SLEIPNER MOTOR AS SIDE-POWER SX35 Manual

SLEIPNER MOTOR AS

P.O. Box 519

N-1612 Fredrikstad

Norway

www.sleipnergroup.com

DOCUMENT ID:

REVISION:

DATE:

LANGUAGE:

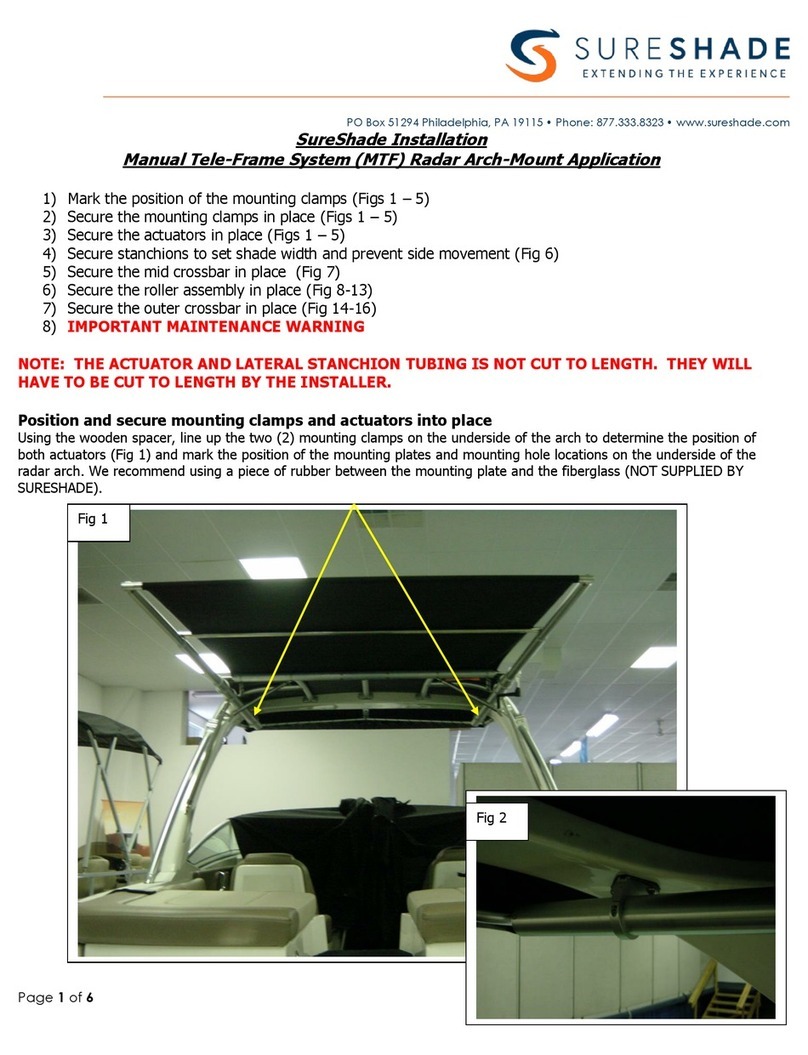

Installation Guide

For DC External Electric Thruster Models

SX35, SX50

EN

I M

5630

23

2022

25630 23 2022

-

SX35 & SX50

Sleipner Motor AS

P.O. Box 519, Arne Svendsensgt. 6-8

N-1612 Fredrikstad, Norway

MC_0020

Contents

Products

SM908124 | SX35/140-12V-50MM - SX35/140 -12V -50mm w/Controller

SM908123 | SX35/140-12V-150MM - SX35/140 - 12V -150mmw/Controller

SM908125 | SX35/140-12V-OEM02 - SX35/140 - 12V -OEM02 w/Controller

SM908126 | SX50/140-12V-150MM - SX50/140 - 12V-150mm w/Controller

SM908127 | SX50/140-12V-50MM - SX50/140 - 12V -50mm w/Controller

Installation Manual

Responsibility of the Installer................................................................................................................................................................... 3

General Installation Considerations and Precautions Guidelines ........................................................................................................... 3

Product Measurements .................................................................................................................................................................... 4 - 5

Product Specications............................................................................................................................................................................ 6

Galvanic Isolation ................................................................................................................................................................................... 6

Positioning the Stern SX Thruster .......................................................................................................................................................... 7

Guide for Stern Thruster Cowls or Grids ................................................................................................................................................ 8

Tunnel Installation .................................................................................................................................................................................. 9

SX Spacer ............................................................................................................................................................................................ 10

Motor Installation ........................................................................................................................................................................... 11 - 12

Propeller Installation............................................................................................................................................................................. 13

Grids or Cowls assembly...................................................................................................................................................................... 14

Electrical Installation............................................................................................................................................................................. 15

Control Box Installation.................................................................................................................................................................. 16 - 17

Visual Wiring Diagram........................................................................................................................................................................... 18

Control Panel Installation ..................................................................................................................................................................... 19

Pre-delivery Checklist ....................................................................................................................................................................... 20

Service and Support........................................................................................................................................................................... 21

Product Spare Parts and Additional Resources.............................................................................................................................. 21

Warranty Statement............................................................................................................................................................................ 21

The installer must read this document to ensure necessary familiarity with the product before installation.

Instructions in this document cannot be guaranteed to comply with all international and national regulations. It is the responsibility of the

installer to follow all applicable international and national regulations when installing Sleipner products.

The recommendations given in this document are guidelines ONLY, and Sleipner strongly recommends that advice is obtained from a person

familiar with the particular vessel and applicable regulations.

This document contains general installation instructions intended to support experienced installers. If you are not skilled in this type of work,

please contact professional installers for assistance.

If required by local regulation, electrical work must be done by a licensed professional.

