NOTE

Emphasizes useful hints and

recommendations as well as

information for efficient and trouble-

free operation.

CAUTION

Indicates a dangerous situation that can

lead to light personal injury or property

damage if precautionary measures are

ignored.

WARNING

Indicates a dangerous situation that

could lead to death or serious injury if

precautionary measures are ignored.

DANGER

Indicates a dangerous situation that will

lead to death or serious injury if

precautionary measures are ignored.

Explanation of signal

words for safety

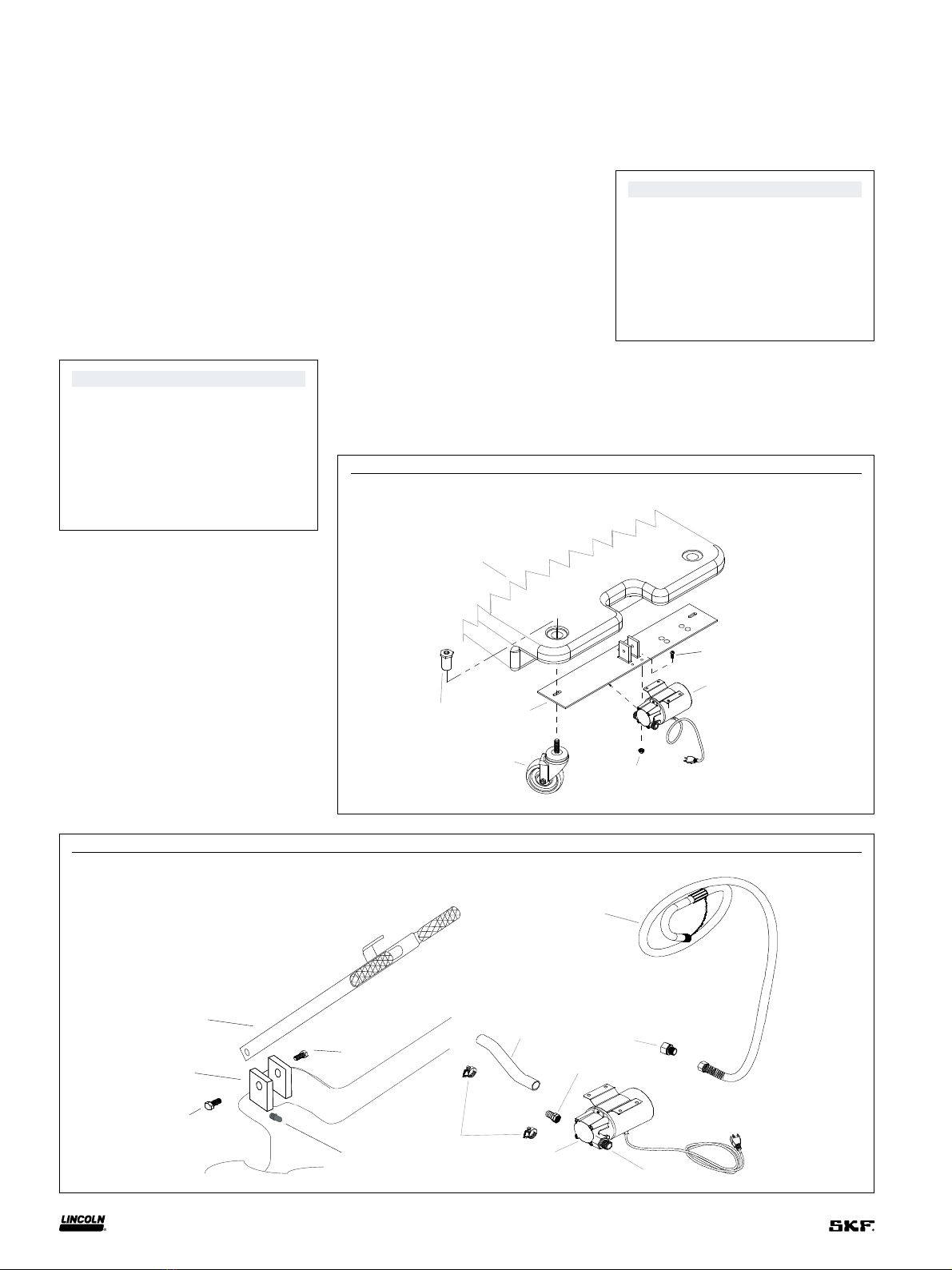

Table 1

Specifications

Reservoir and pump

Capacity 17 U.S. gal (64 liters)

Casters 4 in (101 mm)

Electric pump 115 V AC, 50/60 Hz, 2 A

Extractor hose length 6 ft. (1,8 m)

Pumping capacity 350 gph (1 324 lph)

Pump maximum oil temperature 160 °F (71 °C)

Pump minimum oil temperature 40 °F (4,4 °C)

