Skyworks UG499 User manual

USER GUIDE

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

November 10, 2022

1

UG499: Si828x-AW-GDB Gate Driver Boards

1. Introduction

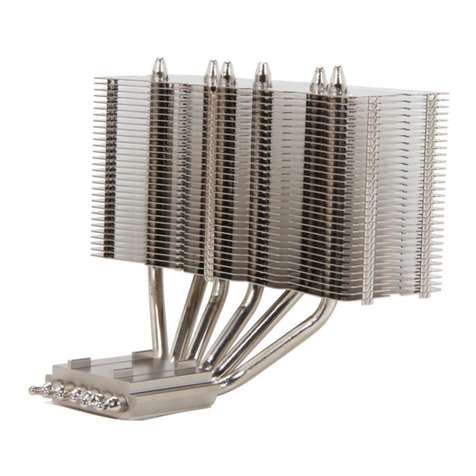

The Si828x Gate Driver Boards (GDB) are ideal for driving

Wolfspeed's XM3 1200 V Half Bridge Power Modules or

other parallel combinations of discrete transistors. This two-

channel isolated gate driver reference design in a half-bridge

configuration features a differential digital interface, opti-

mized on-board isolated power supply, DESAT protection,

gate drive current boost, and user-configurable turn-on (RH)

and turn-off (RL) gate resistors. Status indicator LEDs and

test points make evaluation and prototyping easy.

1.1. Key Features

• Two digital gate drivers for high-side/low-side opera-

tion

• Up to +20 A, -30 A peak output current with integrated

boost circuit

• Independent control of turn on/turn off timing through

gate resistor selection

• Isolated power supplies

• 5 kVRMS safety rated isolation

• 125 kV/µs common mode transient immunity (CMTI)

• Reverse polarity protection for 12 V input supply

• Differential inputs for increased noise immunity

• DESAT detection and soft-shutdown for short-circuit

protection

•Gatesupplyreadyindicator

• Module temperature (NTC) output as frequency modu-

lated digital signal

1.2. Additional System Components

The Si828x GDB is highly versatile and can be combined with

Wolfspeed's CIL boards and CGD12HB00D transceiver board

to provide platforms to evaluate gate driver and SiC device

combinations. The Si828x GDB is also designed to operate in

Wolfspeed's 300kW Three-Phase Inverter platform, where

three Si828x-AW-GDB provide all gate drivers necessary to

drive the XM3 power modules.

Figure 1. Si828x Gate Driver Board (GDB)

1.3. Tested Components Include

•Evaluation Tool for the XM3 Module Platform

•CAB450M12XM3 Power Module

•Differential Transceiver Daughter Board

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

2November 10, 2022

2. System Overview

The Skyworks Si828x-AW-GDB is a printed circuit reference design suitable for interfacing to Wolfspeed XM3 power modules.

The board contains isolated gate drive functions for high-side and low-side transistors in a half-bridge module configuration,

with gate biasing, isolated power supply, and fault indication. Figure 2 provides a Si828x-AW-GDB functional diagram. The

Si828x-AW-GDB is included in the Si828x-AAWB-GDB-KIT.

An I/O header (JT3) provides access to the differential high-side and low-side control signals as well as differential fault indica-

tor outputs and temperature sensor outputs. It also exposes single-ended inputs for power supply disable, transceiver

enable, and driver reset.

A digital transceiver converts the differential high-side and low-side PWM control signal inputs to the single-ended high-side

and low-side gate drive control signals. The transceiver also converts a frequency-encoded NTC (Negative Temperature Coef-

ficient) sensor output into a differential RTD signal and a single-ended signal representing the combined fault signals and

ready signals from the high-side low-side gate drivers into a differential fault signal.

There are two gate drivers on the Si828x-AW-GDB. The low-side isolated gate drive is achieved by the Si8284x Isolated Gate

Driver with Integrated DC-DC Converter. This device is driven by the single-ended low-side PWM signal and drives the gate of

a switching device, either high or low by means of NPN and PNP transistors which provide enhanced drive current. A DESAT

sensing pin provides a means of detecting switch desaturation and a soft shutdown circuit allows the switch to be shut down

in a controlled manner if desaturation is detected. The circuit includes an enhanced Miller Clamp feature to ensure switch

turn off is maintained in the presence of high slew rate drain/collector or source/emitter signals. Desaturation faults are indi-

cated via the /FLT pin. Operation is restored by toggling the /RST pin via the Reset signal on the JT3 I/O header.

