Sicherheitskonzepte Breuer GmbH Broekhuysener Straße 40, 47638 Straelen, Tel.: +49 2834 943 01 00, Fax: +49 2834 943 05 62

info@sicherheitskonzepte-breuer.com, www.sicherheitskonzepte-breuer.com

3

This instruction manual is supplied with every Primo anchor device. It must be read before use and stored in close proximity to the

equipment at all times.

The assembly of the anchor device is described in a separate manual.

aution: nly original parts may be used!

Please check the roof construction before assembly, i.e., always check whether the surface is suitable for attaching the anchor device. If in

doubt, contact a structural engineer.

The Primo anchor device may only be used with safety harnesses in accordance with DIN EN 361, energy absorbers in accordance with DIN

EN 355 and lanyards in accordance with DIN EN 354 for fall protection, according to the instruction manual of the respective manufacturer.

The lanyard should be equipped with a length adjustment in accordance with DIN EN 354. The opening of the carabiner hook must exceed

16 mm.

It is essential for safety that following a fall or when damage (cracks or breakages) are found, the product is only used again after obtaining

the written consent of an expert.

The information in the corresponding instruction manual must be observed.

Load capacity

max. three persons per anchor point (Primo)

Before each use of the Primo

A visual and functional inspection must be conducted for the following points:

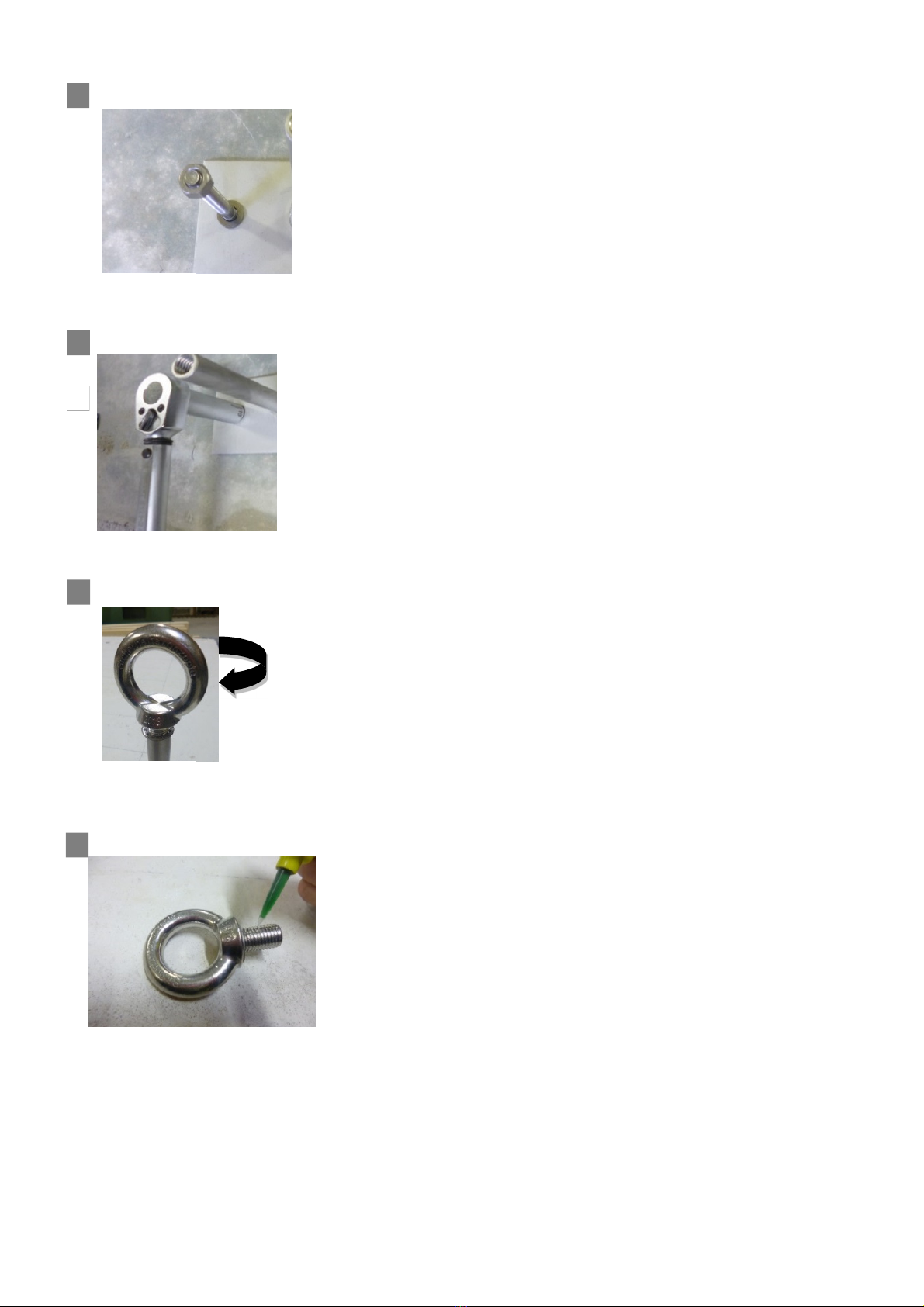

Corrosion

Deformation

Damage (e.g. distortion or cracks)

Label (nameplate) present

Wobble test (perform manually at the anchor point)

Ring bolt secure (screwed all the way in, firm position of the ring bolt)

Check legibility

Application:

Before entering areas where there is a risk of falling (e.g. walking on the flat roof):

Always check whether the components of the personal protective equipment against falling from a height are in order and whether they

comply with that specified in this instruction manual and/or on the inspection card.

