Slaughter 2205 Operation manual

OPERATION AND SERVICE MANUAL

Model 2205

0 –1.0KV DC / 0.1MΩ–200GΩINSULATION RESISTANCE TESTER

SERIAL NUMBER

Model 2205

©Slaughter Company, Inc., 2002

28105 N. Keith Drive

Lake Forest, Illinois, 60045-4546

U.S.A.

Item 99-10268-01 Ver 1.04 Printed April 29, 2013

Warranty Policy

Slaughter Company, certifies that the instrument listed in this manual meets or exceeds

published manufacturing specifications. This instrument was calibrated using standards

that are traceable to the National Institute of Standards and Technology (NIST).

Your new instrument is warranted to be free from defects in workmanship and material for

a period of (1) year from date of shipment. You must return the “Owners Registration

Card”provided within (15) days from receipt of your instrument.

Slaughter Company recommends that your instrument be calibrated on a twelve-month

cycle. A return material authorization (RMA) must be obtained from Slaughter Company.

Please contact our Customer Support Center at 1-800-504-0055 to obtain an RMA

number. It is important that the instrument is packed in its original container for safe

transport. If the original container in not available please contact our customer support

center for proper instructions on packaging. Damages sustained as a result of improper

packaging will not be honored. Transportation costs for the return of the instrument for

warranty service must be prepaid by the customer. Slaughter Company will assume the

return freight costs when returning the instrument to the customer. The return method

will be at the discretion of Slaughter Company.

Except as provided herein, Slaughter Company makes no warranties to the purchaser of

this instrument and all other warranties, express or implied (including, without limitation,

merchantability or fitness for a particular purpose) are hereby excluded, disclaimed and

waived.

Any non-authorized modifications, tampering or physical damage will void your warranty.

Elimination of any connections in the earth grounding system or bypassing any safety

systems will void this warranty. This warranty does not cover batteries or accessories not

of Slaughter Company manufacture. Parts used must be parts that are recommended by

Slaughter Company as an acceptable specified part. Use of non-authorized parts in the

repair of this instrument will void the warranty.

TABLE OF CONTENTS

INTRODUCTION________________________________________________________2

INSTALLATION AND SAFETY___________________________________________________ 2

SERVICE AND MAINTENANCE__________________________________________________ 10

GLOSSARY OF TERMS _________________________________________________________ 12

SPECIFICATIONS_______________________________________________________14

CONTROLS ____________________________________________________________17

QUICK START__________________________________________________________21

SETUP _________________________________________________________________23

OPERATION ___________________________________________________________26

REMOTE I/O ___________________________________________________________29

CALIBRATION _________________________________________________________31

REPLACEMENT PARTS LIST____________________________________________32

SCHEMATIC INDEX ____________________________________________________33

INTRODUCTION

2

INTRODUCTION

This section is prepared to assist the user of Slaughter manually operated bench type test

equipment with the use, installation, inspection and maintenance of the equipment.

Since any electrical equipment can be hazardous, all procedures described should be

conducted by qualified personnel familiar with safety rules applying to electrical equipment

and who have been thoroughly instructed as to the nature of the procedure, the hazards

involved, and the necessary safety precautions.

Defects and weaknesses in the electrical insulation system must be detected to insure that

the product is safe for use by the consumer. In most windings there are two basic types of

insulation systems. The ground insulation separates the windings from a magnetic core

material or an exposed conductive frame or exterior. The second insulation system is the

wire insulation, which in lower voltage windings is typically a thin film coating of the

wire. These two insulation systems perform different functions in the winding and require

different tests to evaluate their integrity. The Dielectric Withstand Test is used to

evaluate the ground insulation system.

This test has been described by many names; Hi-pot Test, Dielectric Withstand Test,

Insulation Leakage and Breakdown Test, Shorts Check, Ground Check and others. What

ever the name, the purpose is to detect failure of the insulation system that separates the

current carrying portions of an electrical device from any exposed conductive components.

For operator safety reasons, and to avoid possible tester damage,

the product under test SHOULD NOT BE CONNECTED in any

way to the AC power lines.

Typically, it is the responsibility of the manufacturer to establish the proper tests needed

for a particular product to insure they comply with all agency requirements.

INSTALLATION AND SAFETY

For operator safety reasons, and to avoid possible tester

damage, the product under test SHOULD NOT BE

CONNECTED in any way to the AC power lines.

When first received, unpack the equipment carefully and inspect for any hidden damage.

If damage is evident, keep the carton and file a claim with the carrier.

Packed with all Slaughter equipment is a certificate of conformance, operator's manual,

test leads and any required interface connectors.

WARNING

CAUTION

INTRODUCTION

3

To check the unit quickly, install any interface connectors, plug the unit into the proper

voltage and follow the steps outlined under operating instructions. If the unit does not

operate, contact the factory for instructions.

Of prime consideration and importance in the layout and installation of a test station is to

insure the safety both to the operator and any visitors or casual bystanders, invited or

otherwise. As a general rule it is suggested that each test area be in a location with

minimum distractions and not subject to extremes of temperature and moisture.

One of the more important ways to promote safety is through operator training. Benefits

of training are twofold. First, thorough training promotes safety which may significantly

reduce injuries on the job. Second, it ensures adequate testing of the product which helps

increase product reliability. Both of these can have a positive impact on profits.

