Slee MCS I User manual

2 Manual_MCS_I_2021-10-002.00_EN.docx

Manual_MCS_I_2021-10-002.00_EN.docx 3

CONTENTS

1. Safety 5

1.1 Introduction 5

1.2 Used symbols 5

1.3 Intended use 5

1.4 Emissions 6

1.5 Sources of danger 6

1.6 Authorized user / Operator 6

1.7 Personal protective equipment 6

1.8 Safety instructions on installation site 6

1.9 Safety equipment 7

1.10. Case of emergency 7

2. Transport / Installation 8

2.1 Technical data 8

2.2 Transport / Storage 8

2.3 Unpacking 8

2.4 Setup and connection 9

2.5 Operation conditions 9

2.6 Functional components 10

3. Operation / Before Operation 11

3.1 Initial Fill Up 11

3.2 Lubrication of the pumping system 11

3.3 Switch On / Check / Initialization 12

3.4 Flushing the unit with Xylene 14

3.5 Fill Up with mounting media (Pertex®) 15

3.6 Evacuation of the system 15

3.7 Mounting media volume, cover glass size, etc. 16

3.7.1 Mounting Media Volume, Cover Glass Size etc. 16

3.7.2 Setup “Arm”(speed and pressure) 17

3.7.3 Programs 17

3.8 Coverglass 18

3.8.1 Filling up coverglass 18

3.8.2 Coverglass positioning 19

3.8.3 Coverglass quality and separation adjustment 21

3.9 Storage 23

4. Regular cleaning and maintenance 24

4.1 Cleaning Instructions 24

4.2 Timing of cleaning and maintenance 25

4 Manual_MCS_I_2021-10-002.00_EN.docx

5. Routine Basics 26

5.1 Direction of specimen on the slides 26

5.2 Short introduction 27

6. Troubleshooting 29

6.1 Changing the fuses 29

6.2 Troubleshooting 30

6.3 Error Messages 30

7. Abandonment/Recycling 32

8. Greasing 32

.

Manual_MCS_I_2021-10-002.00_EN.docx 5

1. SAFETY

1.1 INTRODUCTION

By purchasing this MCS I coverslipping machine, you decided for a quality product of

SLEE medical GmbH, Germany. Intention of this manual is to help you, working with

your unit. Please read it carefully and completely and follow its advices.

