Foreword

DTM temperature controller operating manual

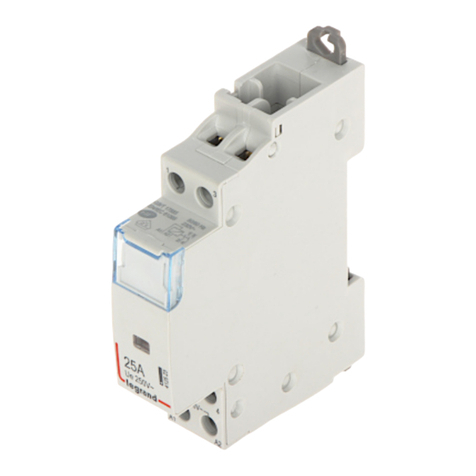

dapplication de ce produit doit donc avoir un

interrupteur ou un disjoncteur, et linterrupteur ou

le disjoncteur doit être dans des endroits facilement accessibles aux opérateurs et avoir des

marquages marche-arrêt clairement visibles.

Pour éviter le danger causé, dans la même cassette dextension ou le même module dextension

E / S, lorsquun canal est connecté à une haute tension, les autres canaux ne peuvent pas être

connectés à un circuit basse tension de sécurité.

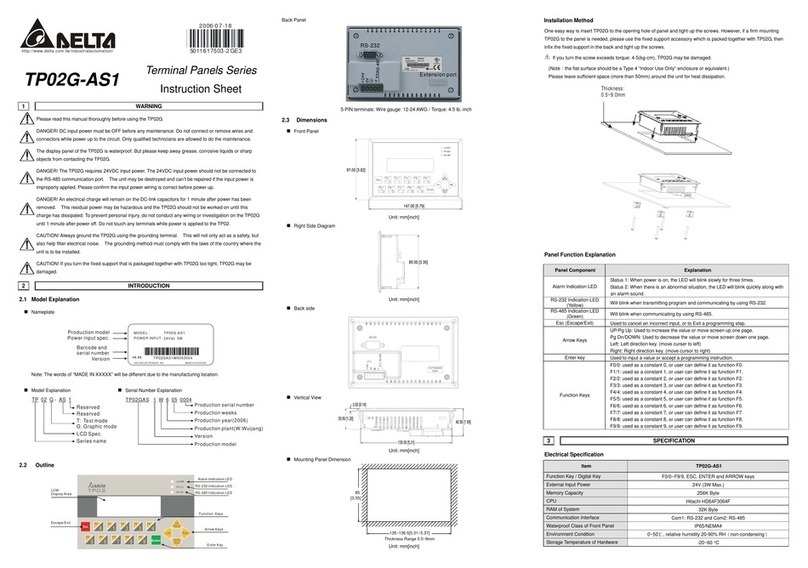

1. Please use needle-type terminals with front-end crimping areas with a diameter smaller than

2.35mm. Avoid using excessive force when attaching wires to the terminals, and confirm that

wires are attached to the correct terminals.

2. If any dust or metal shavings get into the body of the device, this may cause faulty operation;

please install in a dustproof, moisture-resistant, shock/impact-resistant electrical case before

use.

3. Modifying or disassembling this controller without authorization may cause unforeseeable

errors or hazards. Do not use any extra empty terminals.

4. To avoid interference, avoid places with high voltages, high-frequency noise, or high electrical

currents during installation.

5. Avoid using this device in places where the following situations may occur:

(a) Where there are high levels of dust or corrosive or flammable gases; (b) High humidity

and condensation; (c) Vibration and impacts; (d) High radiation.

6. Make sure to turn off power before installing wiring or changing the temperature controller.

7. When extending or attaching thermocouple lead wires, be sure to use compensating lead

wires compatible with the thermocouple type.

8. When using three-wire type platinum measurement impedance body, make sure that the

diameters and lengths of the three wires are the same, which will reduce measurement error.

When extending or attaching platinum measurement impedance body lead wires, to avoid

affecting temperature values, be sure to use lead wires with the correct length and impedance.

9. To avoid interference from noise and inductance, be sure to use only short-distance wires

from temperature detectors to the body of the temperature controller. Make sure to separate

sensor wires from AC power lines and heavy load wires.

10. Before powering up the device, confirm that the power/ signal equipment are correct;

otherwise, there is risk of severe damage.

11. When powering up the device, take care not to touch or try to maintain terminals on the device,

which may cause electrical shocks.

12. When power is turned off for less than 1 min., because electricity in wires may not be fully

discharged, do not touch internal wiring or external terminals.

13. When maintaining the temperature controller, turn off power and use a dry cloth to clean the

surface of the device. To avoid damaged circuits and causing malfunction, do not open the

case and touch the internal circuits. Do not clean using acidic or alkaline liquids.

14. If using a measurement expansion module and I/O expansion module simultaneously, install

the I/O expansion module only after the measurement expansion module has been fully