Appropriate health and safety procedures must be followed during installation.

Faulty installation of Sleipner products will render all warranties given by Sleipner Motor AS.

MC_0038

Responsibility of the Installer

Failure to follow the considerations and precautions can cause serious injury,

damage and will render all warranties given by Sleipner Motor as VOID.

MC_0411

MC_0425

For thruster systems

• Do not install the thruster in a position where you need to cut a stiffener/ stringer/ support that may jeopardise the hull integrity without checking

with the boat builder this can be done safely.

• We advise painting the gear house and propellers with anti-fouling. (NB: Do not paint the anodes, sealing, rubber fi ttings or propeller shafts)

• There is only room for a thin coat of primer and two layers of anti-fouling between the tunnel and the props.

• Never run the thruster out of water.

MC_0440

General Installation Considerations and Precautions Guidelines

MC_0427

For SX/P35 and SX/P50 thruster systems

• Ensure that the external thruster assembly does not disturb the water flow under the hull. At higher speeds, if the thruster is installed to

low it can cause damage to the thruster and/ or add additional drag and unwanted water splashing.

• The minimum tunnel depth from the water surface is 140mm (5,51‘) to the centre of tunnel diameter. Place the Thruster as deep as possible for

better performance and reduced noise.

• When installing the thruster ensure it does not foul existing equipment inside the boat like motor bedding etc.

• If able ensure that stern-drives/ trim-tabs do not interfere with the water flow from the thruster as this can reduce the thrust effectiveness

considerably. We recommend the use of our Sleipner cowls to enhance the performance and allow installation in shallow draft boats. Sleipner

cowls will also minimise the effect if stern-drives/ trim-tabs obstruct the thruster.

• Ensure there is enough space both inside and outside the transom of the boat and the thruster does not get in conflict with existing equipment

inside the boat like steerage links etc. (NB: It is possible to mount the tunnel offset from the boat’s centre line if necessary.)

• Heat protection cut off is calculated from the thruster motor. To avoid cable overheating do not install place the volt cables from the thruster to the

control box near any heat sources. (NB: excluding SXP thrusters)

• Do not lift it by internal cable connections, main terminals.

• The thruster power supply circuit must include the recommended sized fuse and a battery isolation switch.

• The electro motor, components and cables must be mounted so they remain dry at all times.

• Do not use abrasive tools damaging the existing Epoxy coating when preparing for antifouling paint.

3

5630 23 2022

-

SX35 & SX50

The installer must read this document to ensure necessary familiarity with the product before installation.

Instructions in this document cannot be guaranteed to comply with all international and national regulations. It is the responsibility of the

installer to follow all applicable international and national regulations when installing Sleipner products.

The recommendations given in this document are guidelines ONLY, and Sleipner strongly recommends that advice is obtained from a person

familiar with the particular vessel and applicable regulations.

This document contains general installation instructions intended to support experienced installers. If you are not skilled in this type of work,

please contact professional installers for assistance.

If required by local regulation, electrical work must be done by a licensed professional.

Appropriate health and safety procedures must be followed during installation.

Faulty installation of Sleipner products will render all warranties given by Sleipner Motor AS.

MC_0038

Responsibility of the Installer

Failure to follow the considerations and precautions can cause serious injury,

damage and will render all warranties given by Sleipner Motor as VOID.

MC_0411

MC_0425

For thruster systems

• Do not install the thruster in a position where you need to cut a stiffener/ stringer/ support that may jeopardise the hull integrity without checking

with the boat builder this can be done safely.

• We advise painting the gear house and propellers with anti-fouling. (NB: Do not paint the anodes, sealing, rubber fi ttings or propeller shafts)

• There is only room for a thin coat of primer and two layers of anti-fouling between the tunnel and the props.

• Never run the thruster out of water.

MC_0440

General Installation Considerations and Precautions Guidelines

NEVER Disassemble any part of the Ignition Protected assembly. Tampering with the Ignition Protected assembly will cause it to lose this

safety feature. If there is a problem with your Ignition Protected motor, please contact your dealer.

MC_0007

MC_0427

For SX/P35 and SX/P50 thruster systems

• Ensure that the external thruster assembly does not disturb the water flow under the hull. At higher speeds, if the thruster is installed to

low it can cause damage to the thruster and/ or add additional drag and unwanted water splashing.

• The minimum tunnel depth from the water surface is 140mm (5,51‘) to the centre of tunnel diameter. Place the Thruster as deep as possible for

better performance and reduced noise.

• When installing the thruster ensure it does not foul existing equipment inside the boat like motor bedding etc.

• If able ensure that stern-drives/ trim-tabs do not interfere with the water flow from the thruster as this can reduce the thrust effectiveness

considerably. We recommend the use of our Sleipner cowls to enhance the performance and allow installation in shallow draft boats. Sleipner

cowls will also minimise the effect if stern-drives/ trim-tabs obstruct the thruster.

• Ensure there is enough space both inside and outside the transom of the boat and the thruster does not get in conflict with existing equipment

inside the boat like steerage links etc. (NB: It is possible to mount the tunnel offset from the boat’s centre line if necessary.)

• Heat protection cut off is calculated from the thruster motor. To avoid cable overheating do not install place the volt cables from the thruster to the

control box near any heat sources. (NB: excluding SXP thrusters)

• Do not lift it by internal cable connections, main terminals.

• The thruster power supply circuit must include the recommended sized fuse and a battery isolation switch.

• The electro motor, components and cables must be mounted so they remain dry at all times.

• Do not use abrasive tools damaging the existing Epoxy coating when preparing for antifouling paint.