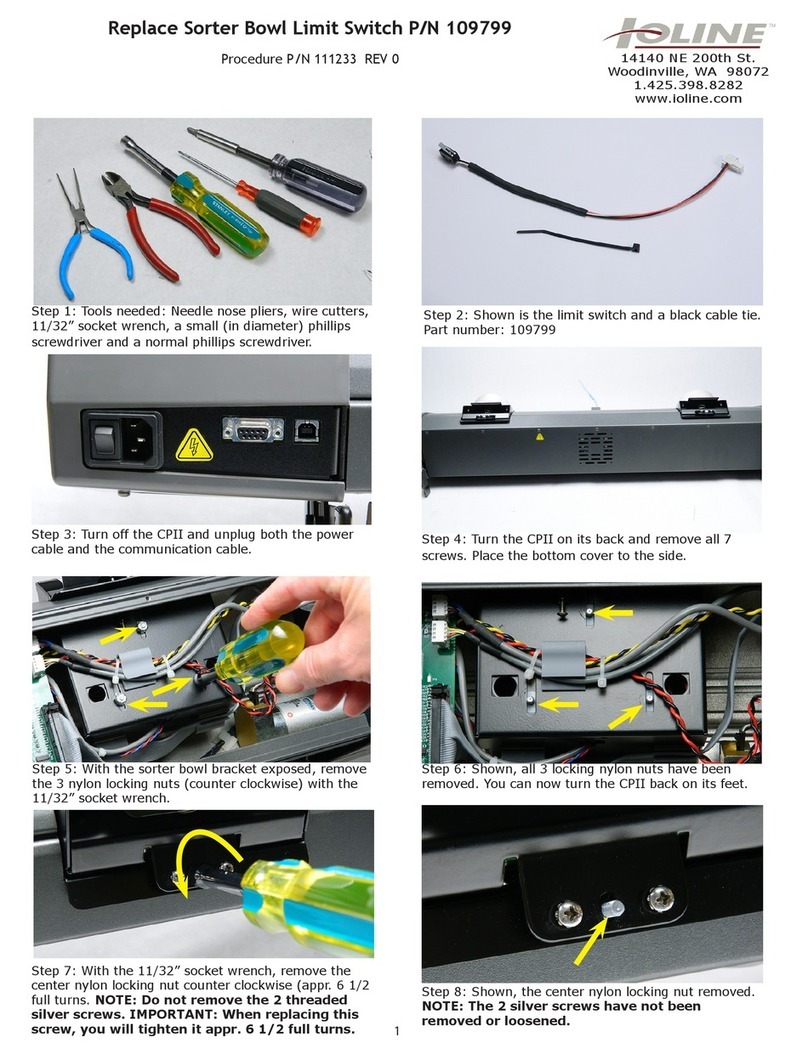

1.2 USED SYMBOLS

This symbol warns you of risks for the life or health of

person. Pay attention!

This symbol warns you of risks for machine, material or

environment. Pay attention!

This symbol stands for areas of information. Pay attention!

1.3 INTENDED USE

The exclusive application of the coverslipping machine MCS I is, to bring mounting

media and cover glass on slides with histological or pathological tissue samples or

cytological smears to save working time of laboratory personal and also have less tiring

work and impairment of health by harmful solvent fumes. A use in food industries and

similar facilities is strictly prohibited. Unauthorized rebuilding or changing to this

laboratory instrument is strictly prohibited due to safety reasons. Use only original SLEE

medical GmbH spare parts in case of replacement issues. Operation, maintenance or

service conditions mentioned in this manual have to be kept strictly

6 Manual_MCS_I_2021-10-002.00_EN.docx

1.4 EMISSIONS

The emissions of solvent steams due to the use of reagents and chemical glue inside the

MCS I are reduced by the powerful fans and the charcoal filter (to be exchanged

regularly) of the MCS I exhaust system. A connector to your central exhaust system is

integrated, so the machine can also be run without filter.

1.5 SOURCES OF DANGER

The work with reagents and medias, as they are used in laboratories to coverslip slides,

is always a danger for health and life. So also by using the MCS I be sure to follow the

common rules and regulations for work with these medias. Further danger can be

caused by the moving mechanical parts (step motor axes) inside the MCS I. For this

reason the safety covers normally prevent of touching moving parts. If one of the covers

are open, the software is not starting the process and an electronic safety board cuts the

power of the motors to offer a double safety.

1.6 AUTHORIZED USER / OPERATOR

Users, working with the MCS I, may only be those, who have been instructed by the

operator. The operator is responsible to third persons on the operating site. The

operator has to provide this instruction manual to the users and to make sure, the users

have read and understood it.

1.7 PERSONAL PROTECTIVE EQUIPMENT

Slides and baskets taken out of the MCS I after coverslipping may still be contaminated

by reagents or colours from the staining machine. So by taking out or by cleaning the

machine you may have direct contact. According to common safety regulations, it is

necessary to wear gloves to prevent contact with your skin.

1.8 SAFETY INSTRUCTIONS ON INSTALLATION SITE

The MCS I has to be installed only on a stable, even and solid basis to be sure, it stands

and works safely. A falling instrument means a big accident risk! Installation has to be

done by trained and certified Slee personal.

Manual_MCS_I_2021-10-002.00_EN.docx 7

1.9 SAFETY EQUIPMENT

The MCS I can be stopped safe by just pressing „break“ which will lead to put on the

last necessary coverglass so nothing will dry out during this break and then releasing the

cover. In this case a restart is offered by the MCS I. For some reason it can be necessary

to have the unit stopped immediately. In this case you have to push the “ON/OFF”

button, which will directly stop the running process, release the cover and cut the power

of the motors. The MCS I confirms this “Emergency Stop” by an Alarm and a message

on the screen. Pushing „ON/OFF“ again will switch the unit into stand-by mode. During

normal process the safety covers prevent users from being hit by moving parts inside.

1.10 CASE OF EMERGENCY

For an instant emergency stop just push the „ON/OFF“ switch, as mentioned in point

1.9 „Safety Equipment“. This will directly stop the running process, release the cover

and cut the power of the motors. The MCS I confirms this “Emergency Stop” by an

Alarm and a message on the screen. Pushing „ON/OFF“ again will switch the unit into

stand-by mode. For cutting the complete Power supply, just switch the main switch on

the right side of the unit or pull out the cable.

