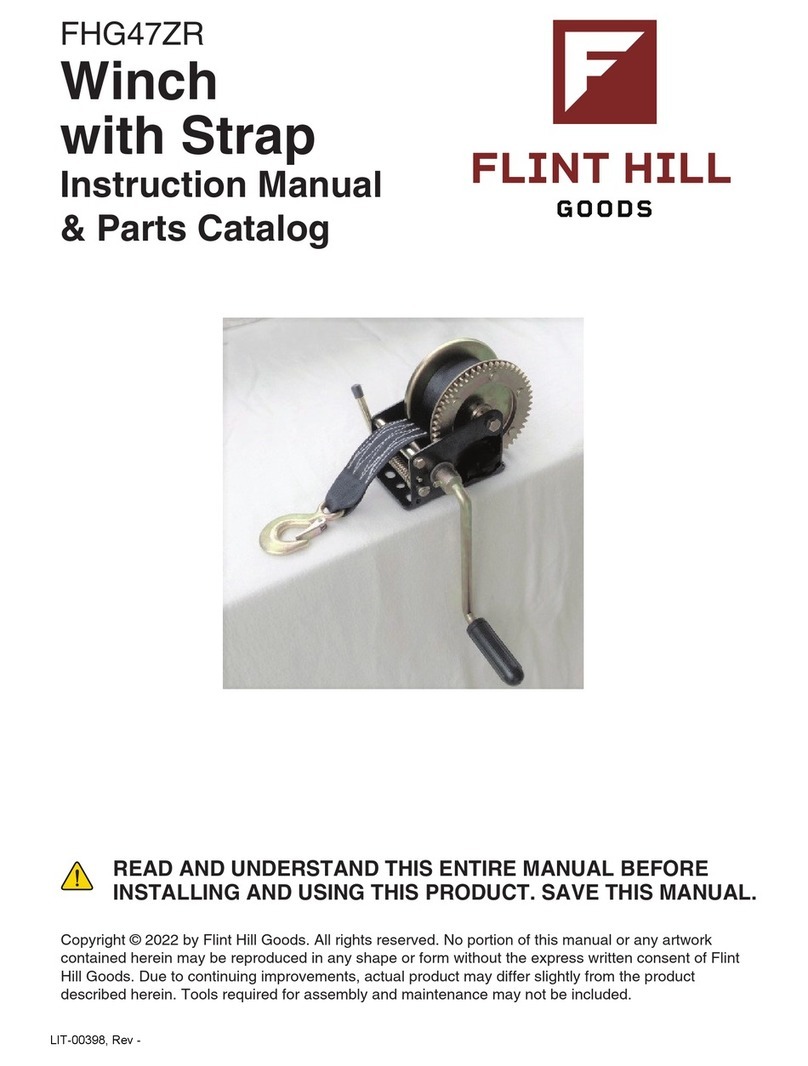

SLG DUKE DU-201 User manual

OPERATION MANUAL

ELECTRIC WIRE ROPE WINCH

Unit R1D Rockingham Gate

Poplar Way West

Cabot Park, Bristol

BS11 0YW

Contact Us

Tel: 0808 123 69 69

Fax: 0117 9381 602

Email: sales@safetyliftingear.com

Page 2

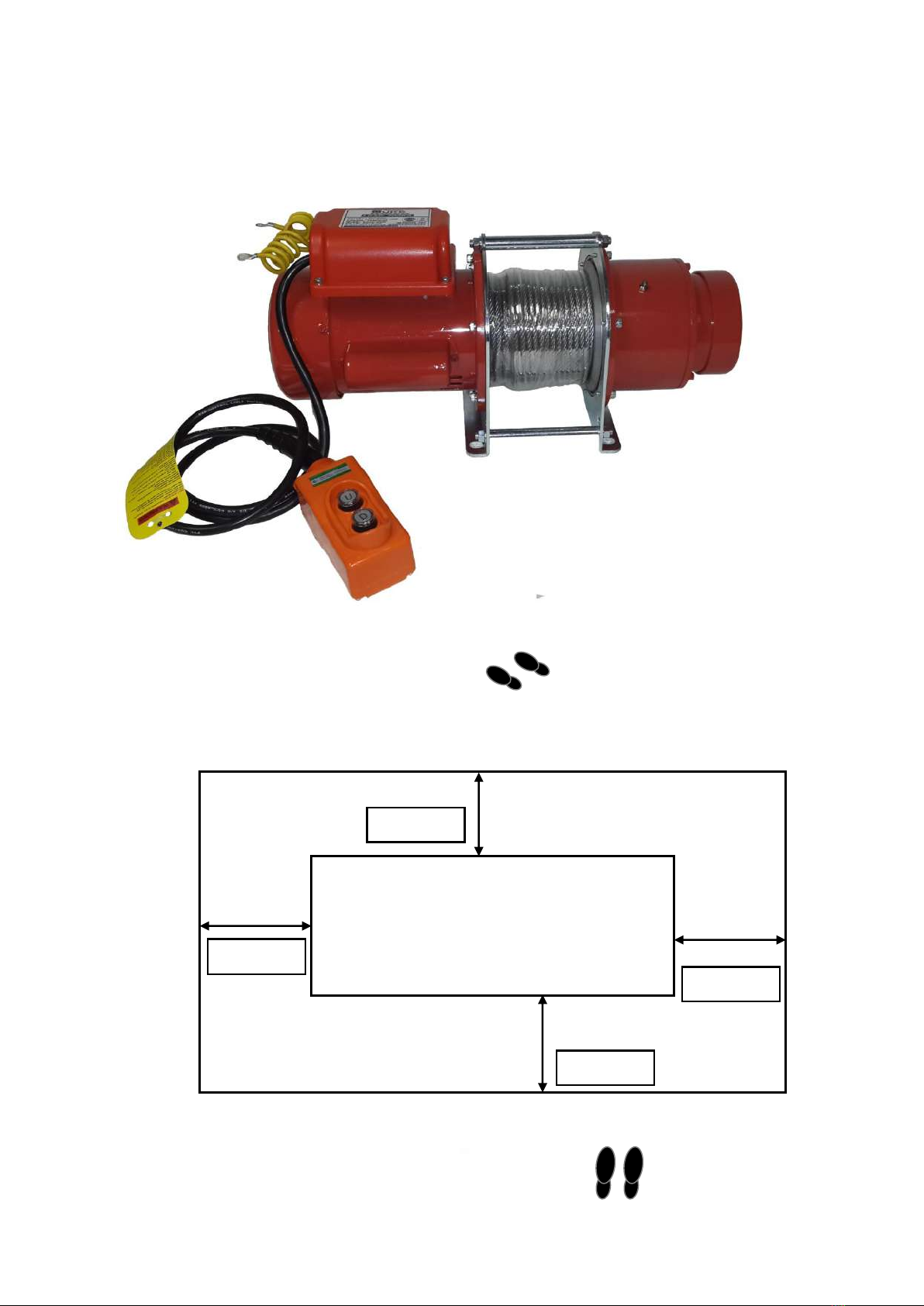

DUKE Electric Wire Rope Winch Introduction

The Duke Electric Wire Rope Winch is designed for building sites, commercial and

domestic, as well as various construction workplaces, such as warehousing, buildings,

storage areas, factories in general, as well as domestic applications.

CONTENTS

1.Preface........................................

3

2.Safety Instruction...................................

4

2-1.Safety regulations..................................

4

2-1-1.General safety rules................................

4

2-1-2.Eiectrical safety rules...............................

5

2-1-3.Safety rules of winch................................

6

2-2.Location of warning sign, CE mark, nameplate....................

7

2-3.Checklist of electrical and safety function......................

8

3.Electric wire winch Description.............................

9

3-1.General characteristics................................

9

3-1-1.Usages......................................

9

3-1-2.Features.....................................

9

3-2.Specifications....................................

10

3-3.Overall dimensions..................................

11

3-4.Working space required and operating position.....................

12

3-5.Main units and name.................................

13

4.Pre-use Preparation...................................

14

4-1.Notice and inspection before operation........................

14

4-1-1.Mechanical check.................................

14

4-1-2.Electrical check.................................

14

4-2.Expected use and limits of use.............................

15

5.Transport and Install.................................

16

5-1.Transport......................................

16

5-2. Install........................................

17

5-2-1.Envirorunent Precautions............................

17

5-2-2.Power Cord Insertion...............................

17

5-2-3.Mounting.....................................

18

5-2-4. Continuous rating...............................

18

6.Operation.......................................

19

6-1.Control device:Control panel.............................

19

6-2.Operating procedure.................................

19

6-3.Handling Precautions.................................

