StoneAge AUTOBOX ABX-2L User manual

PL602 REV C

(05/2015)

AUTOBOX®(ABX-2L)

USER MANUAL

2866-795-1586 • WWW.STONEAGETOOLS.COM

MANUFACTURER’S INFORMATION................................................................ 3

SPECIFICATIONS ........................................................................................ 3

DESCRIPTION OF EQUIPMENT AND INTENDED USE ................................... 3

KEY FEATURES........................................................................................... 3

CE DECLARATION OF INCORPORATION ..................................................... 4

WARNING AND SAFETY INSTRUCTIONS ....................................................... 5

OPERATOR TRAINING................................................................................. 5

PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS.............................. 5

SAFETY LABEL DEFINITIONS....................................................................... 5

PRE-RUN SAFETY CHECK .......................................................................... 6

SYSTEM ASSEMBLY - OVERVIEW .................................................................. 7

LIGHTWEIGHT POSITIONER - OVERVIEW ..................................................... 8

LIGHTWEIGHT POSITIONER CLAMP SELECTION......................................... 9

LIGHTWEIGHT POSITIONER SET-UP............................................................ 10

GUIDE ASSEMBLY - OVERVIEW ..................................................................... 12

GUIDE ASSEMBLY SET-UP .......................................................................... 13

GUIDE ASSEMBLY TO LIGHTWEIGHT POSITIONER ..................................... 14

ABX-2L HOSE TRACTOR - OVERVIEW ........................................................... 15

ABX-2L HOSE TRACTOR DOORS & PIN....................................................... 16

ABX-2L HOSE TRACTOR DRIVE ROLLERS .................................................. 17

ABX-2L HOSE TRACTOR TO GUIDE ASSEMBLY .......................................... 18

CONTROL BOX - OVERVIEW........................................................................... 19

CONTOL BOX SET-UP................................................................................. 20

CONTOL BOX AIR SUPPLY FITTING............................................................. 21

CONTROL BOX TO ABX-2L HOSE TRACTOR ASSEMBLY............................. 22

OPERATION...................................................................................................... 23

COLLET INSERTION, HOSE, AND HOSE STOP INSTALLATION ..................... 23

CONTROL BOX, TEST RUN, AND RUN PROCEDURES................................. 24

HIGH PRESSURE HOSE AND HOSE CLAMP................................................ 24

STORAGE, TRANSPORTATION, AND HANDLING ........................................... 24

MAINTENANCE ................................................................................................ 25

PARTS DIAGRAMS........................................................................................... 26

TERMS AND CONDITIONS .............................................................................. 32

TABLE OF CONTENTS

3

866-795-1586 • WWW.STONEAGETOOLS.COM

StoneAge Inc.

466 S. Skylane Drive

Durango, CO 81303, USA

Phone: 970-259-2869

Toll Free: 866-795-1586

www.stoneagetools.com

Andrew Birt Consulting Ltd.

UK

This manual must be used in accordance with all applicable national laws. The manual shall be regarded as a part of the machine

and shall be kept for reference until the nal dismantling of the machine, as dened by applicable national law(s).

DESCRIPTION OF EQUIPMENT AND

INTENDED USE

The ABX-2L System consists of the ABX-2L Hose Tractor, Control

Box, Guide Assembly, and Lightweight Positioner. This system

was developed for “Hands Free” heat exchanger tube cleaning

applications. It is recommended to be used with StoneAge’s

Banshee line of self-rotary waterblast tools.

The ABX-2L System was designed to accommodate two

simultaneous ex lances ranging in size from 3/2 to 8/4 matched

with the appropriate BN9.5, BN13, BN15, or BN18 size Banshees.

The ABX-2L Hose Tractor utilizes six synchronized drive rollers to

control the rate at which the hose and Banshee tools are advanced

or retracted inside the tube.

The Guide Assembly provides anti-withdrawal protection, and

precise tube pitch adjustment. The Lightweight Positioner can

be mounted to a variety of heat exchanger tube bundles and has

pneumatic powered horizontal and vertical drives.

The Control Box is small and lightweight with an emphasis on

ergonomics. The ABX-2L system was designed with simplicity,

safety, lightweight components, durability, and reliability in mind. It

can be easily carried to the jobsite and setup in minutes.

The AUTOBOX® (ABX-2L) must not be put into service within the

European Community (“EC”) until the nal machinery into which

it is to be incorporated has been declared in conformity with the

Machinery Directive and all other applicable EC Directives.

