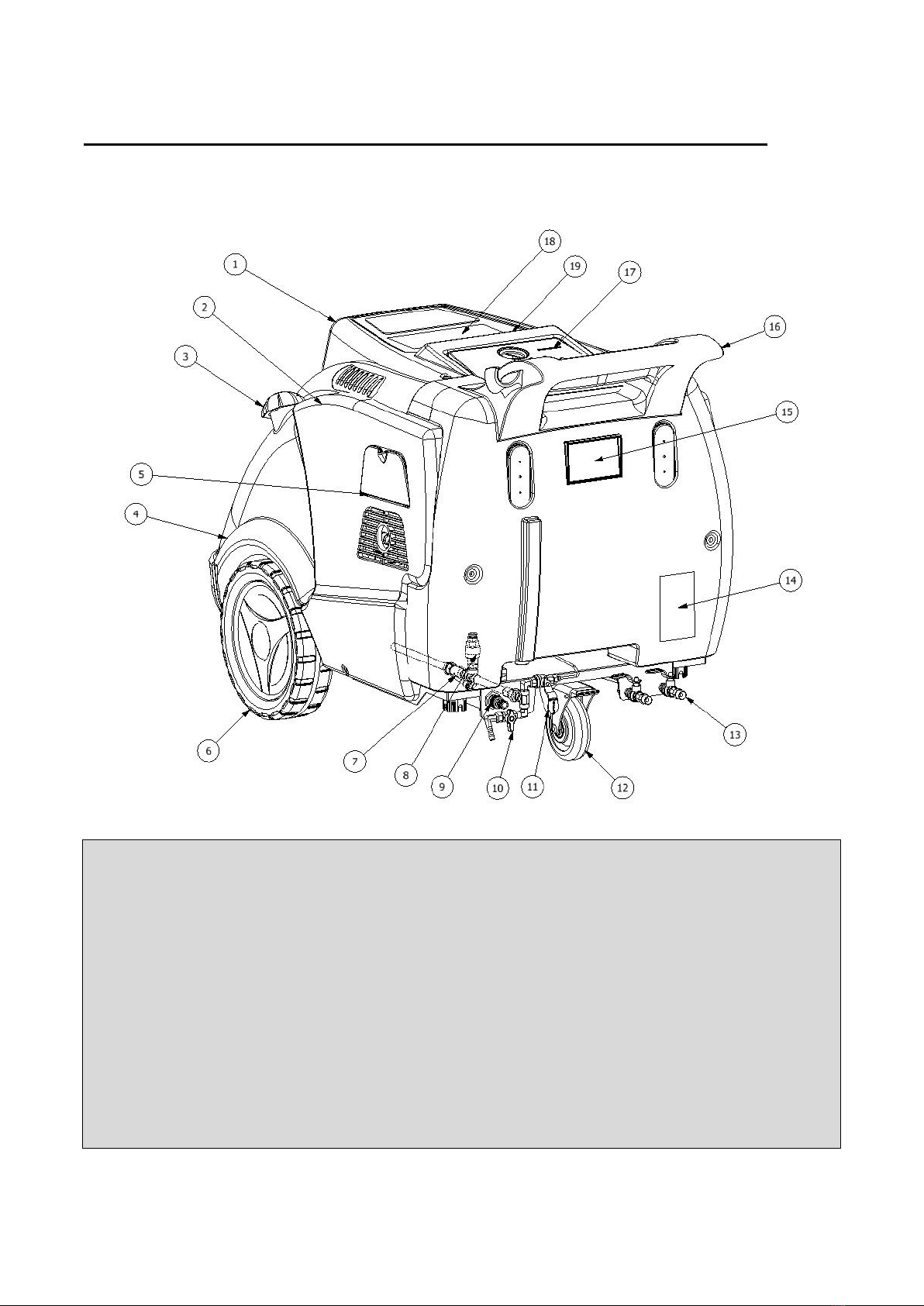

Safety Precautions

Visual Symbols

To ensure correct and safe usage with a full understanding of this product's

performance, please be sure to read through this User's Manual completely and

store it in a safe location. The contents of this User's Manual and the

specifications of this product are subject to change without prior notice.

Caution

Warning!

Risk of Electric shock

Risk of Burns

Risk of Suffocation

Slippery Surface

DO NOT operate on an incline

Wear appropriate protective gloves

(Goggles, ear plugs)

The manufacturer assumes no responsibility for any consequential losses or damages

including but not limited to injury of persons, loss of business or properties which may

occur through use of this product without consulting the User's Manual, regardless of

any failure to perform on the part of this product.

GENERAL SAFETY RULES

•DO NOT direct air or discharge the steam jet at itself, persons, animals or live electricity.

•Use and store the machine on a level ground (surface) only.

