IF1051AEN.doc 03.01.2013 Rev. 1A

TABLE OF CONTENTS

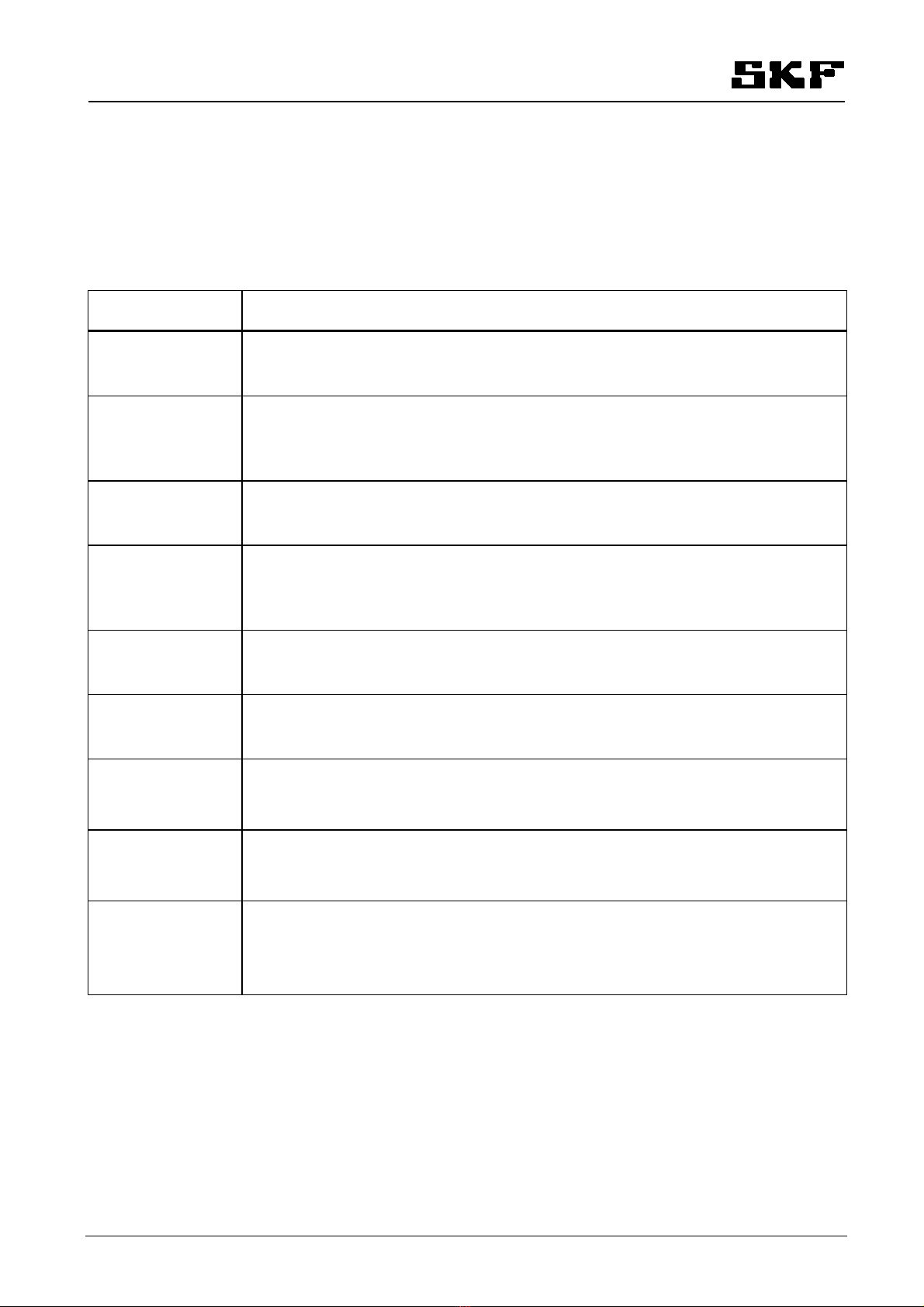

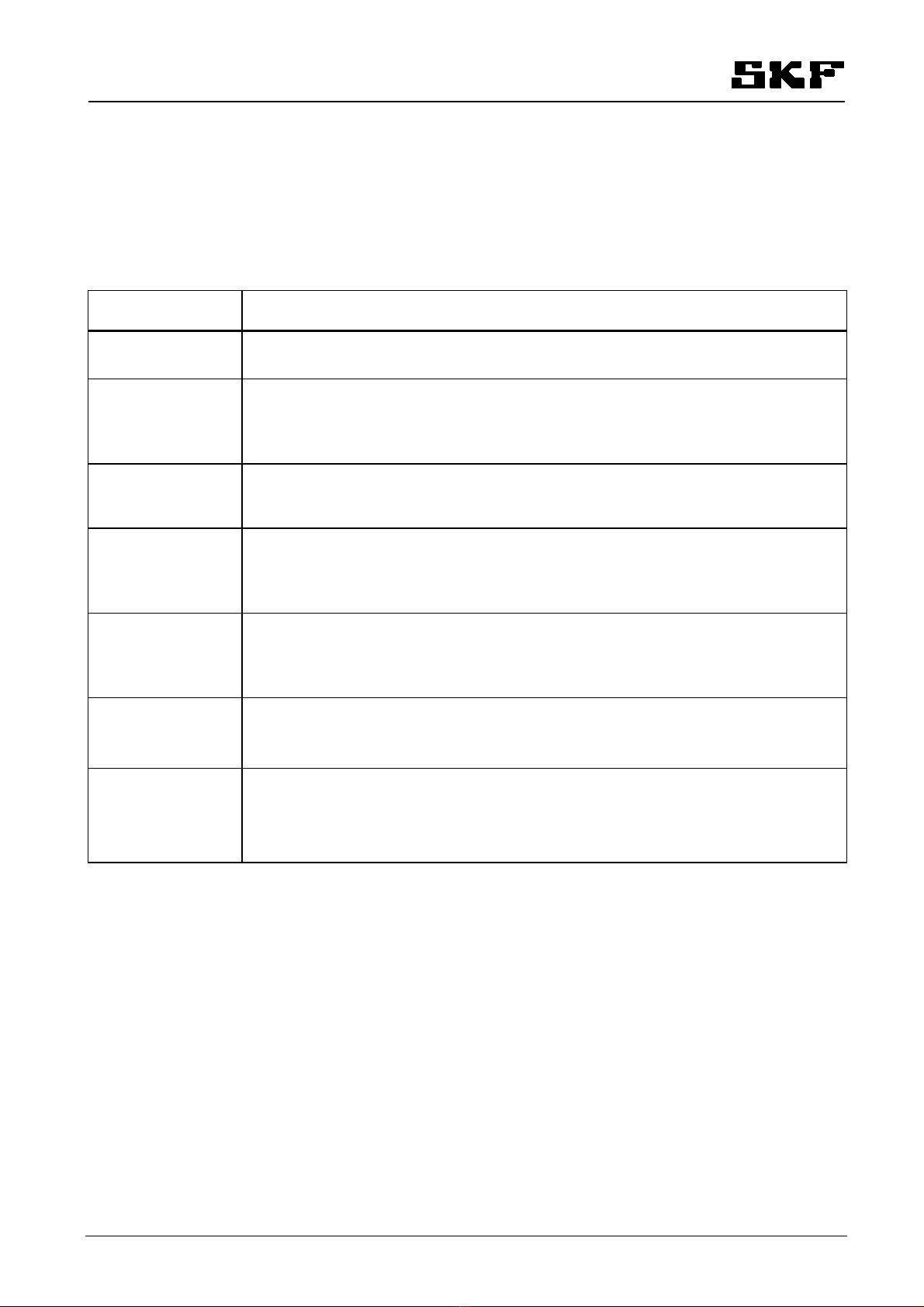

1 General information .....................................................................................................................................1