KEY FEATURES:

Lightweight Positioner

• Modular, lightweight design

• Quick install drive carriages

• Utilizes 2.5 in. (6 mm) box rail

• Stainless Steel air motors

• Variety of clamp and bolt-on attachment options are available

Guide Assembly

• Compact and lightweight design

• Turn knob control provides precise pitch adjustment

• Quick change guide tubes are common material

• 17-4 SS hose stop collets

ABX-2L Hose Tractor

• Six powered drive rollers ensure traction in all

operating conditions

• Quick change drive rollers (two sizes).

• Lightweight and compact design

• Can be used in dual or single lance applications

• Quick pin attachment to guide assembly

• Hinged side doors for easy access to rollers and

drive components

• Independent forward/reverse speed controls

Control Box

• Small, lightweight, ergonomic design that includes a

portable stand and lter-regulator-lubricator assembly

• Tractor controls: forward/reverse hose feed and clamp pressure

• Positioner controls: left/right and up/down

• Pneumatic dump control switch

SPECIFICATIONS

ABX-2L Hose Tractor Weight:

ABX-2L Hose Tractor Size:

Maximum Feed Rate:

Minimum Feed Rate:

Maximum Push/Pull Force:

Mininimum Push/Pull Force:

Manway Access:

Lightweight Positioner Weight:

Guide Assembly Weight:

Pitch Adjustment Range:

Control Box Weight:

Maximum Air Supply Pressure:

System Operating Pressure:

Recommended Operational Temperature Range

42 lbs (19.05 kg) (ABX-2L box only)

7.2 in. wide x 8.3 in. Tall x 16.7 in. Long

(183 mm wide x 211 mm Tall x 424 mm Long)

3.0 ft/sec (914 mm/sec)

0.2 ft/sec (61 mm/sec)

60 lbs (30 lbs per lance) (27.2 kg, 13.6 kg per lance)

10 lbs (5 lbs per lance) (4.5 kg)

18 in. (457 mm)

120 lbs (54.4 kg)

(Includes 6ft rails, horiz., vert., and idler carriage, and 4 clamps)

10 lbs (4.5 kg)

5/8-2.4 in. (16 mm- 61 mm)

43 lbs (19.5 kg) (Includes Control Box, FRL, and stand)

140 psi (0.97 MPa)

100 psi (0.70 MPa)

-20 °F to 140 °F (-29 °C to 60 °C)

MANUFACTURER’S INFORMATION

4866-795-1586 • WWW.STONEAGETOOLS.COM

CE DECLARATION OF INCORPORATION

OF PARTLY COMPLETED MACHINERY

We: StoneAge, Inc. 466 South Skylane Drive Durango, CO 81303, USA

Declare that this “partly completed machinery” supplied with this declaration:

Equipment: AUTOBOX® Hose Tractor

Model name: ABX-2L Is in accordance with the following Directives: and

• is designed and manufactured solely as a non-functional component to be incorporated into a machine requiring completion;

• must not be put into service within the European Community (“EC”) until the nal machinery into which it is to be incorporated

has been declared in conformity with the Machinery Directive and all other applicable EC Directives; and

• is designed and manufactured to comply with the 2006/42/EC Essential Health and Safety Requirements of the Machinery

Directives and the relevant parts of the following specications:

EN ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk reduction

I hereby declare that the equipment named above has been tested and found to comply with the relevant sections of the above

referenced specications and directives.

Signed ______________________________________________________ Date _ 03/03/2015_______

Andrew Birt

Independent Dealer Manager

StoneAge, Inc., Worcester, UK

The technical le for the AUTOBOX® Hose Tractor (ABX-2L) User Manual is maintained at: StoneAge, Inc. 466 South Skylane Drive,

Durango, CO 81303, USA

5

866-795-1586 • WWW.STONEAGETOOLS.COM

OPERATOR TRAINING

Managers, Supervisors, and Operators MUST be trained in Health

and Safety Awareness of High-pressure Water Jetting and hold

a copy the Water Jetting Association (WJA) Code of Practice, or

equivalent (see www.waterjetting.org.uk).

Operators MUST be trained to identify and understand all applicable

standards for the equipment supplied. Operators should be trained

in manual handling techniques to prevent bodily injury.

Operators MUST read, understand, and follow the Operational and

Training Requirements (Section 7.0) of WJTA-IMCA’s Recommended

Practices For The Use Of High-pressure Waterjetting Equipment, or

equivalent.

Operators MUST read, understand and follow the Warnings,

Safety Information, Assembly, Installation, Connection, Operation,

Transport, Handling, Storage, and Maintenance Instructions detailed

in this manual.

StoneAge has designed and manufactured this equipment

considering all hazards associated with its operation. StoneAge

assessed these risks and incorporated safety features in the design.