•DO NOT use the machine if any parts, power cord, safety devices, hoses or spray guns

are visually damaged or suspected of being damaged.

•DO NOT use the machine in a rainy or snowy weather outdoors. The machine is not

weather-proof or water-proof.

•NEVER leave the machine unattended while operating.

•Make sure to comply with safety rules in the event of operating in a danger area.

•NEVER use the machine in an area where a fire and explosion hazard exists.

•DO NOT use the machine below 0℃ (32℉) or in extremely cold weather.

•DO NOT allow water sit in the water pipes and steam vessel if leaving the machine non-

operational in cold weather.

•Store the machine at a room temperature(See page 21, “Freeze Prevention”)

•Heavy object! Be cautious when carrying or lifting. (See page 2, “Product Specifications”)

•Unplug the machine from its power source and release steam pressure from the machine

before carrying.

•Use only "Clean" and "Soft” water in the machine.

•Use of a water softener is recommended to prevent scale build-up

7

•Using any kind of boiler water treatment (solution) can help decrease scale build-up.

•DO NOT add detergent, wax or any cleaning additives in the water tank or steam vessel.

•DO NOT use distilled water or filtered water below 15 ppm.

•Connect to electrical power according to the product specifications. (See page 2,

“Product Specifications”)

•The electric supply connection is to be made by a qualified electrician and comply with

IEC 60364-1.

•Be cautious of the risk of electric shock in the event of connecting to electrical power.

•Ensure the ground connection of Grounding Chain and Ground Wire attached on the

machine to prevent the risk of damage from Electro Static Discharge.

•Users about to use the machine should carry out a visual check for insecure cable at

entry to a plug, evidence of poor wire connections or evidence of appliance or plug

overheating.

•Make sure that all the switches on the machine are off before plug-in power cables.

•In the event of using extension wire/extension cord, ensure that both ends of electric

wires are securely attached and properly insulated.

•Make sure to use right extension cord depending on the electrical parameters and the

length of extension cord. (Contact manufacturer or local distributors)

•Machines shall not be used by children. Children should be supervised to ensure that

they do not play with the machine.

•Children shall not play with the appliance.

•Cleaning and user maintenance shall not be made by children without supervision

•WARNING Do not use the machine within range of persons unless they wear protective

clothing.

•Noise can be reached to 95 decibel(dB) but subject to differ depending on steam

pressure.

•DO NOT use the machine within the range of persons who are not wearing any protective

gear.

•HOT SURFACE. DO NOT touch steam vessel, steam valves, steam hoses and guns in

operation.

•Replace steam hoses immediately if ruptured.

•Use manufacturer approved spare parts and accessories including steam hoses, steam

guns and power cables.

•Unplug the machine from its power source and allow it to cool before carrying out any

maintenance.

•NEVER disable sensors in order to bypass an alarm signal.

•Open the drain valve and release all remaining water from the steam vessel after users

shut down the machine completely. (See page 15, “Shutdown Operation”)

•NEVER spray steam over cleaning hazardous materials or surfaces containing hazardous

substance including asbestos.

