Slaughter 6330 User manual

For Model: 6330

WARNING: THIS GUIDE WAS CREATED FOR OPERATORS HAVING SOME FAMILIARITY WITH

ELECTRICAL SAFETY TESTING. AN ELECTRICAL SAFETY TESTER PRODUCES VOLTAGES AND CURRENTS THAT

CAN CAUSE HARMFUL OR FATAL ELECTRIC SHOCK. TO PREVENT ACCIDENTAL INJURY OR DEATH, THESE

SAFETY PROCEDURES MUST BE STRICTLY OBSERVED WHEN HANDLING AND USING A TEST INSTRUMENT.

6330

6-in-1 Multi-Function

Electrical Safety Tester

Quick Start Guide

SAFETY CHECKLIST

KEEP unqualied/unauthorized personnel away from the test area

ARRANGE test staons in a safe and orderly manner

NEVER touch products or connecons during a test

STOP the test rst in the event of a problem

NEVER perform a Ground Bond test on energized circuitry or equipment

BE SURE to always connect the return test lead rst

HANDLE test clips by insulaon only, never touch clips directly

Safety Made Simple

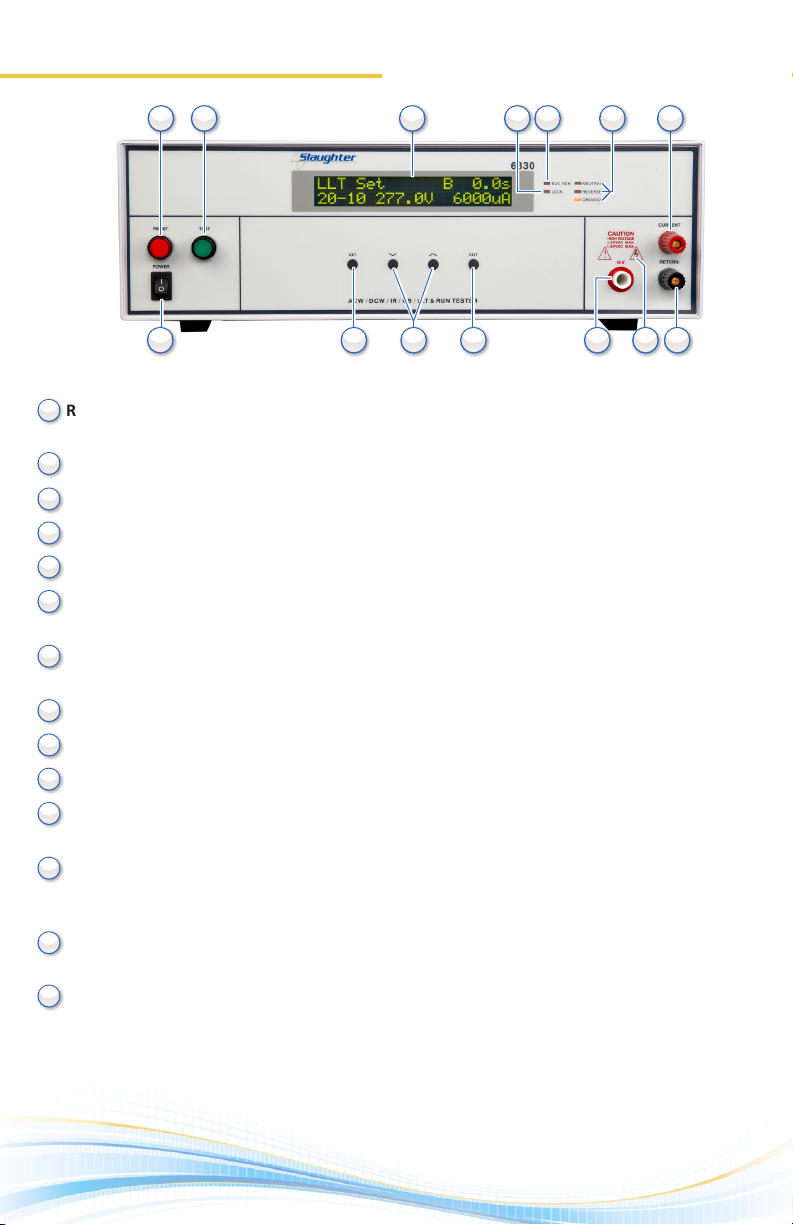

Front Panel Controls

1.

