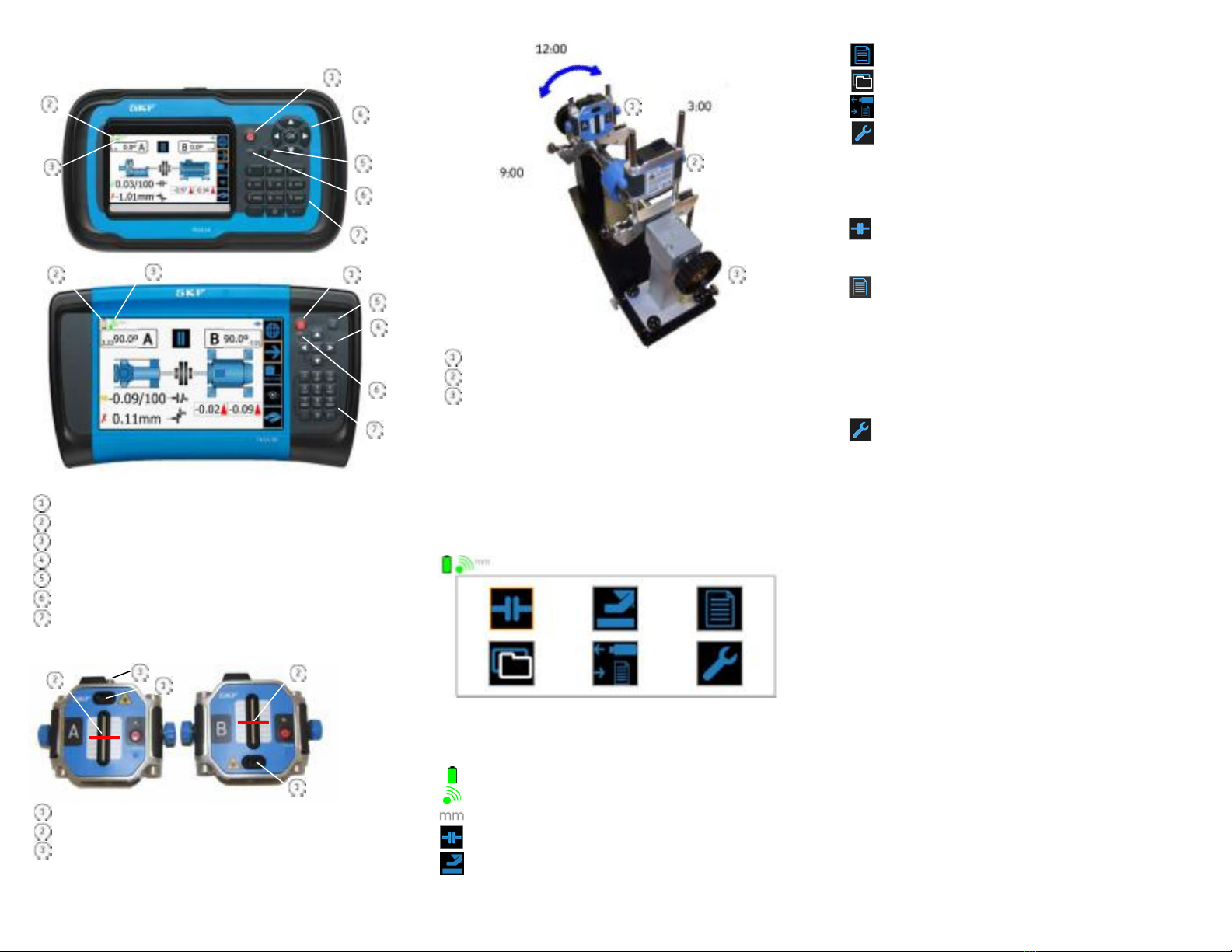

TKSA 60 / 80 Display Units

(hold for two seconds to turn off)