Loss of gate drive supply results in a loss of the RDY signal both on the RDY pin and the combined differential /FLT output at

the header, but RDY is restored when the gate drive supply is restored.

The Si8284x also has a DC-DC controller function. This controller drives an external NMOS switch on the primary side of the

power transformer. The secondary side of the transformer forms both high and low-side driver supplies. These supplies are

+15 Vdc and -3.5 Vdc with a return between them and provide a total of 5 W between high and low-side sections. The high

side supplies are isolated from the low side supplies by the transformer. The DC-DC controller function may be shut down via

the PS-DISb input on the I/O header.

High-side isolated gate drive is achieved by the Si8285 Isolated Gate Driver. This device and its associated circuit provide the

same function as the Si8284 but without the DC-DC controller.

The DC power input to the board is protected from a reverse polarity connection via the P channel MOSFET gate biasing volt-

age UB2.

An RTD connector provides the connection to an external NTC (negative temperature coefficient) resistive sensor for mea-

surement of switch module temperature. The RTD resistance is converted to a frequency that is then isolated and sent to the

differential transceiver, which is converted to a differential signal accessed via the I/O header.

The AN1362: Si828x XM3 Gate Driver Test Report provides more detailed information and a complete schematic of the

Si828x-AW-GDB. It also includes test setup and performance data of the operations between the Si828x gate driver and the

XM3 SiC module on the Evaluation Tool for the XM3 Module Platform.

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

3November 10, 2022

Function Block Diagram

Figure 2. Function Block Diagram

3. Pin Descriptions

3.1. Input I/O Connector (Low-Voltage JT3)

This connector is located in the center of the Si828x-AW-GDB. In the XM3 Evaluation Tool test setup, the JT3 connector pro-

vides the I/O interface connections across the Differential Transceiver Daughter Board Companion Tool to the lab bench

instrumentations including power supply, function generator, control signals, etc. In the XM3 Inverter Reference Design, the

JT3 connector provides direction connection to the controll board, enabling the evaluation of the Si828x-AW-GDB in high

power inverter applications. Table 1 provides a complete list of the signals in the JT3 connector.

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

4November 10, 2022

Table 1: Input I/O Connector (Low Voltage JT3)

•PWM Signals: High-side and low-side PWM are RS-422 compatible differential inputs. The termination impedance of the

differential receiver is 120 Ω.

•FAULT Signal: The fault signal is an RS-422 compatible differential output with a maximum drive strength of 20mA. A high

signal (positive line > negative line) means there are no fault conditions for either gate driver channel. This signal will be

low if an overcurrent fault or UVLO fault condition is detected on either channel. A red LED will indicate a fault condition.

The LED, DT6, indicates a high-side fault and DT8 indicates a low-side fault.

•UVLO Fault: The UVLO circuit detects when the output rails of the isolated DC/DC converter fall below safe operating

conditions for the gate driver. A UVLO fault indicates that the potential between the split output rails has fallen below

the UVLO active level. The gate for the channel where the fault occurred will be pulled low through RG for the duration

of the fault regardless of the PWM input signal. The fault will automatically clear once the potential has risen above the

UVLO inactive level. There is hysteresis for this fault to ensure safe operating conditions. The UVLO faults for both chan-

nels are combined along with the over-current fault in the FAULT output signal. When there is no UVLO fault present, a

green LED indicates a power good state. The LED, DT5, indicates a high-side power good status and DT7 indicates a low-

side power good status.

•Over-Current Fault: An over-current fault is an indication of an over-current event in the SiC power module. The overcur-

rent protection circuit measures the drain-source voltage, and the fault will indicate if this voltage has risen above a

level corresponding to the safe current limit. When a fault has occurred the corresponding gate driver channel will be

disabled, and the gate will be pulled down through a soft-shutdown resistor, RSS. The drain-source limit can be config-

ured through on-board resistors. The over-current fault is latched upon detection and must be cleared by the user with a

high pulse of at least 500 ns on the RESET signal.

•RTD (NTC): RTD output is a differential signal that returns the resistance of the temperature sensor (NTC) integrated into

XM3 modules. The signal is a frequency modulated signal that encodes the resistance of the temperature sensor. The

approximate temperature of the module can be determined from this resistance. See the section RTD (NTC) Temperature

Feedback for further details.

