Electric Recovery Winch

Model: Rhino 15 Pro

PN: 855126 24V DC

Introduction

Feature

Line pull: 6,804 kg / 15,000 lb single line (EN 14492-1 rating)

Brake: Automatic, full load cone brake

Clutch: Turn the T-handle for rapid wire rope payout

Control: Handheld pendant switch powers the winch

Recommended

wire rope:

* 14 mm x 22 m, 1,960 N/mm2 grade with a minimum

breaking strength of 137 KN required for EN 14492-1

rating

Installation

Before using the winch, make sure all electrical components have no

corrosion or damaged; the environment should be clear and dry.

Mounting

.Winch shall be mounted on a flat and hard

surface.

.Winch should be mounted as closed to center

and as horizontal as possible to the direction

of the line pull.

.Wire rope shall be wound in an under-wound

orientation only.

.Eight (8) M12 X 1.75 pitch 8.8 grade w/76 N-m

torque setting (maximum) high tensile steel

bolts must be used in order to sustain the

loads imposed on the winch mounting.

.Two (2) M12 x 1.75 pitch 8.8 grade w/76 N-m

torque setting (maximum) high tensile steel bolts must be used for

fastening the roller fairlead into the mounting channel.

.It is always preferred to use both tie bars in the final installed configuration.

Compliance with EN 14492-1

The winch complies with European Standard of EN 14492:2006

Power-Driven Winches, CE Machinery Directive 2006/42/EC and CE EMC

Directive 2004/108/EC provided that the OWNER or END USER complies

with all responsibilities described below.

1. Refer to the Instruction Manual to install winch for safe winching

operation.

2. Fit the recommended wire rope to comply with EN ratings:

* Rope drives with steel wire rope shall be dimensioned

* At least 2:1 wire rope working coefficient for the first rope layer.

* At least 10:1 D/d ratio to the centre of the rope

* Drum freeboard shall be at least 1.5 x rope diameter.

3. The wire rope must be painted red for 1.6 m on both ends and at least

five (5) wraps of wire rope remained around the drum to comply with

EN ratings;

* At least two rope windings on the drum.

* Rope attachment to withstand 2.5 x the remaining static force.

4. Fit an emergency stop switch to comply with emergency stop function.

5. Fit a hook with a safety latch to comply with a safety hook.

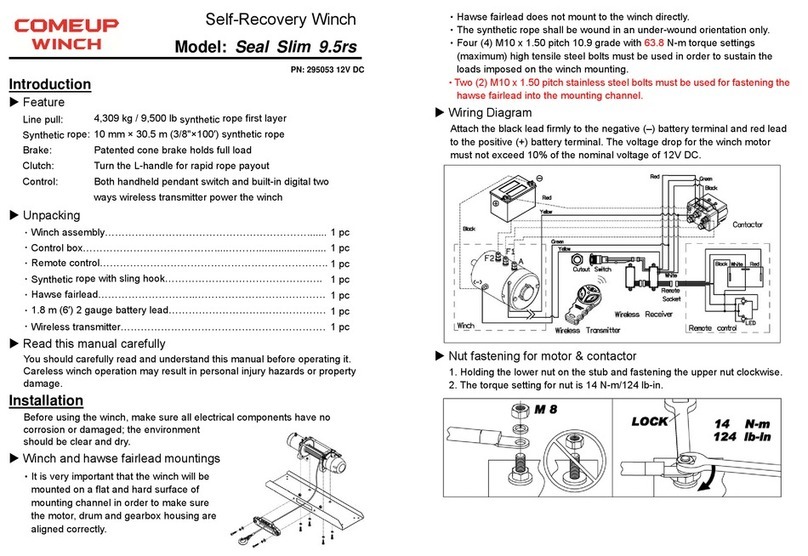

Wiring Diagram

•Connect thermal sensor harness plug, control ground, and cable A/F1/F2 to

the motor.

•Attach the ground lead firmly to the negative (–) battery terminal and power

lead to the positive (+) battery terminal. The voltage drop for the winch

motor must not exceed 10% of the nominal voltage of 24V DC.

•The over-load protector built in the control box shall be manually reset after

reducing the load.

•Always cover the socket with waterproof cap when not in use to prevent

ingress of water or foreign objects.

•Installing ICB control box, it is necessary to install a fuse or battery isolation

switch as additional protection.