Skytech SKY1315CW User manual

High Pressure Cold Water Jet Machine

Operating Manual

Touching New Horizon

+91 96192 68086 sales@skyengg.in

Unit No. 1,Behind Reliable Tech Park, Gavate Compound, Airoli (E) 400708

www.skytechcleaning.com

Model: SKY1315CW

Series: Car Washer

Pressure: 150 Bar

Flow: 13 Lpm

1. INDTRODUCTION

The horizontal Plunger Pumps are designed and manufactured to pump or transfer

are generally driven by: electric

motors,

motors, tractor P.T.O...

Couplings may be fulfilled

flanging, reduction unit or

multiplier,

The Pumps are supplied

standard

Pump from the head (see fig.1).

On

on the left.

The Pump is supplied to be installed on a more complex machine or plant; the

manufacturer of such

machine

the

assembled machine/plant

2. INTENDED USE

Plunger Pumps are designed to be used in machines or systems for transferring pressurized water,

such as the following for example:

Bin Washers, Water Treatment,

Misting,

The temperature of the

workplace

The Pump cannot be used

submerged

3. OPERATIONAL RESTRICTION

The specifications of the liquid to

be

liquids; in particular, it is NOT

possible

In the

presence

for this

type

In

workplaces

In the

presence

material

To

pump

ATEX

workplaces).

To

foodstuffs.

To

wash

To

wash

4. GENERAL WARNING

Never start the

Pump

Constantly check

the

under pressure.

Pipes

shall be

replaced.

The Pump must

never

Protect rotating

parts

The Pump is

designed

systems, which may make the noise level vary, even quite substantially. The manufacturer of

such machine or

system and

inform

Protection

equipme

5. BEFORE START UP

LIQUIDS TO BE

PUMPED

The Pump is designed and

manufactured

The liquid in taken must be free

from

The liquid in taken shall have

viscosity

The maximum temperature of

the liquid to be pumped varies according to the conditions of the

system (see section 6.3 - INLET

Any other use is not admitted

unless

INLET AND

OUTLET OF

The Inlet port for the liquid that

must

The horizontal Plunger Pumps are designed and manufactured to pump or transfer

water.

motors,

endothermic petrol or diesel engines and

hydraulic

Couplings may be fulfilled

by means of transmission

shaft, direct

multiplier,

joints, pulleys and belts.

standard

with the power take-off of the shaft on the right,

looking

On

request, all Pump models can be supplied with

power

The Pump is supplied to be installed on a more complex machine or plant; the

machine

or plant shall add all the information related

to

assembled machine/plant

fulfilled.

Plunger Pumps are designed to be used in machines or systems for transferring pressurized water,

Car Wash, Civil and Industrial Washing Systems, Road

Washers

Misting,

Drain and Pipe Cleaning and Fire-fighting.

workplace

shall be between: Min. 0°C (32°F) - Max.45°C (113°F)

submerged

under any type of liquid.

be

used are described in detail herewith: do not use for

different

possible

to use Pumps in the following conditions:

presence

of water with high salt content, such as seawater

for

type

of use, you are recommended to use Pump stainless

steel

workplaces

where there is a corrosive or explosive atmosphere.

presence

of any liquid that is not compatible with the

constructional

of the Pump.

pump

paint, solvents, fuel and any flammable liquid (not

suitable

workplaces).

foodstuffs.

wash

people, animals, live electrical or electronic equipment.

wash

the Pump itself.

Pump

under pressure.

the

state of wear of the pipes and relevant fittings,

especially

Pipes

with signs of abrasion or that do not guarantee a

perfect

replaced.

never

run dry/without any liquid while in use.

parts

with a cover to prevent contact..

designed

to be integrated in a machine or system,

with

systems, which may make the noise level vary, even quite substantially. The manufacturer of

or

system shall assess the level of noise emitted by the

assembled

inform

the user appropriately, also in relation to the use

of

equipme

n t .

PUMPED

manufactured

to transfer clean liquid or non-aggressive watery

solutions.

from

sand or other solid particles in suspension.

viscosity

and density similar to water.

the liquid to be pumped varies according to the conditions of the

CONDITIONS).

unless

authorized in writing by the Engineering Department of

SKY

OUTLET OF

THE PUMP

must

be pumped is generally located on the lower part of

the

water.

