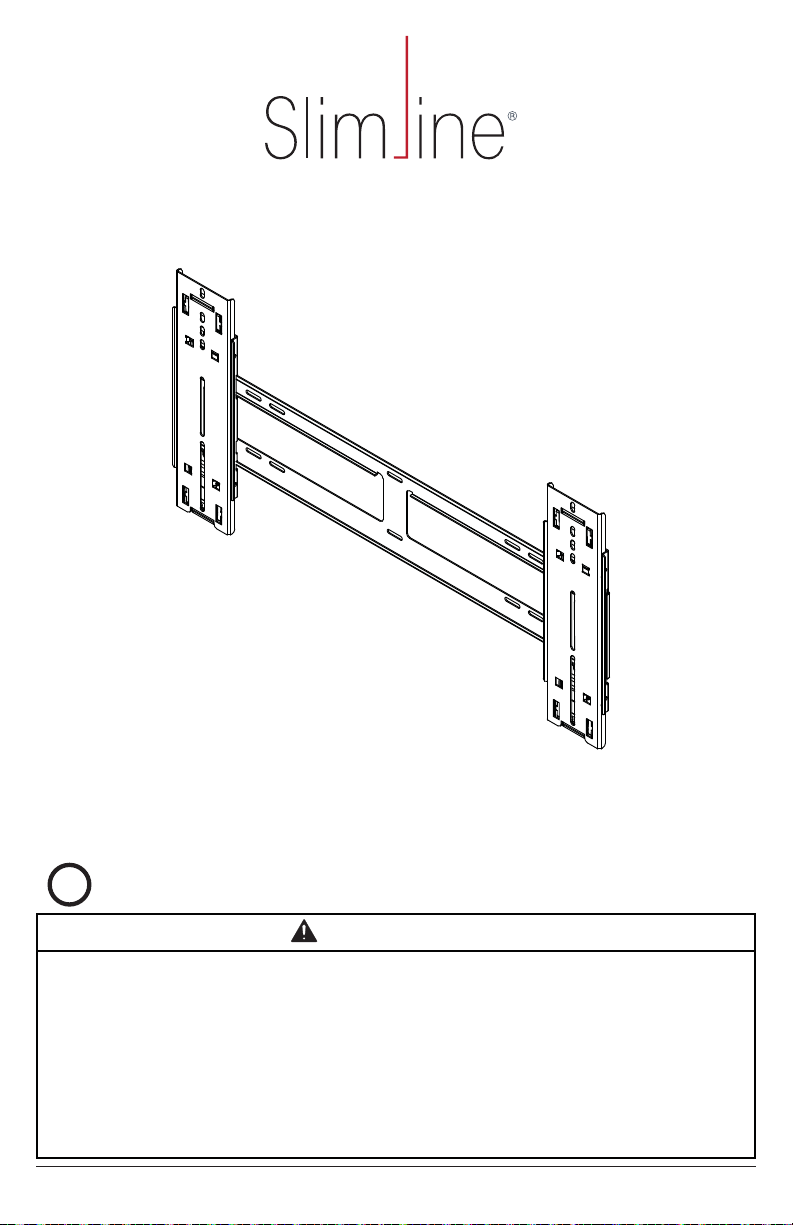

SlimLine SLTLU User manual

ISSUED: 11-30-09 SHEET #: 202-9417-1

©

UL

USC