RESET BUTTON: Red momentary contact switch used to reset the instrument in case of a

failure. Also serves as an abort signal to stop any test in progress.

TEST BUTTON: Starts a test.

LCD DISPLAY: 20 x 2 character display.

LOCK INDICATOR: This LED indicates that the lock feature has been enabled.

BUS INTERFACE INDICATOR: This LED indicates that the bus interface has been enabled.

FAULT CONDITION INDICATORS: These LED’s indicate that the Neutral, Reverse, and

Ground line condions have been acvated during a Line Leakage test.

CURRENT OUTPUT TERMINAL: Used to aach the current test lead or test xture to the

instrument. Provides the high current output from the instrument.

POWER SWITCH: Rocker-style switch with internaonal ON ( | ) and OFF (0) markings.

SET KEY: Use this key to advance forward through the setup menus.

UP-DOWN ARROW KEYS: Use these keys to cycle through test parameter setup.

EXIT KEY: Use this key to exit any menu or to clear an unwanted entry in a

parameter eld.

HIGH VOLTAGE OUTPUT TERMINAL: Provides the high voltage used during a Hipot test.

Connector used to aach the high voltage test lead, adapter box high voltage lead or test

xture high voltage lead to the instrument.

HIGH VOLTAGE INDICATOR: This indicator ashes to warn the operator that high voltage

is present at the high voltage output terminal.

RETURN OUTPUT TERMINAL: Provides the return current path. Connector used to aach

the return test lead, adapter box return lead or test xture return lead to the instrument.

(6330 Front Panel)