An additional consideration in any test station is operator comfort. This is affected by the

operator's position, which includes the chair, table, test equipment, the object under test

and the test procedure itself. The chair and work bench or table should be nonconductive

and the table as large as possible to allow sufficient room for the test equipment and the

object under test. Studies should be made of the test requirements and work habits and

steps taken to ensure that any unusual or unnatural motion is not required and to eliminate

any repetitive motions that may produce injuries such as carpel tunnel syndrome.

After the equipment has been installed, a careful study should be made of the test station

to determine what, if any, safeguards are needed. It is suggested that any electrical test

station involving voltages in excess of 42.4 volts peak (approximately 30 volts RMS)

should be equipped with safeguards. These should operate both for the protection of the

operating personnel and for the protection of casual bystanders. At the minimum,

safeguards should prevent the operating personnel or casual bystanders from coming into

contact with the test circuit. In the event electrical interlocks of any sort are required,

either to insure that guards are in place, or to insure that the operator's hands are in a safe

location, the installer should refer to the proper schematic drawing and install these

interlocks in series with the external interlock terminals provided in the tester. All testers

may be safety interlocked with series manual or automatic safety switches, relays, etc. as

desired. In the simpler units, this is done by inserting such interlocks in the AC supply

ahead of the tester. In some units adapter plugs with remote interface controls are

provided for this purpose. We will be happy to provide suggestions and schematics for

safety interlocking our test equipment.

Any electrical power receptacle utilized to operate this equipment must be a properly

grounded three wire receptacle that has been checked for proper polarity.

The test procedure should be well thought out to ensure that it adequately tests the

product to the desired criteria but, that the procedure does not require the operator to

perform tasks that are unsafe. The product should never be touched during a test and in

INTRODUCTION

4

the case of a grounded part the conductive table or conveyor should not be touched

during a test.

Several models of high voltage test equipment are designed with the high voltage output

"floating". There is no ground on either the High side or the Low side of the high voltage

transformer. One of the test leads of the HV transformer is considered the Low side due

to the winding pattern of the transformer, but it is NOT grounded. This arrangement

provides a one type of safety margin to the operator because someone must come in

contact with both leads to receive a shock.

Some models of test equipment have one lead of the output grounded or production

requirements are such that it is impossible or impractical to test a product in an

"ungrounded" configuration. When the tester and the product are grounded, it is

important to remember that the operator is also grounded and need only touch the

ungrounded lead to receive a shock.

A major consideration in testing products that are "grounded" (touching a conductive

conveyor or table) is to insure that the operator or bystanders cannot or will not come in

contact with the table or conveyor during a test. Under some product failure conditions,

the table or conveyor may become "live" and present a high voltage potential to true earth

ground if the table or conveyor is not properly grounded.

It should never be assumed that a conveyor or conductive table is "grounded" just because

it is bolted to the floor. A proper ground is one that has been verified to return to the

input power line ground (earth ground) with a resistance of less than 1/2 ohm. This will

help eliminate "floating" grounds, ground loops and "phantom" voltages between the

object under test and the tester case which is grounded to the power line ground.

The testing of very large items such as recreational vehicles and mobile homes poses

special problems because the safety hazards involved are considerably greater than those

involved in testing smaller objects.

This is because it is possible under fault conditions for the entire outer skin of the object

being tested to become charged to a high voltage. This is particularly bad because these

units are so large that the person conducting the test is in no position to observe whether

or not any other people are in a potentially dangerous position during the test.

If proper precautions are taken, there will be no hazard, but even so, it is highly desirable

that care be taken to isolate the test object when a test is being conducted. Suggested

methods of doing this are the use of rope barriers, warning signs, and fully enclosed test

areas.

Before conducting a test on these units, care should be taken to see that the frame and

skin of the unit are connected to a solid ground, and also that the ground conductor of the

electrical system is connected to a solid ground. This will eliminate most test hazards, but

INTRODUCTION

5

bear in mind it is possible for some sections of the skin to have poor electrical connection

and that they thereby, can become a potential safety hazard in the event of a fault. This is

why isolation of the vehicle during the test is recommended.

Once these safety precautions have been taken and it has been established that the frame

and skin are properly grounded, the operator can proceed with the dielectric test.

Good safety practice dictates labeling of hazards properly. Since high voltage testing can

be hazardous, the work station should be labeled. Naturally, the location of the label

should be carefully selected so that it can be placed in a location that will do the most

good.

In some cases, this may be on the test instrument itself, and in others, it may be in a

location directly in front of the operator, somewhat removed from the instrument.

In addition to instrument labeling, we are supplying labels that you should apply in

accordance with the above suggestions. If you need a couple more, please let us know...

we will gladly supply them. If you need a large quantity, these are available at a nominal

price.

A final word about high voltage testers: Generally, commercial high voltage test

equipment is not in itself hazardous. The hazards come about when the equipment is

improperly used. These testers, when used properly and in a safe manner, can be a check

on the quality and reliability of your product. If used incorrectly and without proper

consideration for safety, they represent a hazard for both operating personnel and casual

bystanders. We strongly recommend proper training for all personnel involved in testing.