8 Manual_MCS_I_2021-10-002.00_EN.docx

2. TRANSPORT / INSTALLATION

2.1 TECHNICAL DATA

Coverslipping time: 6 – 11 sec. per slide

Mounting media volume: 30 - 150 µl

Volume of mounting media container: 500 ml

Slide specifications:

Size: 26 x 76 mm

Thickness: 0,9 - 1,2 mm

Capacity: 150 pieces, continuously in special

Slee 30 pcs. slide baskets

Coverglass specifications:

Sizes: 24 x 50, 55, 60 mm

Thickness: 0,12 - 0,19 mm

Capacity: 250-300 pieces (anti-adhesive automat coverglass)

Exhaust connection:

Diameter of round connector: 100 mm

Max. air throughput: 195 m³/h

Max. static pressure: 50 Pa

Size (L/D/H): 630 x 670 x 640 mm

Weight: 65 kg

Power supply: 100-240V / 50/60Hz / 85 VA

Operating temperature range +10 to +35 °C

Operating humidity max. rel. 80 % non-condensing

Storage temperature range +5 to +55 °C

Storage humidity max. rel. 80 % non-condensing

2.2 TRANSPORT / STORAGE

The coverslipping machine MCS I is delivered in a protection box. Please move it only

upright and avoid shocks.

2.3 UNPACKING

Put the machine on a flat and stable underground and remove the packing. You should

keep the material for safety in cases of later transports, if possible. Check the integrity of

the delivery. The MCS I comes with the parts, notified on a separate packing list.

Manual_MCS_I_2021-10-002.00_EN.docx 9

2.4 SETUP AND CONNECTION

Before initially switching on the MCS I, leave the unit on the designated workspace for

at least 2 hours or more, to adjust to room temperature. Installing and initial adjusting

only may be operated by engineers specially trained by Slee. Before connecting the

instrument to the power supply, make sure the unit is adequate to your local electrical

power line. The unit is delivered “ready to start”. For the connection to your grounded

laboratory power supply use the delivered cable.

The MCS I can be used with a charcoal filter and has two powerful exhaust fans and so

it can be used even in laboratories without separate central exhaust-system. The filters

have to be exchanged at least once a year, depending on frequency of use. Fitting

replacement filters can be ordered at Slee. If you have an existing central exhaust-

system, you can connect the machine to this unit of course.

Leave space of at least 10cm from a wall or other units to all sides of

the MCS I, to guarantee an optimized air circulation.

For detailed information ask your local SLEE medical GmbH sales

representative.

Don’t put or store inflammable things to the direct neighbourhood of

the MCS I.

2.5 OPERATING CONDITIONS

•The MCS I is concepted for use in combination with Slee´s

multistainer MAS, but may also be operated as stand-alone by

installing a separate loading station.

•Operating of the MCS II is only intended within closed premises.

•Field temperatures may differ from + 15°C to + 40°C (no big oscillations).

•Max. allowed height over sea: 2000 m (EN 61010-1:2001).

•Vibration free and weight-adequate work ground required.

•Relative air humidity max. 80%, not condensing for temperatures up to 31°C,

Linearly decreasing to 50% relative humidity at 40°C.

•No exposure to direct sunlight.

•No variations of electrical power supply more than to 10%.