StoneAge WILL NOT accept responsibility for the results of misuse.

IT IS THE RESPONSIBILTY OF THE INSTALLER/OPERATOR to

conduct a job specic risk assessment prior to use. Job specic risk

assessment MUST be repeated for each different set up, material,

and location.

The risk assessment MUST conform to the Health and Safety at

Work Act 1974 and other relevant Health and Safety legislation.

The risk assessment MUST consider potential material or substance

hazards including:

• Aerosols

• Biological and microbiological (viral or bacterial) agents

• Combustible materials

• Dusts

• Explosion

• Fibers

• Flammable substances

• Fluids

• Fumes

• Gases

• Mists

• Oxidizing Agents

WARNING AND SAFETY INSTRUCTIONS

PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS

Use of Personal Protective Equipment (PPE) is dependent on

the working pressure of water and the cleaning application.

Managers, Supervisors, and Operators MUST carry out a job

specic risk assessment to dene the exact requirements for PPE.

See Protective Equipment for Personnel (Section 6) of WJTA-

IMCA’s Recommended Practices For The Use Of High-pressure

Waterjetting Equipment for additional information.

Hygiene - Operators are advised to wash thoroughly after all

waterjetting operations to remove any waterblast residue which may

contain traces of harmful substances.

First aid provision - users MUST be provided with suitable rst aid

facilities at the operation site.

PPE may include:

• Eye protection: Full face visor

• Foot protection: Kevlar® brand or steel toe capped,

waterproof, non-slip safety boots

• Hand protection: Waterproof gloves

• Ear protection: Ear protection for a minimum of 85 dBA

• Head protection: Hard hat that accepts a full face visor and

ear protection

• Body protection: Multi-layer waterproof clothing approved for

waterjetting

• Hose protection: Hose shroud

• Respiratory protection: May be required; refer to job specic

risk assessment

SAFETY LABEL DEFINITION

The ABX-2L Hose Tractor has the potential

to cause serious injury if ngers, hair, or

clothing become caught between the

hose rollers or drive belts.

DO NOT OPERATE WITH THE DOORS

OPEN. ENSURE THAT ALL FOUR

DOOR PINS ARE SECURED PRIOR TO

OPERATION.

Maximum operating pressure is100

psi (0.7 MPa). Never exceed 140

psi (0.97 MPa) supply pressure.

Exceeding 140 psi (0.97 MPa) supply

pressure may result in injury to the

Operator and/or damage to the

equipment.

6866-795-1586 • WWW.STONEAGETOOLS.COM

WARNING

Operations with this equipment can be potentially hazardous.

Caution MUST be exercised prior to and during machine and water

jet tool use. Please read and follow all of these instructions, in addition

to the guidelines in the WJTA Recommended Practices handbook,

available online at www.wjta.org. Deviating from safety instructions

and recommended practices can lead to severe injury and/or death.

• Do not exceed the maximum operating pressure specied for

any component in a system.

• The immediate work area MUST be marked off to keep out

untrained persons.

• Inspect the equipment for visible signs of deterioration,

damage, and improper assembly. Do not operate if damaged,

until repaired.

• Make sure all threaded connections are tight and free of leaks.

• Users of the ABX-2L Hose Tractor MUST be trained and/

or experienced in the use and application of high-pressure

technology and cleaning, as well as all associated safety

measures, according to the WJTA Recommended Practices

for the use of High-pressure Waterjetting Equipment.

• An anti-withdrawal device (back-out preventer) MUST be used

at all times. The back-out prevention device is the Hose Stop

Collet located within the Hose Guide Assembly. StoneAge

offers several different size Hose Stop Collets. The Collet Size

Reference guide is located on the Hose Guide Assembly.

• The Control Box should be located in a safe location where the

Operator has good visibility of the pipe and hose. The ABX-2L

Hose Tractor and Control Box MUST be supervised at all times

and should never be left unattended.

• Test the Control Box before operating the ABX-2L Hose Tractor

with high-pressure water to verify the control valves move the

hose in the intended direction, and that the dump valve and

hose clamp are working properly.

• Do not fully release the hose clamp (decreasing pressure to

zero) during operation, or the ABX-2L Hose Tractor will release

the hose and may create a dangerous runaway hose condition,

which can result in severe injury and/or death.

• Always de-energize the system before opening the door to

service or replace any parts. Failure to do so can result in severe

injury and/or death.

• When moving the ABX-2L Hose Tractor lift with care to prevent

bodily injury.

• Do not operate the ABX-2L Hose Tractor while either side door

is open.