45630 23 2022

-

SX35 & SX50

MG_0110

H

WL

(a)

(b)

(e)

(c)

(d)

(f)

(g)

* Extended tube for

thicker hull models

(Hull thickness >50mm to <150mm)

* Standard tube

(Hull thickness <50mm)

MC_0239

Product Measurements

Measurement

code Measurement description mm inch

H Motor Height 374 14.72

W Width 183 7.20

L Length 171 6.7

(a) Standard tube length 171 6.7

(b) Extended tube length for thicker hulls 276 10.9

(c) Main tube diameter 50 2

(d) Support bolts diameter 18 0.7

(e) Height of support bolts from tube 35.8 1.4

(f) Distance of support bolts from tube 65 2.6

(g) Distance of support bolts 130 5.1

MG_0132

121 mm

4’76”

187 mm

7’36”

170 mm

6’69”

136 mm

5’35”

110 mm

4’33”

Product Measurements

5

5630 23 2022

-

SX35 & SX50

MG_0110

H

WL

(a)

(b)

(e)

(c)

(d)

(f)

(g)

* Extended tube for

thicker hull models

(Hull thickness >50mm to <150mm)

* Standard tube

(Hull thickness <50mm)

MC_0239

Product Measurements

Measurement

code Measurement description mm inch

H Motor Height 374 14.72

W Width 183 7.20

L Length 171 6.7

(a) Standard tube length 171 6.7

(b) Extended tube length for thicker hulls 276 10.9

(c) Main tube diameter 50 2

(d) Support bolts diameter 18 0.7

(e) Height of support bolts from tube 35.8 1.4

(f) Distance of support bolts from tube 65 2.6

(g) Distance of support bolts 130 5.1

MG_0132

121 mm

4’76”

187 mm

7’36”

170 mm

6’69”

136 mm

5’35”

110 mm

4’33”

Product Measurements

65630 23 2022

-

SX35 & SX50

MC_0149

Product Specifi cations

Description SX35

SXP35

SX50

SXP50

Nominal Voltage 12V 12V

Thrust 12V 43 kg / 94 lbs 62 kg / 136 lbs

Thrust 10.5V 35 kg / 77 lbs 50 kg / 110 lbs

Maximum Operation Time S2 motor at 2 - 3 min. duty cycle at 20°c (ambient temperature) S2 motor at 2 - 3 min. duty cycle at 20°c (ambient temperature)

Power 1.8kw / 2hp 2.8kw / 3.75hp

Weight 15.3 kg / 33.73 lbs 15.3 kg / 33.73 lbs

Product SX35

SXP35

SX50

SXP50

Nominal voltage 12V 12V

Max current 250A 380A

Motor duty cycle Short time duty (S2) Short time duty (S2)

Max ambient temp 50ºc 50ºc

Min ambient temp -25ºc -25ºc

Cross section power cables 35 - 70mm² 2.8kw * 3.75hp

SX/P Thruster

SX/P Control Box

Galvanic Isolation MC_0483

The SX models are produced with a seawater resistant aluminium frame. Without galvanic isolation from other electrical sources the SX seawater

resistant aluminium frame will act as an anode on the vessel. This will add considerable corrosion to the SX thruster frame.

WARRING

IF installing on any metal surface with contact to the SX seawater resistant aluminium frame (vessel hull, supports or frames) the SX thruster

must include a galvanic isolation solution.

MG_0565

Metal hull, support or

frame for mounting the

SX thruster

Galvanic isolation will

prevent any current flow

to the SX thruster

Material to isolate the

contact area of the two

surfaces

SX seawater resistant

aluminium frame

7

5630 23 2022

-

SX35 & SX50

MC_0072

Positioning the Stern SX Thruster

For best performance, the thruster must be installed as deep on the stern as possible but not disturb the natural water flow dynamic of the hull as the

vessel travels.

The thruster should be installed as deep under the waterline as possible for two reasons:

1. So it does not suck air from the surface which will reduce performance and increase noise levels.

2. To receive maximum effi ciency in turning force.

The thruster must be installed to ensure the propulsion water flow must not be obstructed by other objects. Objects that obstruct the water flow from

the thruster will greatly reduce the thrust output.

Position

The thruster can be installed in multiple locations on the boat transom. Installing the thruster slightly off centre will not affect the overall effectiveness

of the thruster. Installing the thruster off centre may be required to avoid any obstructions externally or internally on the vessel.

Ensure that the external stern thruster assembly does not disturb the water flow under the hull. At higher speeds, if the thruster is installed to low can

cause damage to the thruster, additional drag and unwanted water splashing.

Alignment

The thruster can be installed at a slight angle if required for the water flow to avoid obstructions. These obstructions can include propellers systems,

trim tabs or the hull. The average force the thruster propels water is 5-7 meters per sec, therefore angled installations must be as deep as possible

under the water to minimise spray breaking beyond the water surface. (NB: install the thruster at an angle only if no other suitable location can be

found.)

MG_0109

Thruster tunnel is

clear from obstruction.

Ensure the attachment bolts and

wiring are not obstructing objects

internally in the boat such as

steering legs or motors

Steering Arm

Installing the thruster at an angle

close to the water line will blast

water beyond the water surface.

Do not install the SX thruster inverted

or at an angle over a reasonable level

to deliver appropriate thrust

Engine

The thruster can be installed in multiple

locations based on object obstructions

on the stern.

Engine

Water line Water line

Water line

Engine

Engine

Thruster assembly does not disturb

the water flow under the hull.