20

7.Maintenance and Adjustment.............................

21

7-1.Periodical Checking.............................

21

7-2.Maintenance..................................

22

7-3.Troubleshooting..................................

23

8.Drawings and Part list..................................

24

8-1.Assembly and part list.............................

24

8-2.Electrical system drawings and part list........................

32

Page 3

Please read this Instruction Manual carefully before you start using the electric

winch. You will find many useful hints which will help you to keep the winch always

in its first-class condition.

You are kindly requested to read this manual thoroughly, to follow scrupulously

the instructions given and for safety reasons, avoid controlling, adjusting or

performing procedures other than those specified.

This winch has been designed and built in full compliance with EN ISO 12100, ISO

14121 and EN 60204 standards on machine and further modification, with

high-quality materials and particularly studying the possibilities to reduce as much

as possible the risks of accident.

Foreword to the operating instructions

The operating instructions are designed to familiarize the user with the winch and

its designated use.

The instruction manual contains important information on how to operate the winch

safety, properly and most efficiently. Observing these instructions helps to avoid

danger, to reduce repair costs and downtimes and to increase the reliability and

life of the winch.

The instruction manual is to be supplemented by the respective national rules and

regulations for accident prevention and environmental protection.

The operating instructions must always be available wherever the winch is in use.

These operating instructions must be applied by any person in change of carrying

out work with and on the winch, such as

operation including setting up, troubleshooting in the course of work, care of

consumables

maintenance (serving, inspection, repair) and/or

transport

This electric winch is designed and built in full compliance with the safety standard,

please read carefully before installing the machine.You will find many hints to keep

the machine in its best condition, also to avoid the risk of accident.

In addition to the operating instructions and to the mandatory rules and regulations

for accident

Prevention and environment protection in the country and place of use of the winch,

the generally recognized technical rules for safe and proper working must also be

observed.