PRE-RUN SAFETY CHECK

Refer to WJTA-IMCA’s, Recommended Practices For The Use Of

High-pressure Waterjetting Equipment and/or The Water Jetting

Association’s, WJA Code of Practice for additional safety information.

• Complete a job specic risk assessment and act on the resulting

actions.

• Adhere to all site specic safety procedures.

• Ensure the waterblasting zone is properly barricaded and that

warning signs are posted.

• Ensure the work place is free of unnecessary objects (e.g. loose

parts, hoses, tools).

• Ensure all Operators are using the correct Personal Protective

Equipment (PPE).

• Check that the air hoses are properly connected and tight.

• Check all hoses and accessories for damage prior to use. Do

not use damaged items. Only high quality hoses intended for

waterblast applications should be used as high-pressure hoses.

• Check all high-pressure threaded connections for tightness.

• **Ensure that a anti-withdrawal device (back-out

preventer), whip checks (hose whips), and all other

applicable safety devices are installed and set-up

properly.**

• Ensure the doors of the ABX-2L Hose Tractor are closed and

securely latched.

• Test the Control Box before operating the ABX-2L Hose Tractor

with high-pressure water to verify the control valves move the

hose in the intended direction, and that the dump valve and hose

clamp are working properly.

• Ensure that Operators never connect, disconnect, or tighten

hoses, adaptors, or accessories with the high-pressure water

pump unit running.

• Ensure no personnel are in the hydroblasting zone.

WARNING AND SAFETY INSTRUCTIONS

7

866-795-1586 • WWW.STONEAGETOOLS.COM

LIGHTWEIGHT POSITIONER, GUIDE ASSEMBLY,

ABX-2L HOSE TRACTOR AND CONTROL BOX SYSTEM ASSEMBLY

CONTROL BOX

(SEE PAGES 19, 20, 21, 22) ABX-2L HOSE TRACTOR

(SEE PAGES 15, 16, 17, 18)

LIGHTWEIGHT POSITIONER

(SEE PAGES 8, 9, 10, 11)

GUIDE ASSEMBLY

(SEE PAGES 12, 13, 14)

HOSES RUN TO

HIGH PRESSURE

SUPPLY

NOTE: Heat exchanger tube

bundle face, shown for

graphic representation only.

Not included in assembly.

SYSTEM ASSEMBLY - OVERVIEW

8866-795-1586 • WWW.STONEAGETOOLS.COM

LIGHTWEIGHT POSITIONER

HORIZONTAL

DRIVE

ASSEMBLY

VERTICAL

DRIVE

ASSEMBLY

VERTICAL

SLOTTED

RAIL

HORIZONTAL

SLOTTED RAIL

POSITIONER

CONTROL LINE

ASSEMBLY

RAIL STOP

ASSEMBLY

NON-SLOTTED RAIL

BLANK HORIZONTAL

ASSEMBLY

RAIL STOP ASSEMBLIES

RAIL EXTENTIONS

(2,4, OR 6 FT LENGTHS)

(.61 m, 1.2 m, OR 1.8 m)

SLOTTED

QUICK CLAMP

CLAMP TYPES

QUICK CLAMP

PLATE CLAMP

25 FT / 7.6 m

STANDARD

LENGTH

LIGHTWEIGHT POSITIONER - OVERVIEW

9

866-795-1586 • WWW.STONEAGETOOLS.COM

CLAMP SELECTION

Is dependent upon the heat exchanger geometry, bolt holes, hole spacing,

and ange accessibility.

QUICK CLAMPS

Use if heat exchanger ange provides a robust clamping surface or if

ange holes are inaccessible. Align clamps on the surface of the ange to

maximize ange engagement to clamps. (Figure 2)

SLOTTED QUICK AND PLATE CLAMPS

Use if heat exchanger ange has bolt holes that are easily accessible.

Use quick clamps or plate clamps, depending on the spacing of the hole

pattern. (Figures 1 & 3)

SLOTTED QUICK

CLAMP

QUICK CLAMP

PLATE CLAMP

CLAMP TYPES

FIGURE 1 FIGURE 2 FIGURE 3

LIGHTWEIGHT POSITIONER CLAMP SELECTION

10 866-795-1586 • WWW.STONEAGETOOLS.COM

1. Mount the appropriate frame Positioner Clamps to the tube

bundle as shown on the previous page. (Shown in Figure

1 with Slotted Quick Clamps) Positioner Clamps should be

aligned horizontally with the direction of the tube rows. (Figure

1)

NOTE: Heat exchanger tube bundle face, shown for

graphic representation only. Not included in assembly.