Water flow

MC_0149

Product Specifi cations

Description SX35

SXP35

SX50

SXP50

Nominal Voltage 12V 12V

Thrust 12V 43 kg / 94 lbs 62 kg / 136 lbs

Thrust 10.5V 35 kg / 77 lbs 50 kg / 110 lbs

Maximum Operation Time S2 motor at 2 - 3 min. duty cycle at 20°c (ambient temperature) S2 motor at 2 - 3 min. duty cycle at 20°c (ambient temperature)

Power 1.8kw / 2hp 2.8kw / 3.75hp

Weight 15.3 kg / 33.73 lbs 15.3 kg / 33.73 lbs

Product SX35

SXP35

SX50

SXP50

Nominal voltage 12V 12V

Max current 250A 380A

Motor duty cycle Short time duty (S2) Short time duty (S2)

Max ambient temp 50ºc 50ºc

Min ambient temp -25ºc -25ºc

Cross section power cables 35 - 70mm² 2.8kw * 3.75hp

SX/P Thruster

SX/P Control Box

Galvanic Isolation MC_0483

The SX models are produced with a seawater resistant aluminium frame. Without galvanic isolation from other electrical sources the SX seawater

resistant aluminium frame will act as an anode on the vessel. This will add considerable corrosion to the SX thruster frame.

WARRING

IF installing on any metal surface with contact to the SX seawater resistant aluminium frame (vessel hull, supports or frames) the SX thruster

must include a galvanic isolation solution.

MG_0565

Metal hull, support or

frame for mounting the

SX thruster

Galvanic isolation will

prevent any current flow

to the SX thruster

Material to isolate the

contact area of the two

surfaces

SX seawater resistant

aluminium frame

85630 23 2022

-

SX35 & SX50

MC_0072

Guide for Stern Thruster Cowls or Grids

Installing a stern thruster cowl for stern thrusters that will allow installations in boats with shallow drafts or due to other obstructions on the stern.

These can include obstacles such as trim tabs, jets or surface drive propeller systems where shallow installation of a stern thruster is the only option.

Cowls:

Designed to aid in water redirection and reduce air entering the tunnel in shallow installations.

Grid’s:

Designed to protect the thruster from objects while in use.

MG_0017

Shallow installation

Cowl water flow redirection

An angled edge further

preventing air attraction into

the tunnel

Composite material with smooth

inner walls for optimal water flow

and strength

A standard Sidepower stern

thruster tunnel with add-on cowls

for shallow installation

cowls to change the

water flow direction to

avoid obstructions on

the stern

cowls help prevent air

from the water surface

entering the tunnel in

shallow installations

Radius corners prevent

turbulence

Easy installation for easy

bolt-on fitting

A

B

C

D

IMPORTANT

Angled cowls out of horizontal, must be

installed deeper to avoid air entry in the

thruster tunnel

Model # 90126 90080 90077 90136 90130 90220 90560

A (mm/ in) 528/ 20.8 681/ 26.6 823/ 32.4 850/ 33.5 1010/ 39.75 1208/ 47.6 1580/ 62.2

B (mm/ in) 166/ 6.5 172/ 6.8 243/ 9.6 260/ 10.2 330/ 13 393/ 15.5 515/ 20.3

C (mm/ in) 130/ 5.1 240/ 9.4

D (mm/ i n) 170/ 6.7 256/ 10.1 256/ 10.1 288/ 11.3 340/ 13.4 419/ 16.5 540/ 21.3

100mm

177mm

537mm

174mm

9

5630 23 2022

-

SX35 & SX50

MC_0072

Guide for Stern Thruster Cowls or Grids

Installing a stern thruster cowl for stern thrusters that will allow installations in boats with shallow drafts or due to other obstructions on the stern.

These can include obstacles such as trim tabs, jets or surface drive propeller systems where shallow installation of a stern thruster is the only option.

Cowls:

Designed to aid in water redirection and reduce air entering the tunnel in shallow installations.

Grid’s:

Designed to protect the thruster from objects while in use.

MG_0017

Shallow installation

Cowl water flow redirection

An angled edge further

preventing air attraction into

the tunnel

Composite material with smooth

inner walls for optimal water flow

and strength

A standard Sidepower stern

thruster tunnel with add-on cowls

for shallow installation

cowls to change the

water flow direction to

avoid obstructions on

the stern

cowls help prevent air

from the water surface

entering the tunnel in

shallow installations

Radius corners prevent

turbulence

Easy installation for easy

bolt-on fitting

A

B

C

D

IMPORTANT

Angled cowls out of horizontal, must be

installed deeper to avoid air entry in the

thruster tunnel

Model # 90126 90080 90077 90136 90130 90220 90560

A (mm/ in) 528/ 20.8 681/ 26.6 823/ 32.4 850/ 33.5 1010/ 39.75 1208/ 47.6 1580/ 62.2

B (mm/ in) 166/ 6.5 172/ 6.8 243/ 9.6 260/ 10.2 330/ 13 393/ 15.5 515/ 20.3

C (mm/ in) 130/ 5.1 240/ 9.4

D (mm/ i n) 170/ 6.7 256/ 10.1 256/ 10.1 288/ 11.3 340/ 13.4 419/ 16.5 540/ 21.3

100mm

177mm

537mm

174mm

MG_0112

Push two tunnel

ends together.

Check snap lock

positions around the

tunnel.

Snap lock

Ensure top lips tabs

into the motor

inserts.

1

Tunnel Installation

1. Connect both ends of the tunnel to the thruster motor. All hooks must be completely interlocked making the inside of the tunnel smooth. (NB:

Ensure tunnel moulding around the gear leg and tunnel top align.)

MC_0074

IMPORTANT

Ensure all snap-lock positions are correctly connected into place.

