9.808-216.0 English Rev B (01/21) 5

Good service work requires extensive and pracce-oriented

training as well as well-structured training materials. Hence we

oer regular basic, advanced and expert training programs

covering the enre product range for all cered distributor

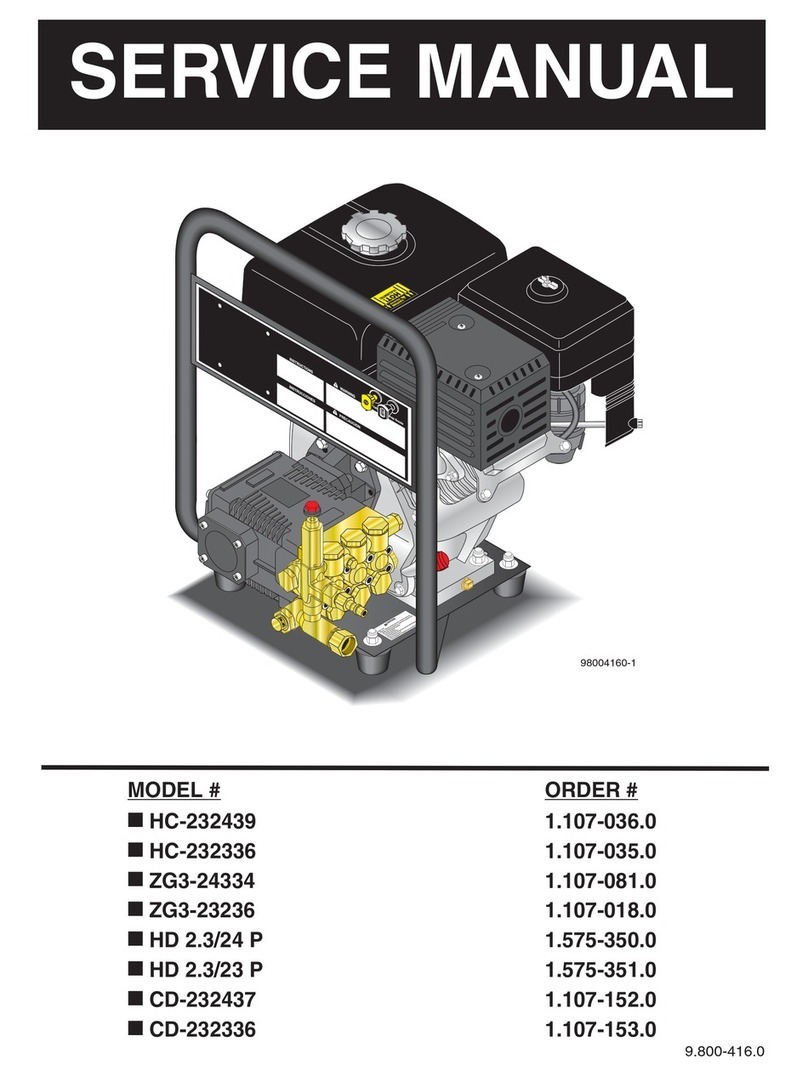

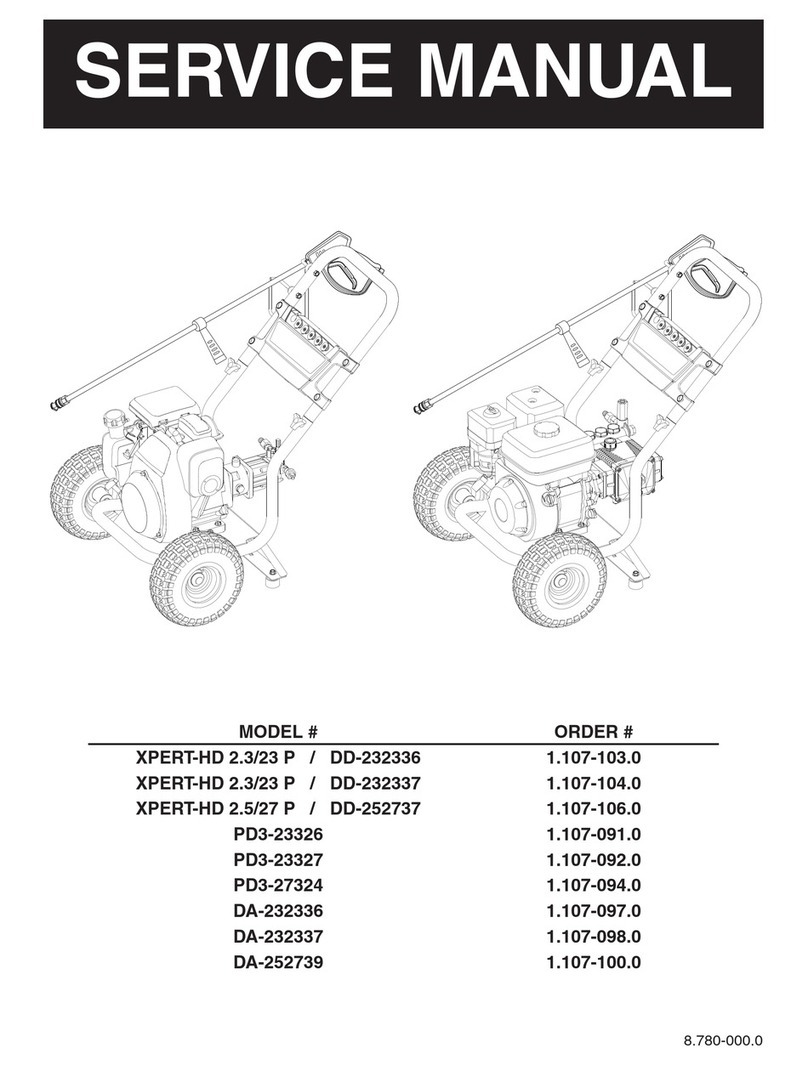

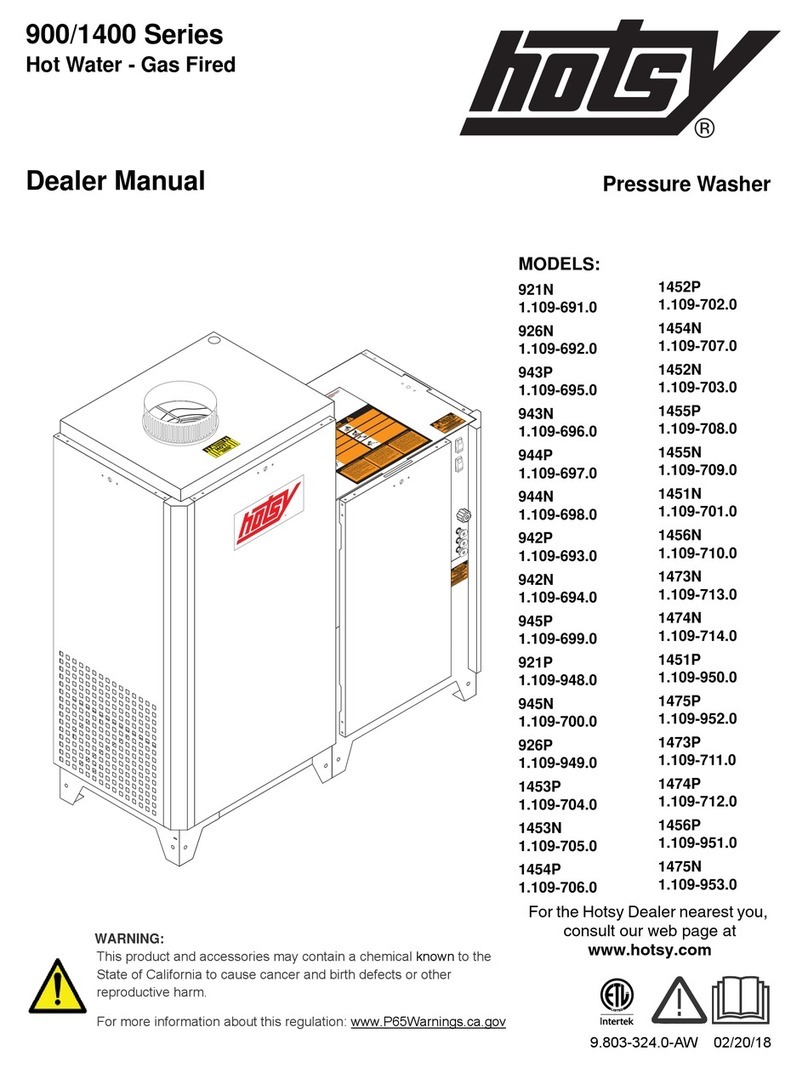

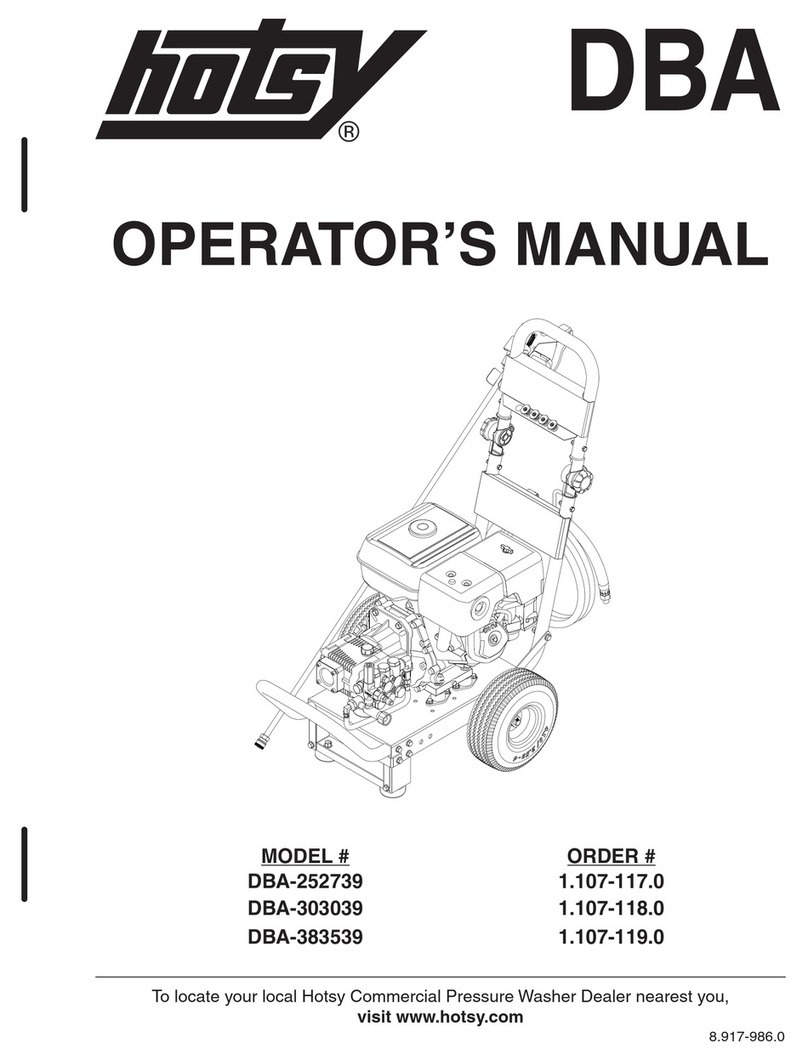

technicians. In addion to this, we also prepare service manu-

als for important appliances—these can be inially used as

instrucon guides and later on as reference guides. Apart from

this, we oer regular informaon about product enhance-

ments and their servicing.

If you should require addional assistance, have correcons or

quesons regarding this document, please do not hesitate

contacng us at: www.Hotsy.com and click on customer feed-

back to enter any info you may have for us or you can also

contact any of our Technical Support Specialists at 800-220-

5409.

Copying and duplicaon of texts and diagrams as well as

third-party access to this informaon is permied only with

the explicit permission of the company: KARCHER NORTH

AMERICA 6398 N Kärcher Way, Aurora, CO 80019.