Pump type Impeller

Duty cycle: intermittent Maximum 30 minutes

Thermal protection Automatic

Motor amps 1.40 A

Pump material

Body Bronze SS

Motor shaft 303 SS

Retainer ring BL-22

Cover SS

Screws SS

Pump gasket Non ASB

Lip seal Nitrile

Impeller Nitrile

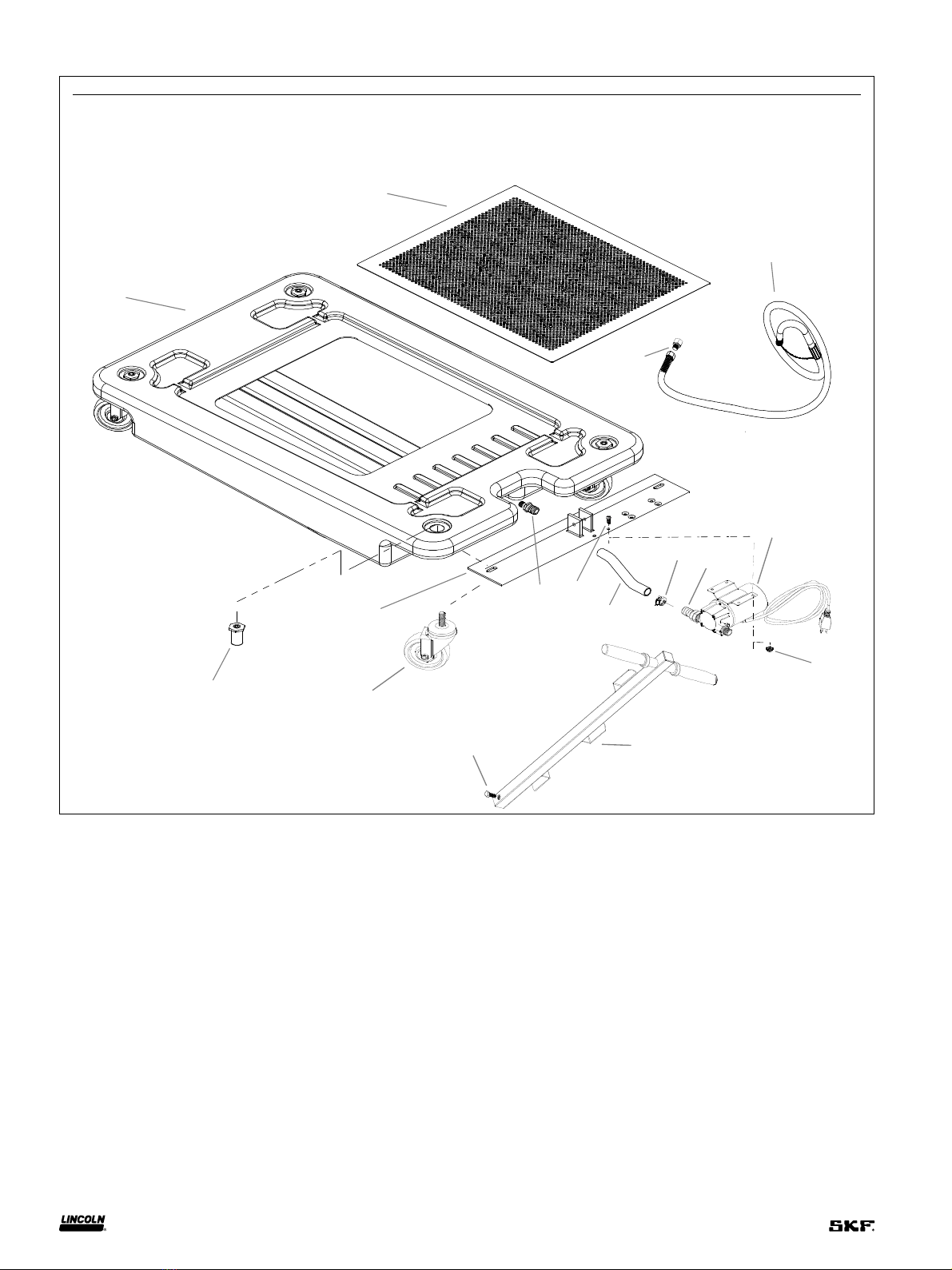

Safety

Read and carefully observe all assembly,

operating and troubleshooting instructions

before starting these procedures. The truck

drain must be assembled, maintained and

repaired exclusively by persons familiar with

the instructions in this manual.

Assemble and operate the truck drain only

after safety instructions , warnings and pro-

cedures have been read and are completely

understood.

Adequate personal protection must be

used to prevent splashing of material on the

skin or in the eyes.

Always disconnect power source (lock

out/tag out) before starting installation of

this equipment. Never assemble or disas-

semble the truck drain while connected to a

power source.

Any other use not in accordance with

instructions in this manual will result in loss

of claim for warranty or liability.

• Do not use the drain on surfaces that are

covered with oil or grease.

• Do not use the drain on surfaces that are

not flat and level.

• Do not exceed the drain load capacity.

• Do not allow the load to become uneven.

• Do not allow anyone in the vehicle while

using the drain.

• Do not drain oil above 160 °F (71 °C) into

the drain.

• Do not use the drain near flames or

heat sources.

• Do not misuse, over-pressurize, modify

parts, or use worn and/or damaged parts.

• Do not use the drain on a vehicle that

is running.

• Dispose of used oil properly.

• Failure to comply may result in personal

injury and/or damage to equipment.

WARNING

Read manual prior to installation or use

of this product. Keep manual nearby for

future reference. Failure to follow

instructions and safety precautions may

result in death or serious injury.

3