10 5630 23 2022

-

SX35 & SX50

MG_0262

Hull

Hull

12mm

Spacer

Apply MS Polymer sealant or

equal to back surface face

50mm

Spacer

Drill

8.5 / 9 mm

Drill

8.5 / 9 mm

4 65 IMPORTANT

The spacer and hull have different hole

diameters for the support bolts. This is to

allow the compression rings to be inserted

into the hull only.

The spacer and hull for the main tube have

the same hole diameter so compression

rings can be inserted for the total length of

the hole.

Compression

ring

Compression

ring

SX Spacer

Follow the installation of the SX thruster in the Motor Installation to step 3. see next page

1. Defi ne the location to install the thruster. (NB: Ensure the thruster does not protrude past the transom profi le on any side and there is no

obstruction to the thrusters water flow. Also, check internally the thruster will not obstruct any objects.)

2. Mark the locations of the three drill holes using the defi ned measurements in this manual or from a template. (NB: Maximum hull thickness is

50mm including optional spacer or 150mm for extended hull thickness models.)

3. Drill main hole, then two support bolt holes. Clean the area from dust for installation of the thruster. (NB: Hull holes must be drilled fi rst before

attaching the spacer as the top support holes are larger than the spacers.)

---------

4. Drill out the two support bolt holes in the spacer.

5. Apply MS Polymer sealant or equal to the back surface face of the spacer.

6. Place the spacer to the hull.

Continue the installation of the SX thruster from step 4 in the Motor Installation.

MC_0074

IMPORTANT

If using the 50mm spacer ensure you have the extended tube SX model.

MG_0113

130 mm

5,12”

65 mm

2,56”

35,80 mm

1,41”

50 mm

1,97”

Drill holes in hull

Control box

installation location

SX cable leads

Hole size

for hull

18 mm

0,71”

All rings need

+10% Compression

Nut and Washer

Hull thickness

Maximum hull thickness

is 50 mm or 150mm

1

4

5

2 3

Ensure SX thruster drilling holes do not

obstruct internal boat frame/ supports

Approximate the

location of the

control box.

Max 0.75m

11

5630 23 2022

-

SX35 & SX50

MG_0262

Hull

Hull

12mm

Spacer

Apply MS Polymer sealant or

equal to back surface face

50mm

Spacer

Drill

8.5 / 9 mm

Drill

8.5 / 9 mm

4 65 IMPORTANT

The spacer and hull have different hole

diameters for the support bolts. This is to

allow the compression rings to be inserted

into the hull only.

The spacer and hull for the main tube have

the same hole diameter so compression

rings can be inserted for the total length of

the hole.

Compression

ring

Compression

ring

SX Spacer

Follow the installation of the SX thruster in the Motor Installation to step 3. see next page

1. Defi ne the location to install the thruster. (NB: Ensure the thruster does not protrude past the transom profi le on any side and there is no

obstruction to the thrusters water flow. Also, check internally the thruster will not obstruct any objects.)

2. Mark the locations of the three drill holes using the defi ned measurements in this manual or from a template. (NB: Maximum hull thickness is

50mm including optional spacer or 150mm for extended hull thickness models.)

3. Drill main hole, then two support bolt holes. Clean the area from dust for installation of the thruster. (NB: Hull holes must be drilled fi rst before

attaching the spacer as the top support holes are larger than the spacers.)

---------

4. Drill out the two support bolt holes in the spacer.

5. Apply MS Polymer sealant or equal to the back surface face of the spacer.

6. Place the spacer to the hull.

Continue the installation of the SX thruster from step 4 in the Motor Installation.

MC_0074

IMPORTANT

If using the 50mm spacer ensure you have the extended tube SX model.

MG_0113

130 mm

5,12”

65 mm

2,56”

35,80 mm

1,41”

50 mm

1,97”

Drill holes in hull

Control box

installation location

SX cable leads

Hole size

for hull

18 mm

0,71”

All rings need

+10% Compression

Nut and Washer

Hull thickness

Maximum hull thickness

is 50 mm or 150mm

1

4

5

2 3

Ensure SX thruster drilling holes do not

obstruct internal boat frame/ supports

Approximate the

location of the

control box.

Max 0.75m

Motor Installation

1. Defi ne the location to install the thruster. (NB: Ensure the thruster does not protrude past the transom profi le on any side and there is no

obstruction to the thrusters water flow. Also, check internally the thruster will not obstruct any objects. Ensure cables internally do not obstruct

any objects. Do not place cables or control box close to high heat radiating parts EG. Turbo/ exhaust manifolds etc.) Roughly estimate the

location of the control box inside the vessel. Plan for the control box to be installed above the waterline.

2. Mark the locations of the three drill holes using the defi ned measurements in this manual or from a template. (NB: Maximum hull thickness is

50mm including optional spacer or 150mm for extended hull thickness models.)

3. Drill main hole, then two support bolt holes. Clean the area from dust for installation of the thruster.

4. Install a bolt and washer to ensure top bolts contact surface area is level with the main tube. Temporally place the thruster through the holes to

ensure correct fi tting. Using the cable leads from the thruster defi ne the fi nial location within the vessel for the installation of the control box.

(NB: If using a spacer the support bolt and washer are not required.)

5. Check the length of the compression rings. Compression rings must be longer than hull thickness to allow for compression (NB: Cut compression

sealants to length top achieve 10% compression.)

MC_0074

Before installations all aluminium parts of the thruster must be coated with an epoxy primer before antifouling process.

12 5630 23 2022

-

SX35 & SX50

MG_0504

6 7

8 9

Sealant (MS Polymer)

Thruster and attachment bolts

Drill holes

in hull

SX surface area

on the outer hull

Cover the

entire surface

Motor Installation

6. The thruster assembly must sit flush on the transom. Grind and sand the area if required to ensure a secure fi t. (NB: Use caution when grinding/

sanding surfaces as to not remove too much fi breglass.)