They

hydraulic

shaft, direct

looking

at the

power

take-off

The Pump is supplied to be installed on a more complex machine or plant; the

to

safety of

Plunger Pumps are designed to be used in machines or systems for transferring pressurized water,

Washers

and

different

for

example;

steel

series.

constructional

suitable

for

especially

those

perfect

seal

with

various supply

systems, which may make the noise level vary, even quite substantially. The manufacturer of

assembled

machine or

of

suitable personal

solutions.

the liquid to be pumped varies according to the conditions of the

SKY

.

the

Pump's

head and may also be called the

suction

generally located on the upper

part

The Inlet and outlet ports may

be

dismantling or inverting

the closure

The Inlet and Outlet

CANNOT

INLET

CONDITIONS

Pump

is

mounted

abovethe

supply tank.

Max. difference of level

between

Pump and supply tank:

0,5 m/1.6 ft.

Max. working pressure:150

bar (2200 PSI).

Max inlet vacuum:

-0.2 bar (-6 inch.Hg).

Max. Pump speed: 1450 RPM.

Max.

Inlet

water

temperature:

40°C (104°F).

The inlet pipeline must comply

with

-

Any point of the inlet

pipeline cannot

-

Be absolutely leak-proof to

avoid

-

Not have 90° bends near the

Pump

-

Not have contractions or

restrictions.

-

Avoid any turbulence near

the

-

If an inlet filter is used, it must

cause any

contraction or any pressure drop. The filter should be grant a filtration degree between 50

and 80 meshes and should be

cleaned

Any other use is not admitted

unless

OUTLET

CONDITIONS

Make sure the delivery line and all the accessories are connected correctly, secured firmly, hermetically

that the pipes are sized appropriately. All pressurized pipes must be

pressure, which must never be less

than

SPEED AND

ROTATION

The rotation

speed

of the actual

Pump.

The minimum RPM admitted

The rotation direction of the

shaft

suction

port or supply port. The Outlet port for the

pumped

part

of the head and may also be called the delivery port.

be

used either on the right or the left side of the

Pump's

the closure

plugs.

CANNOT

be inverted.

CONDITIONS

(SUCTION)

abovethe

Pump is mounted below

the supply tank in gravity

feeding.

Pump is

pressure

between

Max. Pump speed: 1750 RPM.

Max. Inlet

pressure:6

bar (90 PSI).

Max. inlet water

temperature up to 150

Bar

The feeding source must

provide 50% more

than

Pump flow.

(2200 PSI) of

Working pressure: 50°C

(122°F).

If a pressure

feeding

used, it must be

started

the plunger Pump.

Max.

Inlet

water

temperature

over to 150 bar (2200 PSI) of

working pressure: 35°C

Max.

Inlet

water

temperature:

50°C (122°F).

(95°F).

with

the following requirements:

pipeline cannot

be smaller than the diameter of the Pump inlet.

avoid

any air infiltration

Pump

inlet.

restrictions.

the

Pump inlet and in the supply tank.

allow 200% more flow than the flow required by the

Pump.

contraction or any pressure drop. The filter should be grant a filtration degree between 50

cleaned

on a regular basis to ensure its proper

functionality.

unless

authorized in writing by the Engineering

Department

CONDITIONS

Make sure the delivery line and all the accessories are connected correctly, secured firmly, hermetically

that the pipes are sized appropriately. All pressurized pipes must be

marked durably with the

maximum

than

the maximum working pressure of the Pump, written on

the Label

ROTATION

DIRECTION

speed

of the shaft of the Pump must never exceed the RPM

written

Pump.

is: maximum RPM x 0.6.

shaft

of Pumps may be clockwise or anticlockwise.

pumped

liquid is

Pump's

head, by

pressure

fed.

pressure:6

The feeding source must

than

the

feeding

Pump is

started

before

temperature:

Pump.

It must not

contraction or any pressure drop. The filter should be grant a filtration degree between 50

functionality.