Pin Number Parameter Description

1 VDC Power supply input pin (+12 V Nominal Input)

2 Common Common

3 HS-P Positive line of 5 V differential high-side PWM signal pair. Terminated Into 120 Ω

4 HS-N Negative line of 5 V differential high-side PWM signal pair. Terminated into 120 Ω

5 LS-P Positive line of 5 V differential low-side PWM signal pair. Terminated into 120 Ω

6 LS-N Negative line of 5 V differential low-side PWM signal pair. Terminated into 120 Ω

7FAULT-P

Positive line of 5 V differential fault condition signal pair. Drive strength 20 mA. A low state on FAULT indicates when

a desaturation fault has occurred. The presence of a fault precludes the gate drive output from going high.

8FAULT-N

Negative line of 5 V differential fault condition signal pair. Drive strength 20 mA. A low state on FAULT indicates

when a desaturation fault has occurred. The presence of a fault precludes the gate drive output from going high.

9RTD-P

Positive line of 5 V temperature dependent resistor output signal pair. Drive strength 20 mA. Temperature measure-

ment is encoded via frequency.

10 RTD-N Negative line of 5 V temperature dependent resistor output signal pair. Drive strength 20mA. Temperature mea-

surement is encoded via frequency.

11 PS-DIS Pull down to disable power supply. Pull up or leave floating to enable. Gate and source are connected with 10 kΩ

when disabled.

12 Common Common

13 PWM EN Pull down to disable PWM input logic. Pull up or leave floating to enable. Gate driver output will be held low

through turn-off gate resistor if power supplies are enabled.

14 Common Common

15 RESET When a fault exists, bring this pin high to clear the fault.

16 Common Common

Note:

Inputs 3 to 10 are differential pair.

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

5November 10, 2022

•PS-DISb: The PS-DISb signal disables the output of the isolated DC/DC converters for the two channels. It is a single-

ended input that must be pulled low to turn off the power supplies. With the power supplies disabled the gate will be

held low with a 10 kΩresistor. This signal can be used for startup sequencing.

•PWM-EN: This is a single-ended input that enables the PWM inputs for both channels. When this signal is pulled down

the differential receivers for both channels are disabled and the gates will both be pulled low through R_G-OFF. All pro-

tection circuitry and power supplies will continue to operate including FAULT and RTD outputs.

•RESET: This single-ended input clears a desaturation-induced fault state, allowing PWM inputs to function as soon as

RESET is released. When the signal is set high, FAULT will assume a high state if there are no UVLO conditions. The signal

should be returned to low in order to operate the device.

•Over-Voltage and Reverse Polarity Protection: Power input on pin 1 is protected against connecting a power source with

over-voltage or reverse polarity; there is a diode and a Zener diode across the power input, and a MOSFET in-line with

the power input.

3.2. Module Connectors (High-Voltage)

These connectors are located at the bottom of the Si828x-AW-GDB and provide direct connections to the Wolfspeed XM3 SiC

half-bridge modules. Table 2 provides a listing and locations of the signals on the module connectors.

•HS-Gate: The high-side gate pin is driven by the Si8281 Isolated Gate Driver IC and external BOM circuitry meant to

enhance the drive, soft shutdown, and Miller clamp functions for higher gate capacitance switch devices / arrays.

•HS-Source: The high-side source pin is connected to the VMID-H supply and the low-side DESAT detection circuit.

•HS-Drain: The high-side drain pin is connected to the high-side DESAT detection circuit.

•LS-Gate: The low-side gate pin is driven by the Si8285 Isolated Gate Driver IC and external BOM circuitry meant to

enhance the drive, soft shutdown, and Miller clamp functions for higher gate capacitance switch devices / arrays.

•LS-Source: The low-side source pin is connected to the VMID-L supply.

•RTD-1 and RTD-2: The RTD pins connect to a resistive temperature sensor in the switch device / module. The resistance

is sensed and converted to a frequency which is then sent across an isolation barrier to the digital transceiver and out

the I/O connector.