8

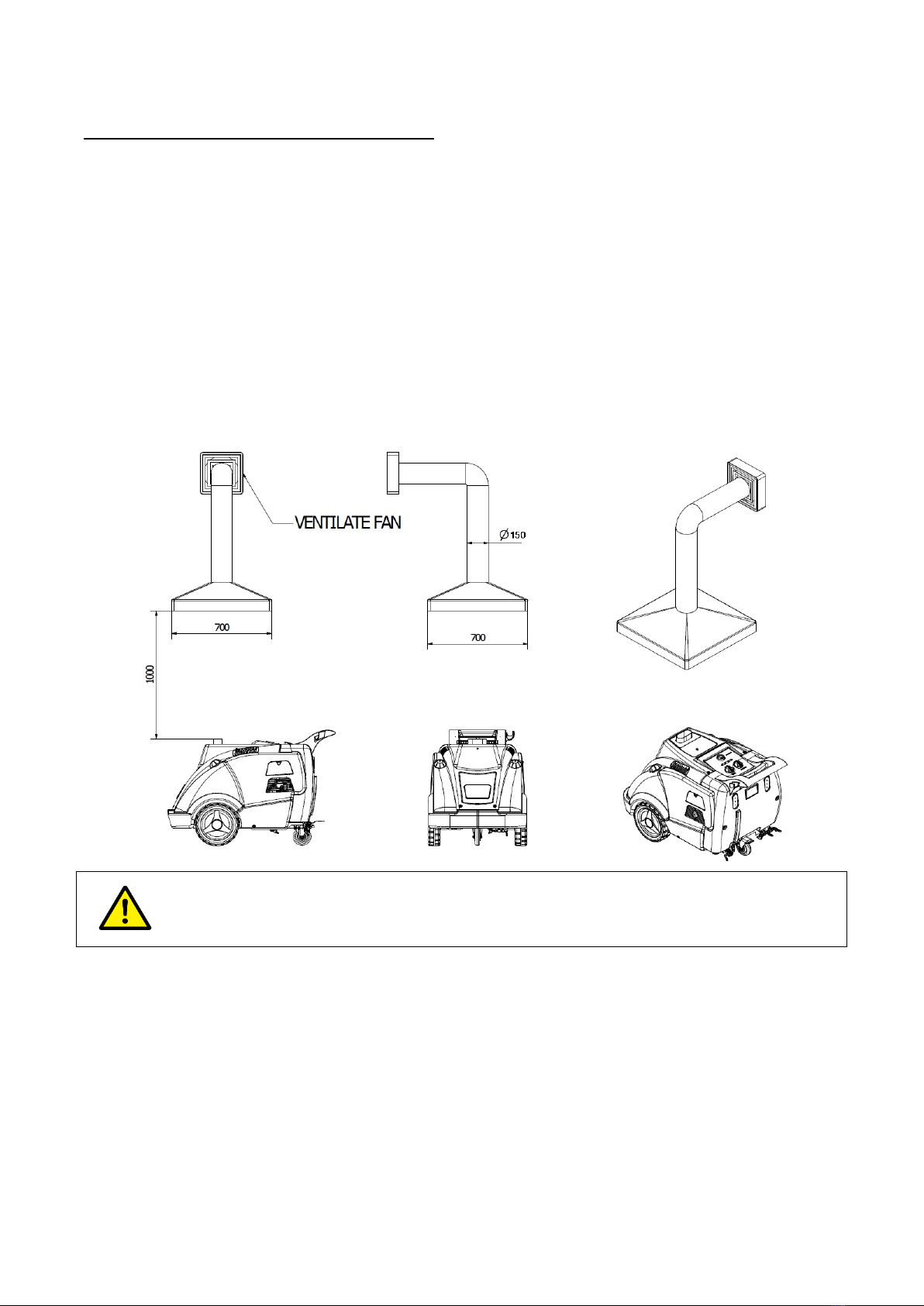

SAFETY RULES for OPTIMA DMF

•Use clean diesel only.

•Ensure switches of the machine are off before refilling fuel.

•BURN HAZARD. DO NOT touch exhaust flue in operation.

•DO NOT operate the machine in a confined space.

•DO NOT breathe in smoke from the exhaust flue to avoid smoke inhalation.

•Use the machine in well-ventilated indoor area and install exhaust duct system if

necessary. (See page 8, "Ventilation set-up”)

[Sample of Ventilation set-up for Optima DMF]

Users about to use the OPTIMA DMF indoors should carry out installation of exhaust duct

system.