High Voltage Testing

High Voltage Testing has historically been the most misunderstood, misapplied,

misinterpreted inspection function in the average factory. Some manufacturers have

looked upon the High Voltage Dielectric Withstand test or Hipot test as it is more

commonly known, as an extra operation that must be performed to satisfy some agency

requirement. Though many times the high voltage test is simply a safety measure, its value

in quality control should not be overlooked.

First and foremost, the hipot test is done to ensure the safety of customers by detecting

"grounded" or "shorted" products. By applying a high voltage between "live" current

carrying parts of the product and the framework which is normally supposed to be "dead,"

or well insulated from the "live" parts, the product is "proof tested" against grounds or

shorts which at the least might cause inconvenience and at the most can cause fire or

injury. During the hipot test, all insulation is abnormally stressed for the duration of the

test. Additionally, it is possible to detect "potential" shorts. Consider there is a bare

conductor about .015" from the frame. In the factory, the product is clean and new, but

after a year or two of service, contaminants, dust, and moisture may cause this gap to

bridge at line voltage resulting in a shock hazard to the consumer.

INTRODUCTION

6

Secondly, hipot testing is done as a quality control measure. Incipient failures in the

insulation of any portion of the product, whether due to workmanship, components or

materials are detected by the hipot test before the product is shipped out to cause

inconvenience, dissatisfaction and expense in the field.

The most often asked questions are, "Is hipot testing destructive?" and "Should I use AC

or DC for the hipot test?"

Today's modern, commercially available high voltage production line testing equipment is

generally not destructive. For most consumer product testing, testers have sufficient

sensitivity and response time that short circuit currents can be held to non-destructive

levels.

The question of AC or DC is best answered by the question, "What do the specs say?"

For the production hipot test, agency requirements almost invariably specify an AC test.

Generally, AC hipot testing is considered by many to be more stressful to the insulation

than DC hipot testing because of the periodic polarity reversal. Some believe AC testing

tends to accelerate breakdown due to material flaws. During use, products are more likely

to experience AC voltage transients than to experience DC voltage transients. Therefore,

AC hipot tests provide more realistic conditions than DC hipot tests.

The next most common question about hipot testing is, "How much voltage should I use?"

Again, "What do the specs say?" As a rule-of-thumb, many applications will require 1000

volts plus twice the normal operating voltage for one minute. Increasing the test voltage

by 20% usually allows the test time to be reduced to one second. Automotive products

will generally specify 500 volts.

Armatures are produced in both a "single insulated" and a "double insulated"

configuration. With single insulated armatures, the commutator and windings are

insulated from the iron stack and the shaft which, electrically speaking, are common.

Double insulated armatures additionally have the iron stack insulated from the shaft. This

provides "double insulation" between the current carrying components, the commutator

and the windings, and any exposed dead metal components, normally the shaft.

On single insulated armatures, the dielectric withstand test voltage is normally applied

between the commutator and the shaft.

Double insulated armatures, however, will normally have a dielectric withstand voltage

applied between the commutator and the iron stack and another dielectric withstand

voltage between the iron stack and the shaft. If these two voltages are applied

simultaneously and the voltage sources are properly phased, a consequential voltage equal

to their sum will be applied between the commutator and the shaft.

INTRODUCTION

7

A hipot test attempts to detect or measure phenomena that indicate electrical problems

such as leakage, breakdown and arcing.

Leakage is a flow of current. Leakage becomes significant under two conditions. Any

increase in resistive leakage is a "red flag" indication that quality in insulating materials

used in the device has in some manner deteriorated. Total leakage becomes significant if it

reaches such a level that it becomes perceptible to the user of the equipment. UL

extensively researched the area of perception threshold and electrical shock. They found

that, generally, "women are more sensitive to leakage current than men and a current flow

of 0.5 milliamperes or less at 60 hertz does not produce a reaction which is considered to

be hazardous to the individual or to those nearby."

Some leakage exists in any product, though, in many cases, it will be so minute to defy

measurement. It exists for two reasons; first leakage current exists simply because no

insulating materials are perfect and have infinite resistance. This is generally referred to as

resistive leakage and can be calculated from Ohms Law, E=IR where E is the applied

voltage, I is current flow in amperes and R is the resistance in ohms. Second, any

electrical device, by virtue of the fact that it is made of conductive material with electrical

circuits in close proximity, exhibits what can be called an "inherent capacity effect." This

is actually a capacity and, if we apply AC voltage, current will flow. This is generally

referred to as capacitive leakage. The equivalent resistive value of the capacitance (Xc)

may be calculated from the formula, Xc=1/(2πfC) where Xc is the equivalent resistance in

ohms, f is frequency of the applied voltage in hertz and C is the capacitance in farads. The