Wireless communications status with measuring units

avigate display screens and select highlighted item

tton - delete last character typed

Battery charging LED indicator

Alpha/numeric data entry keypad

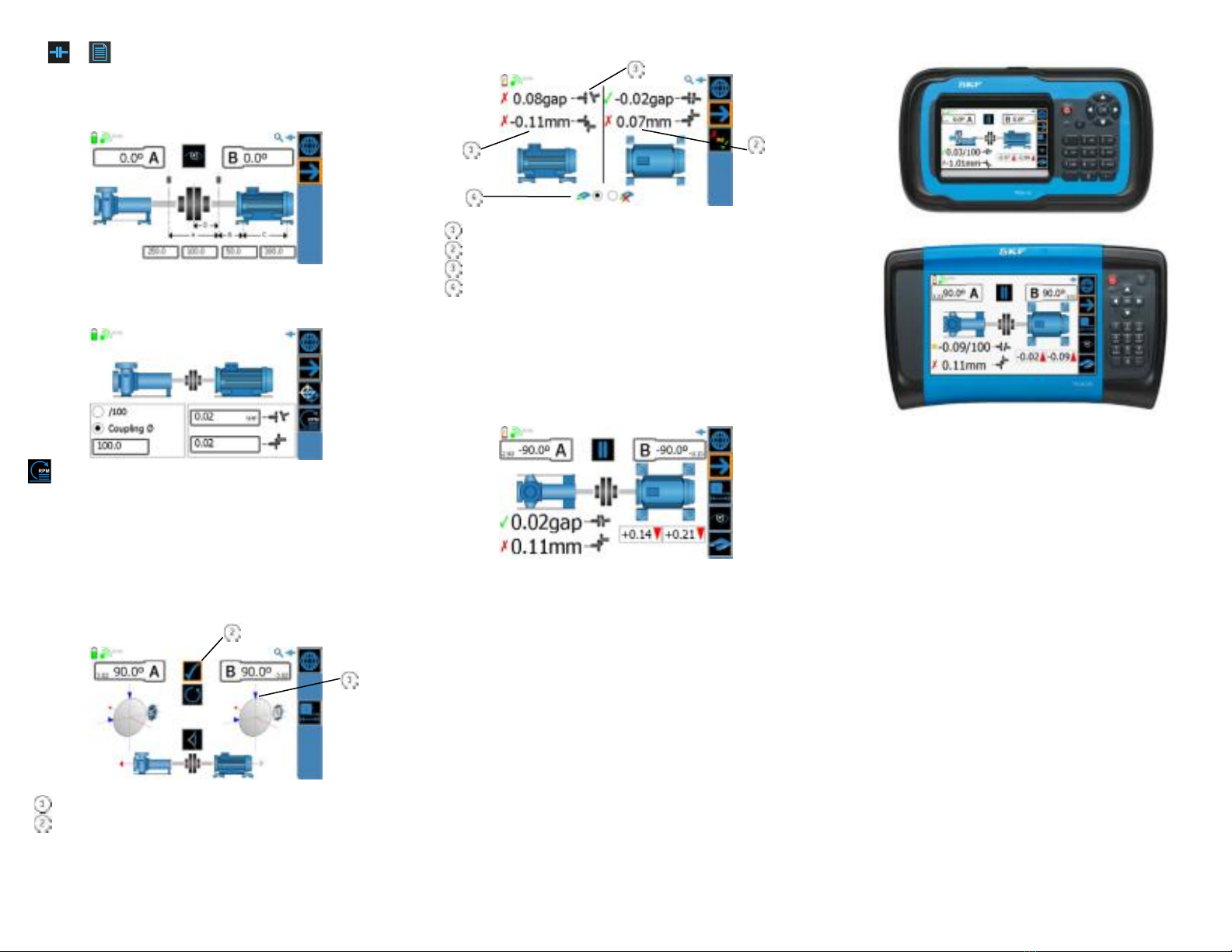

TKSA 60 / 80 Measuring Units

CCD sensors and sensor grids

Measuring unit on the stationary mach

ine

Measuring unit on the movable machine

The above clock positions (9, 12, and 3 o’clock) are the most

common for alignment measurements; however, measurements

can be taken from any clock position. Also, while it is strongly

recommended to take measurements that are 90 degrees apart,

the TKSA 60 / 80 Alignment Tools will accept a minimum rotation

angle of 30 degrees from the previous measurement position.