1. Preface

Page 4

2. Safety Instruction

2-1 Safety regulations

2-1-1 General safety rules

1. This electric winch is designed for lifting products only. Do not apply the electric

winch for lifting person.

2. The electric winch should be mounted on a flat solid place.

3. Installing the electric winch at a proper levelling condition to ensure the steel rope

arranged neatly. This may avoid steel rope friction against the winch body due to

regular winding.

4. Make sure your power source comply with the voltage indicated on the electric

winch before connecting the power wires to the power source.

5. Connect the power wires. Tighten the terminals securely.

6. Make sure the electric winch has been properly grounded. The power circuit should

be equipped with an electric shock breaker.

7. Before operating the electric winch, read and follow the instructions for allowable

lifting weight, speed and voltage etc. Indicated on the attached plate.

8. Do not exceed the rated lifting capacity of the electric winch. Allowable lifting

weight is indicated on the attached plate.

9. The electric winch should be operated by a skilled operator. Before operating the

electric winch check again if all lock screws are tightened securely without

loosening.

10. Before operating the electric winch check to see if the steel rope drum runs to the

correct direction and the brake works normally.

11. Do not allow any person approaches under the electric winch, bracket or weight.

12. Select a proper location for mounting the electric winch, to prevent the lifting weight

bumping against any construction, steel frame or construction beam etc while

lifting.

13. Always keep the steel rope in a good condition.When applying the electric winch

for lifting heavy load, keep the steel rope at least 3 turns wounded around the drum.

14. Lift weight vertically. Do not lift weight in a slant or horizontal direction. Do not have

weight hooked on the steel rope for a long time.

15. Do not use the electric winch to pull out any object fixed in the floor or any

construction.

16. When the electric winch is running, keep your hands or any object away from it to

avoid danger.

17. Prevent control wire or power wire from hooking or contacting by the wire rope. This

may avoid electric shock or any danger.

18. In case any malfunction or abnormal noise occurs during operation, stop the electric

Page 5

winch immediately. Check and repair it immediately for safety.

19. Do not alter the electric circuit or use any other replacement parts not supplied from

the original manufacturer.. This avoids affection on the winch performance or any

accident.

20. The operator is requested to fully obey the safety rules listed for safety protection.

2-1-2 Electrical safety rules

1. Before installing, please pay attention to the input rated voltage and current and

make sure the winch is grounded, in order to prevent accident.

2. There must be a main power switch (main breaker) at main input side of electric

control system.

3. Remember to disconnect the main power before repair, maintenance and clean.

4. Unauthorized or untrained personnel cannot repair or maintain any electric

equipment.

5. The keys of electric box and mode select should be conserved by authorized

personnel. Don’t give the key or authorized code to unauthorized personnel.

6. Comply with the maintenance instruction to repair and maintain the electric

equipment.

7. Before operating the winch, check all of the electric equipments and parts are

broken or damaged or not. If there is something broken or damaged, replace a new

one immediately and please note its original rated specification.

8. After connecting power, check the direction of motor rotation and the direction of

winch is correct or not.

9. Please check whether the function of emergency stop button is normal or not. The

emergency stop button is used under emergency situation to cut off power of winch.

(Operator usually misunderstand that the winch is broken down when they forgot to

release the emergency stop button.)

10. Please check whether the function of each safety parts is normal or not, such as

emergency stop button, emergency stop wire, interlocking switch, main power

switch, safety valve, limit switch, and etc.

11. Please check whether the screws of each terminal base are tightened or not. If the

screws loose, screw them tightly.

12. The wiring practices of electric control system must be complied with circuit

diagram.

Page 6

2-1-3 Safety rules of winch

1. Don't misuse the winch, to avoid danger.

2. Before start the winch, make sure all the protecting covers are not breakdown and

damage.

3. If the mechanism or any part breakdown, operator should stop the winch

immediately and then examine and repair it.

4. If it results abnormal sound during operation, operator should stop the winch

immediately and then examine and repair it.

5. If abnormal temperature phenomenon happens during operation, operator should

stop the winch immediately and then examine and repair it.

6. Don’t modify the original design of mechanical structure, in order to keep the best

efficiency and security.

7. Please store the spare parts and tools well, and avoid moist and damage.

8. Untrained or unauthorized operator is prohibited operating, installing or

maintaining winch.