7. Ensure both bolts and washers to the support bars on the thruster are attached.

Prepare surface according to sealant supplier specifi cation:

- the inside surface of the cut-out holes on the hull.

-To the surface of the washer to the thread and

- in the recess of the main tube to the thread.

- 1cm deep inside all compression ring.

place all compression rings to bolt threads. (NB: Ensure ample sealant (MS Polymer) around the bolts and centre tube for a watertight fi tting.)

8. Insert the thruster with compression rings into the hole.

9. Fasten the thruster

MC_0074

13

5630 23 2022

-

SX35 & SX50

MG_0504

6 7

8 9

Sealant (MS Polymer)

Thruster and attachment bolts

Drill holes

in hull

SX surface area

on the outer hull

Cover the

entire surface

Motor Installation

6. The thruster assembly must sit flush on the transom. Grind and sand the area if required to ensure a secure fi t. (NB: Use caution when grinding/

sanding surfaces as to not remove too much fi breglass.)

7. Ensure both bolts and washers to the support bars on the thruster are attached.

Prepare surface according to sealant supplier specifi cation:

- the inside surface of the cut-out holes on the hull.

-To the surface of the washer to the thread and

- in the recess of the main tube to the thread.

- 1cm deep inside all compression ring.

place all compression rings to bolt threads. (NB: Ensure ample sealant (MS Polymer) around the bolts and centre tube for a watertight fi tting.)

8. Insert the thruster with compression rings into the hole.

9. Fasten the thruster

MC_0074

Propeller Installation

1. Centre the drive pin and Insert the propeller onto the shaft spine. Rotate the propeller until the drive pin aligns with the internal slot in the

propeller.

2. Insert the washer to the end of the shaft spline. Tighten with the propeller lock-nut.

3. Apply anti fouling to the gear leg and propeller. Do not apply anti fouling to any rubber elements of the gear leg or anodes.

MC_0016

WARNING

Do not use abrasive tools damaging the existing Epoxy coating when preparing for antifouling paint.

MG_0478

14 5630 23 2022

-

SX35 & SX50

MC_0074

Grids or Cowls assembly

1. Attach the cowls or grids with included bolts. (NB: If installation of the cowls ensure the appropriate twist of the cowl to direct water away from

obstacles)

MG_0145

*Cowl

*Grid

Grids and cowls can not be installed in

combination. Only one option is possible

at a time.

Tighten 2Nm

Correct rotation of the grid/ cowl requires the longer

spaced bolts at the top and the shorter spaced bolts at

the bottom

15

5630 23 2022

-

SX35 & SX50

MC_0074

Grids or Cowls assembly

1. Attach the cowls or grids with included bolts. (NB: If installation of the cowls ensure the appropriate twist of the cowl to direct water away from

obstacles)

MG_0145

*Cowl

*Grid

Grids and cowls can not be installed in

combination. Only one option is possible

at a time.

Tighten 2Nm

Correct rotation of the grid/ cowl requires the longer

spaced bolts at the top and the shorter spaced bolts at

the bottom

MC_0479

Electrical Installation

WARNING

Check the following with the main switch is set to off. After all electrical connections have been completed check with an ohm meter that

there is no electrical connection between

1. electro-motor flange and the positive terminal on the motor

2. electro-motor flange and the battery negative terminal on the motor

(If unsure contact skilled personnel.)

1. Plan the location of all electrical components before starting with the electrical installation. Main electrical components will typically consist of

battery, fuse, main switch, Proportional Power Controller (PPC) and Control Box, see Wiring Diagram chapter for an overview.

For safety reasons it is always recommended to install a fuse and a main switch on the power cable and as close as possible to the positive battery

pole. Distance between battery and fuse should be less than 1 meter. The main switch must be installed such that is easily accessible to disconnect

the thruster when not on-board or in the case of an emergency. Sleipner offers both manual main switches and Automatic Main Switches (AMS).

Sleipner AMS is controlled by the control panel in addition to the option of manual operation. Turning on the control panel does also turn on the

automatic main switch. When the control panel is turned off the automatic main switch is also turned off. This ensures that the control electronics

and motor is only energized when the control panel is turned on. Sleipner offers AMS supporting either S-Link or ON/OFF control panels. Ensure to

select a main switch with voltage and current ratings according to the specifi cations of the chosen thruster motor. Note that the AMS requires separate

power supply which should be protected by a dedicated fuse.

For installations which requires ignition protected equipment ensure to use ignition protected fuse and main switch. Ensure to follow your national

regulations.

2. Estimate the total length of the power cables to determine the recommended cross section. The total power cable length is defi ned as the

distances from the positive battery pole, via fuse, main switch and PPC to the Control Box and all the way back to the negative battery pole.

Compromising the cable sections named B+, M- and B- on the drawing in the Wiring Diagram chapter.

3. Find the recommended power cable cross section for you installation by using the estimated total power cable length and the table shown in

Electrical Reference Guide chapter. Note that maximum cross section that fi ts through the grommet of the Control Box is 70mm2. Maximum

cross section that fi ts with the power cable terminal inside the Control Box is 50mm2. If a 70mm2 cable is used some of the wire strands must be

cut off to fi t the cable inside the terminal. If recommended cross section exceeds 70mm2 it is recommended to use as short as possible cables

between PPC and Control Box with maximum 70mm2 cross section. The recommended cross section or larger should then be used for the rest of

the power cables.

4. Find the recommended fuse rating by using the table shown in Electrical Reference Guide chapter. Use slow blow rated fuses to hold stated

nominal current for minimum 5 minutes.