Department

of SKY.

Make sure the delivery line and all the accessories are connected correctly, secured firmly, hermetically

sealed and

maximum

admitted

the Label

written

on the Label

6. CONTROLS ON SYSTEM

UNLOADER

VALVE

A pressure regulator valve must

indicated on the Label of the

Pump.

Use of the Pump, even

for

the Pump itself.

The regulator valve shall be

compatible

values written on the Label and in

Incorrect installation of the pressure regulator valve could cause serious personal injuries and

damage to property as

well

The circuit must be

equipped

being exceeded in the

case

NOZZLE

A deteriorated nozzle could

cause

valve in the attempt to increase the pressure of the system because when the delivery line closes, this

would cause a boost in

pressure, which

If the pressure

drops, it is advisable to replace the nozzle and adjust the system's pressure again. The

flow rate of the Pump must be

at least

excess flow rate must

be discharged.

PULSATION

DAMPENER

For applications in which pulses produced by the Pump on the delivery line are harmful or undesired,

install an appropriately sized

pulse

PRESSURE

GAUGE

Install a gauge as near as possible to the outlet of the Pump because the

on the Pump's Label refers to the

pressure

on other accessories.

All the components of

the

An example of

the diagram

a Circuit

VALVE

be installed to avoid the pressure exceeding the

maximum

Pump.

for

a short period, with a pressure higher than such limit

would

compatible

with the maximum pressure, flow rate and

temperature

the "INLET CONDITIONS".

Incorrect installation of the pressure regulator valve could cause serious personal injuries and

well

as seriously damaging the actual Pump.

equipped

with another safety valve to prevent the maximum

pressure

case

of anomalies in the pressure regulator valve.

cause

a drop in pressure; in this case, do not adjust the

pressure

valve in the attempt to increase the pressure of the system because when the delivery line closes, this

pressure, which

could damage the Pump.

drops, it is advisable to replace the nozzle and adjust the system's pressure again. The

at least

10% higher than

the

flow rate that

the

utilities

demand; the

be discharged.

DAMPENER

(ACCUMULATOR)

For applications in which pulses produced by the Pump on the delivery line are harmful or undesired,

pulse

dampener.

GAUGE

Install a gauge as near as possible to the outlet of the Pump because the

maximum pressure written

pressure

detected on the head of the Pump and not on

the

the

machine or of the circuit must have technical

specifications

An example of

the diagram

of

a Circuit

maximum

limit

would

damage

temperature

Incorrect installation of the pressure regulator valve could cause serious personal injuries and

pressure

from

pressure

regulator

valve in the attempt to increase the pressure of the system because when the delivery line closes, this

drops, it is advisable to replace the nozzle and adjust the system's pressure again. The

demand; the

For applications in which pulses produced by the Pump on the delivery line are harmful or undesired,

maximum pressure written

the

nozzle or

specifications

compatible

with the data written on

the

7. INSTALLATION, START UP AND

SWITCHING

POSITIONING

Smaller and lighter Pumps can be handled by hand in compliance with current standards. Heavier

Pumps must be handled using the dedicated hook and

you need to use a lifting device, use appropriate strap/s, being careful not to damage the product. The

weight of the Pumps is written in

the

If the Pump is used in particularly dirty

recommended to

protect it, respecting

ASSEMBLY

Fit the Pump on a rigid surface keeping the power take

correct drainage in the

case of leakage of water or oil. The Pump must be secured firmly on a base,

which must be perfectly aligned with the transmission components. In the case of belt transmission,

make sure the pulleys are aligned

Use

appropriately sized hoses, both on the inlet and outlet of the Pump, according to the technical

specifications written on the

Label.

START UP

Before starting, check the

following:

Replace the RED cap

on

accessories supplied.

Check the oil level

through

Check the pressure

value

The pressure regulator

valve

Start and run the Pump for approximately 10 seconds until all the liquid has discharged from the

delivery line. Once the intake cycle is complete, you can set the Pump at the required pressure, by

adjusting the pressure

regulator valve, without ever exceeding the maximum pressure written on the

Pump's Label.