System components must be checked for completeness and correctness.

The other personal protective equipment against falling from a height must be checked for external signs of damage and for completeness

before use, in accordance with the associated instruction manuals.

After entering areas where there is a risk of falling (e.g. walking on the flat roof):

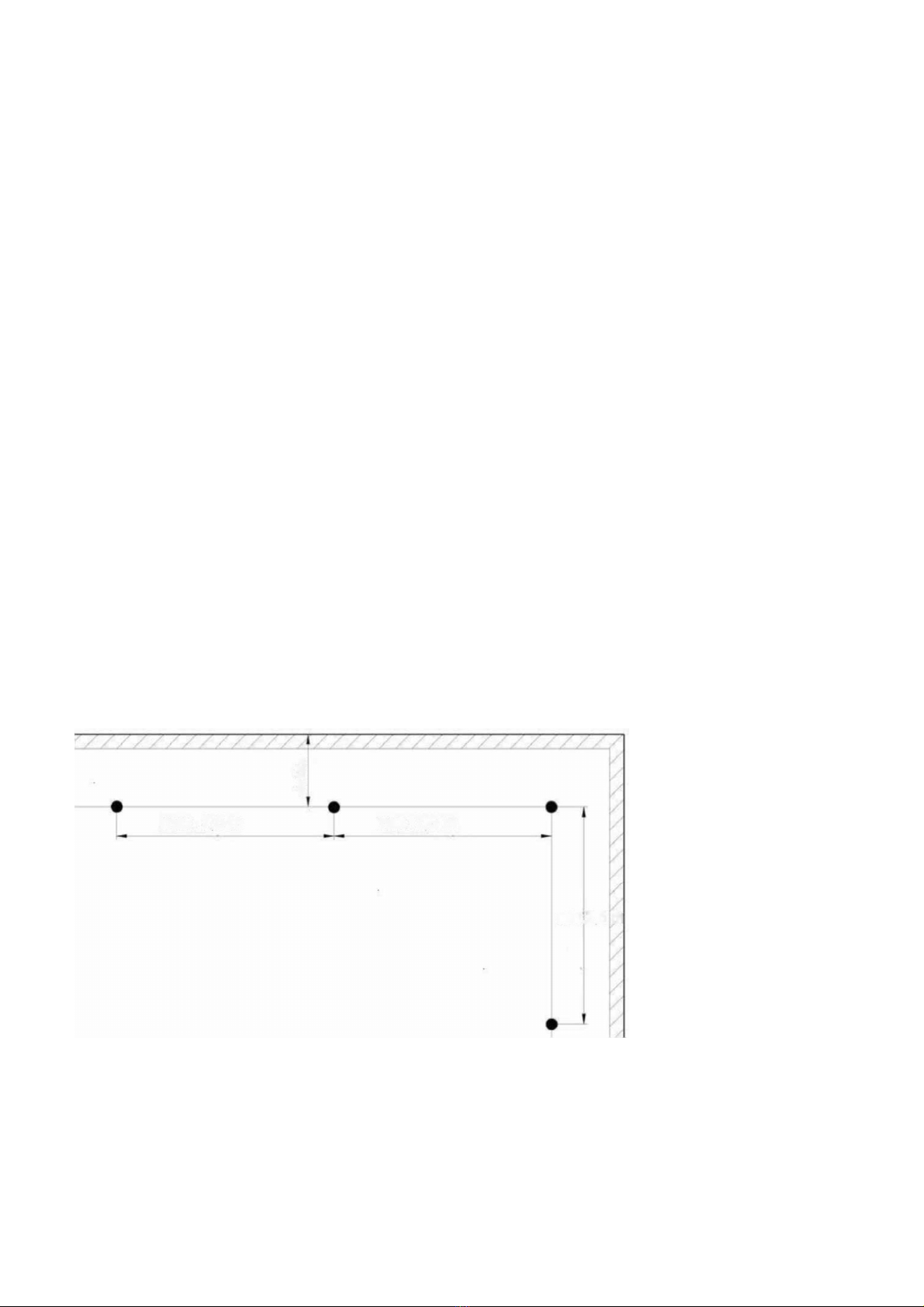

The Primo anchor device can be used as a single anchor point, i.e., the person to be protected hooks the carabiner hook of his/her personal

protective equipment against falling from a height directly into the eyelet of the anchor point. In this case, no more than 3 persons may be

secured per eyelet.

aution: Unlocked carabiner hooks can inadvertently release from the anchor point!