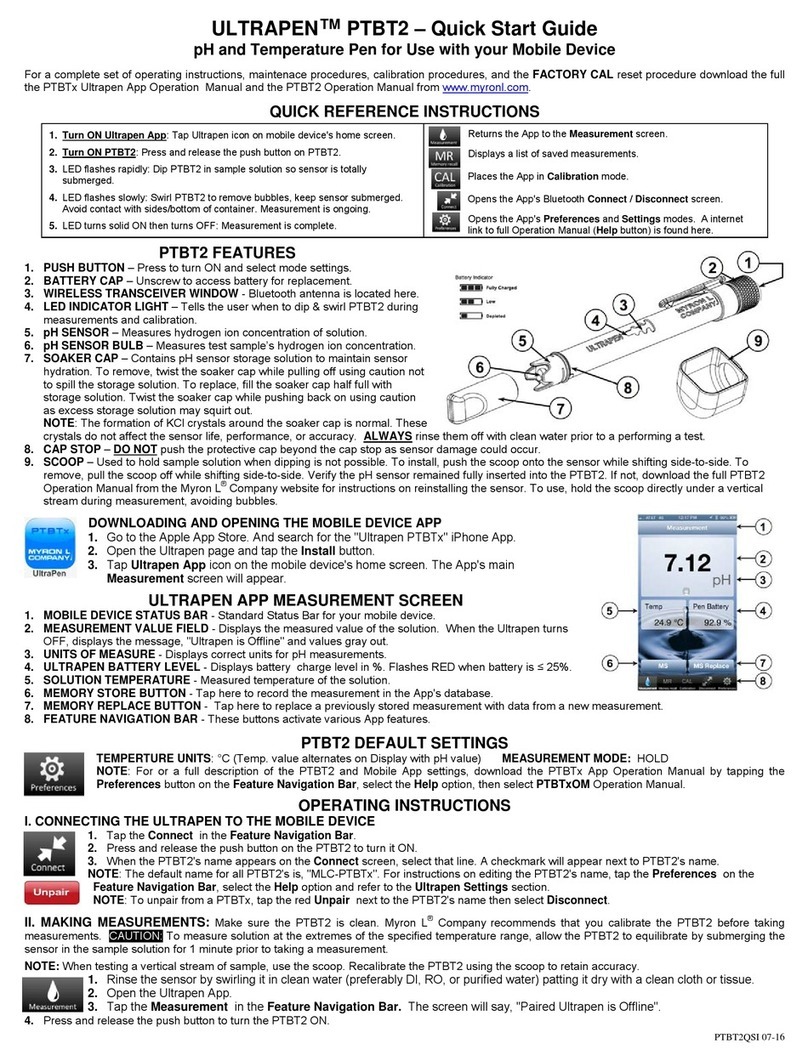

combination of these two components of leakage (figure 1.) is referred to as the total or

complex leakage.