9

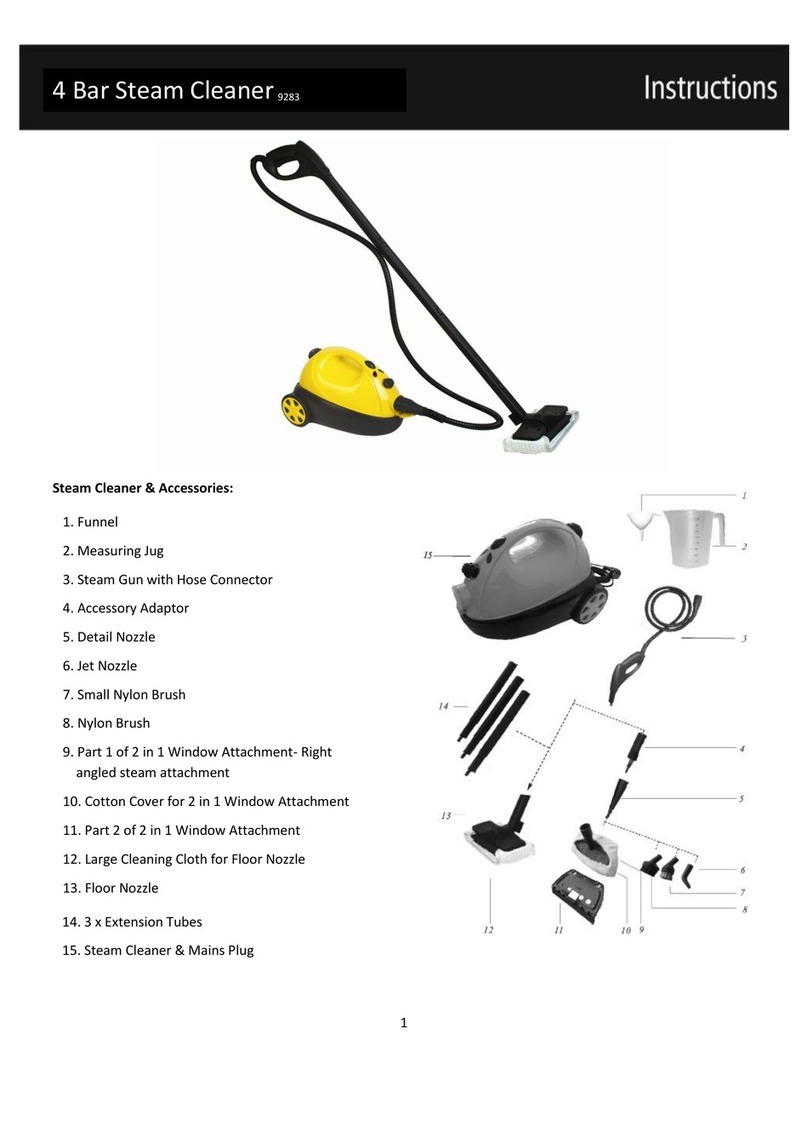

Included Items and Accessories

OPTIMA DMF

OPTIMA EST (05K/12K/18K/27K)

Steam Gun with nozzle 3.5 1EA

Steam Gun with Quick Coupler 1EA

(OPTIMA DMF, EST18K&27K)

Steam hose 10m 1EA

(OPTIMA EST05K&12K)

Steam hose 10m 2EA

(OPTIMA DMF, EST18K&27K)

OR

Steam Nozzle 1EA

(OPTIMA DMF, EST18K&27K)

Silent Nozzle 1EA

(OPTIMA DMF, EST18K&27K)

Couplings D. 1/2-5/8 PTC 1EA

OR

Garden hose adapter 3/4 1EA

(US Only)

L-wrench 3.0mm 1EA

(OPTIMA DMF only)

L-wrench 4.0mm 1EA

(OPTIMA DMF, EST)

T-Box wrench 10mm 1EA

T-Box wrench 12mm 1EA

T-Box wrench 14mm 1EA

Screwdriver 1EA

Multi Spanner 1EA

OR

Water probe sensor 3EA

O-ring D.17 2EA

O-ring D.22 2EA

OPTIMA DMF :

Fuse 4A 4EA OR

Fuse 6.3A 4EA (US Only)

OPTIMA EST : Fuse 4A 2EA

Water Filter 1EA

Fuel Filter Cartridge 1EA

(OPTIMA DMF only)

Microfiber Towel 3EA

※Included items and accessories are subject to change without prior notice.

10

Pre-Start Procedure

Wear appropriate protective gloves before using the product.

Surface of exhaust flue and valves may be hot.

Take precautions when users resume operations.

Steps:

1. Connect steam hoses and guns to the steam outlet valves. Ensure a tight connection using

appropriate tools.