2. Insert the Top Rail (slots facing out) into the upper mounting

brackets. If the rail is not closely aligned with the tube rows,

loosen one of the upper mounting brackets and adjust until

the top rail is parallel with the horizontal tube rows. Tighten the

clamps securing the rail to the mounting brackets, and ensure

upper mounting brackets are securely clamped or bolted to

the tube bundle ange. (Figure 2)

3. Insert the Lower Rail (non-slotted) into the lower mounting

brackets. It is not critical that this rail is aligned as precisely as

the top rail, but it should be close to parallel with the top rail for

best performance. Tighten the clamps securing the rail to the

mounting brackets, and ensure lower mounting brackets are

securely clamped or bolted to the tube bundle ange. (Figure

3)

4. Loosen the Quick Adjust Handle and pull the gearbox away

from the carriage plate. This will allow the Horizontal Drive

Carriage to slide onto the rail without pneumatic power to

rotate the drive. Center the carriage on the top rail and push

the gearbox back toward the carriage plate. This will engage

the gear into the rail slots. Verify the gear is engaging the slots

correctly and retighten the adjustable handle. (Figure 4)

LIGHTWEIGHT POSITIONER STEP BY STEP SET-UP

LIGHTWEIGHT POSITIONER SET-UP

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

11

866-795-1586 • WWW.STONEAGETOOLS.COM

5. Slide the Idler Carriage onto the Lower Non-Slotted Rail.

(Figure 5)

6. Loosen the Large Adjustable Handle for the Vertical Rail

Clamp.Align the Idler Carriage with the vertical rail clamp on

the horizontal carriage. Install the Vertical Rail with (slots

facing out) down through the horizontal carriage clamp

and between the rollers on the idler carriage. Adjust the

position of the vertical rail as required and secure the clamp

on the horizontal carriage by tightening the large adjustable

handle. (Figure 6)

7. Loosen the Quick Adjust Handle and pull the gearbox

away from the carriage plate. This will allow the Vertical

Drive Carriage to slide onto the rail without pneumatic

power to rotate the drive. Center the carriage on the vertical

rail and push the gearbox back toward the carriage plate.

This will engage the gear into the rail slots. Verify the gear

is engaging the slots correctly and retighten the adjustable

handle. (Figure 7)

8. Install the four Rail Stops at both ends of the top, slotted,

horizontal rail, and both ends of the vertical slotted rail.

(Figure 8)

NOTE: Verify the mounting brackets and rail clamps

are securely tightened and that the drive carriages

are securely engaged and the adjustable handles are

tightened.

Never loosen the vertical gearbox once the guide

assembly and tractor are installed, as it may result in the

carriage falling vertically down. This may cause damage

and/or injury.

LIGHTWEIGHT POSITIONER SET-UP

FIGURE 5

FIGURE 6

FIGURE 7

FIGURE 8

12 866-795-1586 • WWW.STONEAGETOOLS.COM

COLLET REFERENCE

GUIDE

COLLET

(MULTIPLE SIZES)

HOSE STOP CLAMPS

(MULTIPLE SIZES)

GUIDE TUBES

(MULTIPLE SIZES)

MOUNTING

BRACKET

PITCH ADJUST KNOB

QUICK RELEASE PIN

GUIDE TUBE

ADAPTER SCREWS

TUBE CLAMP

HOUSING

GUIDE ASSEMBLY

GUIDE ASSEMBLY - OVERVIEW

13

866-795-1586 • WWW.STONEAGETOOLS.COM

GUIDE ASSEMBLY

1. Select the appropriate Guide Tube size and length for the

application. The length of the Guide Tubes for an exchanger

bundle with no channel head is 12.5 in. (318 mm). The guide

tube assembly has approximately 5 in. (127 mm) of adjustment.

A deeper channel head will require extended Guide Tubes.

The depth of the channel head added to the 12.5 in. (318 mm)

length will give the desired tube length. Longer guide tubes

are available if required for use with channel heads. Note: The

Banshee tool should not have excessive clearance if the correct

length Guide Tube size is used.

2. To remove the existing Guide Tubes, loosen the Tube Clamp

Bolt and the two 3/16 in. Socket Head Cap Screws (SHCS)

located on top of the Guide Assembly. After selecting the

appropriate guide tubes, install the Guide Tubes into the Guide

Assembly.

3. Secure the Guide Tubes by tightening the two 3/16 in. SHCS.

2

1

3

*NOTE: BN9.5 guide tubes ( Ø.625 in. / 6 mm O.D.) require

an ABX 114 adapter. BN18 guide tubes require an ABX 124

to be installed into the Guide Assembly.