9. Please maintain and repair the winch according to service instruction.

10. Please replace broken part according to the specification in part list.

Page 7

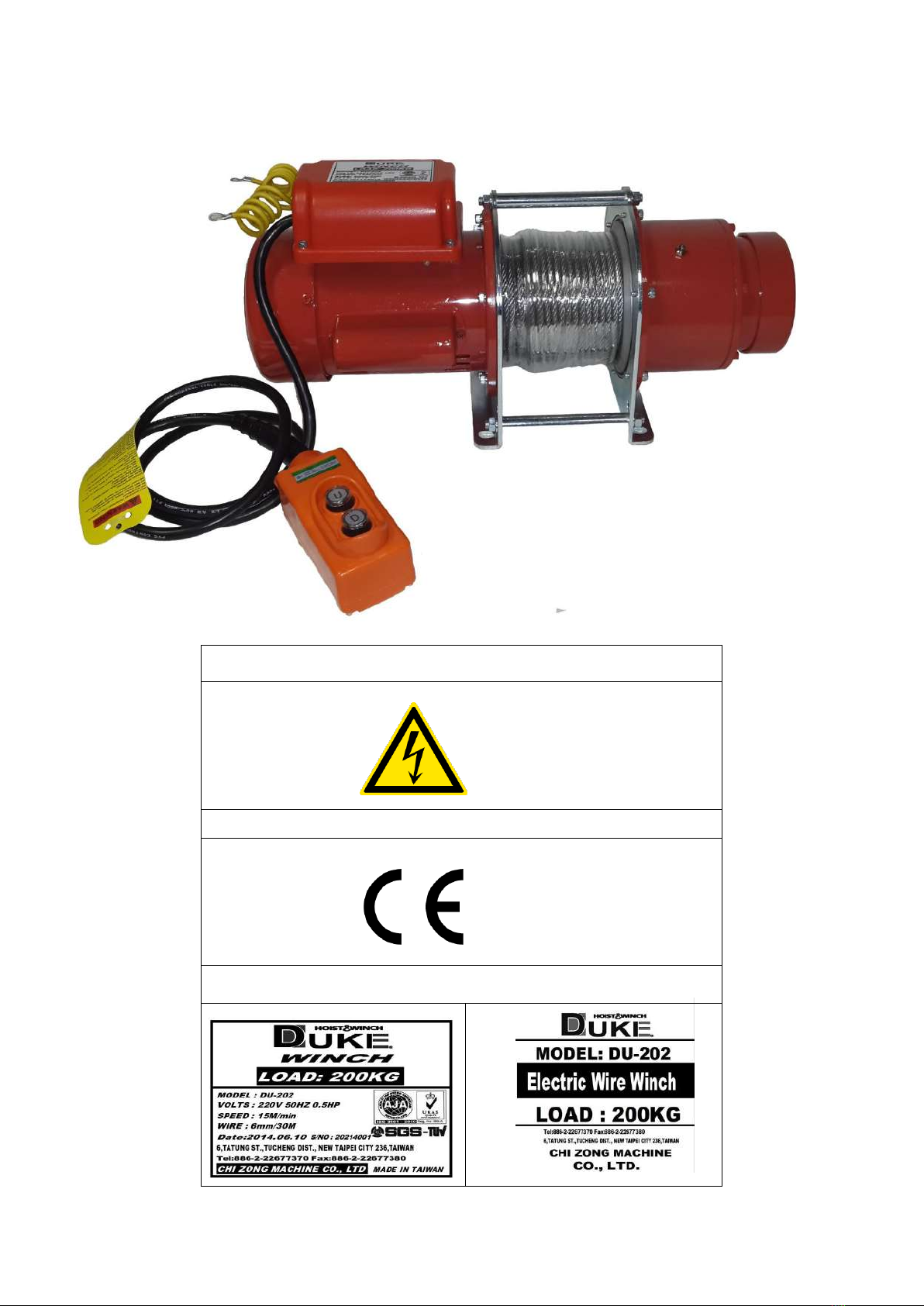

2-2. Location of warning sign, CE mark, nameplate

Electric shock

CE symbol

Nameplate

Page 8

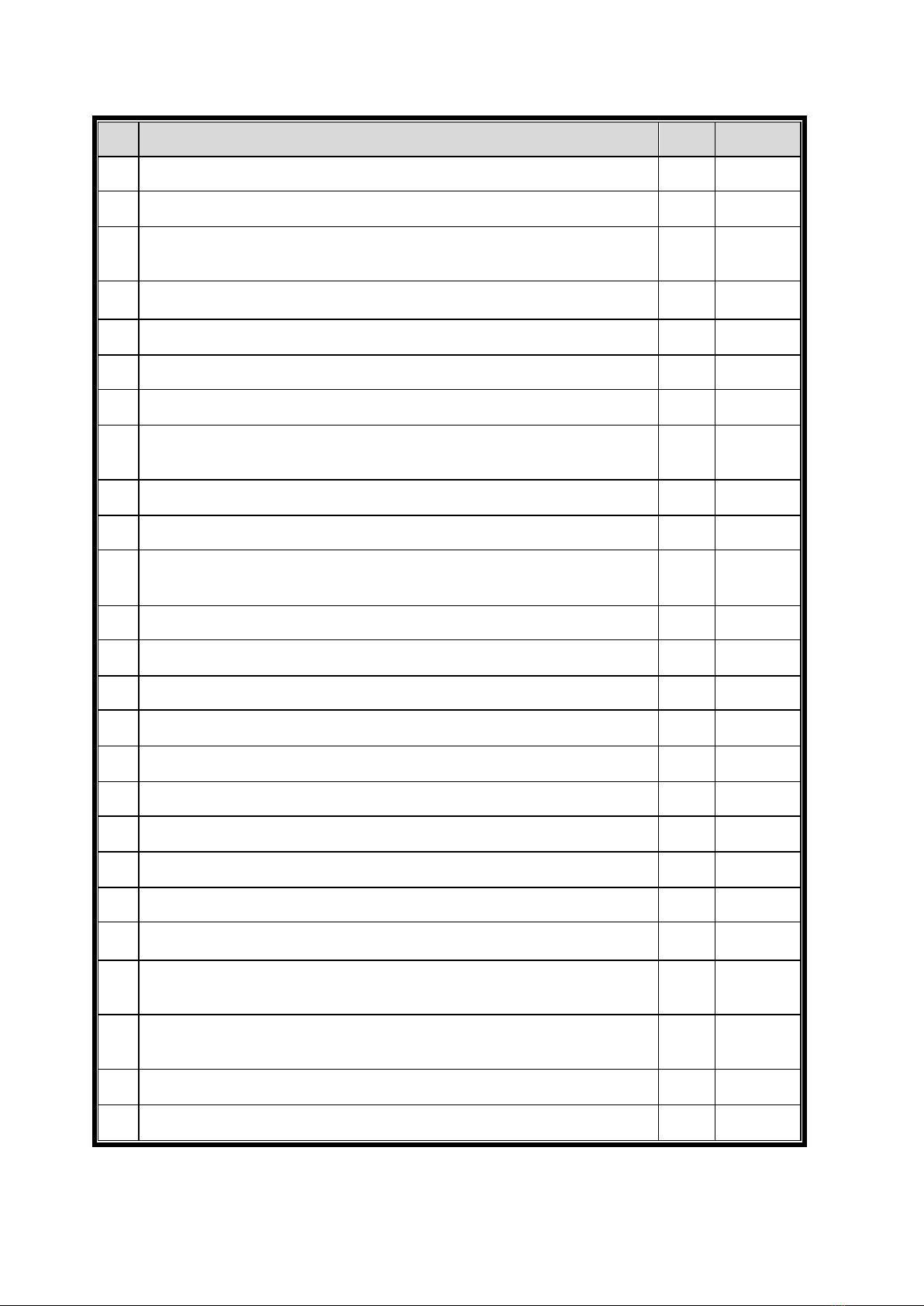

2-3.Checklist of electrical and safety function

Item

Content inspection and safety requirement

Result

Comment

1

Is every terminal protected by isolation plate (IP2X)?

YES

2

Does technician follow the procedure number to wire?

YES

3

Are the diameter of grounding wire and each circuit accord

with safety requirement of designed electrical circuit?

YES

4

Is fuse accord with safety requirement of designed

electrical circuit?

YES

5

Are these screws on electric box fixed tightly?

YES

6

Is the electric box equipped with a ventilator (e.g. fan)?

YES

7

Does the design of electric box conform to IP requirement?

YES

8

Is all the function of every control switch and component

described specifically on this operation manual?

YES

9

Are input voltage, frequency, and phase marked correctly?

YES

10

Is the machine earthed?

YES

11

Is there an independent earth copper plate equipped inside

electric box?

YES

12

Is every function of control device regular?

YES

13

Is the emergency stop device functional?

YES

14

Is the rotary direction of motor or transmission correct?

YES

15

Is the cover functional (fixed or movable)?

YES

16

Is the machine set stable?