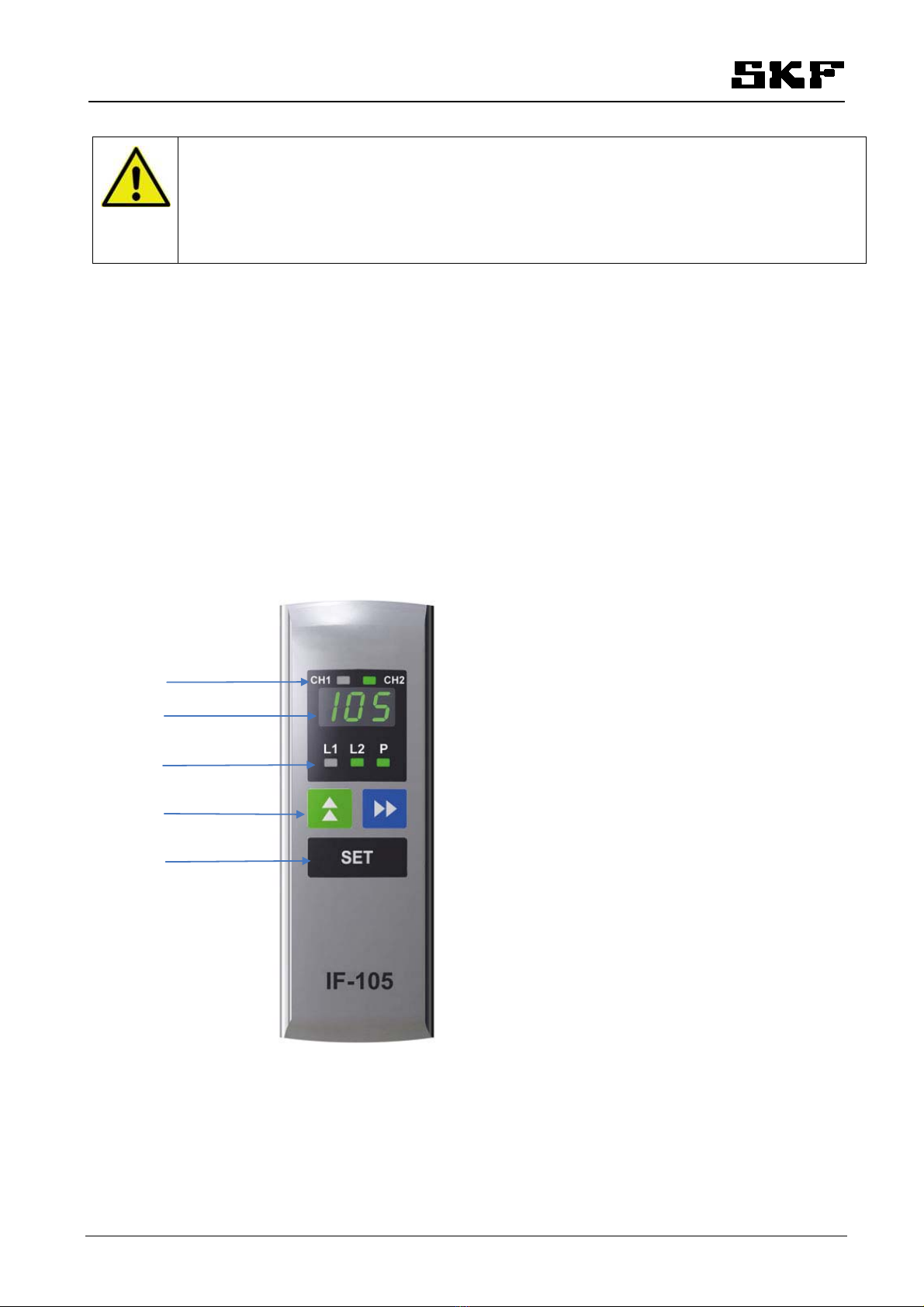

2 Design..........................................................................................................................................................1

2.1 LED-signals for channels...........................................................................................................................................................2

2.2 LED-signals for operation .........................................................................................................................................................2

2.3 Buttons.........................................................................................................................................................................................3

2.4 Display..........................................................................................................................................................................................3

3 Operation.....................................................................................................................................................4

3.1 Normal mode ..............................................................................................................................................................................4

3.1.1 Functions..............................................................................................................................................................................4

3.1.2 Phase codes for normal mode and alarm mode ............................................................................................................5

3.1.3 Normal mode displays, MonoFlex and and DuoFlex lubrication systems ...................................................................6

3.1.4 Normal mode displays, ProFlex lubrication system .......................................................................................................7

3.1.5 Pressure and pulse displays for lines...............................................................................................................................8

3.2 Power failure...............................................................................................................................................................................8

3.3 Alarms..........................................................................................................................................................................................8

3.3.1 Low level alarm...................................................................................................................................................................9

3.3.2 Pressure alarm, MonoFlex and DuoFlex lubrication systems.......................................................................................9

3.3.3 Pulse alarm, ProFlex lubrication system .........................................................................................................................9

3.3.4 Alarm from SKF Doser monitor -doser operation indicator.........................................................................................9

3.3.5 Alarm from the air pressure switch of the grease spray system .............................................................................. 10

3.3.6 Warning message for pump change (doubled pumping center/Dualset)................................................................. 10

3.4 Manual operation..................................................................................................................................................................... 10

4 Settings .....................................................................................................................................................11

4.1 General...................................................................................................................................................................................... 11

4.2 Entering password................................................................................................................................................................... 11

4.3 Entering settings...................................................................................................................................................................... 11

4.3.1 Lubrication cycle counter................................................................................................................................................ 11

4.3.2 Lubrication cycle............................................................................................................................................................... 12

5 Technical specification................................................................................................................................12

5.1 Technical data.......................................................................................................................................................................... 12

5.2 Symbols .................................................................................................................................................................................... 12

6 Contact information....................................................................................................................................12