5. Select appropriate dimensioned battery with Cold Cranking Amps (CCA) according to according to recommendations in Electrical Reference

Guide chapter. Battery voltage must be compliant with the voltage rating of the thruster motor and control circuitry. Capacity and rated discharge

current of battery should be according to rated nominal current drawn and typical duty cycle for thruster operation. Nominal current drawn is

listed in Electrical Reference Guide chapter. The actual voltage at the motor while running the thruster determines the motor RPM and thrust.

Cable losses can reduce the voltage level and result in reduced thrust. Use larger cable cross section and high-capacity battery for improved

performance.

6. Install the Control Box according to instructions in Control Box Installation chapter.

7. Install the control panel according to instructions in the installation manual of the selected Control Panel.

8. Install the battery, fuse, main switch and wiring according to instructions in Wiring Diagram chapter and installation manual of selected fuse and

main switch.

Electrical Reference Guide MC_0077

Model Size System

Voltage

Nominal

current

draw

Min. battery

CCA

Rec.

fuse

Cross Section Guide for Power Cables

Unit

<7m

total + & -

7-14m

total + & -

15-21m

total + & -

22-28m

total + & -

28-35m

total + & -

36-45m

total + & -

Min. Rec. Min. Rec. Min. Rec. Min. Rec. Min. Rec. Min. Rec.

35/140 12V 245 A

DIN: 200

SAE: 380

EN: 330

ANL 150

mm² 35 50 50 70 70 95 95 120 120 2 x 70 2 x 70 2 x 95

AWG 2 1/0 1/0 2/0 2/0 3/0 3/0 4/0 4/0 2 x 2/0 2 x 2/0 2 x 3/0

50/140S 12V 370 A

DIN: 350

SAE: 665

EN: 600

ANL 325

mm² 50 50 70 95 120 2 x 70 2 x 70 2 x 95 2 x 95 2 x 120 2 x 120 2 x 120

AWG 1/0 1/0 2/0 3/0 4/0 2 x 2/0 2 x 2/0 2 x 3/0 2 x 3/0 2 x 4/0 2 x 4/0 2 x 4/0

16 5630 23 2022

-

SX35 & SX50

Control Box Installation

Follow the below steps to install the Control Box. Additional installation details can be found in the corresponding graphics.

1. Pull the blue SX Thruster Hose around the cable harness coming out of the SX Thruster. Fasten the hose clamp.

2. Defi ne the location to install the Control Box. It can be mounted in any orientation, preferably with cables facing down. The control box must be

positioned within 0.75 meters from the thruster attachment bolts. Ensure that the SX Thruster Hose will not obstruct any objects and not placed

near any object that radiate high temperatures.

3. Mark the locations of the four drill holes and drill the holes. Ensure that the back wall where the Control Box is to be mounted have suffi cient

thickness and strength.

MC_0075

MG_0530

Control box

installation location

SX thruster hose

Max 0.75m

1 2

3

Hose claps

17

5630 23 2022

-

SX35 & SX50

Control Box Installation

Follow the below steps to install the Control Box. Additional installation details can be found in the corresponding graphics.

1. Pull the blue SX Thruster Hose around the cable harness coming out of the SX Thruster. Fasten the hose clamp.

2. Defi ne the location to install the Control Box. It can be mounted in any orientation, preferably with cables facing down. The control box must be

positioned within 0.75 meters from the thruster attachment bolts. Ensure that the SX Thruster Hose will not obstruct any objects and not placed

near any object that radiate high temperatures.

3. Mark the locations of the four drill holes and drill the holes. Ensure that the back wall where the Control Box is to be mounted have suffi cient

thickness and strength.

MC_0075

MG_0114

B-B+

SX50

CONTROL BOX

SX35

CONTROL BOX

4Tighten to

8 - 9.5 NM

6 - 7 ft/lb

Temp

switch NC

NTC

A1 A2

Control Box

hose clamp

Battery + / - cable

A1 / A2 cable

B-B+

Tighten to

3.6 - 3.9 NM

2.7 - 2.9 ft/lb

Temp

switch NC

NTC

A1 A2

SX/P 35 does not come with

a control box cover

65

Control Box Installation

4. Follow the cable marking and fasten motor power cables coming from the SX Thruster in the control box. The motor power cables are marked

A1 and A2 and should be fastened to the terminal with corresponding marking. Place the ring cable lug connected to the white wire between the

lug of the motor power cable and the nut. Fasten the nut with recommended torque. Ensure that the ring cable lug is kept at same terminal as

originally placed.

- Insert the B+ and M- power cables into the grommet as shown in fi gure below. Fasten the power cables to the terminals with recommended

torque.

- Connect the Temp Switch and NTC connector

5. Tighten hose clamp on Control Box.

6. Fasten the control box to the hull.

MC_0075

IMPORTANT

It is the installers full responsibility to follow instructions and ensure total Ignition Protection.

18 5630 23 2022

-

SX35 & SX50

MG_0039

Visual Wiring Diagram

Control Box

4-lead cable

SX thruster

hose

SX thruster

-

+

B+

B-

++

THRUSTER

BATTERY

12V

Control

panel

Refer to your control panel manual for

detailed information on connecting the SX

system to your control device

*Automatic

MAIN SWITCH

(See Main Switch

installation manual)

Fuse 5A

*Automatic Main Switch can be replaced by a fuse holder and manual main switch.

19

5630 23 2022

-

SX35 & SX50

MG_0039

Visual Wiring Diagram

Control Box

4-lead cable

SX thruster

hose

SX thruster

-

+

B+

B-

++

THRUSTER

BATTERY

12V

Control

panel

Refer to your control panel manual for

detailed information on connecting the SX

system to your control device

*Automatic

MAIN SWITCH

(See Main Switch

installation manual)

Fuse 5A

*Automatic Main Switch can be replaced by a fuse holder and manual main switch.