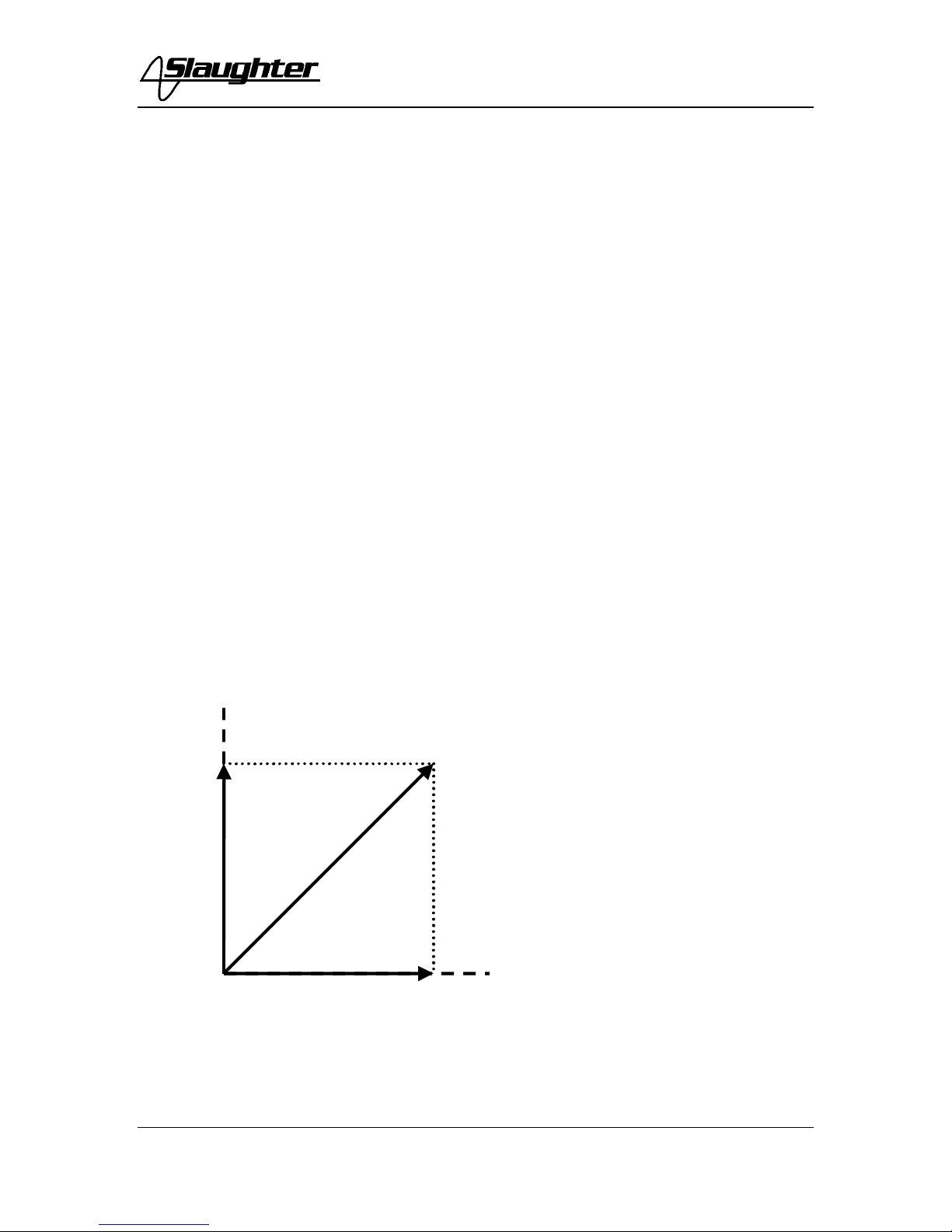

Current Vector

figure 1.

I(r)

I(c)

I(t) I(c) = CAPACITIVE CURRENT

I(r) = RESISTIVE CURRENT

I (t) = TOTAL CURRENT

INTRODUCTION

8

The capacitive leakage is an inherent characteristic of the device controlled primarily by

design details. The resistive leakage is a characteristic of insulating materials used and the

amount of resistive leakage is generally an indication of the quality of the insulation. This

is particularly true when identical devices are being comparatively tested. Both capacitive

and resistive leakages vary, almost linearly, with the applied test voltage.

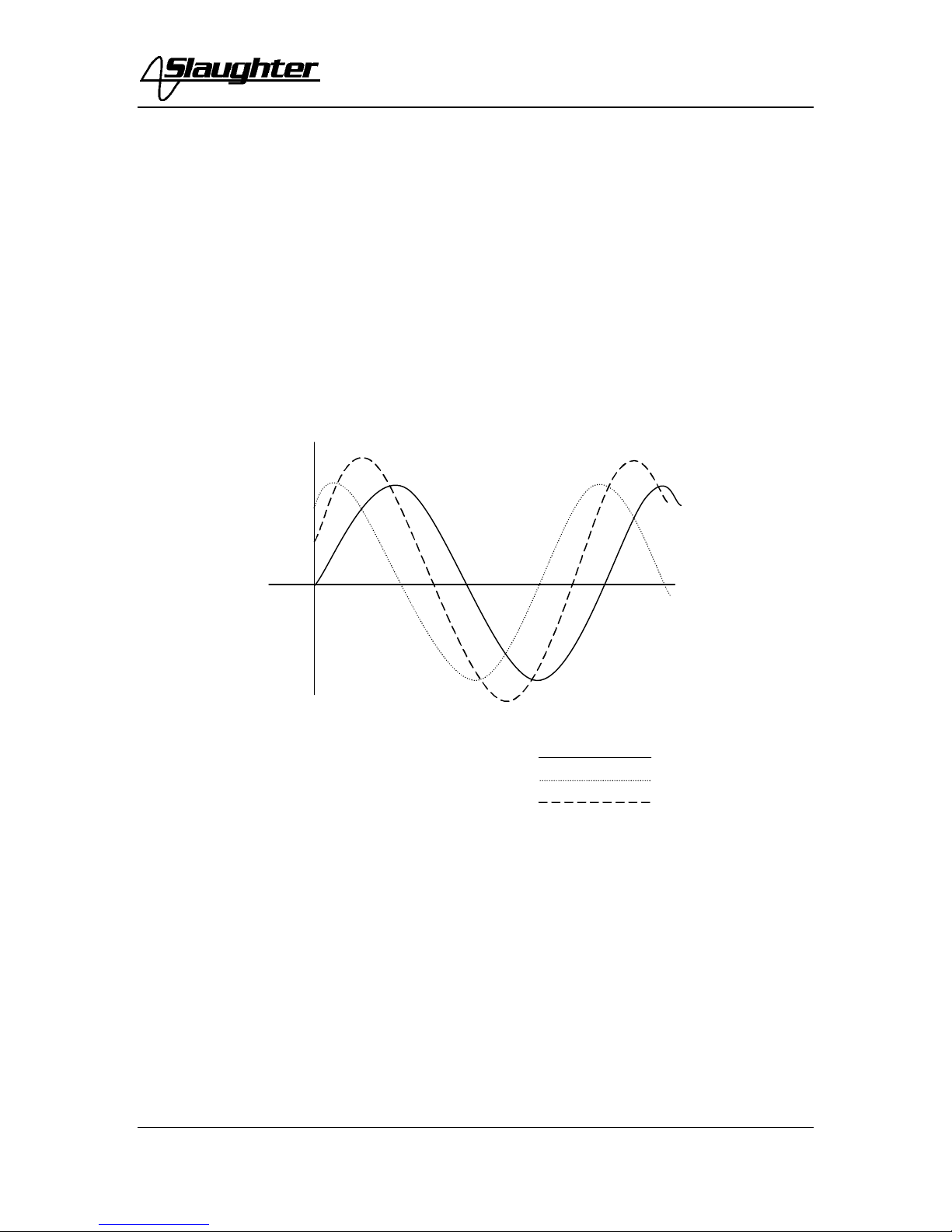

In the average electrical device during AC hipot tests, the resistive current flow is

normally much smaller than the capacitive current flow, so changes in the resistive current

do not have a significant effect on the total current. The capacitive current, however, is

out of phase with the resistive current and can be cancelled in the measurement (figure 2.).