WARNING

Appropriate size Collet selection is critical to ensuring proper

backout prevention of the tool.

GUIDE ASSEMBLY SET-UP

StoneAge (SA) PART NUMBER

COLLET REFERENCE CHART

SA PART NUMBER COLLET SIZE

ABX 121-297 .297 in. / 8 mm

ABX 121-328 .328 in. / 8 mm

ABX 121-406 .406 in. / 10 mm

ABX 121-438 .438 in. / 11 mm

ABX 121-460 .460 in. / 12 mm

ABX 121-484 .484 in. / 12 mm

ABX 121-516 .516 in. / 13 mm

ABX 121-547 .547in. / 14 mm

ABX 121-594 .594 in. / 15 mm

ABX 121-625 .625 in. / 16 mm

StoneAge (SA) PART NUMBER

GUIDE TUBE REFERENCE CHART

SA PART NUMBER SA TOOL INSIDE DIAMETER, LENGTH

ABX 115-12 *BN9.5 .459 in / 12 mm, 12.5 in. / 318 mm

ABX 115-36 *BN9.5 .459 in / 12 mm, 36 in. / 914 mm

ABX 116-12 BN13 .546 in / 14 mm, 12.5 in. / 318 mm

ABX 116-36 BN13 .546 in / 14 mm, 36 in. / 914 mm

ABX 117-12 BN15 .674 in / 17 mm, 12.5 in. / 318 mm

ABX 117-36 BN15 .674 in / 17 mm, 36 in. / 914 mm

ABX 119-12 *BN18 .745 in / 19 mm, 12.5 in. / 318 mm

ABX 119-36 *BN18 .745 in / 19 mm, 36 in. / 914 mm

StoneAge (SA) PART NUMBER

HOSE STOP CLAMP REFERENCE CHART

SA PART

NUMBER HOSE DIAMETER

HS 121-27-34 .27-.34 in. / 7-9 mm

HS 121-34-42 .34-.42 in. / 9-11 mm

HS 121-42-50 .42-.50 in. / 11-13 mm

HS 121-50-56 .50-.56 in. / 13-14 mm

HS 121-56-61 .56-.61 / 14-16 mm

14 866-795-1586 • WWW.STONEAGETOOLS.COM

1

2

GUIDE ASSEMBLY TO LIGHTWEIGHT POSITIONER SET UP

ATTACH GUIDE ASSEMBLY TO LIGHTWEIGHT POSITIONER

1. Using a 9/16 in. wrench, loosen all four rail clamp bolts located on the vertical carriage. Install the Guide Assembly into the rail

clamps and adjust position until the Guide Tubes are approximately 1/2 in. (13 mm) away from the tube sheet face. Tighten the

four rail clamp bolts.

2. Turn the pitch adjustment knob until the guide tubes are at the same pitch as the tubes in the bundle. Adjust the Tube Clamp

Bolt until the Guide Tubes are resting in the bottom of the “V” blocks. Make any ne adjustment to the Guide Tube pitch if

required and tighten the Tube Clamp Bolt.

NOTE: Over-tightening the Tube Clamp may damage thin wall guide tubes.

ABX 114 ADAPTER FOR BN9.5

( Ø.625 in. / 6 mm O.D.)

Guide Tubes

ABX 124 ADAPTER FOR BN18

( Ø.875 in. / 22 mm O.D.)

Guide Tubes

NOTE:

Adjust position until

the Guide Tubes are

approximately 1/2 in.

(13 mm) away from the

tube sheet face.

15

866-795-1586 • WWW.STONEAGETOOLS.COM

AUTOBOX®(ABX-2L) HOSE TRACTOR

HANDLE

FORWARD

AND REVERSE

SPEED

CONTROLS

DOOR PIN

COLOR CODED

JIC FITTINGS

WITH DUST CAPS

MOUNTING

BRACKET

FOR GUIDE

ASSEMBLY

MOUNTING

BRACKET

DRIVE ROLLERS

DOOR

PNEUMATIC SUPPLY LINES

25 FT / 7620 mm

ABX-2L HOSE TRACTOR - OVERVIEW

16 866-795-1586 • WWW.STONEAGETOOLS.COM

DOOR

Always run the ABX-2L Hose Tractor with the doors closed and locked.

DOOR PIN

The Door Pin is a spring plunger with a pull ring. To unlock the door, pull and twist the pull

ring, then release it so that it is no longer in the groove. Close the door by raising it into

position. To lock the door, pull and twist the pull ring, then release it into the groove of the pin.