2. Ensure that valves including drain valve, steam outlet valves are fully closed.

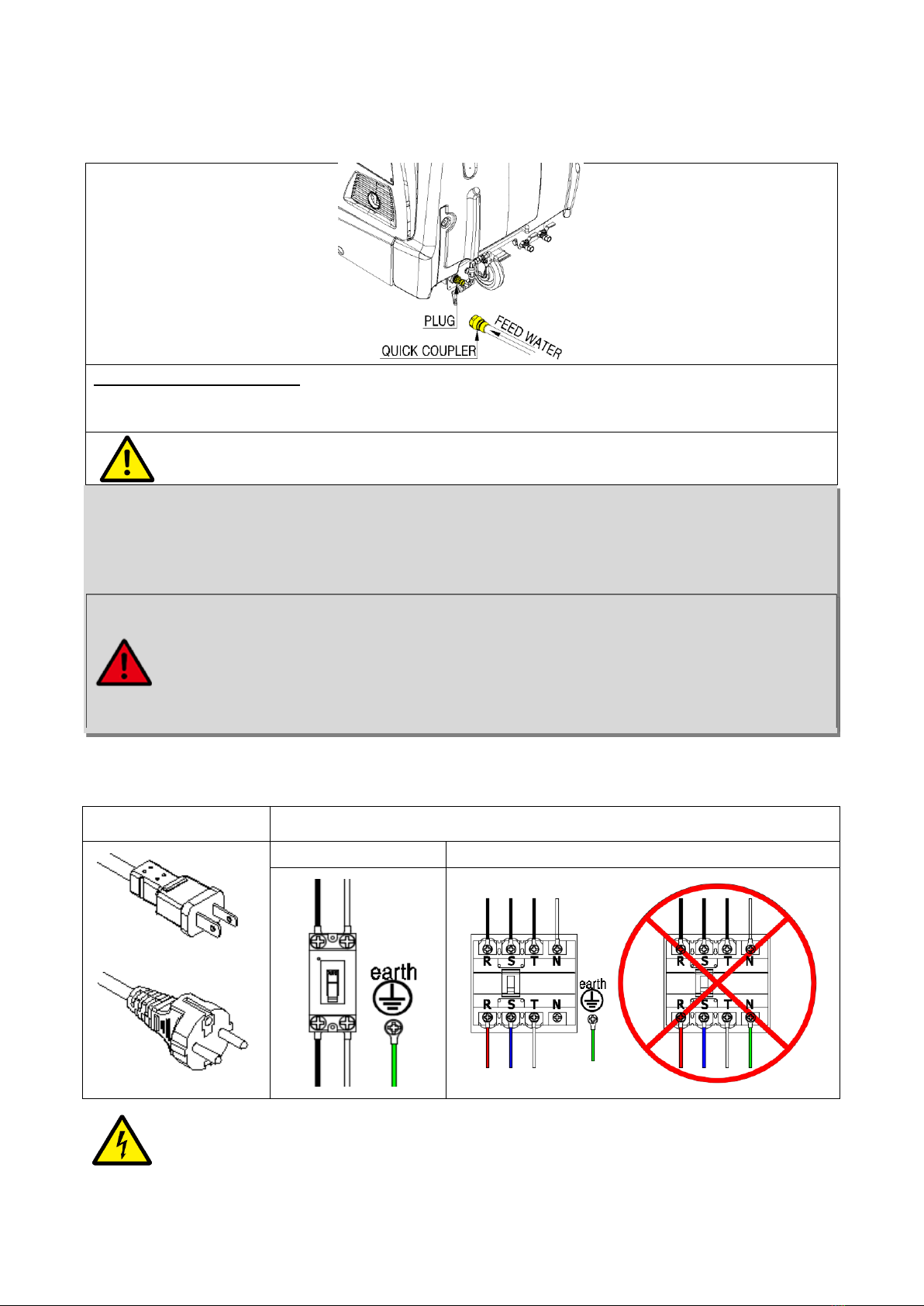

OPTIMA DM(DMF) / EST

3. Ensure that tank drain cap and water feeding tube are connected firmly.

(See illustrations below)

OPTIMA DM(DMF)

OPTIMA EST

4. Fill the fuel tank.

OPTIMA DM(DMF)

Ensure the location of fuel tank before

fuel replenishment.

11

5. Fill the water tank with clean water. When tap water or hard water is used, use of a water

softener is recommended to prevent scale build-up.

Continuous Water Supply

In the event of using continuous water supply, connect water hose attached with Quick

Coupler to the Plug of the machine.

Water pressure needs to be below 2bar from the tap for Floater to run effectively.

6. Check for electrical specifications before connecting to electrical power outlet.

In the event of using extension cords, take waterproof measures on the electrical sockets and plugs.

OPTIMA DMF

OPTIMA EST

Single Phase 5K

3 Phase 12K, 18K, 27K

※Alert users to the presence of “dangerous voltage” inside the product that might cause bodily harm

or electric shock.

For the use of OPTIMA XE, make sure to connect the GROUND WIRE(G) to GROUND TERMINAL.

Never connect GROUND WIRE to NEUTRAL(N) TERMINAL.

Water Quality Matters!

Water quality can greatly affect the machine's life span and performance. It is important to

use SOFT WATER. If tap water or hard water is used, use of a water softener is

recommended in order to prevent scale build-up.

DO NOT use distilled water.

DO NOT add any detergent, wax or cleaning additives into the water tank or steam

vessel.

The use of water temperature above 5℃ (40℉) recommended.

Use filtered water above 15 ppm.

