SkyVac Interceptor User manual

SkyVac Interceptor Instrucon Manual

IMPORTANT PLEASE READ THESE INSTRUCTIONS AND HONDA OWNERS MANUAL

CAREFULLY BEFORE OPERATING THE MACHINE

SERIAL NUMBER……………………………………………………………. TO COMPLETED BY THE USER

This Spinaclean Heavy Duty Vacuum Cleaner is designed to handle a wide range of

cleaning and debris collecon operaons in industrial areas

CAUTION

This vacuum cleaner must not be used for the collecon of health endangering

ammable or explosive material

ENGINE SAFETY

1) To prevent re hazards and to provide adequate venlaon, keep the engine at

least one metre away from buildings and other equipment during operaon.

DO NOT place ammable objects close to the engine

2) Children and pets must be kept away from the area of operaon due to a

possibility of burns from hot engine components or injury from any equipment.

3) Know how to stop the engine quickly , and understand the operaon of all

controls. Never permit anyone to operate the engine without proper

instrucons.

4) Petrol is extremely ammable and explosive under certain condions

5) Re-fuel in a well venlated area with engine stopped. DO NOT smoke or allow

ames or sparks in the refuelling area or where petrol is stored.

6) DO NOT over ll the tank. Aer refuelling make sure the tank cap is closed properly

and securely

7) Be careful not to spill fuel when re-fuelling. Fuel vapour or spilled fuel may

ignite. If any fuel is spilled, make sure the area is dry before restarng

8) Never run the engine in an enclosed or conned area. Exhaust contains

poisonous carbon monoxide gas, exposure may cause loss of consciousness and

may lead to death

9) The muer becomes very hot during operaon and remains hot for a while aer

stopping the engine. Be careful not to touch the muer while it is hot.

To avoid severe burns or re hazards, let the engine cool before transporng it or

storing it indoors

PREPARATION FOR EACH USE

1) Check for petrol leaks (clean up any spillages)

2) Check HT (spark plug) lead for damage

3) Check trailing grounding lead is intact and touching the ground

4) Check oil level is correct

5) Check that collecon drum is empty, or has sucient capacity .