10

10

11

11

12

12

13

13

14

14

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

1

1

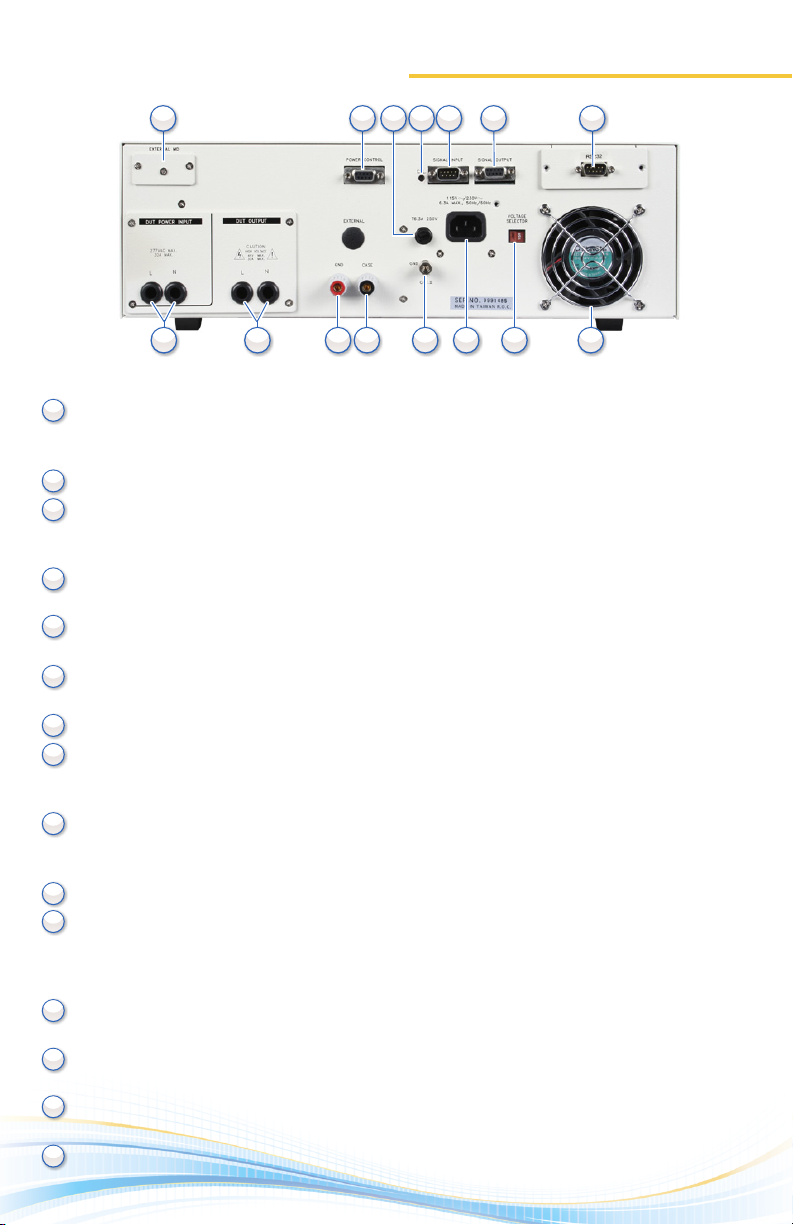

Back Panel Controls

2.

(6330 Back Panel)

10

11

12

13

14

15

2

3

4

5

6

7

8

9

1EXTERNAL MEASURING DEVICE: Provides an access port for a custom measuring device. The

port may be acvated during Line Leakage tesng from the instrument’s menu system. The

operator must supply the appropriate measuring device as none is provided.

POWER CONTROL: N/A

FUSE RECEPTACLE: Fuse rang is 6.3 A at 250 VAC. To change the fuse, unplug the power (mains)

cord and turn the fuse receptacle counterclockwise. The fuse compartment will be exposed.

Please replace the fuse with one of the proper rang.

CALIBRATION BUTTON: To put the instrument into the calibraon mode push this buon and

turn on the power switch simultaneously.

SIGNAL INPUT: 9-pin D-type subminiature male connector for remote control of TEST, RESET,

AND INTERLOCK funcons as well as remote memory tests recall.

SIGNAL OUTPUT: 9-pin D-type subminiature female connector for monitoring PASS, FAIL, and

PROCESSING output relay signals.

BUS INTERFACE: Oponal connector for interconnecon to RS-232 bus interface.

DUT POWER INPUT: Provides the line and neutral connecons for an input power source to be

used during Funconal Run and Line Leakage tesng. Only a U.S. style single phase unbalanced

power source may be used.

DUT POWER OUTPUT: Provides the line and neutral connecons from the 6330 to the DUT during

Funconal Run and Line Leakage tesng. Provides the high voltage connecons to the DUT during

ACW, DCW and IR tesng if the DUT OUTPUT and DUT-HV parameters are turned ON.

GROUND CONNECTION: Connector used to aach the adapter box ground lead to the instrument.

CASE CONNECTION: Provides the return connecon during ACW, DCW or IR tesng. This

terminal is wired in parallel with the return terminal during a Ground Bond test and may be

used in place of the front panel connecon. During a Line Leakage test this connecon provides

a connecon to one side of the measuring device (MD).

CHASSIS GROUND (EARTH) TERMINAL: This safety terminal should be connected to a good

earth ground before operaon.

INPUT POWER RECEPTACLE: Standard IEC 320 connector for connecon to a standard NEMA

style line power (mains) cord.

VOLTAGE SELECT SWITCH: Sets the line voltage conguraon of the instrument. In the le

posion it is set for 115 volt operaon, in the right posion it is set for 230 volt operaon.

THERMAL FAN: Runs connuously to cool the instrument.

2 3 4 5 6 71

10 11 12 13 14 158 9

3.

Setting Up The Instrument

Editing System Parameters

WARNING: LOCATE A SUITABLE TESTING AREA WITH A THREE-PRONG, GROUNDED OUTLET. BE SURE

THAT THE THREE PRONG OUTLET HAS BEEN TESTED FOR PROPER WIRING. MAKE SURE YOU READ THE SAFETY

CHECKLIST OF THIS GUIDE BEFORE USING THE INSTRUMENT.

1. Adjust the line voltage select switch on the rear panel of the instrument to the

appropriate input voltage rang, either 115 VAC or 230 VAC.

2. Connect the female end of the standard NEMA style line power (mains) cord into the

input power receptacle on the rear panel of the instrument and plug the male end of

the cord into a grounded power source.

3. Turn the instrument power switch ON. Upon power up, you will see the Slaughter

Company name, Model Number, and current soware version briey appear on the

LCD display and then you will see the default test parameters as follows:

Congure the instrument system parameters to your preferences. The instrument

system parameters are global and will aect all tests that are performed regardless of

memory locaon and memory step.