12

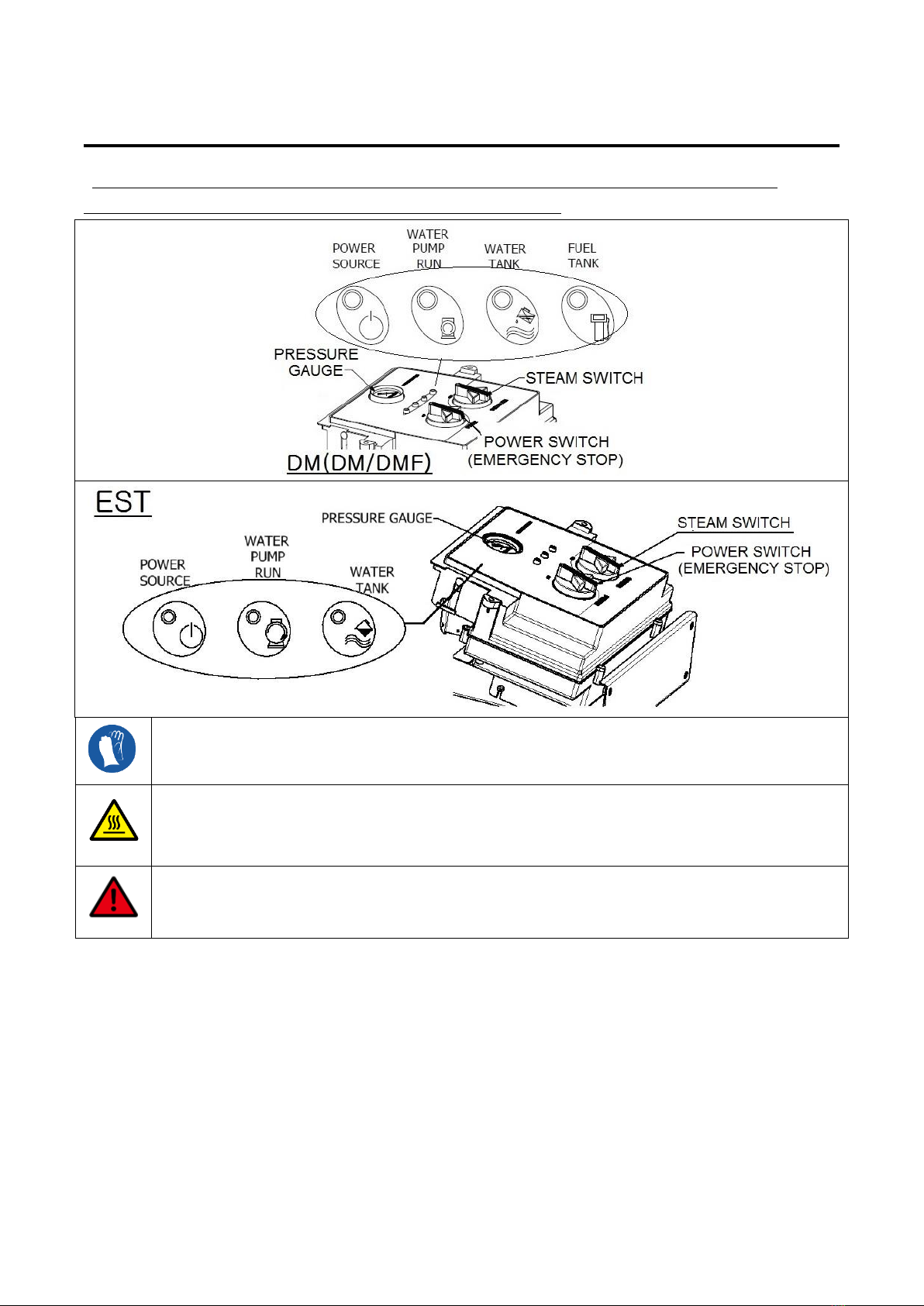

Standard Operating Procedure

Make sure to advance the steps of Pre-Start Procedure before users follow Standard

Operating Procedure. (See page 10, "Pre-Start Procedure”)

Wear appropriate protective gloves before using the machine.

NEVER leave the machine unattended while operating.

Surface of an exhaust flue or valves may be HOT.

Take precautions while operating.

DO NOT apply any physical impact to the control panel box or leave any objects on it.

13

LED ICON LEGEND

POWER

WATER

WATER PUMP

FUEL

OFF

SOLID

BLINKING

SOLID or OFF

ALARM BEEPS ONCE

ALARM BEEPS CONTINUOUSLY

Standard Operating Procedure

step

Description

1

Turn on the POWER (EMERGENCY STOP) switch and then turn on the STEAM switch.

You will see one of the following signal indications.

2

POWER and WATER PUMP Indicators are turned to the on position.

The water pump supplies water to the steam vessel.

(Programmed feed-water time: DMF –180 sec, EST –300 sec)

3

When the low water probe sensor detects water level in the steam vessel,

ignition system functions.

4

When the high water probe sensor detects water level in the steam vessel,

water pump stops.

5

When internal pressure reaches the operating pressure (8.5 bar), ignition stops

and steam spraying is ready.

Repeat “Standard Operating Procedure” if users drain water from the steam vessel

completely and resume the operation.