Table 2: Module Connectors (High Voltage)

Connector

Reference

Parallel

Connector Pins

Si828x-AW-GDB

Signal Name Description

JT1 2, 4 HS-Gate High-side gate lead of switch module

JT1 1, 3 HS-Source (LS-Drain) High-side source lead of switch module; primary output

JT2 1, 2, 3, 4 HS-Drain High-side drain lead of switch module

JT6 2, 4 LS-Gate Low-side gate lead of switch module

JT6 1, 3 LS-Source Low-side source lead of switch module

JT5 1, 3 RTD-1 Lead 1 of switch module resistive temperature sensor

JT5 2, 4 RTD-2 Lead 2 of switch module resistive temperature sensor

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

6November 10, 2022

4. Truth Table

Table 3 provides the truth table of the input to output signals under various operating conditions.

Table 3: Si828x-AW-GDB I/O Truth Table

HS-PWM LS-PWM PWM-EN2PS-DIS4Reset_Input3Overcurrent

UVLO FAULT8HS-Gate LS-Gate Output

(HS-Source/LS-Drain)

L L H or Z H or Z L or Z No H L L Z

L H H or Z H or Z L or Z No H L H L

H L H or Z H or Z L or Z No H H L H

H H H or Z H or Z L or Z Yes5LH9H9Z9

XX L6H or Z L or Z No H L L L

XX X L7 X No LLL Z

X X H or Z H or Z L or Z Yes L L L Z9

Notes:

1. H = High | L = Low | X = Irrelevant | Z = High Impedance

2. PWM-EN is active high and has a pull up resistor on the input.

3. Reset_Input is active high and has a pull down resistor on the input.

4. PS-DIS\ is active low and has a pull up resistor on the input.

5. An Overcurrent condition is induced when both PWM inputs are high. This condition must be disallowed by external overlap protection.

6. A low on PWM-EN disables the outputs of the PWM receivers; they are pulled low by resistors in this case.

7. When PS-DIS\ is low, the gate driver output power supply is disabled. The HS-Gate and LS-Gate signals are pulled to their respective sources by resis-

tors.

8. The FAULT output is active low; it goes low when there is an overcurrent / UVLO fault or a driver IC indicates a non-READY state.

9. When an overcurrent condition is induced, the gate signals are pulled low and the output becomes high-impedance after the fault condition is indi-

cated by a driver chip.

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

7November 10, 2022

5. Gate Driver Connections

Figure 3. Si828x Gate Driver Board Top-Side Silkscreen

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

8November 10, 2022

6. Temperature Feedback

The XM3 power module uses a thermistor to provide temperature feedback to the controller. The resistance of the thermis-

tor sensor is converted to a 50% duty cycle square wave with a frequency that varies inversely with the resistance. The resis-

tance to frequency relationship is displayed in the Table 4 below. The resistance to frequency circuits is located on the high

voltage side to provide direct connection to the XM3 thermistor sensor. Then, a digital isolator is used to transmit the fre-

quency-encoded signal back to the primary side and its differential signals are connected to pin 9 and pin 10 of the JT3 low

side connector.

Figure 4. Thermistor Resistance vs Output Frequency

Table 4: Thermistor Resistance vs Output Frequency

Thermistor Resistance (Ω)Frequency Output (kHz)

13491 4.6

4700 10.3

1928 17.1

898 22.8

464 26.4

260 28.3

156 29.5

99 30.1

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

9November 10, 2022

7. User Configuration Options

7.1. Series Gate Resistors

The Si828x GDB has 1 Ωseries gate resistors in series with the gate drive signal for both the high side and the low side chan-

nels. In addition, these resistor values are the same for both turn on (RG-ON) and turn off (RG-OFF).

However, the user can select any value for turn-on and turn off timing control independently. Resistors R348 and R350 con-

trol the turn-on timing for the high side and low side channels respectively. Resistors R349 and R51 affect the turn-off time

for the high side and low side respectively. This configuration provides the user with complete flexibility in tuning the turn-on

and turn-off times for each channel.

7.2. Negative Gate Bias

The default configuration of this driver board provides a gate drive signal that swings from +15 V to -3.7 V with respect to the

source pin connection.

7.3. Isolated Driver Power Supply Voltage

The Si828x GDB uses a dc-dc converter integrated into the Si8284 gate driver. This converter regulates the output of one sec-

ondary of the transformer used in the application. The design of the transformer provides regulation of the other secondary

winding to provide separate, isolated power supplies for both the high side and low side driver. The default configuration pro-

vides a driver power supply that is regulated to 19 V. Since the source pin of each channel is biased about 3.6 V above the

converter's reference, the gate will see a voltage swing from +15 V to -4 V when measured with respect to the source pin.

