Note: If you cannot see the notch of the inspection tip, slide the movable part of the inspection tip with the

trigger towards the nozzle.

Setting up the Multifiber Source Inspecting Multiple Fiber Ends

When you connect an MF-Ready probe to your smart device, you can view and inspect multiple fiber ends right

away. This type of inspection requires three captures. As soon as the third capture is performed, the analysis

process starts. If you only want to inspect a connector without testing polarity and continuity, ensure that the

MFS is turned off before proceeding. Otherwise, the light emitted by the MFS could be mistaken for dirt which

would result in an erroneous fail status.

6

8

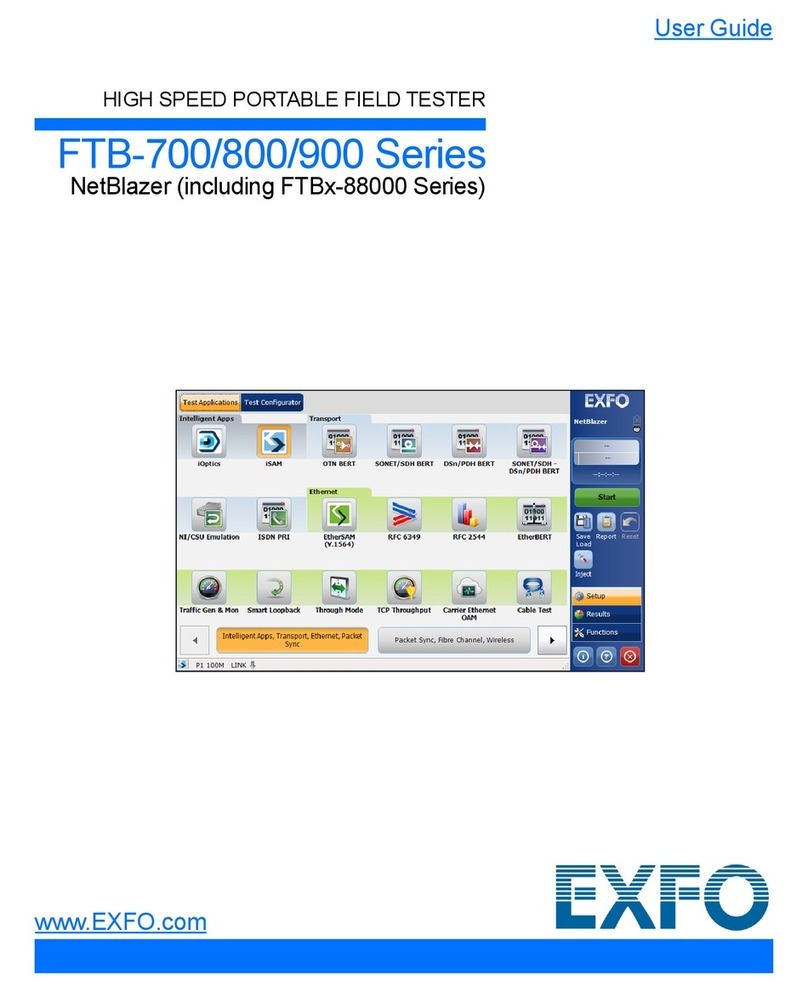

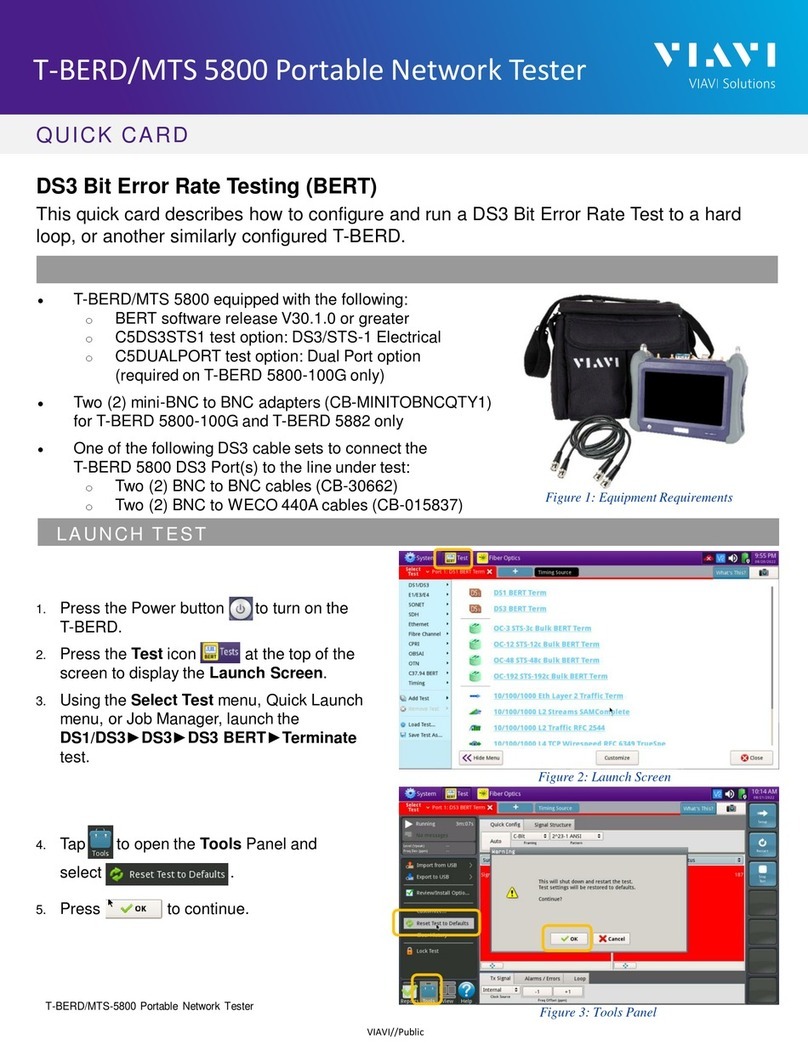

In Live Video mode, tap the Test Configuration

row.

The MFS allows you to test continuity and polarity (based on A, B, or C polarity types) on multifiber links

terminated with MPO connectors. Its design includes a cable management system that allows you to use a

patchcord as connector savers for the MPO connectors on the source.

1Connect the APC connector of the

patchcord to the adapter.

On/Off button with power LED

Battery level indicator

3

If you are using a

patchcord having a

single connector, you

can connect it to any of

the two adapters. With

an MPO-24 split (Y)

patchcord, you must

connect each of its ends

to one of the adapters.