1. Press EXIT from the Perform Test screen to edit the system parameters.

2. Press the SET key to toggle through the parameters and use the up or down arrow

keys to edit the parameters.

Default system parameters shown below:

(Perform Test Screen)

To Grounded

Power Source

PLC Remote Single Step Fail Stop Lock Memory Lock Alarm DUT-HV Set

OFF OFF OFF OFF OFF 5 ON

4.

Editing Test Parameters

Selecting A Memory Location

If you wish to change the default test sengs, you will need to begin by choosing a

memory locaon rst.

There are 20 memory locaons each of which contains 10 steps. The steps can be

connected sequenally to form a mul-step test roune. Only one electrical safety test type

can be selected for each step. In order to connect a step, the “Connect” parameter needs

to be turned ON.

1. Press the SET key from the Perform Test screen to select a memory locaon. Use the up

or down arrow keys to select memory locaons 1 – 20.

2. Press the SET key again to select the step. Use the up or down arrow keys to cycle

through steps 1-10.

3. Press the EXIT key to store changes and return to the Perform Test screen.

Now that the memory locaon has been set up, you may now congure your test roune.

1. Press the SET key from the Perform Test screen to conrm the memory locaon.

2. Press the SET key again to conrm the memory step number. You should start by

modifying step 1.

3. Press the SET key a third me unl one of the following test types appear:

4. Use the up and down arrow keys to toggle the test type between ACW, DCW, IR, GND,

RUN, and LLT.

5. Press the EXIT key to save the seng and return to the Perform Test screen OR press

the SET key to toggle between the parameters for the selected test type.

6. Use the up or down arrow keys to edit each test parameter.

7. When you are nished eding the test parameters press the EXIT key to save your

sengs and return to the Perform Test screen.

Default test type parameters are shown on next page.

Memory Locaon Memory Step Number

5.

Editing Test Parameters

Default test type parameters are shown below.

There are a total of 8 dierent Line condions that may be congured. They are displayed

in the following table:

AC Hipot Mode

• Voltage: 1.24 kV

• HI-Limit: 10.00 mA

• Lo-Limit: 0.00 mA

• Ramp: 0.1 s

• Dwell: 1.0 s

• Frequency: 60 Hz

• Arc Detect: OFF

• Arc Sense: 5

• DUT Output: On

• Connect: O

Funconal Run

• Volt-Hi: 125.0 V

• Volt-Lo: 0.0 V

• Amp-Hi: 10.0 A

• Amp-Lo: 0.0 A

• Power-Hi: 1000 W

• Power-Lo: 0 W

• PF-Hi: 1.000

• PF-Lo: 0.000

• Leakage-Hi: 10.00 mA

• Leakage-Lo: 0.00 mA

• Delay: 0.2 s

• Dwell: 1.0 s

• Connect: O

DC Hipot Mode

• Voltage: 1.50 kV

• HI-Limit: 5.00 mA

• Lo-Limit: 0.00 mA

• Ramp: 0.1 s

• Dwell: 1.0 s

• Arc Detect: OFF

• Arc Sense: 5

• DUT Output: On

• Connect: O

Line Leakage Mode

• Volt-Hi: 125.0 V

• Volt-Lo: 0.0 V

• Leakage-Hi: 6000 µA

• Leakage-Lo: 0.00 µA

• Line: 7

• MD: MD A

• Probe: G-L

• Delay: 1.0 s

• Connect: OFF

Insulaon Resistance

• Voltage: 500 V

• HI-Limit: 0 mΩ

• Lo-Limit: 1 mΩ

• Delay: 1.0 s

• DUT Output: On

• Connect: O

Ground Bond Test

• Current: 30 Amps

• HI-Limit: 100 mΩ

• Lo-Limit: 0 mΩ

• Dwell: 1.0 s

• Oset: 0 mΩ

• Frequency: 60 Hz

• Connect: O

Line 12345678

Neutral OPEN OPEN OPEN OPEN CLOSE CLOSE CLOSE CLOSE

Reverse OFF ON OFF ON OFF ON OFF ON

Ground OPEN OPEN CLOSE CLOSE OPEN OPEN CLOSE CLOSE

6.