14

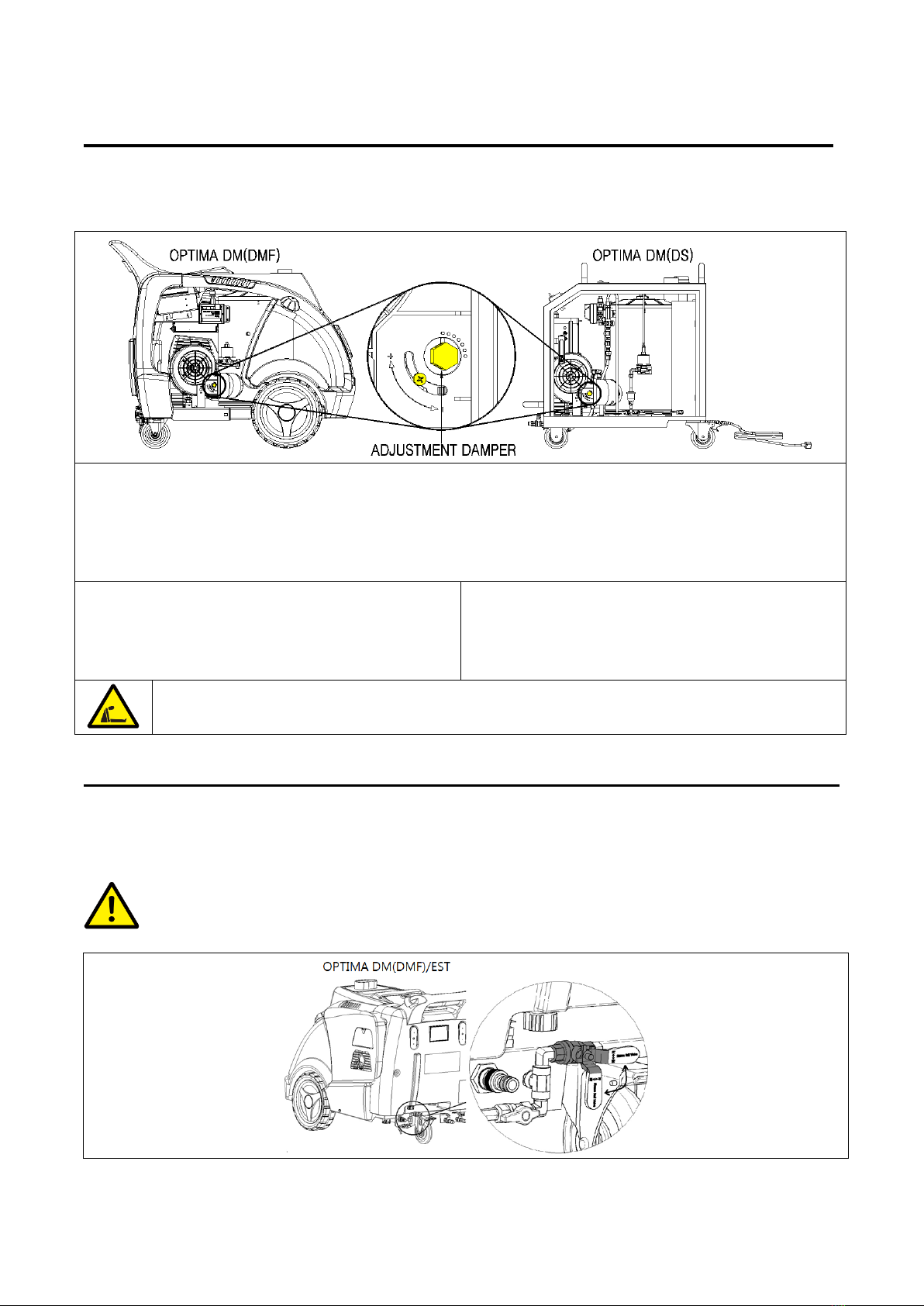

Air Adjustment

Amount of air intake can be subject to differ depending on ambient environment.

Combustion gas should be visually transparent.

1. Open the plastic cover on the right side.

2. Slightly untighten air adjustment damper using a screw driver(+) and adjust an amount of

air intake manually.

3. Retighten the screw of air adjustment damper

Black Smoke from exhaust flue :

Move air adjustment damper clockwise

Whitish Smoke from exhaust flue :

Move air adjustment damper counter-

clockwise

DO NOT breathe in combustion gas from the exhaust flue.

Moisture Control

Users can spray moisturized steam (wet steam) by opening the moisture control valve.

In the event of cleaning interior surfaces or water sensitive areas, ensure that the moisture

control valve is fully closed to minimize surface moisture.

Using two steam guns with the moisture control valve open continuously may consume

steam faster than what can be replenished. Open the moisture control valve by 1/3 allowing

pressure to build up.

15

Pause Operation

1. Switch off the STEAM.

2. Close the steam outlet valves and release all the remaining steam from the hoses by

pulling the gun trigger. It prevents remaining of condensed water residue in the steam

hoses afterwards and increases the life span of the steam hoses and guns.

Shutdown Operation

1. Switch off the STEAM.

2. After blower fan stops automatically (applied to DMF model), switch off the POWER.

3. Release steam from the steam vessel by pulling the gun trigger until the pressure drops

down to 1~2 kgf/㎠(28.4 psi).

4. Close the steam outlet valves and release all the remaining steam from the hoses by

pulling the gun trigger.

5. Release remaining steam from the steam vessel by opening the drain valve.

In the event of draining water from the steam vessel, ensure to keep your workspace

area including steam hoses and power cable neat and tidy.