With this type of test arrangement, the masking effect of the capacitive current is greatly

reduced or eliminated and small variations in insulation resistance become detectable.

RESISTIVE CURRENT

CAPACITIVE CURRENT

TOTAL CURRENT

figure 2.

Breakdown is also a flow of current. However the term is usually used to denote an

actual insulation failure. It is readily distinguishable from leakage because the current does

not vary linearly with the applied voltage, but instead rises suddenly when the critical or

breakdown voltage is reached. Often, but not always, arcing is associated with

breakdown.

Arcing occurs in solids and liquids as well as gases. Arcing typically involves currents on

the order of 0.4 amperes or more and indicates a potentially dangerous breakdown of

insulation or abnormal current flows inside a device.

INTRODUCTION

9

The ability of high voltage test equipment to react to the excessive current flow or failure

of the product under test is often referred to as "sensitivity."

For many years, users of high potential (hipot) dielectric testers tolerated considerable

sensitivity differences between individual testers. Products rejected by one tester might be

accepted by another. If the two testers were distinctly different models or were made by

different manufactures, the question of which tester to rely upon was a difficult one.

Unfortunately, the tester chosen was sometimes the one that would accept the products.

In a majority of these situations, the real problem was a lack of an acceptable standard for

tester sensitivity. Many low cost production line testers in the past were essentially

designed as "go/no-go" testers and sensitivity was often whatever was convenient for the

manufacturer.

The variance of the sensitivity curves between different manufacturers and different

models was a major factor in U.L.'s (Underwriters Laboratories) move to try and

standardize production line hipot test equipment sensitivity. These tester performance

requirements have come to be commonly known as the "120 K requirement."

Unless the hipot tester was designed to meet the "120 K" specifications, it is unlikely that

it will meet all of the requirements. The tester's suitability must be verified.

In general, the original U.L. "120 K" specifications require the tester to reject within .5

seconds when connected to an impedance of 120,000 (120 K) ohms at the specified

testing voltage. Additionally, the output voltage sign wave tolerance is specified and the

output voltage regulation is required to be -0%, +20%.

Various agencies other than U.L. have their own versions of the "120 K" type

specifications. As with all testing specifications, the manufacturer must ensure that they

are in compliance with the latest testing requirements for their particular product.

The Insulation Resistance Test

Some dielectric analyzers today come with a built in insulation resistance tester. Typically,

the IR function provides test voltages from 500 to 1,000 volts DC and resistance ranges

from kilohms to gigaohms. This function allows manufacturers to comply with special

compliance regulations. BABT, TÜV, and VDE are agencies that may under certain

conditions require an IR test on the product before a Hipot test is performed. This

typically is not a production line test but a performance design test.

The insulation resistance test is very similar to the hipot test. Instead of the go/no go

indication that you get with a hipot test the IR test gives you an insulation value usually in

Megohms. Typically the higher the insulation resistance value the better the condition of

the insulation. The connections to perform the IR test are the same as the hipot test. The

measured value represents the equivalent resistance of all the insulation which exists

between the two points and any component resistance which might also be connected

between the two points.

INTRODUCTION

10

Although the IR test can be a predictor of insulation condition, it does not replace the

need to perform a Dielectric Withstand test.

TYPES OF FAILURES DETECTABLE ONLY WITH A HIPOT TEST

•Weak Insulating Materials

•Pinholes in Insulation

•Inadequate Spacing of Components

•Pinched Insulation

SERVICE AND MAINTENANCE

User Service

To prevent electric shock do not remove the instrument cover. There are no user

serviceable parts inside. Routine maintenance or cleaning of internal parts is not

necessary. Any external cleaning should be done with a clean dry or slightly damp cloth.

Avoid the use of cleaning agents or chemicals to prevent any foreign liquid from entering

the cabinet through ventilation holes or damaging controls and switches, also some

chemicals may damage plastic parts or lettering. Schematics, when provided, are for

reference only. Any replacement cables and high voltage components should be acquired

directly from Slaughter Company. Refer servicing to a Slaughter Company authorized

service center.

SLAUGHTER COMPANY, INC.

28105 N. KEITH DRIVE

LAKE FOREST, IL 60045-4546 U.S.A.

(PHONE: 1 (847) 932-3662

1 (800) 504-0055

FAX: 1 (847) 932-3665

E-MAIL : support@hipot.com

www.hipot.com

Service Interval

The instrument and its power cord, test leads, and accessories must be returned at least

once a year to a Slaughter Company authorized service center for calibration and

inspection of safety related components. Slaughter Company will not be held liable for

injuries suffered if the instrument is not returned for its annual safety check and maintained

properly.

User Modifications

Unauthorized user modifications will void your warranty. Slaughter Company will not be

responsible for any injuries sustained due to unauthorized equipment modifications or use

of parts not specified by Slaughter Company. Instruments returned to Slaughter Company

with unsafe modifications will be returned to their original operating condition at your

expense.