6) Check the lter/oat valve for cleanliness/operaon

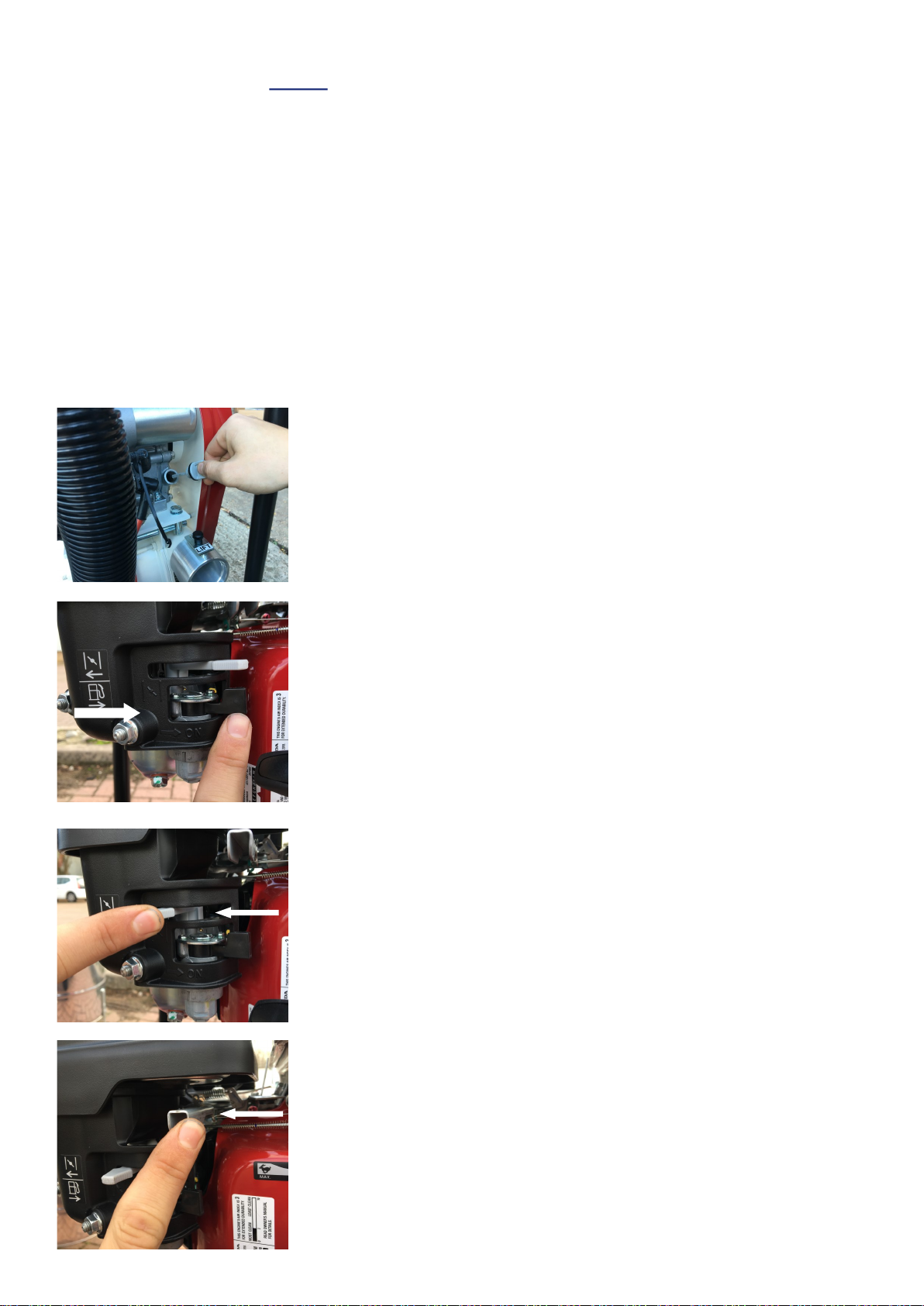

2) Move the choke lever to the CLOSED posion.

Note the choke may not be needed if the engine is

warm or the air temperature is high

3) Move the throle lever slightly to the le

Ensure the Interceptor is on level ground. Remove

the grey dipsck and ll with mulgrade 10w 40

engine oil. Pour up to the boom of the thread in

the dipsck chamber

STARTING THE ENGINE

1) Turn the black fuel valve to the ON posion

To Fill the Engine with Oil

4) Start the engine

A. Recoil start—Turn the engine switch to the ON posion. Pull the

starter grip lightly unl resistance is felt, then pull briskly. DO NOT

allow the starter grip to snap back against the casing, return it

gently to prevent damage to starter.

B. Electric Key Start—Turn the engine switch to the start posion and

hold unl engine starts (no more than 5 seconds) and return switch

to the ON posion. If the engine fails to start wait 10 seconds

before retrying.

5) Posion the throle lever to normal operang posion and begin

vacuuming

6) Vacuuming with higher rpm is permissible but should not be

undertaken for prolong periods of me

NOISE EMISSION Sound Power Level (LWA) 107 dB

91 dB(A) @ 1M at Normal Operang Level 3,000—3,300 rpm

96 dB(A) @ 1M at Maximum set 3,850 rpm

Ear Protecon MUST be worn at ALL mes when equipment is in use

HANDLING

The vacuum cleaner weight is 78Kg (Key Start 87Kg) empty and will be

considerably heavier when the collecon drum is full, be parcularly careful when

manoeuvring and liing for which a Risk Assessment should be undertaken and

consideraon given to Liing Aids and Shared Lis

WET PICK UP

The vacuum cleaner contains a oat valve that automacally closes when liquid

reaches its predetermined level in the tank. This is indicated by a change of sound

of the vacuum cleaner and suspension of pick—up. The cleaner should be turned

o when the oat valve closes and emped

Check the oat valve is clean and free to operate prior to wet pick up

CONNECTING THE HOSE SUCTION FEATURE

When vacuuming, the hose is connected directly

to the drum. PUSH the hose end directly into the

drum, and it will lock into place. To remove the

hose LIFT the “catch” under the drum inlet (hose

connecon) and withdraw the hose from the inlet.

CONNECTING THE HOSE BLOW FUNCTION

FEATURE

When using the BLOW funcon feature, the hose

is connected directly to the exhauster outlet

adapter. Li the knob and insert the hose end,

then release the knob when the hose is fully

inserted and it will lock it into posion. To release

the hose, li the knob and withdraw the hose

HOW TO EMPTY THE DRUM

Remove the head from the drum, lt the drum forward using the handles

Table of contents