Leave the drain valve open until the next use

BURN HAZRD. Hot steam and water in the event of opening drain valve.

6. In cold weather, take precautionary measures to keep water pipes from freezing and

bursting. (See page 21, "Freeze Prevention").

16

Maintenance

Must-do before carrying out maintenance

Must cool down the product.

Must get rid of pressure in the product.

Wear appropriate protective gloves.

Unplug to shut down the power.

Caution of burn

Keep the below maintenance schedule.

Maintenance Schedule

Maintenance items

Daily

Monthly

Every

3months

Every

6months

A

Drain water from the steam vessel

B

Drain water tank / fuel tank

C

Replace filters

D

Check water probe sensors. Clean or replace

if necessary

E

Check electrodes and fuel nozzle. Clean if

necessary (Contact local distributor)

F

De-scale vessel (Contact local distributor)

G

Remove soot build-up from the vessel and

inner cylinder (Contact local distributor)

※For your safety, the Safety Relief Valve must be replaced when a leak is present.

If no leak occurs, the Safety Relief Valve must still be replaced every 3 years.

OPTIMA DM(DMF)

OPTIMA EST

17

A. Drain Water from the Steam Vessel

1. Reduce pressure below 2 kgf/㎠(28.4 psi)

2. Open the drain valve and drain out all the remaining water.

3. Leave drain valve open until the next use.

Wear appropriate protective gloves for hands because steam is very hot.

In the event of vessel drain, ensure to keep your workspace area including steam hoses

and power cable neat and tidy.

Leave the drain valve open until the next use.

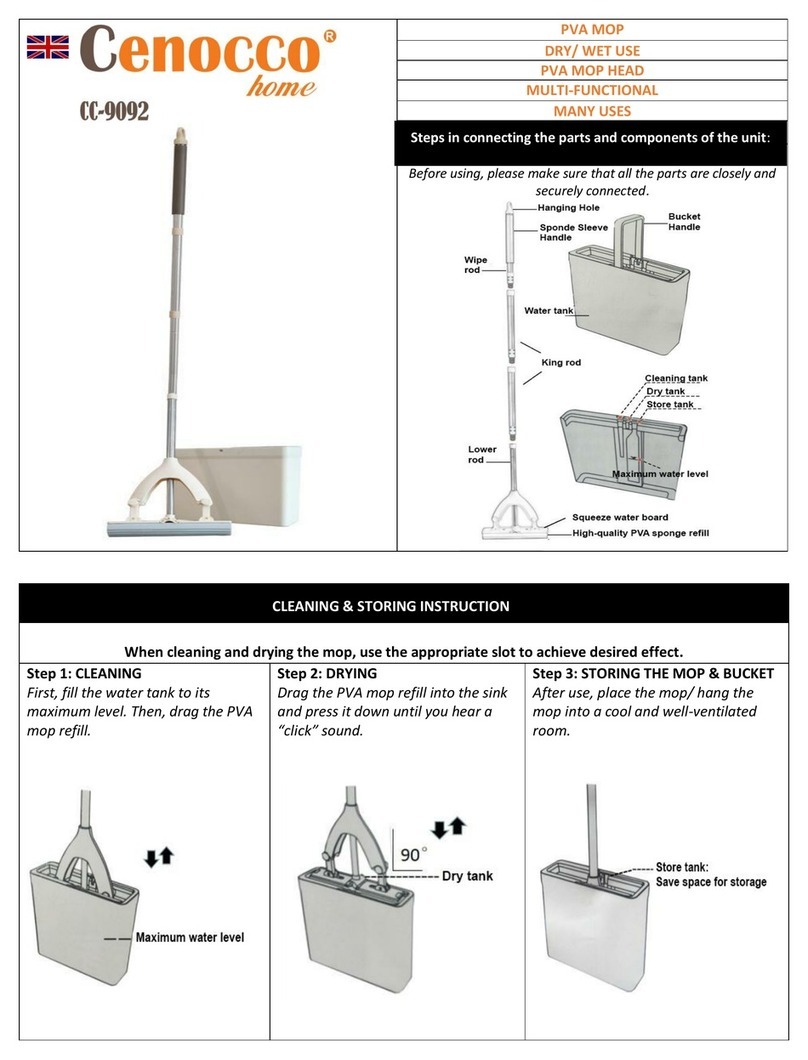

OPTIMA DM(DMF) / EST

B. Drain Water tank / Fuel tank

Open drain cap underneath the tank or pull the water feeding tube.

Caution : Slippery When Wet

OPTIMA

DM(DMF)

Open drain cap

underneath the tank.

OPTIMA

EST

Pull the water feeding tube while

pressing down the the blue plastic part

of One-Touch Nipple.

Other manuals for OPTIMA DM Series

1

Table of contents

Other SJE Steam Cleaner manuals