YES

17

Have all the acute angle and fur been ground?

YES

18

Has the machine been pasted a CE mark?

YES

19

Has the machine been pasted a nameplate?

YES

20

Has the machine been pasted related warning marks?

YES

21

Have the listed related safety parts in TCF 1.6 been installed

indeed?

YES

22

Have all the safety information and attentions been

provided completely for user?

YES

23

Does the written language of manual and machine conform

to local country?

YES

24

Has the operation manual been provided?

YES

25

Has the EC Declaration of Conformity been signed?

YES

Page 9

3. Electric Wire Winch Description

3-1 General characteristics

3-1-1 Usages

Fit for various workplace applications, such as general factories, warehouse,

construction, plumbing, and agriculture industries. Designed for unique rigging

applications encountered at small venues, lightweight, quiet, and portable. Operates on

1-phase 100V~240V, or 3-phase 220V~380V depends on request.

3-1-2 Features

Braking: designed for both static and dynamic loading. Brake will automatically apply

in the event of power loss.

Gearing: Precision machined gears heat treated for strength and durability, the ball or

needle bearings at all rotating points run in oil bath lubrication for a quieter, smoother

and cooler operation. Planetary gearing for maximum mechanical efficiency.

Motor: Equipped with induction motor, quiet and durable.

Switch: Simply layout of the control with 2M power cable as standard and emergency

stop as option.