SWITCHING OFF

After use or if the Pump is to be put away in storage, wash it internally. You can do this by running the

Pump for several minutes with

clean water, then disconnect the supply line and leave the Pump to run

for approximately 15 seconds so

that

A few minutes devoted to the

internal

pump's lifetime.

Do not wash the Pump externally: water could get into the Pump crankcase, for example

through the oil vent cap.

After switching off, the

Pum

Do not throw the liquid

used

PRECAUTIONS

AGAINST

If shutdown during winter or in the case of places and seasons subject to frost, once the Pump has

finished working, run it for the time required to pump an emulsion of 50% of clean water and

antifreeze fluid through it in order

to prevent freezing

The Pump must not be used to

Pump

In the presence of ice or very

cold

started; otherwise the Pump

could

completely defrosted.

the

Pump's Label.

SWITCHING

OFF

Smaller and lighter Pumps can be handled by hand in compliance with current standards. Heavier

Pumps must be handled using the dedicated hook and

suitable lifting device. If there is no eyelet and

you need to use a lifting device, use appropriate strap/s, being careful not to damage the product. The

the

table on page 25.

If the Pump is used in particularly dirty

workplaces or is exposed to atmospheric agents, you are

protect it, respecting

the ventilation conditions.

Fit the Pump on a rigid surface keeping the power take

-

off and support feet horizontal to ensure

case of leakage of water or oil. The Pump must be secured firmly on a base,

which must be perfectly aligned with the transmission components. In the case of belt transmission,

and check the tension of the belts.

appropriately sized hoses, both on the inlet and outlet of the Pump, according to the technical

Label.

following:

on

the Pump Crankcase with the venting cap in the

through

the dedicated oil reservoir or inspection cap; top-up if

necessary.

value

on the accumulator, if installed; inflate or deflate if

necessary.

valve

must be set at "0" pressure to favour intake.

Start and run the Pump for approximately 10 seconds until all the liquid has discharged from the

delivery line. Once the intake cycle is complete, you can set the Pump at the required pressure, by

regulator valve, without ever exceeding the maximum pressure written on the

AND STORAGE

After use or if the Pump is to be put away in storage, wash it internally. You can do this by running the

clean water, then disconnect the supply line and leave the Pump to run

that

all the water in the head is discharged.

internal

washing of the pump brings considerable benefits in

terms

Do not wash the Pump externally: water could get into the Pump crankcase, for example

Pum

p could remain very hot for some time.

used

to wash the Pump outdoors but observe current

standards.

AGAINST

FREEZING

If shutdown during winter or in the case of places and seasons subject to frost, once the Pump has

finished working, run it for the time required to pump an emulsion of 50% of clean water and

to prevent freezing

and damage to the Pump.

Pump

antifreeze fluid that is not mixed with water.

cold

temperatures at the workplace, the Pump must

never

could

be seriously damaged. To start the system, the whole

circuit

Smaller and lighter Pumps can be handled by hand in compliance with current standards. Heavier

suitable lifting device. If there is no eyelet and

you need to use a lifting device, use appropriate strap/s, being careful not to damage the product. The

workplaces or is exposed to atmospheric agents, you are

off and support feet horizontal to ensure

case of leakage of water or oil. The Pump must be secured firmly on a base,

which must be perfectly aligned with the transmission components. In the case of belt transmission,

appropriately sized hoses, both on the inlet and outlet of the Pump, according to the technical

kit of

necessary.

necessary.

Start and run the Pump for approximately 10 seconds until all the liquid has discharged from the

delivery line. Once the intake cycle is complete, you can set the Pump at the required pressure, by

regulator valve, without ever exceeding the maximum pressure written on the

After use or if the Pump is to be put away in storage, wash it internally. You can do this by running the

clean water, then disconnect the supply line and leave the Pump to run

terms

of the

Do not wash the Pump externally: water could get into the Pump crankcase, for example

standards.

If shutdown during winter or in the case of places and seasons subject to frost, once the Pump has

finished working, run it for the time required to pump an emulsion of 50% of clean water and

50% of

never

be

circuit

must be

8. MAINTENANCE

ROUTINE

MAINTENANCE

If the Pump is used for light-duty

purposes,

After the first 50 hours:

Oil

Every 200 - 300 hours:

Oil

Every 1000 hours:

Replace

rings for heavy-duty

purposes,

jobs more often.

