7

Rev. 04082020

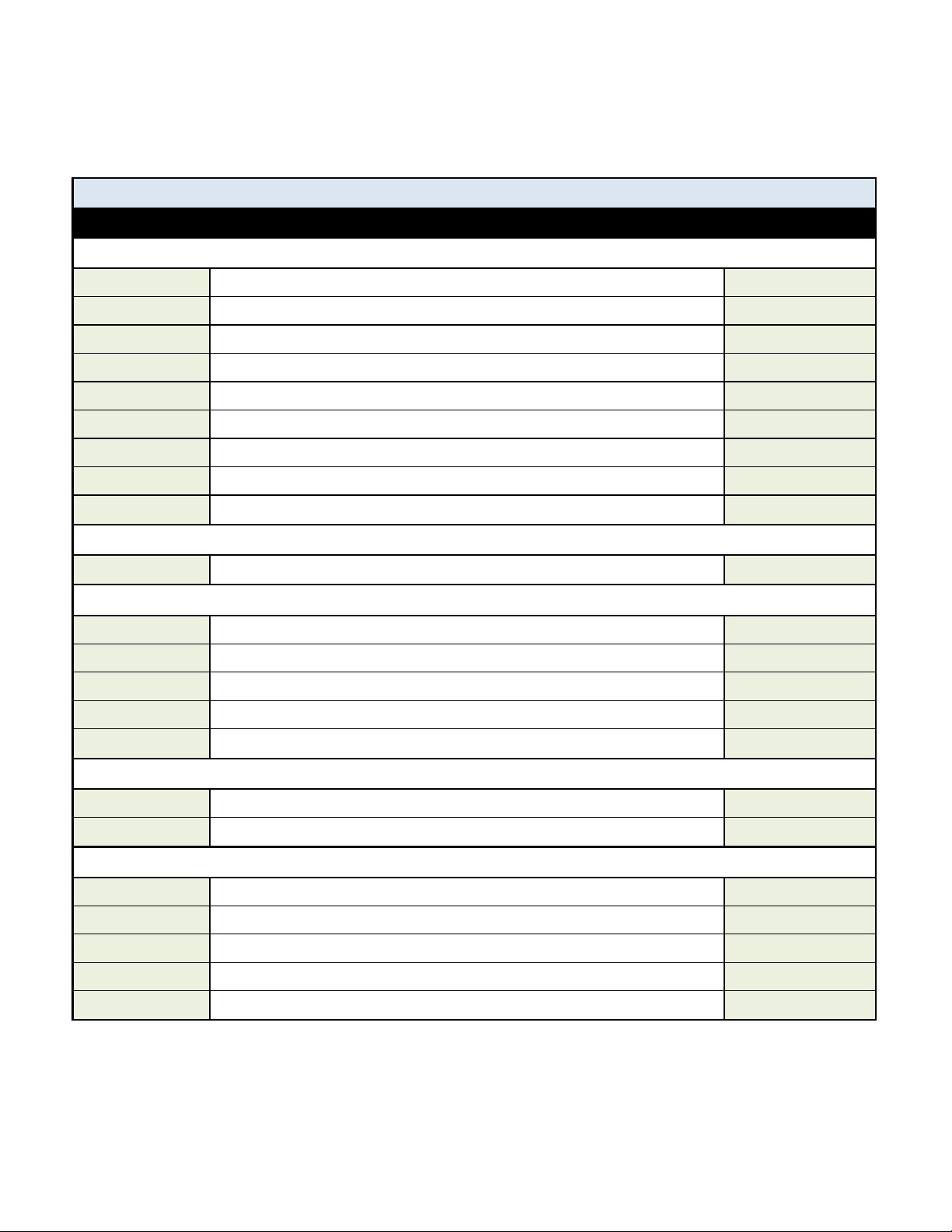

Chart 4: PARTS LIST— 6600

HH-6600 V-HULL STRAIGHT FRAME

Part Description Expected Qty

TANK ASSEMBLY

HH-3000 TANK- HARBORHOIST GEN 1.5 6

HH-2650 KIT BOX, HARBORHOIST GEN 1 MOD TANK SET 3

HH-2601 TOP PLATE - HH GEN 1 MOD- ALUMINUM 6

HH-LPL-1024 GASKET - TOP HARBORHOIST 6

HH-LPL-1028 GASKET - UNDERNEATH - HARBORHOIST 12

HH-LPL-1027 GASKET - BOTTOM - HARBORHOIST 12

HH-LPL-1026 BEAM STRAP - ALUMINUM - HARBOR HOIST 12

HH-LPL-1040 CHANNEL - SUPPORT HH - ALUMINUM 12

HH-LPL-1025 STRAP PLATE - ALUMINUM HARBORHOIST 12

CROSS BEAM

HH-LPL-1018 I BEAM - 84 IN. - 8800 HH 6

WALKWAY

HH-1428 WALKWAY PANEL - HARBORHOIST G1.5 29

HH-2515 SUPPORT-WALKWAY HARBORHOIST 6

HH-LPL-1034 BEAM - 48IN SPAN - ALUM. HH. 4

HH-LPL-1033 TUBE - SPACER, 3X3 ALUMINUM 4

HH-2525 END CAP- HH WALKWAY WITH DECAL 4

HULL PADS

1035105 ASSY HYH HARBORHOIST ALUM BUNK - 16FT 2

1035195 HARDWARE KIT - HARBORHOIST HILL PADS (1 PER TANK SET) 3

CONTROL

HH-2740X CONTROL - HARBORHOIST GEN 1.5 4V EXTERNAL SENSOR 1

HH-2517 CONTROL STAND HARBORHOIST GEN 1.5 1

HHE-2655 KIT, HARDWARE, CONTROL HARDWARE HH 2018 1

3072510 HOSE - RUBBER 1-1/4 in. ID X 75 ft. - CUT 1

HH-2687 KIT, HARDWARE HOSE CLAMPS AND TEES, 6600 1