INTRODUCTION

11

Packaging

Original Packaging: Please retain all original packaging materials if you do not have an

alternate method of repackaging. If you are returning your instrument to us for servicing

please repackage the instrument in its original container or use an alternate packaging

solution. Please do not reuse the original packing material if there appears to be damage

or missing packing material. Contact our customer support department (1-800-504-0055)

for an RMA (return materials authorization) number. Please enclose the instrument with

all options, accessories, and test leads. Indicate the nature of the problem or type of

service needed. Also, please mark the container "FRAGILE" to insure proper handling.

Other Packaging: If you do not have the original packaging materials please follow these

guidelines:

1). Wrap the instrument in a bubble pack or similar foam. Enclose the same information

as above.

2). Use a strong double-wall container that is made for shipping instrumentation. 350 lb.

test material is adequate.

3). Use a layer of shock-absorbing material 70 to 100 mm (3 to 4 inch) thick around all

sides of the instrument. Protect the control panelwith cardboard.

4). Seal the container securely.

5). Mark the container "FRAGILE" to insure proper handling.

6). Please ship model 2205 via Federal Express or UPS air.

7). Please refer in all correspondence to your RMA number.

INTRODUCTION

12

GLOSSARY OF TERMS

ACCURACY is the condition or quality of conforming exactly to a standard. The

accuracy of an instrument is the extent to which the average of many measurements made

by the instrument agrees with the true value or standard being measured. The difference

between the average and the true value is the error. When this condition is a result of the

measuring instrument, it is known as out of calibration. An instruments measuring

accuracy must be considered over the whole range of the measuring instrument. This is

often expressed as linearity.

AVERAGE VOLTAGE is the sum of the instantaneous voltages in a half cycle wave

shape divided by the number of instantaneous voltages. In a sine wave, the average

voltage is equal to .637 times the peak voltage.

EMF (electromotive force) is the energy per unit charge supplied by a source of electricity

(normally expressed in volts).

The FULL SCALE VALUE is equal to the largest value of the actuating electrical

quantity which can be indicated on the scale or, in the case of instruments having their

zero between the ends of the scale; the full scale value is the arithmetic sum of the values

of the two ends of the scale.

IMPEDANCE is the apparent resistance, expressed in ohms, offered by an alternating

current circuit to the passage of electrical energy. Since frequency is one of the factors

affecting impedance, the frequency of applied energy must be specified.

INDUCTANCE is the property of an electric circuit by which a varying current induces

an emf in that circuit or a neighboring circuit.

L = a²n²/(9a + 10b)

a = coil radius in inches

b = coil length in inches

n = number of turns

LOADED TEST(ing) VOLTAGE is the actual testing voltage developed across the load

(product under test). This voltage will be lower than the open circuit voltage because of

the internal impedance of the H.V. transformer and any series limit resistance of the tester.

OPEN CIRCUIT VOLTAGE is the output voltage of the tester prior to the connection

of a load (product under test).

PEAK VOLTAGE is the maximum value present in a varying or alternating voltage.

This value may be either positive or negative. The peak value is equal to 1.414 (√2) times

the R.M.S. value.

INTRODUCTION

13

PRECISION or REPEATABILITY is the variation in readings obtained when repeating

exactly the same measurement. The precision of an instrument is the ability to repeat a

series of measurements on the same piece and obtain the same results for each measured

value. The variation in the measured values can be expressed in terms of a standard

deviation of the measuring error. The instrument will be more precise if the standard

deviation is smaller.

Accuracy versus Precision: Confusion often exists between the terms accuracy and

precision because the terms are often interchanged in their usage, but they are two

different concepts. The accuracy of an instrument can be improved by recalibrating to

reduce its error, but recalibrating generally does not improve an instrument’s precision.

R.M.S. (ROOT MEAN SQUARE) is the square root of the mean of the instantaneous

values squared.

R.M.S. VOLTAGE is the effective value of a varying or alternating voltage. The

effective value is that value which would produce the same power loss as if a continuous

voltage were applied to a pure resistance. In sine wave voltages, the R.M.S. voltage is

equal to .707 times the peak voltage.

SENSITIVITY is the impedance through which a tester will detect a fault. Sensitivity is

usually expressed in Ohms. One of the most common examples is the UL 120K ohm

minimum sensitivity requirement.

VOLT AMPERE (VA) is the product of the R.M.S. voltage applied to a circuit and the

R.M.S. current, in amperes, flowing through it.

SPECIFICATIONS

14

SPECIFICATIONS

KEY FEATURES & BENEFITS OF MODEL 2205

1. Pass/fail operation

A programmable limit can be set for pass/fail operation, eliminating operator

judgments. An audio alarm and reject lamp notify the operator of failures.

2. No load setup of trip current and output voltage.

Operators can set output voltage and resistance limits to the desired levels in the

absence of high voltage.

3. Automatic storage of test program.

The instruments will power up with the parameters that were used during the last test

to avoid operator set-up errors.

4. All parameters for the setups can be adjusted through a simple menu driven program.

The easy to follow setup screens ensure that the operator correctly sets up all test

parameters.

5. Line and load regulation.

Tests are more repeatable and reliable, since proper voltage is consistently applied to

all devices being tested, regardless of fluctuations in the line input voltage or the

load created by the device under test.