When inspecting or

replacing

caps over the valves (see

LUBRICATION

The Pump is supplied with the

correct

Periodically check the oil level in

the

Use OIL type SAE 15W-40 or

equivalent.

BRAND

AGIP

BP

CASTROL

ESSO

MOBIL

SHELL

TOTAL

The oil is to be changed by

draining

Pump stopped.

Every time you unscrew the oil

drain

DO NOT START

THE

During

maintenance,

Use and wear suitable personal protection equipment (i.e.

gloves). Wait

for

stopped

completely.

During

maintenance,

If the Pump is to

be

1.

Separate the

various

metal etc.).

2.

Use public or

dispose of

waste.

3.

This device

could

disposal could

have

MAINTENANCE

purposes,

the following routine maintenance jobs are

advised:

Oil

change (see section 9.2 - Lubrication)

Oil

change (see section 9.2 - Lubrication)

Replace

the valves - replace piston seal

purposes,

carry out the maintenance

replacing

the Pump valves, be careful which type of Loctite®

you

table on page 26-27).

correct

amount of lubrication oil (see table on page 25).

the

Pump through the oil level indicator.

equivalent.

Here are some recommended types of oil:

TYPE

F.1 Supermotoroil 20W-40

Vanellus C 20W-40

CASTROL

GTX 20W-40

Uniflo 20W-40

Super M 20W-40

Rimula R4 20W-40 / Helix Super

20W40

Rubia 20W-40 / Quartz 5000 20W-40

draining

it through the dedicated bottom oil drain plug and strictly

drain

plug we suggest replacing its gasket

THE

PUMP IF THERE IS NO OIL IN THE PUMP!

maintenance,

you are recommended to:

Use and wear suitable personal protection equipment (i.e.

for

the machine to cool down and to have

completely.

maintenance,

d not throw residues outdoors but observe current

standards.

be

scrapped:

various

parts depending on their type (i.e. plastic,

harmful

private waste disposal systems envisaged by local law

to

waste.

could

contain harmful substances: improper use or

incorrect

have

negative effects on human health and on the

environment.

advised:

you

use on the

with the

standards.

harmful

fluids,

to

incorrect

environment.

PROBLEMS

PROBABLE CAUSES

SOLUTIONS

The Pump

doesn’t

reach

required

pressure.

Incorrect or worn or plugged nozzle.

Change

to

proper

size

nozzle;

replace nozzle or clean nozzle.

Belt

slippage.

Tighten

or

replace

belt.

Air

leak

in

inlet

plumbing.

Check

or

replace

hoses

or

fittings.

Inlet

suction

strainer

clogged

or

improper size.

Check and clean, use adequate size.

Worn

seals.

Abrasives in Pumped fluid; severe

cavitations; inadequate

water supply.

Install and maintain proper filter.

Replace seals. Check inlet supply:

Max. -0,2 bar (-6 inch.Hg) vacuum.

Pressure

gauge

is

broken

or

not

registering accurately.

Check

with

new

gauge;

replace

worn

or

damaged

gauge.

Relief / unloader

valve stuck,

partially plugged or improperly

adjusted.

Adjust

or

repair

or

replace

relief / unloader valve.

Dirty

or

worn

inlet

or

outlet

valves.

Check

and

clean

or

replace

valves.

Leaky outlet hose.

Check

or

replace

discharge hoses

or

fittings.

Pump is noisy.

Air

leak

in

inlet

plumbing.

Check

or

replace

hoses

or

fittings.

Inlet

strainer

clogged

or

improper

size or insufficient supply of water to

the

Pump.

Check and clean, use adequate

size; increase water supply if not

sufficient.

Dirty

or

worn

inlet

or

outlet

valves.

Check

and

clean

or

replace

valves.

Worn

seals

or

o

-

rings.

Replace

seals

or

o

-

rings.

Plugged

inlet

filter or

improper

size.

Clean

or replace

filter.