Control Panel Installation

For Control Panel installation please refer to the Installation Guide accompanying the control panel to be installed.

MC_0398

Control Panel

SLEIPNER MOTOR AS

P.O. Box 519

N-1612 Fredrikstad

Norway

www.sleipnergroup.com

DOCUMENT ID:

REVISION:

DATE:

LANGUAGE:

Installation Guide

20 5630 23 2022

-

SX35 & SX50

MC_0081

Pre-delivery Checklist

�.......... Propeller is fastened correctly to the shaft.

�.......... Propeller turns freely in tunnel.

�.......... Primer and anti-fouling have been applied to the gear house and propeller but NOT on the

anode or the gear house lid where the propeller is fastened. (NB: Do not use abrasive tools

damaging the existing Epoxy coating when preparing for antifouling paint.)

�.......... Correct drive direction as per control panel.

�.......... The bolts holding the thruster to the hull are tightened correctly.

�.......... All electrical connections are clean, dry and tight, and the correct cable, fuse and main

switch size.

�.......... No water leakage around hull penetrated studs

�.......... Check that there is no electrical connection between the electro motor body and positive

terminal on the motor, and between the electro motor body and the negative (A1) terminal

on the motor with an ohm meter.

The thruster has been installed as per the instructions in this manual and all points in checklist above have been controlled.

Signed: .........................................................................................

Date: .............................................................................................

Extra pre-delivery tests by installer / yard who does not use other quality control systems !

Thruster type: ................................................................................................................................................................................................

Serial number:...............................................................................................................................................................................................

Date of delivery:.............................................................................................................................................................................................

Correct drive direction as per control panel: ..................................................................................................................................................

The compartment for the thruster has been isolated from general bilge water and has no obvious or suspected risks for flooding:

......................................................................................................................................................................................................................

......................................................................................................................................................................................................................

......................................................................................................................................................................................................................

Other comments by installer: ........................................................................................................................................................................

.......................................................................................................................................................................................................................

.......................................................................................................................................................................................................................

......................................................................................................................................................................................................................

Other manuals for SIDE-POWER SX35

1

This manual suits for next models

1

Table of contents

Other SLEIPNER MOTOR AS Boating Equipment manuals

SLEIPNER MOTOR AS

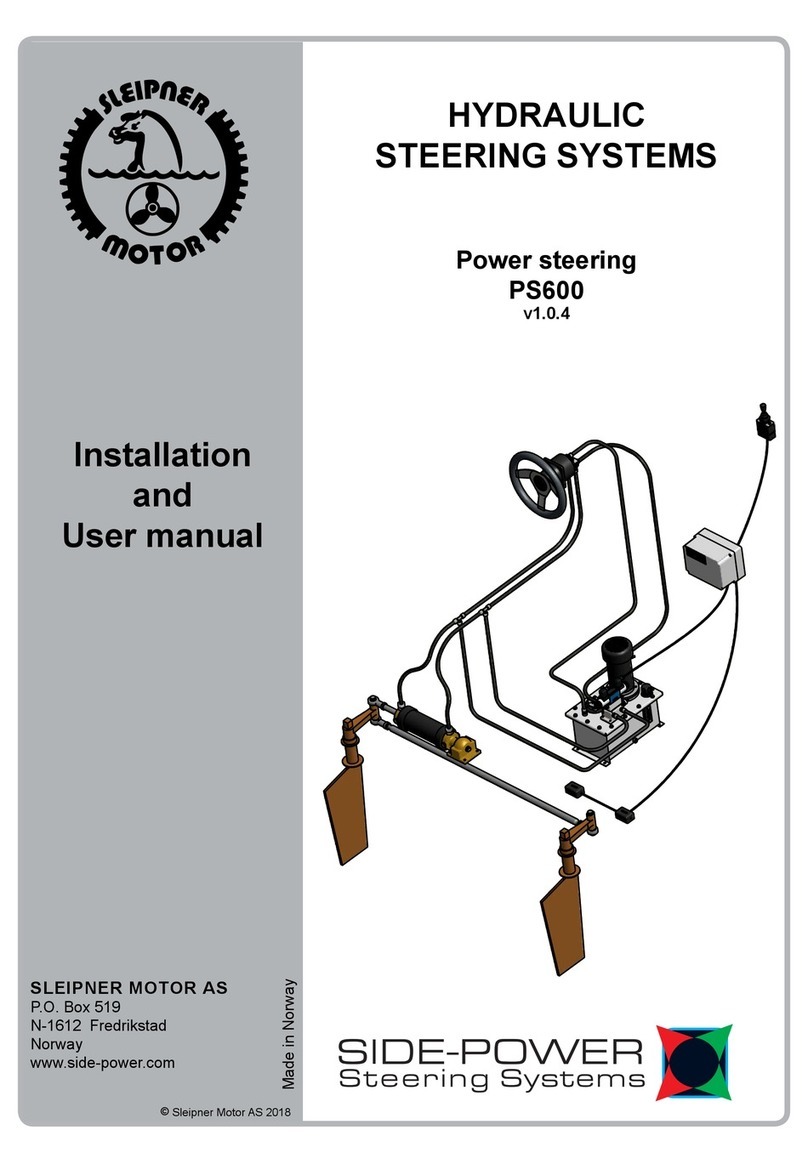

SLEIPNER MOTOR AS PS600 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SE 80 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SE 30 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER SE-50/140 S User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SP 240 TCi User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER MIDI-202 User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS Side-Power Automatic Main Switch User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER WINDLASS Series User manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS Side-Power Series User manual