Page 10

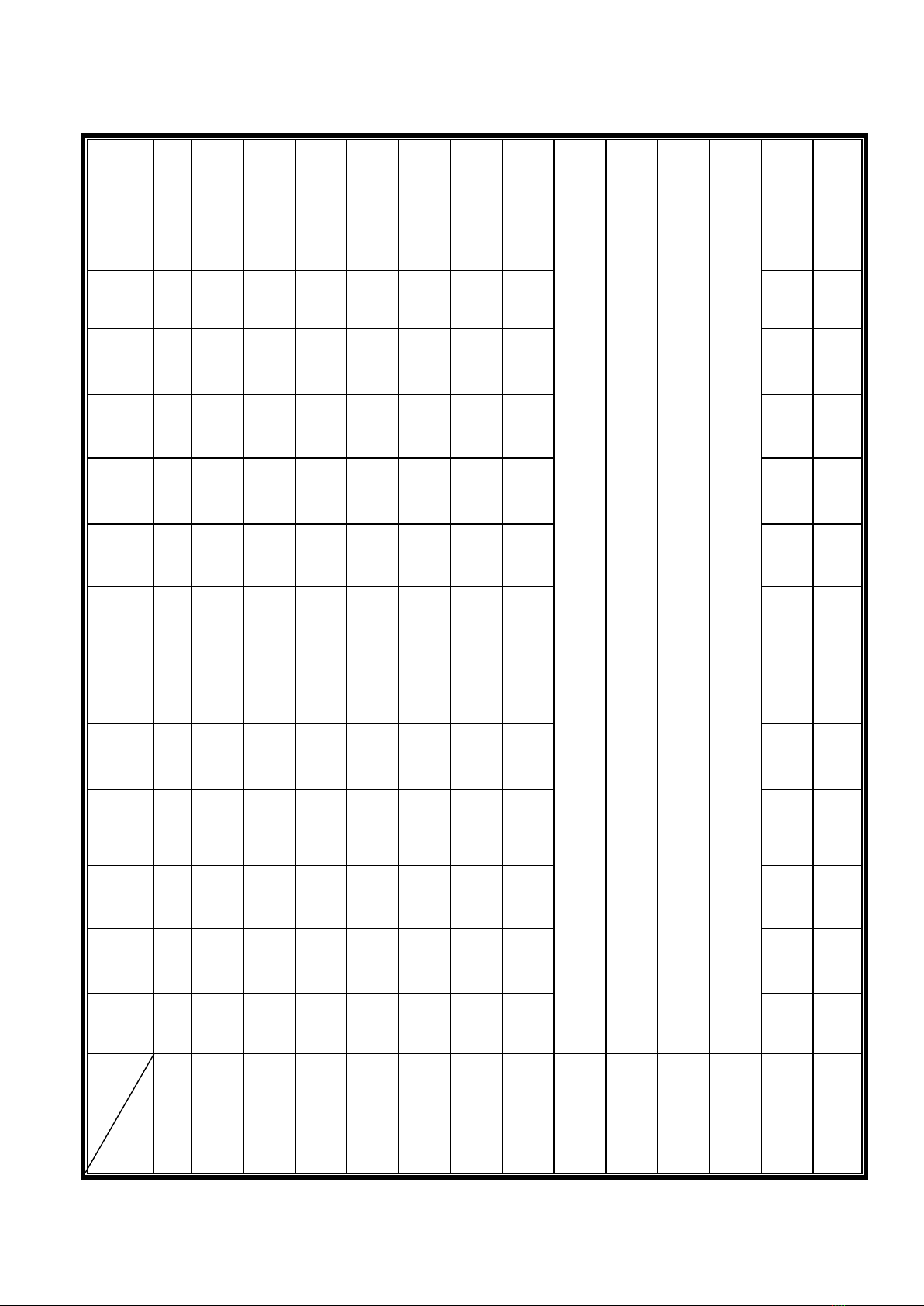

3-2 Specifications

DU-215

1450

590

520

5000

70

10

12

16

WLL X 1.25

F

40%

240

395

426

DU-214

1350

590

520

3000

70

10

12

14

375

405

DU-3K

1240

400

365

3000

45

10

12

14

193

205

DU-213

1290

590

520

2000

70

10

12

12

364

392

DU-2K

1190

400

365

2000

45

10

12

12

171

183

DU-212

1120

385

340

1000

70

2

12

10

133

145

DU-210

710

310

285

500

45

2

21

8

70

76

DU-223H

675

220

283

350

45

2

38

7

66

71

DU-208

585

201

233

350

45

2

15

6

42

43

DU-205

580

201

233

300

30

2

15

7

38

39

DU-221H

585

201

233

250

30

2

33

7

41

45

DU-204

525

201

201

250

30

2

15

6

35

37

DU-202

520

201

201

200

30

2

15

6

34

36

DU-201

380

190

230

150

25

2

15

5

27

28

Model

Dimensions

Length (mm)

Width (mm)

Height (mm)

Capacity (kg)

Standard Lift(m)

Control Cable(m)

Lifting Speed(m/min)

Wire rope(mm)

Safety Factor

Insulation Class

ED%

No. Of Starts per hr

N..W (kg)

G.W (kg)

Page 11

3-3 Overall dimensions

MODEL

Length(mm)

Width(mm)

Height(mm)