4Open the dust cap and connect the DUT to the appropriate adapter according to the

connections you made in the previous step. If you have connected an MPO-24 split

patchcord, you will have to connect the DUT, in turn, to each of the two adapters.

5Connect the other end of the DUT

to the removable nozzle of the

probe.

2

Secure the

patchcord in

place by

wrapping it

around the unit.

11 Select Multiple Fiber Connector,

and then set the other parameters

according to your needs.

Key orientation of the connector (key up

or key down, depending on the position

of the nozzle)

Fiber configuration of the connector you

use

To validate the

cleanliness of the fibers

of the connector

To stop the analysis as soon as a fail status is detected

on a fiber

Type of expected polarity for your tests

Tap the arrow.

10

Select a test configuration to use for your test.

12

13 If the connector is dirty, remove it from the probe, clean it and reinspect it.

Note: If you are working with an FIP-435B, you can

activate the auto focus feature using the down

arrow in live video mode.

1Turn on the probe.

2Ensure the Wi-Fi is activated on your smart device.

3Go to the device Settings and select Wi-Fi.

4Select the wireless probe you want to work with.

5Start the ConnectorMax2 Mobile application.

Tap Start Live Video.

7Insert the connector into the removable nozzle you have already installed.

Tap the Measurement Name row to configure

the automatic file naming.

9