10 Manual_MCS_I_2021-10-002.00_EN.docx

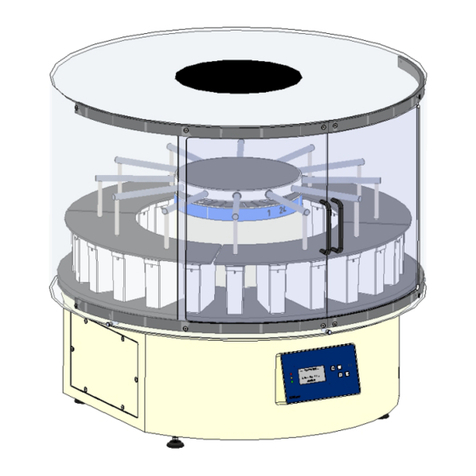

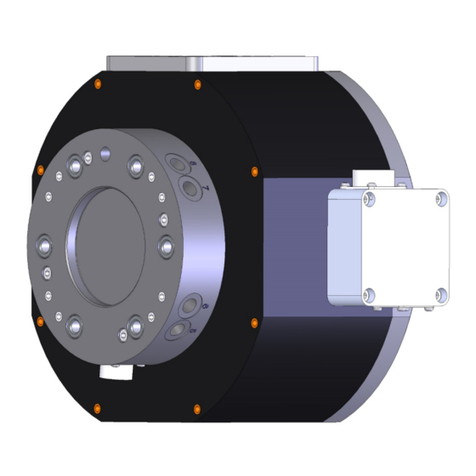

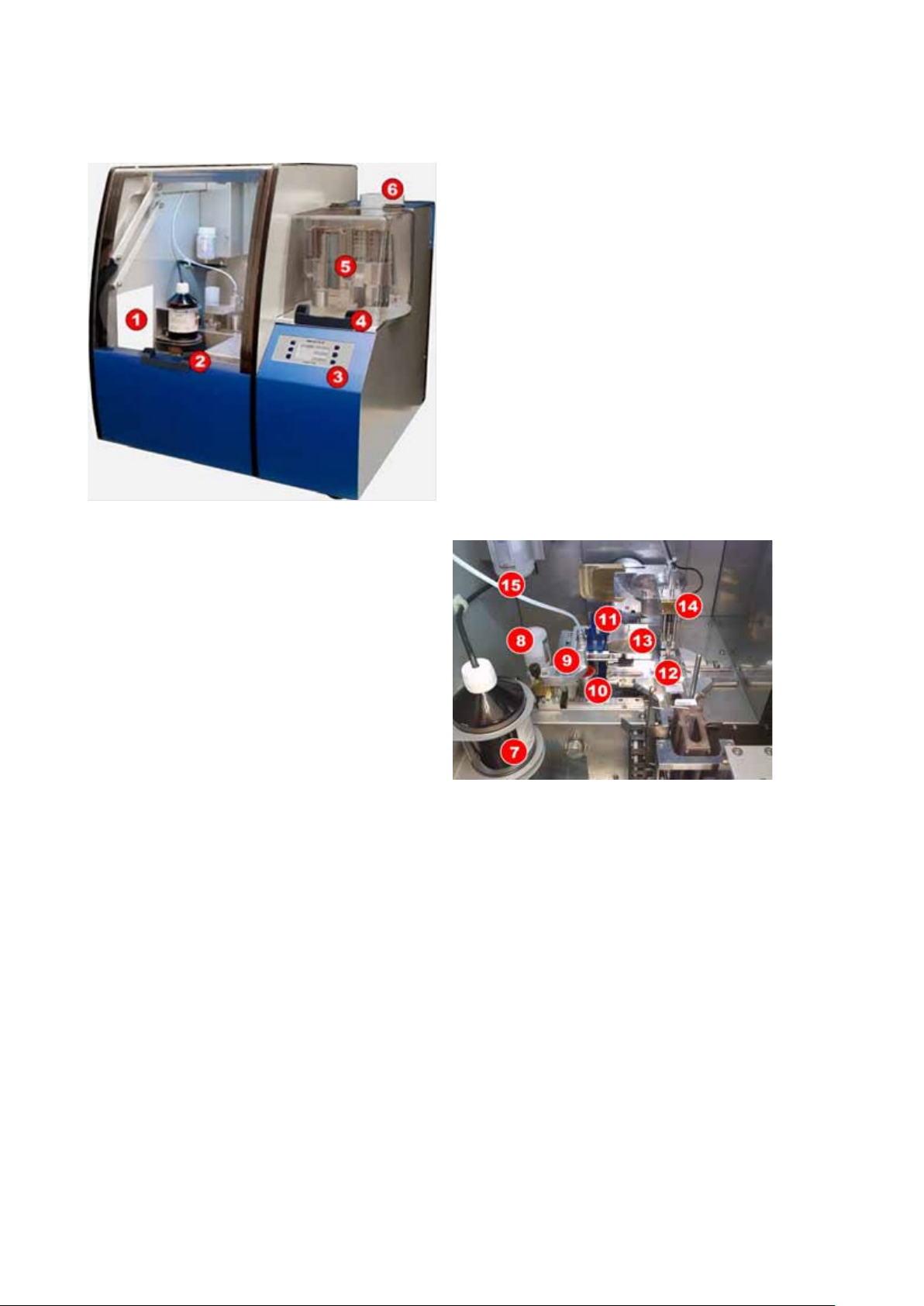

2.6 FUNCTIONAL COMPONENTS

1 – Area of transfer unit

2 – Safety hood

3 – Display / Operator panel

4 – Storage

5 – Storage cover

6 – Exhaust connector

7 – Mounting media bottle (Pertex)