DU-201

380

190

230

DU-202

520

201

233

DU-204

525

201

233

DU-221H

585

201

233

DU-205

580

201

233

DU-208

585

201

233

DU-223H

675

220

283

DU-210

710

310

285

DU-212

1120

385

340

DU-2K

1190

400

365

DU-213

1290

590

520

DU-3K

1240

400

365

DU-214

1350

590

520

DU-215

1450

590

520

Page 12

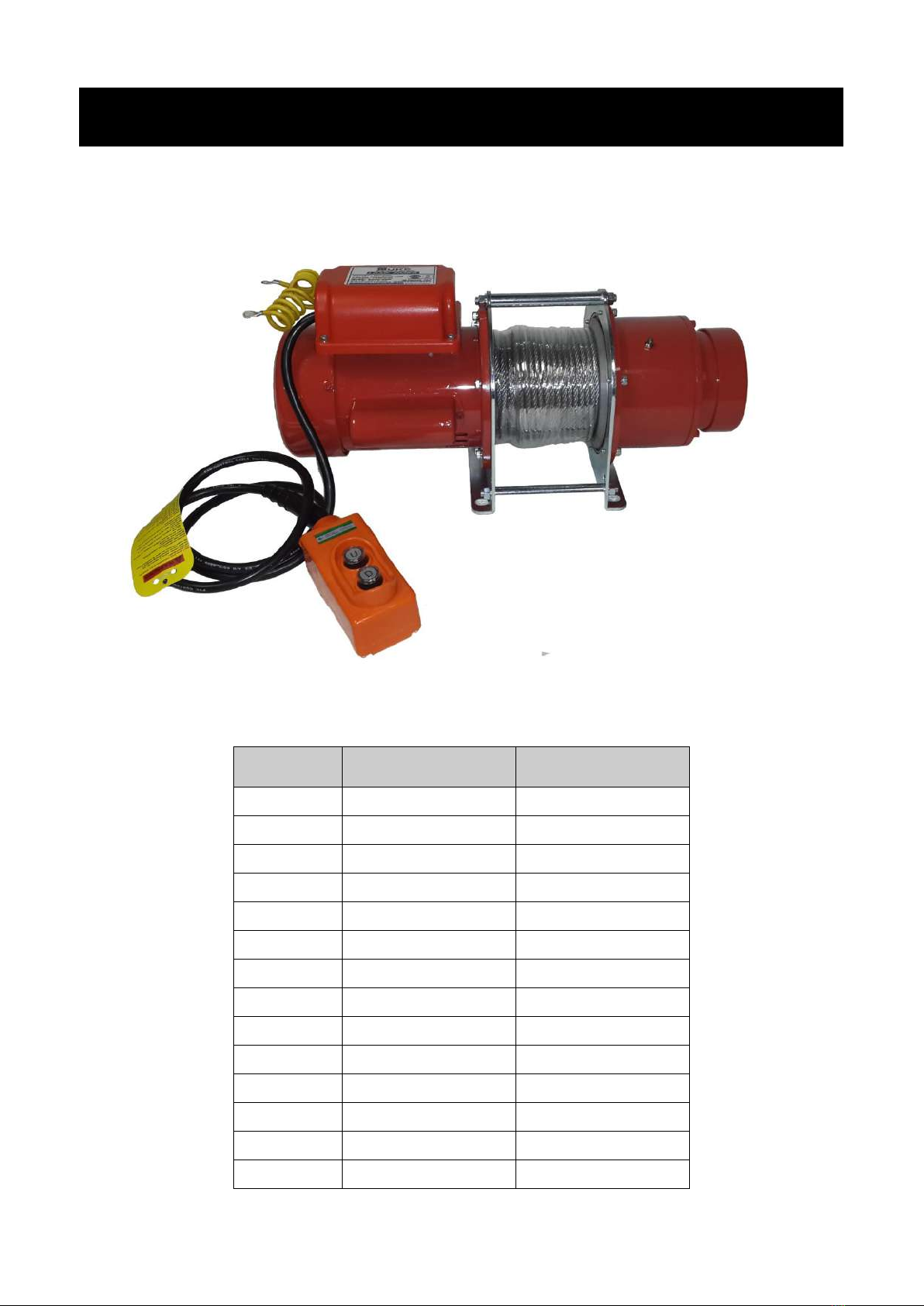

3-4 Working space required and operating position

FRONT OPERATOR

Top View

1500mm

1500mm

1500mm

1500mm

FRONT OPERATOR

Page 13

3-5 Main units and name

Item

Part’s name

1

Electric Department

2

MOTOR

3

PUSH BUTTON

4

WIRE ROPE

5

GEAR BOX

1

2

3

4

5

Page 14

4-1 Notice and inspection before operation

4-1-1 Mechanical Check

1. Are all transport protection facilities removed?

2. Is there any mechanical damage?

3.Are all the safety device, safety covers refitted from the set-up installation?

4. Are all winch unit correctly aligned and locked in position?

5. Are all mobile and rotating parts exempt of foreign bodies? Is there mobility

unimpaired (tools wire, yarns, waste, etc.)

4-1-2 Electrical Check

1. Are all ground conductors connected?

2. Are all cables connected?

3. Is there any mechanical damage of electrical control operating and indicator units

4. Are all plug-in connection to the winch fitted correctly?

5. Are all the cable near mobile parts fixed correctly?

6. Are the cable fitting tightened?

7.Were wire rests and metal objects removed and cleaned away from switch box,

junction box, control cabinets, and operating panel?

8. Are frequency inverters motor set for the correct V/Hz ratio if applied?

9. Are the drive rotating direction correct?

4. Pre-use Preparation

Page 15

4-2 Expected use and limits of use

Specification of essential parts:

Please refer to the list of specification in operation manual.

This winch is expected to be used under industrial environment:

The well lighting, well ventilation, clean environment, dry, and maintains a normal

temperature (-10°C to +50°C).

The winch needs the following supplies:

Electric power: 1-phase / 240V / 50Hz, or 3-phase / 415V / 50Hz (or base on previous

designation).

Working Duty (ED%):

40%.

No more than 20 minutes use within 60 minutes frame.

The required technique and experience during safety operation and use.

They should be a proficient operator or trained staff.

Page 16

5.Transport and Install

5-1 Transport

Always carry the winch with two hands to prevent a strike.