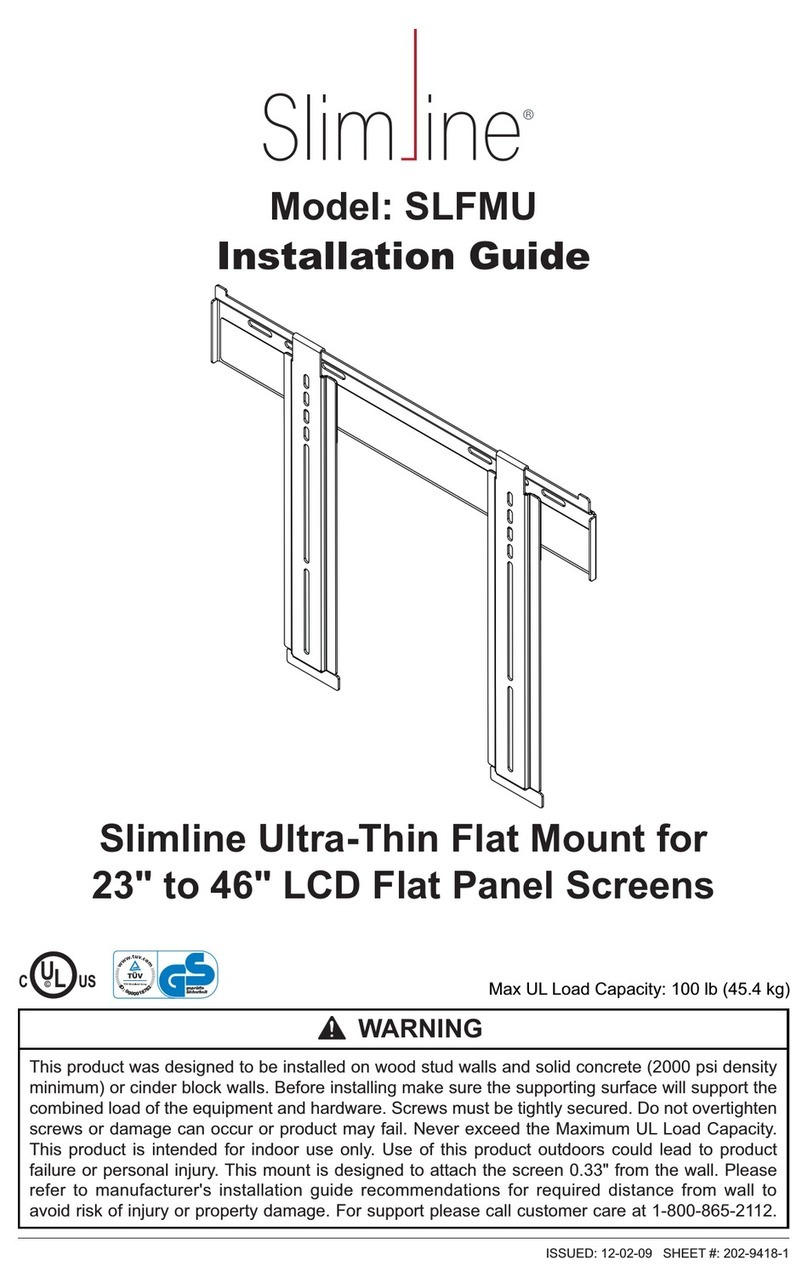

Slimline Ultra-Thin Tilt Mount

for 37" to 60" LCD Flat Panel Screens

Max UL Load Capacity: 100 lb (45.4 kg)