8 – Xylene reservoir for dispenser needle

9 – Dispenser needle

10 – Waste container

11 – Coverglass box

12 – Turntable / Disk

13 – Coverglass waste box

14 – Arm / CG-head

15 – Xylene reservoir for media pump

Manual_MCS_I_2021-10-002.00_EN.docx 11

3. BEFORE OPERATION

Attention! Use only baskets, that are signed with the Slee logo

inside your MCS I!

3.1 INITIAL FILL UP

After installation the machine needs at first a bottle of mounting media. Slee is strictly

recommending Pertex®. Using other mounting media types can cause damage due to

wrong viscosity and different dry-out processes! Before fill up, Slee recommends to have

a system flush with suitable solvent (when using Pertex® this is xylene).

Especially reagents based on orange substances are known for

sticking mechanical parts within a short time.

Slee does not assume any liability when using other mounting media types and suitable

solvents!!

Insert a bottle, glass or container with xylene into the mounting media holder on the left

inside wall of the unit and put the end of the tubing into this container. The unit is now

prepared for the next steps. Follow step 3.2

3.2 LUBRICATION OF THE PUMPING SYSTEM

To ensure the lubrication of the complete pumping system, it is necessary to keep all

mechanical parts clean and smooth with suitable solvent to protect it from dry out and

sticking. (For best control and least possible fume emission of used solvents, Slee created

refillable cartridges (reservoirs), which easily show the fill level all the time. To refill the

cartridges, you may open the MCS I, after it took in its refill position and opens the

hood after switching on, or anytime during operation, by pressing the “BREAK” button).

Go on with step 3.3.

12 Manual_MCS_I_2021-10-002.00_EN.docx

3.3 SWITCH ON / CHECK / INITIALIZATION

Connection and main switch “ON”

Connect the MCS I with your laboratory power supply.

Turn on the main switch (at the power connector on the

right side) and close both covers if open.

Press “ON/OFF” key at the display

With connected power cable the unit now is in standby

and can be switched to operation with the power key on

the display (left side, upper button).Press this power

switch and hold it for 2 seconds.

Eventually „power failure“

Quit the „power failure“ if shown. (This means, the unit

was not correctly shut down after last time running,

maybe due to a power blackout).

Check and confirm filling levels

Now check the levels of xylene cartridges and the

mounting media bottle. The machine has released the

hood locking now, so it's easy for you to open it and

have a closer look at cartridges and the bottle, and to

refill them, if necessary. Also check for the cover glass

waste container and the purge cap (mounting media

waste, which has to be replaced and emptied regularly).

The purge caps are available as consumables at Slee.

The MCS I asks you to confirm your check by pressing

“OK”.

Manual_MCS_I_2021-10-002.00_EN.docx 13

Refill, clean, take out

Refill, clean, take out

The needle cartridge on the left (preventing of

needle dry out) is always free for taking out, while

check function at start-up and when hood is

released anytime you use the “BREAK” function.

It can be taken out by pulling it up.

Now you can refill the cartridge outside the unit

(best is to use a wash bottle).

If level is below the mark, it is time to refill the

cartridge. Please keep the cartridge clean – as

mounting media off course will leave remains that

can dry out. See on the right, how to check / take

out the parts.

Cartridge for system lubrication

The upper cartridge (for lubrication of the media

pump system) also has to be kept at correct level.

After pressing the „OK“ button now, the unit will

execute its initialisation run and turn to the

“operation screen“.

Initialization

While initialization, a % line shows you the actual

progress.

14 Manual_MCS_I_2021-10-002.00_EN.docx

3.4 FLUSHING THE UNIT WITH XYLENE

If needed, (before a longer period of non-use of the instrument, a transport and re-

installation on a new site and similar situations) you should start a system flush with

xylene. (At initial setup after receiving a new MCS I, after re-installation on a new site

and transports it is also strictly necessary to ensure, no remaining mounting media can

get hardened out and stick inside the mounting media system!)