Pulley

loose

on

crankshaft

or

worn

key.

Check

pulleys

and

key.

Broken

or

worn

bearings.

Replace

bearings.

Water

leakage

underthe

Pump

head.

Worn

low

pressure

seal

or

o

-

ring.

Replace

seal

or

o

-

ring.

Cracked

plunger.

Install

new

plunger.

Water in

crankcase. Oil

is

changing

colo

r into white.

High humidity in air (condensing).

Change

oil

every 250

hours

instead of

500.

Worn

crankcase

oil

seal.

Replace

crankcase

oil

seal.

Worn

low

pressure

seal.

Replace

seal.

Oil leak

between

crankcase and

head.

Worn crankcase oil seal.

Check plunger rod.

Replace crankcase oil

seal.

Oil leak in

the area of

crankshaft.

Worn

crankshaft

oil

seal.

Replace

crankshaft

oil

seal.

Worn

bearing

case

o

-

ring.

Replace

bearing

case

o

-

ring.

Bad

bearings.

Replace

bearings.

Oil leak at the

reared of the

Pump.

Damaged

or

improperly

installed

sight glass or crankcase cover seal or

drain plug.

Replace sight glass, plug or seals.

Frequent

or

premature

failure of

the

packing.

Scored

plungers.

Replace

plungers.

Over

pressure

in

inlet

manifold.

Reduce

inlet

pressure.

Abrasive

material

in

the

fluid

being Pumped.

Install proper filter

on

Pump

inlet

plumbing.

Corrosive additives in the fluid

being Pumped.

Use clean water or contact SKY

Technical Service Department for

more information’s.

Excessive

temperature

of

fluid

being Pumped.

Assure fluid inlet temperature

are within specified range (see

page

20).

Running

Pump

dry.

Do

not

run

Pump

without

fluid.

Excessive

vibrations

in outlet

line.

Air

leak

in

inlet

plumbing.

Check

or

replace

hoses

or

fittings.

Pulsation

damper

pressure

too

low.

Check

and

repressure.

Dirty

or

worn

inlet

or

outlet

valves.

Check

and

clean

or

replace

valves.

9. TROUBLE SHOOTING

DENOMINAZIONE - TITLE

CODICE - PART NO. REV.

MV925 G 3/8 F - G 1/4 F Campelli

15/03/13

4012205000 0

VIETATO RIPRODURRE O DIVULGARE IN TOTO O IN PARTE IL PRESENTE

DISEGNO SENZA AUTORIZZAZIONE SCRITTA DELLA TECOMEC S.p.A.

IT IS FORBIDDEN TO PARTIALLY OR TOTALLY COPY, USE OR DISCLOSE THIS MATERIAL

WITHOUT PRIOR WRITTEN CONSENT FROM TECOMEC S.p.A.

DWN

DISEGN.

VISTO

APPROVED

DATA

DATE

RF

CODICE CLIENTE - CUSTOMER PART NO.