Adapter Box Connecons

The adapter box may be used for products that are terminated in either a two prong or

three prong line cord. It is easy to use the adapter box for all six test funcons.

See back page for diagram.

1. Remove the cover plate on the rear panel of the 6330 to access the DUT Output

Connecons. These connecons provide power to the DUT during a Line Leakage or

Funconal Run test.

2. Connect the adapter box (P/N 99-10467-01) to the DUT Output L (line), N (neutral)

terminals, and the ground terminal.

3. Aach the black case lead (P/N 99-10457-01) to the case terminal and connect the

ground return clip to the dead metal on the chassis of the DUT.

4. Plug the line cord from the DUT into the adapter box receptacle (P/N 99-10467-01).

The adapter box will now provide power to the DUT during Funconal Run and Line

Leakage tesng.

Test Connections

DUT Power Input Connecons

Remove the cover plate on the rear panel of the 6330 to access the DUT Power Input

Connecons. These terminals provide the connecons from an external power source to

the 6330. See back page for diagram.

5. Use the black 10 AWG cables (P/N 99-10469-01 & 99-10470-01) to connect to an

unbalanced, single-phase power source for applicaons not exceeding 30 amps.

Note: The 220 - 240 volt U.S. style line power cord is NOT suitable to connect to the DUT

inputs. This style of power distribuon is a balanced type with two HOT or LINE conductors.

If voltage is applied to pin 2, N (neutral) terminal of the DUT Power Input and you aempt

to execute a Run test or Line Leakage test, a warning will appear on the screen that says

Neutral-V.

If this message appears, the voltage problem will need to be corrected before the

instrument allows you to execute Funconal Run or Line Leakage tests.

WARNING: BE SURE THAT THE HOT LEAD OF THE POWER SOURCE IS CONNECTED TO PIN 1,

(LINE) TERMINAL OF THE DUT POWER INPUT TERMINAL BLOCK AND THE RETURN OR LOW VOLTAGE

LEAD IS CONNECTED TO PIN 2, N (NEUTRAL) TERMINAL OF THE DUT POWER INPUT TERMINAL BLOCK.

DO NOT CONNECT A LINE CONDUCTOR TO THE N OR NEUTRAL TERMINAL OF THE DUT POWER INPUT.

THIS CONDITION CAN BE VERY DANGEROUS TO THE OPERATOR.

6330-3/13

www.hipot.com Toll Free (800) 504-0055 or (847) 932-3662

© 2013 Slaughter Company, Inc.

Scan the QR code

to get further

support or visit

www.hipot.com

Safety Made Simple

View test results by pressing the up and down arrow keys from the Perform Test screen.

PASS: If the DUT passes the test, you will hear a short audible beep and the display will

indicate the test results.

FAIL: If a failure occurs, you will hear a long audible alarm and the red ashing indicator

will light up. To stop the alarm press the red RESET buon.

(PASS/FAIL Indicaon Screen)

CAUTION: THE ADAPTER BOX (P/N 99-10467-01) MAY BE USED TO PERFORM HIPOT, GROUND BOND,

INSULATION RESISTANCE, FUNCTIONAL RUN, AND LINE LEAKAGE TESTS. THE ADAPTER BOX IS RATED FOR A

MAXIMUM OF 20 AMPS OF INPUT CURRENT. IF CURRENT LEVELS GREATER THAN 20 AMPS ARE NEEDED FOR

EITHER THE FUNCTIONAL RUN TEST OR THE LINE LEAKAGE TEST, THE STAND ALONE TEST LEADS MUST BE USED.

Test Connections

Test Results

DUT POWER INPUT

NL

GND CASE

DUT OUTPUT

CAUTION

HIGH VOLTAGE

5KVAC MAX.

6KVDC MAX.

1.

2.

3.

4.

5.

Other manuals for 6330

1

Table of contents

Other Slaughter Test Equipment manuals

Popular Test Equipment manuals by other brands

Hioki

Hioki MEMORY HiCORDER 8855 instruction manual

Seaward

Seaward 227A910 Operation instructions

Keysight Technologies

Keysight Technologies Infiniium 90000A Series Service guide

HP

HP 54501A Programming reference

Gossen MetraWatt

Gossen MetraWatt METRATESTER 5+ operating instructions

HP

HP 608E Operating and service manual