From the operation screen you can press „Setup“, and then „Arm&Disp“ and then

„Dispenser“ to get into the needed pump menu.

Be sure, you emptied and replaced the purge cap before operating.

Put a container / glass with xylene into the mounting media bottle position, insert the

tube, put an empty purge cap (for mounting media waste) and start the system flush

with the key “Cleaning“. The unit now starts pumping xylene from your xylene

container to fill and clean the complete system. You will have to exchange / empty the

purge cap after the MCS I asks you to check xylene and Pertex® 3 times during this

cycle. You should restart the “Cleaning“ run perhaps for a second and third time after it

has finished. In cases of system cleaning after longer non-use of the MCS I, be sure to

have 3-4 runs before changing to Pertex® again and then start 2 runs with Pertex®

(Point 3.4). (To ensure a clean and primed unit, you should have a system flush in

intervals of every 2nd or 3rd mounting media exchange).

After a system flush the MCS I is prepared for filling up with Pertex®! (step 3.5)

Manual_MCS_I_2021-10-002.00_EN.docx 15

3.5 FILL UP WITH MOUNTING MEDIA (PERTEX ®)

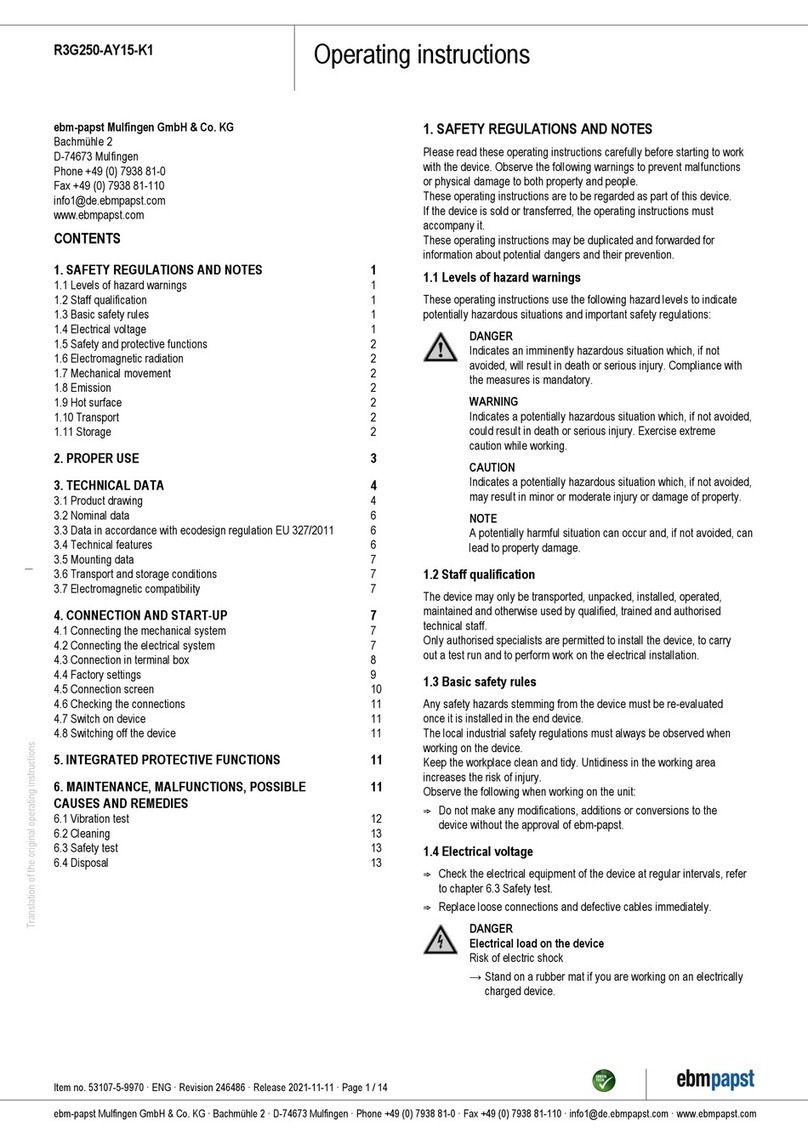

Open a bottle of Pertex® and put it into the designated position at

the left inside wall of the MCS I. The end of the tube has to be

placed into the bottle. With a special adaptor it can be secured

against falling out as shown on the left picture. Be sure, the end of

the tube is positioned nearly at the ground of the bottle, to ensure

an optimized gain per bottle. Before each start of operation, you

need to check the fill level of Pertex®. You should never run the

bottle completely empty, because this will bring up air into the

system, which may make the mounting media dry out and stick

inside the tubes or at least may cause air bubbles on your slides.