NOTE: Make sure to lock both doors on each side of the Hose Tractor before operating

ABX-2L Hose Tractor.

LOCKED

UNLOCKED

DOOR

PIN DOOR

PINS

CLOSED DOOR

POSITION

OPEN DOOR

POSITION

ABX-2L HOSE TRACTOR - DOORS & PIN

17

866-795-1586 • WWW.STONEAGETOOLS.COM

WARNING

Always de-energize the system before servicing or replacing any parts. Failure to do so can result in severe injury and/or death.

Keep hands, hair, and clothing clear of rotating parts.

TO REPLACE THE DRIVE ROLLERS:

1. Select the correct roller size for the particular hose being used:

• ABX 271 (DARK GRAY/BLACK) rollers should be used with 5 mm and 6 mm I.D. hoses.

The O.D. range for the ABX 271 roller is .44-.50 in (11 mm - 13 mm)

• ABX 272 (ORANGE) rollers should be used with 3 mm and 4 mm I.D. hoses.

The O.D. range for the ABX 272 is .27-.41 in (7 mm - 10 mm)

2. Slowly run the Drive Rollers in order to orient the key ways of the Drive Rollers upward and the spring plungers downward.

NOTE: Rollers should be removed with the keyway facing up to prevent losing keys.

3. Use a small common screwdriver or similar tool to depress the ball spring plunger, and pull the rollers straight out from the shafts.

4. Prior to reinstalling the Drive Rollers onto the shafts, apply a liberal coat of Anti-seize to the shaft OD and keys.

We recommend Mariners Choice Never-Seez®.

5. Reinstall the rollers by sliding into place until the spring plungers snap out.

NOTE: Rollers should be installed with the keyway facing up to prevent losing keys.

6. Once the correct rollers are installed, close and lock the doors. The Hose Tractor can now be installed onto the Guide Assembly.

ABX 271 (DK GRAY/BLACK)

DRIVE

ROLLERS (X6)

ABX 272 (ORANGE)

SPRING PLUNGER

ORIENTATION

KEY WAY

ABX-2L HOSE TRACTOR - DRIVE ROLLERS

18 866-795-1586 • WWW.STONEAGETOOLS.COM

ATTACH ABX-2L HOSE TRACTOR TO GUIDE ASSEMBLY

1. Remove the lower quick release pin from the ABX-2L Hose Tractor.

2. Slide the mounting bracket over the block on the Guide Assembly and lay the pin onto the top slot on the Guide Assembly block.