The DC-DC converter may be operated with a different set of output voltages by changing the resistor divider (R1/R2+1) *

1.05V to obtain the desired supply voltage. The limit of VDDB - VSSB is 30V, and the VDDB/VSSB ratio is fixed by the turns

ratios of transformer T1. Operating the device at a higher voltage may impair operation or damage the device.

7.4. Overcurrent/Desaturation Trip Level

The overcurrent (OC) fault detection circuit measures the on-state VDS voltage across each switch position and triggers a

fault condition if the voltage rises above a set level. The internal comparator trip voltage in the Si828x gate driver IC is 7 V.

Considering the forward voltage of the high-voltage blocking diodes and a tunable Zener diode, the overcurrent trip level is

calculated with the following equation:

VOC-Trip = 7V - VZ - 2VF

where the forward voltage of the high-voltage diodes, VF, is approximately 0.5 V, and the Zener voltage, VZ, included on the

gate driver is 3.9 V (On Semi MMSZ4686T1G). As shipped, the Zener diode is replaced with a 0 Ohm resistor and the overcur-

rent trip level is 6 V. If it is desired to change the overcurrent trip level, the Zener diode should be in a SOD123 package such

as the diodes in the MMSZ series from On Semi. The Zener diodes are labeled D323 and D324 on the PCB.

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

10 November 10, 2022

Figure 5. Over-Current Trip Level

Figure 6. DESAT Behavior

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

11 November 10, 2022

To set an appropriate overcurrent trip level, see the module data sheet for the ID vs. VDS output characteristic curves. For

example, the pulse-current rating of the CAB450M12XM3 is 900 A at TJ = 25 °C; it follows that an overcurrent trip point of

1000 A at 25 °C should be selected. The drain-to-source voltage at the 1000 A operating condition is approximately 3.0 V, as

seen on the ID vs. VDS curve. From that, the overcurrent trip voltage, VOC-Trip, should be approximately 3.0 V. This trip volt-

age can be used to calculate the required Zener voltage, VZ, with the equation above.

Note that the HS-Drain connector, JT2, cannot be left floating because the over-current fault will trip immediately when the

high-side gate is taken high. If bench testing of the gate driver is required without the XM3 module, one may short the HS-

Drain connection to the high-side source to prevent the overcurrent fault from tripping. The low-side exhibits the same

behavior, and one may short the high-side source (low-side drain) to the low-side source for bench testing. The Reset signal

must be activated to acknowledge the over-current fault condition so as to return the gate driver to normal operation.

7.5. Si828x-AW-GDB - XM3 Test Circuits

The Si828x-AW-GDB is designed to operate with Wolfspeed's XM3 Evaluation Tool and the XM3 Three-Phase Inverter Demon-

stration Platform. The Si828x-AW-GDB was tested extensively with the XM3 module on the Wolfspeed's XM3 Evaluation Tool

with excellent test results. The Si828x-AW-GDB fits directly to the gate driver slots of the XM3 Three Phase Demonstration

Platform. Below are the links to the documentation for test setup and test results.