To prevent upcoming cleaning and flushing time or service calls

because of this, you should exchange the bottles already a while

before the level reached the critical mark. Pertex®, which has been

left in a bottle, should be kept to put into the next bottle after there

is enough space again after some time of use and to consume it

completely by this way. The fill level of the Slee Pertex® bottles is

easy visible.

3.6 EVACUATION OF THE SYSTEM

From normal operation screen change to the setup menu by pressing the „Setup“ key

and then go on into “Arm&Disp” and then “Dispenser”. This menu offers a „Cleaning“

function and a „Bubble free“ function. „Cleaning“ gives you the possibility to flush the

system with xylene. For a fill up with mounting media, you should only run “Bubble

free”, as this runs slower, to prevent the media from gas bubbles due to vacuum in the

tubing. „Bubble free“ operates a special gentle and slow fill up process and also

removes already existing air bubbles from the system by this way. While all these

functions, again make sure to have an empty „purge cap“ in the correct place!

16 Manual_MCS_I_2021-10-002.00_EN.docx

3.7 SETUP DATA

3.7.1 MOUNTING MEDIA VOLUME, COVER GLASS SIZE, ETC

To set the position of the start and end points of the mounting media line and the

volume of the media, Slee specially focused on simplicity for users. The volume of

Pertex® can be changed in 5µl steps anytime during the process using the two upper

keys on the right side of the display between 30 and 150µl. (In operation screen) For

more elementary settings, you may go to the „Setup“ menu by pushing the „Setup”

key, where all possibilities for an individual setting are open.

By entering „Arm&Disp“ you go on with “Dispenser” into the setting functions for the

„mounting media“. Here, you can choose between „Position“ and the cleaning or

bubble free functions.

By choosing „Position“ you will get the possibility, to set the start and end positions of

the mounting media – according to your used cover glass and type of samples. You can

change the distance from the left slide edge to the start point of the line (X1) with the

left two upper keys at the display and the length of the mounting media line (X2) with

the right upper keys at the display in 1mm steps.

Because the media spreads after cover glass is applied, it normally is sufficient, to enter a

value for X1 from left slide edge to cover glass edge and add about +5mm and for X2

of about cover glass length minus 10mm. Otherwise too much media might be pressed

out to the sides.

The “delay” time should only be changed, if you have problems with the start point of

the line.(~150ms).

For first tests Slee recommends to set the volume to the lowest value (30µl) and to

increase this volume during the test runs till results are optimized. This can be done

easily during the process with „volume+” and „volume-„ in the operation screen. You

don’t need to change to the „Setup“ menu!

Get out of any screen – back to the last one – easily by pressing exit in any screen.

All changes will be directly stored inside the program.

Manual_MCS_I_2021-10-002.00_EN.docx 17

3.7.2 SETUP “ARM” (SPEED AND PRESSURE)

To set the pressure and / or the speed of the coverglass head while bringing up the

coverglass onto the slide, go into “Setup” / “Arm & Disp” / “Arm” and adjust the

pressure and speed parameters from values between “10” and “200” to find the best

solution between reducing air-bubbles and being fast.

Best is, to have the MCS I adjusted by your local Slee sales or service representative. Slee

strictly recommends “automat star” coverglass from Knittel with a thickness of 0,12 to

0,19mm to receive best results without having problems of sticking to each other, that

can lead to crashes and damage of slides in bad cases, as the MCS I is working very fast

and has to bring all slides back into the basket, which may be impossible if too many

covers or splinters are placed there.

!!! Risk of broken slides and splinters of coverglass if ignored!!!

Be sure to guarantee a correct stock keeping of your coverglass! Avoid temperature

differences and high humidity! If still having such problems, there are some special

functions for Slee personal to activate a save mode of coverglass pickup. In these cases,

please call your local SLEE medical GmbH representative and ask for help in activating

and adjusting.