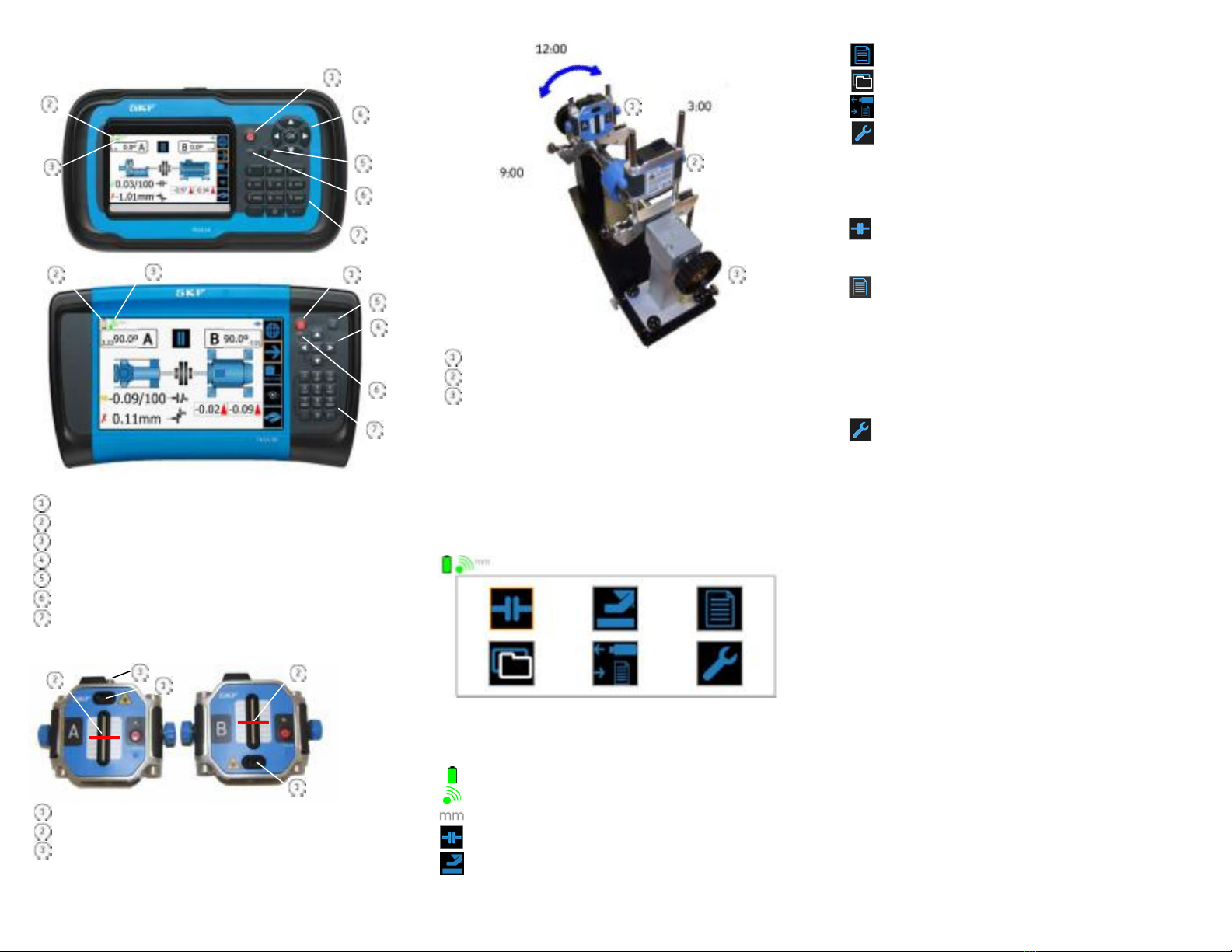

The Display Unit - Home Screen

When first powered on, the Display Unit displays its Home screen.

Icon Description

Display unit’s battery status

Wireless communication status with measuring units

Length units of measurement

Initiate a Quick Alignment

Initiate a Quick Soft Foot job

Set up and perform a Full Alignment job

Open a previously stored alignment job

Export reports to a USB memory stick for transfer to PC

Modify system settings

Two Alignment Method Options

The TKSA 60 / 80 Alignment Tools provide two methods for

performing alignment inspections:

Quick Alignment

The Quick Alignment feature is designed to allow you to quickly

perform an alignment inspection on a motor / pump machine train.

Full Alignment Job

Full alignment jobs require more setup at the beginning of the

alignment job and provide a more structured alignment job

process. Also, you can specify alignment inspections on machine

trains other than motor / pump machine trains, including machine

trains consisting of more than two machines.

To Modify System Settings:

From either the Home screen or the right panel menu, select

the Settings icon to display the main Settings screen. Then specify

Display Unit settings, Measuring Unit settings, Units of

Measurement settings, and Date and Time settings.

Standard Alignment Job Process

Set up the job – Set up the two alignment measuring units; input

machinery dimension information, and alignment targets and

tolerances.

Perform as-found inspections – Perform initial measurements

for the alignment inspection and for other selected inspections.

View results – View as-found inspection results and determine

whether corrections are required for each inspection.

Make corrections - If corrections are required, make corrections

for each inspection requiring correction.

Perform a final as-corrected alignment inspection – After all

corrections are made, re-inspect machine alignment to verify

accuracy and record as-corrected job results.

Save the Job – Save the job for historical reference and for use

with future alignment jobs.

To Perform an Alignment Inspection:

1 – Turn off power to the drive machine.

2 – Attach and adjust the v-brackets and measuring units as

described in the user manual. Laser lines should hit the centre of

the other unit’s white sensor grid.

3 – Power on the measuring units and display unit.