Below table shows net weight and gross weight for each model of winch.

MODEL

NET WEIGHT (kg)

GROSS WEIGHT (kg)

DU-201

27

28

DU-202

34

36

DU-204

35

37

DU-221H

41

45

DU-205

38

39

DU-208

42

43

DU-223H

66

71

DU-210

70

76

DU-212

133

145

DU-2K

171

183

DU-213

364

392

DU-3K

193

205

DU-214

375

405

DU-215

421

447

Page 17

5-2 Install

5-2-1 Environment Precautions

The following environmental conditions may adversely affect the winch

Low temperature below -10°C

High temperature above 40°C

High humidity conditions above 90%

In organic, chemical, or explosive conditions

In wet weather conditions or snow (Cause rust or short circuit)

In heavy dusty conditions

(Cause malfunction or poor performance)

5-2-2 Power Cord Insertion

Insert the power plug into the power

receptacle of the winch, firmly hand tighten

by turning the locking ring clockwise.

Be sure to lock the cord onto

the holder mounted on the winch.

Do not allow the cords to be tangled

into the wire rope and drum

Determining the appropriate cord based on length required

Grounding

To prevent the risk of electric shock, the power plug must be plugged into a

matching grounded socket.

Switch/Pendant cord connection

Insert the pendant plug into the pendant receptacle of the winch and tighten it by

turning the locking ring clockwise. Be sure to hook the cord on the holder.

To extend the length of the cord connect an extension cord of 15feet max.

Do not exceed 50feet in total

Page 18

5-2-3 Mounting

The winch is designed to be hung or mounted on a firm or stable bar or bracket.

Which ensures the winch doesn’t move from side to side, or swing in a 360°

As an optional accessory the winch Bracket can be purchased.

When hung, do not allow the body or load to be caught by any obstruction.

Be sure to lock the hanger for extra safety

Never hang from the hook only.

This hook is not designed to take a load

5-2-4 Continuous rating

Never use the winch beyond the 20 minutes permitted per hour.

The life of the winch depends on the conditions of the load and working frequency.

During long operating periods make sure to use the winch within its continuous

rating.

Continuous Rating means the amount of allowable usage within one hour which is

35% or 20 minutes per hour or 300 starts per hour.

The maximum number of starts means the number of times the motor starts within

the hour.

Page 19

6. Operation

6-1 Control device: Control panel

6-2 Operating procedure

The person who is untrained or unfamiliar with the operation procedure is prohibited

from operating machine.

Preparation before Working3.Working Me

Check all safety and environmental conditions

Ensure there are a minimum of five(5) wraps of wire wound around the drum

Check the wire rope and discard should there be any signs of excessive wear, too many

broken wires, corrosion, or other defects.

One wire rope consists of 7 strands. One strand has 19 wires. So one of the 7 strands

must not have more than 3 of the 19, damaged wires.

Connect the main power source and ensure grounding.

Do not lift loads exceeding the rated load.

Always use power source at the rated voltage.

Up and Down Control Switch

To Lift a Load. Press ▲Button

To Lower a Load. Press ▼Button

Page 20

6-3 Handling Precautions

WARNING

Pay close attention to the following instructions.

Incorrectly operating the winch may result in personal injury or equipment damage.

Never try to lift a load more than the rated capacity

Always remain in control. Never leave a load

Don’t work, walk or stand under and operating winch

Never ride on the hook, sling, or load

A minimum of five (5) wraps of rope around the drum is necessary to support the

rated load

Always look up when working the winch.Watch for overhead danger

Be sure to lift a load vertically. Any slack may allow wire to be tangled.

Prior to lifting make sure the brake is performing correctly.

If any malfunction is detected stop the operation immediately.

Never wrap the load with the wire rope

Wire rope with one or more of the following defects must be replaced immediately.

1. Kink

2. Distortion

3. Corrosion

4. Showing signs of excessive wear or if 1 of the 7 strands has more than 3 of the

19 wires damaged

Do not pull the control pendant to move/pull a load

Do not exceed the continuous rating

Do not rapidly change from Lifting to Lowering

Never work on or weld on a suspended load

Stop operation immediately if the wire rope slackens.

Ensure the slings are fixed in the centre of the swivel hook

Other Important Precautions

Stop operating the winch if there is an abnormal noise or vibration in the gear box.

Do not use the winch or the wire rope as grounding for a welding machine

Make sure the load being lifted is well balanced and secured before commencing.

This manual suits for next models

13

Table of contents

Popular Winch manuals by other brands

Harken

Harken 60.2STEC Installation and maintenance manual

Warn

Warn 90250 User's installation guide

Harken

Harken 40.2ST E Parts Installation

Ingersoll-Rand

Ingersoll-Rand FORCE FA7i Product information

Wallenstein

Wallenstein FX Series Operator's manual

Prowinch

Prowinch PWG Series User's Manual and Safety Warnings

BGU

BGU FSW 5.5 H Evolution Original user manual

IKH

IKH AWD3855 instruction manual

Prowinch

Prowinch PWCD Series user manual

Columbus McKinnon

Columbus McKinnon Yale Mtrac Mini Translated Operating Instructions

Champion Power Equipment

Champion Power Equipment C20049 owner's manual

Kings Adventure

Kings Adventure domin8r 32'' instructions