3.7.3 PROGRAMS

The MCS I can store up to 4 individual settings in different “programs”. Changes inside

the actual chosen program (indicated as “P#” in the lower left corner of the operation

screen – for example “P1”) will automatically be stored and used by the controller.

Mounting media length, volume, pressure or speed – all changes will only take effect in

the program, which you currently activated! This means, if you should need slower

speed and pressure for a special kind of samples, maybe due to air bubbles on the slides

for example, you may switch to another program no.# .For example “P2”. Now all

parameters changed to the values, which were actually stored in “P2”. You can now set

all parameters here to the same values, as in your “standard” program and only change

speed and pressure to a lower level. Finally set values are now automatically stored in

“P2” and it is easy now to switch the MCS I to these values, each time you run these

samples again, just by choosing “P2” again. Afterwards, you may switch back to your

standard / routine values by turning back to “P1”. The actual chosen program is

indicated in the main screen on the lower left side of the display (for example: “P1”). To

call up other programs, just turn to “SETUP” and choose another one by pressing

“P1(P2/P3/P4) change”. P1 changes from P1 to P2, then P3 or P4, then starts back at P1,

each time you hit this key one time.

18 Manual_MCS_I_2021-10-002.00_EN.docx

3.8 COVERGLASS

3.8.1 FILLING UP COVERGLASS

Slee offers you different sizes of cover glass boxes, adequate to your used cover glass.

These specially are designed for a high capacity (up to 300 pieces) of cover glass. All

available boxes can be easily pulled out of the holder and be quickly refilled outside. This

again guarantees you easy work with your MCS I, as well as a high capacity of

throughput before next refill. The cover glass box has to be refilled, when the MCS I

warns you with muted beep tones (at about 5% remaining pieces) – But the machine

will continue working until it finally doesn't have no further covers glass pieces. Then it

shows up an empty-problem, so now it is quite necessary to fill up the CG-box. To refill

the box, go on like shown in the next pictures. If the MCS I still works, just stop a

running process with the „BREAK“ key, to release the cover and hold all movements.

Only operate coverglass of high quality, that doesn‘t bring up

sticking problems, to ensure an optimized progress!

Manual_MCS_I_2021-10-002.00_EN.docx 19

3.8.2 COVERGLASS POSITIONING

To adjust your coverglass more to the front or

more back on the slides, just press “SETUP” to get

into the SETUP menu. Then press “Change CG”.

The MCS I will go to a special position and release

the hood to have best possibility to adjust the

coverglass container to the CG-Head.

As shown in the left picture, by turning the

adjusting-wheel, the coverglass-box will go more to

the front or more to the back.

Be careful and read attentively!!!

Due to the fact, that the CG-Head has to get into

the coverglass box without crash, it is strictly

necessary to adjust also the CG-Head to the new

position of the coverglass box!!!

Read and follow the next step before leaving

the adjustment function if you changed the

position of the coverglass box!!!

To Check with your fingers, if space to get

into the coverglass box in front and on the

backside is equal so it should be perfect for

the CG-Head to get inside the box.

Read and follow the next step before

leaving the adjustment function if you

changed the position of the coverglass

box!

20 Manual_MCS_I_2021-10-002.00_EN.docx

The CG-Head can also be adjusted by

just turning the adjustment-wheel (in

the upper area) as seen in the left

picture. So here again is the

information, to check with your fingers,

if space to get into the coverglass box

in front and on the backside is equal so

it should be perfect for the CG-Head to

get inside the box. See it in this picture:

The picture on the right again shows the

adjustment-wheel for the coverglass position.

When the position is perfectly adjusted, you

will need to check, if the separation pressure

(bending the coverglass) (fig. 1) is optimized

to your coverglass, as every glass has different

flexibility and separation characteristics! This

is explained in the next step

Table of contents

Other Slee Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Ebmpapst

Ebmpapst R3G250-AY15-K1 operating instructions

FRONIUS

FRONIUS OPT/i TWIN SyncBox operating instructions

StoneAge

StoneAge AUTOBOX ABX-2L user manual

Alfalaval

Alfalaval BaseLine M instruction manual

Delta

Delta DTM Series manual

Premier Manufacturing Co.

Premier Manufacturing Co. 235SM Installation, Inspection, Operation & Maintenance Guide