1Preface

Service and maintenance tasks may only be performed

by qualified and specially trained specialists.

Observe safety information in the chapters!

DANGER

Please read the operating instructions for your

machine before using it, and pay particular attention to

the following safety instructions.

Warning and information plates on the machine

provide important directions for safe operation.

Apart from the notes contained herein, the gen-

eral safety provisions and rules for the prevention of acci-

dents of the legislator must be observed.

Switch off the appliance and, in case of applianc-

es connected to mains, pull out the power cord before

cleaning and performing any maintenance tasks on the

machine.

Relieve the high pressure system of all pressure

prior to all work on the appliance and the accessories.

Only use accessories and spare parts which have

been approved by the manufacturer. The exclusive use of

original accessories and original spare parts ensures that

the appliance can be operated safely and trouble free.

Only use the fuels specified in the Operations

Manual. Risk of explosion due to the use of inappropriate

fuels.

In petrol engine appliances, ensure that no petrol

comes in contact with hot surfaces.

Ensure that there is adequate ventilation or provi-

sion for diverting the exhaust gas while operating the ap-

pliance in closed rooms (risk of poisoning).

Do not close the exhaust.

Please ensure that there are no exhaust emis-

sions near the air inlets.

Do not use high pressure cleaners when there

has been an oil spill; move the appliance to another spot

and avoid any sort of spark formation.

Do not store, spill or use fuel in the vicinity of

open flames or appliances such as ovens, boilers, water

heaters, etc. that have an ignition flame or can generate

sparks.

Do not use unsuitable fuels, as they may be dan-

gerous.

Keep even mildly inflammable objects and mate-

rials away from the muffler (at least 2 m).

Warning

Do not bend over the exhaust or touch it.

2Safety instrucons

2.1 Hazard levels

DANGER

For an immediate danger which can lead to severe injuries or

death.

WARNING

For a possibly dangerous situaon which could lead to severe

injuries or death.

CAUTION

For a possibly dangerous situaon which can lead to minor

injuries or property damage.

ATTENTION

Pointer to a possibly dangerous situaon, which can lead to

property damage.