42124- REGGIO EMILIA - ITALY

1

2

3

4

5

6

8

11

14

19

KIT 1 - KIT RICAMBI SE E GUARNIZIONI - REPAIR KIT SEAT GASKET Cod. 4019900025

KIT 2 - KIT RICAMBI LEVA COMPLETA - REPAIR KIT TRIGGER Cod. 4019900026

KIT 3 - KIT RICAMBI SCOCCHE E VITI - REPAIR KIT SHELL SCREW Cod. 4019900029

Num. Codice escrizione Completa Quant. Kit1 Kit2 Kit3

1 C00015011 CORPO MV925 G 1/4 F 1

2 000117 A.A. 3,00x 7,40x1,30 TB 1 X

3 060143 GUOR 2.62X2.84 104 VITON 75 NERO 1 X

4 R00300014 RON ELLA 3 X 7 X 1,5 OTTONE 1 X

5 P00004004 PERNO PREMISFERA MV925 1 X

6 0106200140 SE E MV2001 CONIATA CON OR NBR 90 1 X

7 160013 SFERA 5/16 G28 AISI 420C HRC 56 MIN 1 X

8 M00201052 MOLLA INOX 1,7 X 9,4 X 16,5 1

9 0110750700 GUOR 1.5X11 NBR 90 NERO 1 X

10 T00000096 TAPPO MV 925 VERS. STAN AR 1

11 T00303044 TUBO L.130 MM ZINCATO G 1/4 M 1

12 R00000212 RACCOR O ENTR. OTT G 3/8 F 1

13 L00002049 LEVA MV 925 NERA 1 X

14 P00004005 PERNO PER LEVA MV925 .4X22 INOX 1 X

15 P00000087 PERNO PER LEVA MV925 .5X33 IX 1 X

16 0100740520 SICURA MV951- ROSSA - 1 X

17 S02301247 SCOCCA MV 925 ESTRA NERA 1 X

18 T00200169 TARGHETTA MV 925 ESTRA ROSSA 1 X

19 S02301248 SCOCCA MV 925 SINISTRA NERA 1 X

20 0116730010 VITE AUTOF. 4 X 19 UNI 9707 6 X

21 T00200170 TARGHETTA MV 925 SINISTRA ROSSA 1 X

15

BETTAGLIO- ETAIL B

A

ETTAGLIO- ETAIL A

20

9

10

18

13

21

17

12

7

16

DENOMINAZIONE - TITLE

CODICE - PART NO. REV.

VRT3 G 3/8 F 31 MPA + MANOPOLA

0215010260 3

VIETATO RIPRODURRE O DIVULGARE IN TOTO O IN PARTE IL PRESENTE

DISEGNO SENZA AUTORIZZAZIONE SCRITTA DELLA TECOMEC S.p.A.

IT IS FORBIDDEN TO PARTIALLY OR TOTALLY COPY, USE OR DISCLOSE THIS MATERIAL

WITHOUT PRIOR WRITTEN CONSENT FROM TECOMEC S.p.A.

CODICE CLIENTE - CUSTOMER PART NO.