6. PLC Remote Control.

Inputs and outputs for PLC control are available through a 9-pin D type connector

on the back panel.

7. LED display with meter memory.

Easy-to-read digital display simplifies the task of setting test parameters and

interpreting test results, which reduces errors and makes the operator’s job easier.

Meter memory allows operators to review the last test results.

8. Flashing high voltage indicator.

A flashing LED located to the right of the display clearly indicates when high voltage

is active to provide maximum operator safety.

9. Tamper-resistant front panel design.

Prevents operators from inadvertently or accidentally modifying test parameters and

ensures consistent and reliable test results, minimizing the need for costly and time

consuming product re-testing.

SPECIFICATIONS

15

Model 2205 Functional Specifications

Insulation Resistance Tester

INPUT

Voltage 115 / 230 V selectable, ±15% variation

Frequency 50 / 60 Hz ±5%

Fuse 1 Amp 250VAC fast acting

INSULATION RESISTANCE TEST

Output Voltage Range:

Resolution:

Accuracy:

Ripple:

30 –1000VDC

1 Volt

±(1% of Setting + 1V) (relative to displayed

output)

< 2%

Voltage Display Low Range:

High Range:

Resolution:

Accuracy:

0.0V –100.0VDC

101V –1000VDC

0.1V (Low Range), 1V (High Range)

±(2% of reading +2V)

Resistance Display Range:

Accuracy:

0.01MΩ–200.0GΩ(4 Digit, Auto Ranging)

30 –499V

0.1MΩ–1GΩ

±(3% of reading + 2 counts)

1 –20GΩ

±(5% of reading + 2 counts)

500 –1000V

0.1MΩ–1GΩ

±(2% of reading + 2 counts)

1 –20GΩ

±(3% of reading + 2 counts)

20 –200GΩ

±(10% of reading + 2 counts)

Timer Display Range:

Resolution:

Accuracy:

0.0 –999.9 seconds

0.1 second

±(0.1% of reading + 0.05 seconds)

SPECIFICATIONS

16

INSULATION RESISTANCE TEST

Failure Settings Low Limit: 0.1MΩ–999.9MΩ

1000MΩ–9999MΩ

10.0GΩ–200.0GΩ

Dwell Time Setting 1.0 –999.9 seconds, 0.1 second / step

“0”for continuous running

Delay Time Setting 0.1 –999.9 seconds, 0.1 second / step

Discharge Automatic Discharge of Device Under Test

Indicator: Green < 30 V, Red > 30 V

GENERAL

Remote Interface Provided through 9 pin D type connector

1. Inputs: test , reset, safety interlock

2. Outputs: pass, fail and test in progress

Line Cord Detachable 6 ft. (1.8m) power cable terminated in a three prong

grounding plug.

Terminations High Voltage Output –Alden Socket

Shielded Return –BNC Connector

Mechanical Dimensions: (W x H x D): (120mm x 133mm x 300mm)

Environmental Operating Temperature:

Relative Humidity: 32° − 104°F (0° − 40°C)

0 –80%

Calibration Traceable to National Institute of Standards and Technology

(NIST). Calibration controlled by software. Adjustments are

made through front panel keypad in a calibration mode activated

by rear panel switch. Calibration information stored in non-

volatile memory.

Table of contents

Other Slaughter Test Equipment manuals

Popular Test Equipment manuals by other brands

National Refrigeration Products

National Refrigeration Products LV5 operating instructions

Glas-Col

Glas-Col 099D HST230N User instructions

Laversab

Laversab 6500 user manual

Keysight

Keysight Infiniium 90000A Series Service guide

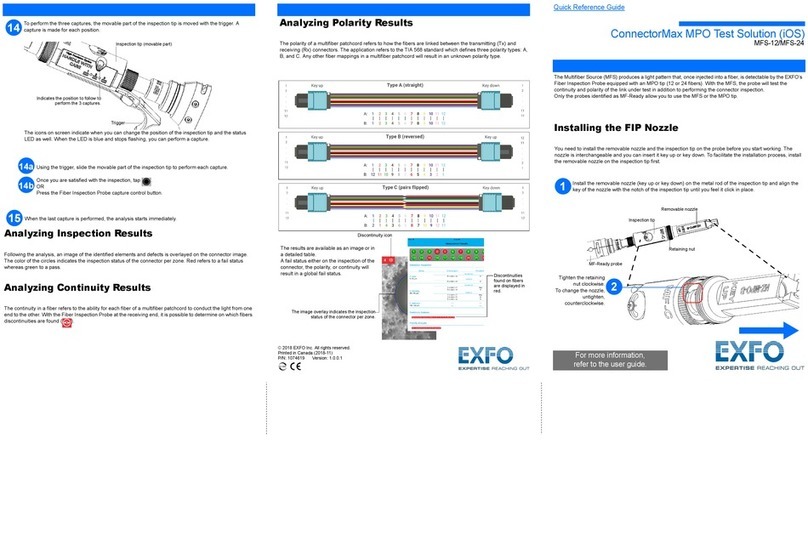

EXFO

EXFO ConnectorMax MFS-12 Quick reference guide

Ametek

Ametek Crystal HPC51 Operation manual