Si828x-XM3 Test Report: AN1362

XM3 Evaluation Tool: KIT-CRD-CIL12N-XM3

Differential Transceiver Daughter Board

XM3 Three-Phase Inverter Reference Design User Guide: AN30

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

12 November 10, 2022

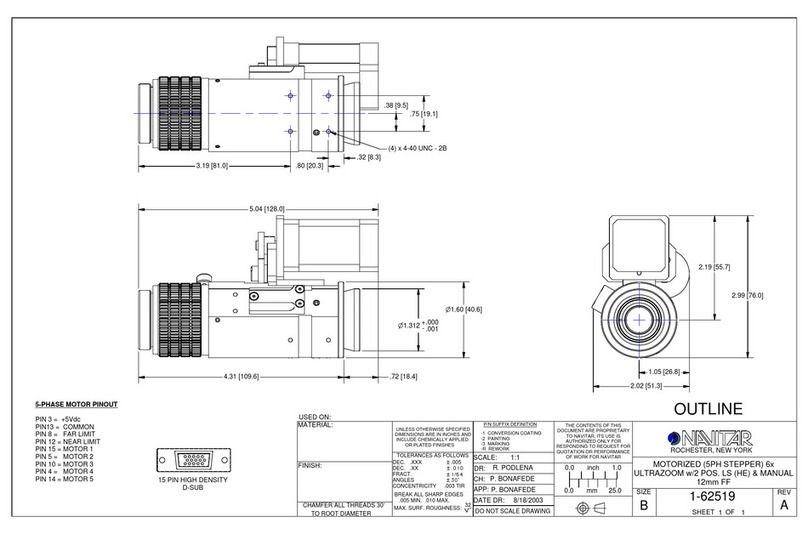

8. Dimensions

Figure 7. Si828x Gate Driver Board (GDB) Dimensions

USER GUIDE UG499: Si828x-AW-GDB Gate Driver Boards

206359B • Skyworks Proprietary Information • Products and Product Information are Subject to Change without Notice

13 November 10, 2022

Ordering Information

Copyright © 2022, Skyworks Solutions, Inc. All Rights Reserved.

Information in this document is provided in connection with Skyworks Solutions, Inc. ("Skyworks") products or services. These materials, including the infor-

mation contained herein, are provided by Skyworks as a service to its customers and may be used for informational purposes only by the customer. Skyworks

assumes no responsibility for errors or omissions in these materials or the information contained herein. Skyworks may change its documentation, products,

services, specifications or product descriptions at any time, without notice. Skyworks makes no commitment to update the materials or information and

shall have no responsibility whatsoever for conflicts, incompatibilities, or other difficulties arising from any future changes.

No license, whether express, implied, by estoppel or otherwise, is granted to any intellectual property rights by this document. Skyworks assumes no liability

for any materials, products or information provided hereunder, including the sale, distribution, reproduction or use of Skyworks products, information or

materials, except as may be provided in Skyworks' Terms and Conditions of Sale.

THE MATERIALS, PRODUCTS AND INFORMATION ARE PROVIDED "AS IS" WITHOUT WARRANTY OF ANY KIND, WHETHER EXPRESS, IMPLIED, STATUTORY, OR

OTHERWISE, INCLUDING FITNESS FOR A PARTICULAR PURPOSE OR USE, MERCHANTABILITY, PERFORMANCE, QUALITY OR NON-INFRINGEMENT OF ANY

INTELLECTUAL PROPERTY RIGHT; ALL SUCH WARRANTIES ARE HEREBY EXPRESSLY DISCLAIMED. SKYWORKS DOES NOT WARRANT THE ACCURACY OR COM-

PLETENESS OF THE INFORMATION, TEXT, GRAPHICS OR OTHER ITEMS CONTAINED WITHIN THESE MATERIALS. SKYWORKS SHALL NOT BE LIABLE FOR ANY

DAMAGES, INCLUDING BUT NOT LIMITED TO ANY SPECIAL, INDIRECT, INCIDENTAL, STATUTORY, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIM-

ITATION, LOST REVENUES OR LOST PROFITS THAT MAY RESULT FROM THE USE OF THE MATERIALS OR INFORMATION, WHETHER OR NOT THE RECIPIENT OF

MATERIALS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Skyworks products are not intended for use in medical, lifesaving or life-sustaining applications, or other equipment in which the failure of the Skyworks

products could lead to personal injury, death, physical or environmental damage. Skyworks customers using or selling Skyworks products for use in such

applications do so at their own risk and agree to fully indemnify Skyworks for any damages resulting from such improper use or sale.

Customers are responsible for their products and applications using Skyworks products, which may deviate from published specifications as a result of

design defects, errors, or operation of products outside of published parameters or design specifications. Customers should include design and operating

safeguards to minimize these and other risks. Skyworks assumes no liability for applications assistance, customer product design, or damage to any equip-

ment resulting from the use of Skyworks products outside of Skyworks' published specifications or parameters.

Skyworks, the Skyworks symbol, Sky5®, SkyOne®, SkyBlue™, Skyworks Green™, ClockBuilder®, DSPLL®, ISOmodem®, ProSLIC®, and SiPHY® are trademarks or

registered trademarks of Skyworks Solutions, Inc. or its subsidiaries in the United States and other countries. Third-party brands and names are for identifica-

tion purposes only and are the property of their respective owners. Additional information, including relevant terms and conditions, posted at www.sky-

worksinc.com, are incorporated by reference.

Part Number Part Description

Si828x-AAWB-KIT KIT contains the Si828x-AW-GDB evaluation board described in this document

Table of contents

Other Skyworks Computer Hardware manuals