42124- REGGIO EMILIA - ITALY

9

15

17

1

12

13

23

9

7

15

22

14

26

27

25

KIT RICAMBIO VRT3 31 MPa Co . 4079900005

Num. Co ice Descrizione Completa Quant. Kit

1 0109712650 CORPO VRT3 G 3/8 F MV 0316 01B 1

3 4079500001 SEDE VRT3 Ø8 CONIATA CON OR NBR 90 1 X

4 0112720010 SFERA DIAM.13/32 AISI 44OC TEMP G20 1 X

5 0107720820 MOLLA SFERA MV 0316 28 1

6 0110751311 GUOR 1.78X17.17 2068 NBR 90 NERO 2 X

7 0115712280 RAC.SEDE3/8GF SF13/32' MV 0316 15A 1

8 0104720230 STELO VRT3 MV 0316 04 1

9 000125 A.A.11,50x15,9x1,20 TBT 000125B 2 X

10 0110750910 GUOR 2.62X10.78 3043 NBR 70 NERO 1 X

11 0110750170 GUOR 2.62X7.6 3030 NBR 70 NERO 1 X

12 0122790030 A.A.8X12,6X1,2 MV 0316 05 1 X

13 0115712250 RAC.GUIDA STELO VRT3 MV 0316 06 1

14 0118720120 SPINA ELASTICA UNI ISO 28748 3X14 1

15 030200 DADO VRTVHP M 8 x 4 OTT. 2

16 0107770080 MOLLA 5,7X20,7X56 31 MPA MV 0316 19 1

17 150204 RONDELLA D. 8,5x24,0x2,0 Z.B. 1

18 400305 MANOPOLA VRT2VHP ROHS 1

19 030101 DADO AUTOBLOC.BASSO M8x8 Z.B. 1

20 0128740090 COPERCHIO MAN.31MPA MV 0316 22 1

21 060109 GUOR 3.0X6.0 NBR 90 NERO 1 X

22 0157710040 OTTURATORE VRT3 MV 0316 07 1

23 0107720800 MOLLA OTTURATORE VRT3 MV 0316 08A 1

24 0110751321 GUOR 1.78X15.6 2062 NBR 90 NERO 1 X

25 0115712260 RACCORDO RITEGNO G3/8 F 1

26 060200 GUARNIZIONE D.14 x8,3x1,5 RAME 2

27 170101 TAPPO E.I. G3/8 CILINDRICO OTTONE 2

26

27

6

11

10

5

6

21

24

19

18

20

3

4

16

8

Table of contents

Other Skytech Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Fieldmann

Fieldmann FDW 201402-E operating instructions

Nilfisk-Advance

Nilfisk-Advance E130.3 X-TRA Repair manual

Comet

Comet KT 1750 extra instruction manual

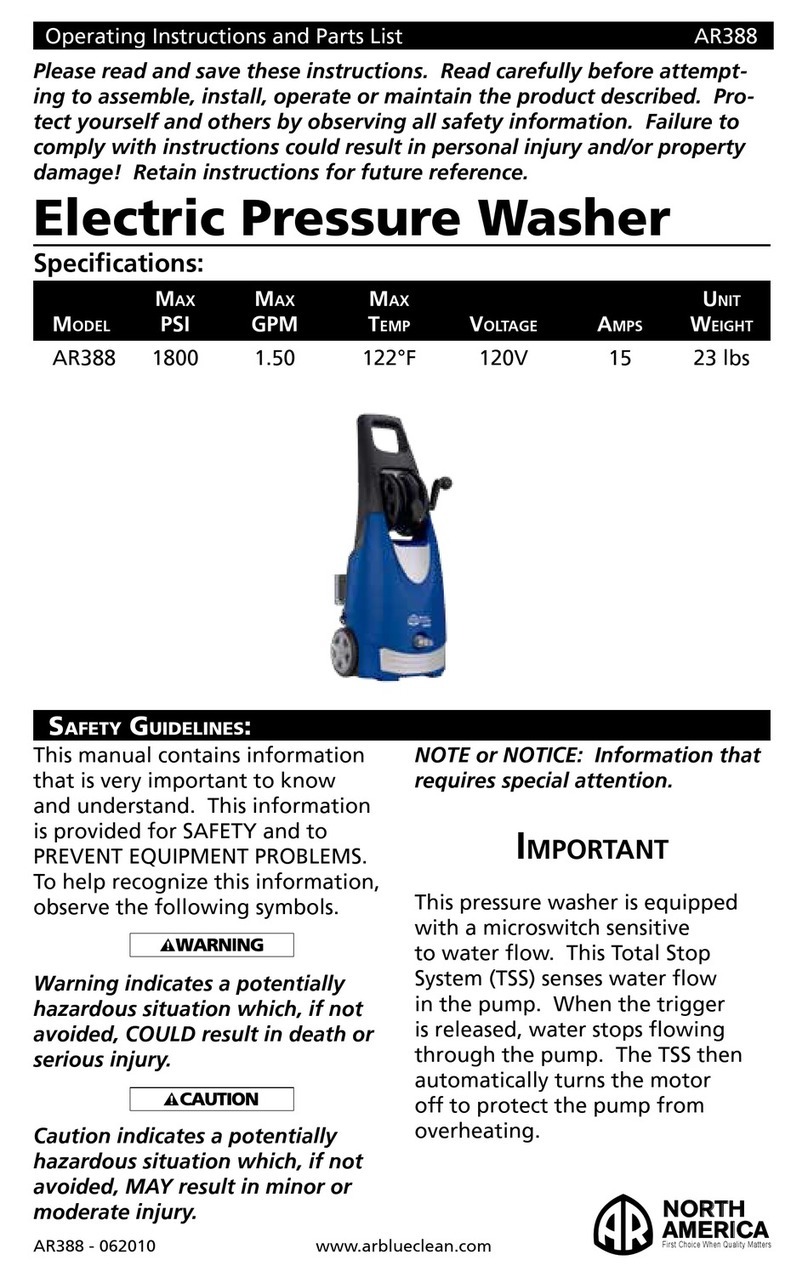

A.R.North America

A.R.North America AR388 Operating instructions and parts list

Parkside

Parkside PDR 12 A1 Translation of the original instructions

DeWalt

DeWalt DPD3000IC instruction manual