3. Install the lower pin through the mounting bracket on the Hose Tractor and the block on the Guide Assembly.

1

3

2

The tractor is now

securely mounted to the

Guide Assembly

ABX-2L HOSE TRACTOR TO GUIDE ASSEMBLY

19

866-795-1586 • WWW.STONEAGETOOLS.COM

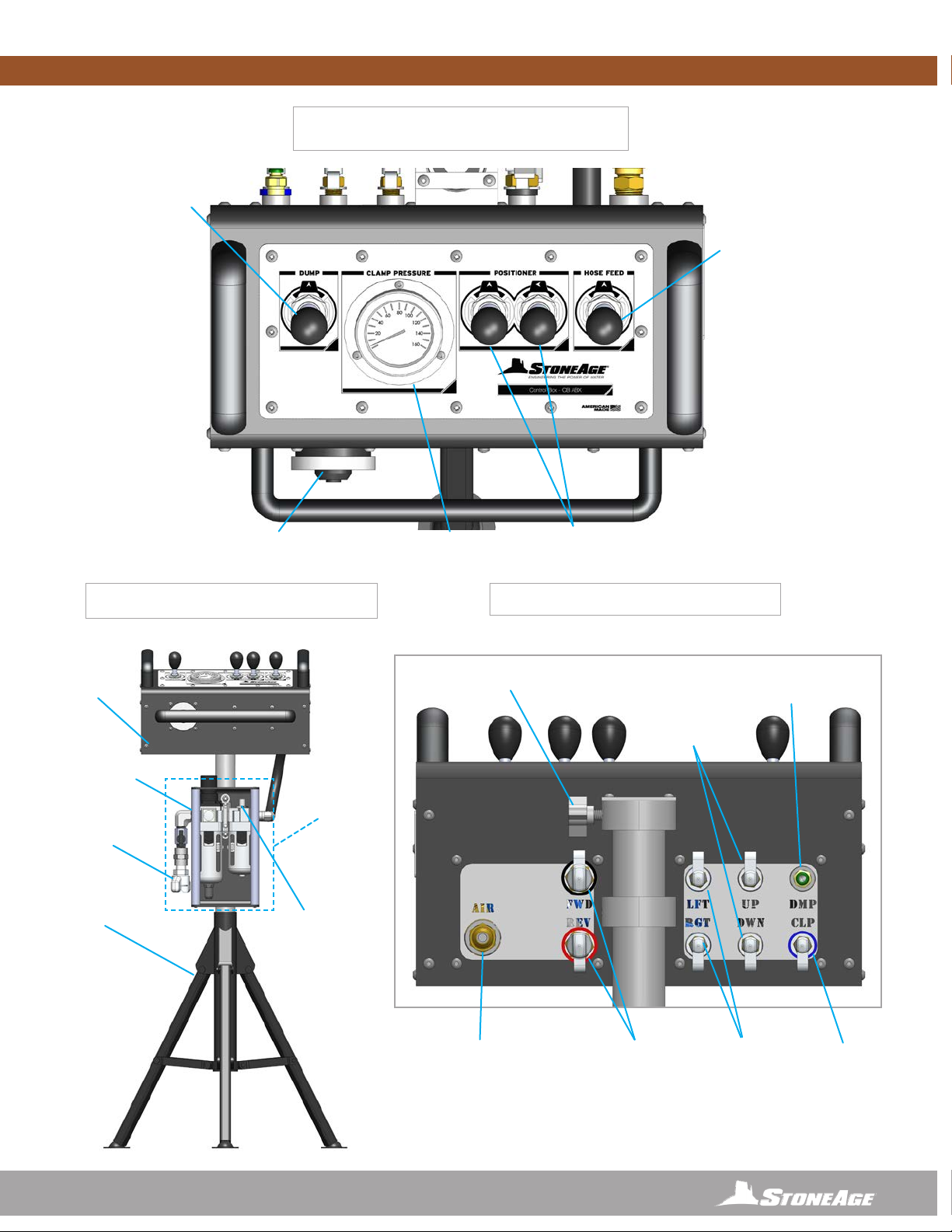

AIR SUPPLY

FITTING

WITH DUST CAP

1/4” (6.35 mm) PUSH CONNECT

PNEUMATIC DUMP

CONTROL FITTING

INLET AIR

FITTING

TRIPOD

LEGS

PRESSURE

REGULATOR

MAIN BOX

FRAME

COLOR CODED

JIC FITTING

WITH DUST CAP

COLOR CODED

JIC FITTINGS

WITH DUST CAPS

VERTICAL

POSITIONER

FITTINGS

WITH DUST CAPS

POLE MOUNT

WITH THUMB SCREW

HORIZONTAL

POSITIONER

FITTINGS

WITH DUST CAPS

HOSE FEED

LEVER

HOSE CLAMP

PRESSURE REGULATOR

HOSE CLAMP

PRESSURE GAUGE

POSITIONER

CONTROLS

MOMENTARY

PNEUMATIC

DUMP CONTROL

INLINE OILER

FEED

ADJUSTMENT

FILTER,

REGULATOR,

LUBRICATOR

CONTROL BOX

FRONT VIEW

CONTROL BOX

TOP VIEW

CONTROL BOX

REAR VIEW

CONTROL BOX - OVERVIEW

20 866-795-1586 • WWW.STONEAGETOOLS.COM

THUMBSCREW

KNOB

TUBE

INSERT

THUMBSCREW

KNOB

(ALIGN WITH

PRE-DRILLED

HOLE ON

TUBE INSERT)

THUMBSCREW

KNOB

(ALIGN WITH

PRE-DRILLED

HOLE ON

TUBE INSERT)

FILTER, REGULATOR,

LUBRICATOR, ASSEMBLY

(FRL)

2

1

3

5

4

CONTROL BOX SET-UP

ASSEMBLE CONTROL BOX, FRL, AND TRIPOD BASE

1. Setup the tripod base in a location with good visibility to the

bundle face, but at a safe distance away from waterblast zone.

2. Slide the vertical tube into the tripod base. Secure with the

supplied thumbscrew knob. Note: The vertical tube has a hole

through one wall that the thumbscrew must engage.

3. Slide the Filter, Regulator, Lubricator (FRL) assembly over the

vertical tube down to the tripod base. Secure with the supplied

thumbscrew knob.

Note: The vertical tube has a hole through one wall that

the thumbscrew must engage.

4. Slide the Control Box over the vertical tube. The Control Box

has a stop that keeps it located at the top of the vertical tube.

Secure with the supplied thumbscrew knob.

5. Install and tighten the short 1/2 in. (13 mm) I.D. hose between

the FRL and the Control Box.

Table of contents

Other StoneAge Industrial Equipment manuals