Model: SLTLU

Installation Guide

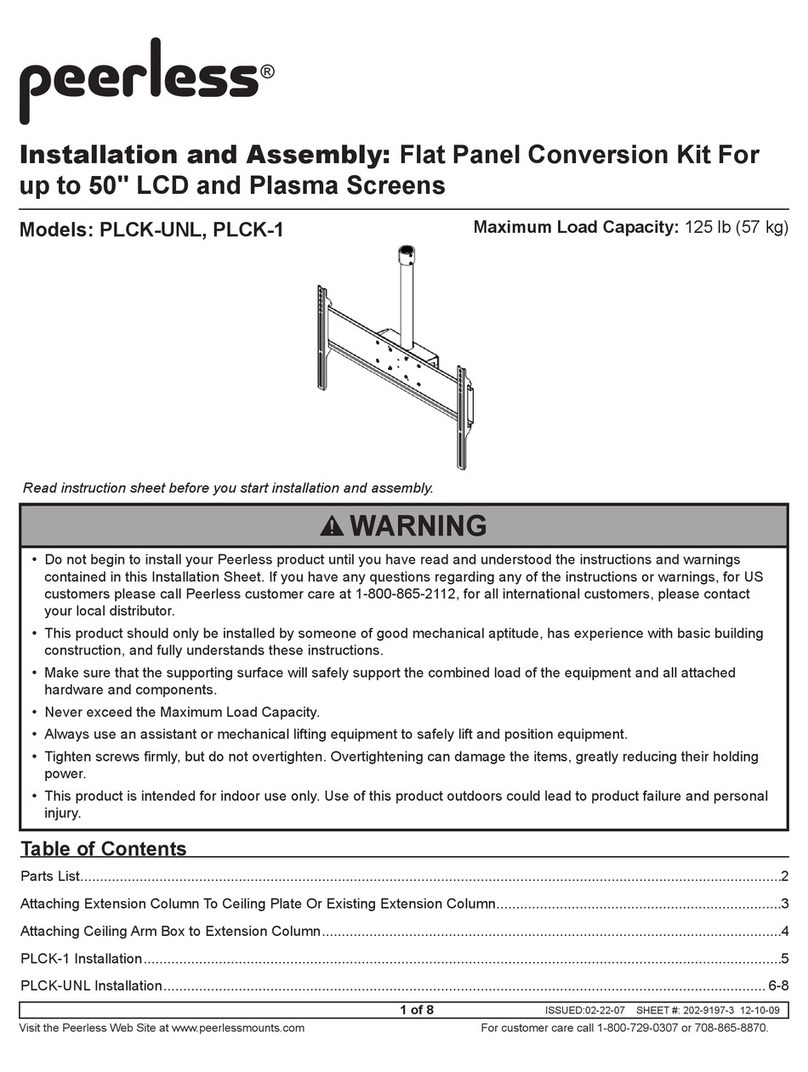

This product was designed to be installed on wood stud walls and solid concrete (2000 psi density

minimum) or cinder block walls. Before installing make sure the supporting surface will support the

combined load of the equipment and hardware. Screws must be tightly secured. Do not overtighten screws

or damage can occur or product may fail. Never exceed the Maximum UL Load Capacity. This product

is intended for indoor use only. Use of this product outdoors could lead to product failure or personal

injury. Depth of screen must be less than 2". This mount is designed to attach the screen 0.68" from the

wall. Please refer to manufacturer's installation guide recommendations for required distance from wall

to avoid risk of injury or property damage. For support please call customer care at 1-800-865-2112.

WARNING

2 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

A (1)

B (2)

Tools Needed for Assembly

recommended)

phillips screwdriver

drill

level

hammer (optional)

3 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

C(6)

E(6)

M4 x 12 mm

D(6)

F(4)

M4 x 25 mm G(4)

M5 x 12 mm

H(4)

M5 x 25 mm

I(4)

M6 x 12 mm J(4)

M6 x 20 mm K(4)

M6 x 25 mm L(4)

M6 x 30 mm

M(6)

M8 x 16 mm

N(4)

M8 x 25 mm O(4)

M8 x 40 mm

T(1)

P(4)

ID .219" (5.56 mm)

Q(4)

ID .344" (8.74 mm)

R(6)

S(1)

4 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

Installing on Wall with Two Wood Studs

1

Use wall plate (A) as a template, make sure it is level, and mark four mounting holes along the center

A) and

attach to wall with four wood screws (C

A

C

Do not over tighten screws, or damage may occur.

WARNING

C

ATOP CUTAWAY VIEW

Wood screws must

center in stud

STUD

WARNING

5 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

Installing on Wall with Three Wood Studs

1

Use wall plate (A) as a template, make sure it is level, and mark six mounting holes along the center

A) and

attach to wall with six wood screws (C

C

A

Do not over tighten screws, or damage may occur.

WARNING

C

ATOP CUTAWAY VIEW

Wood screws must

center in stud

STUD

WARNING

6 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

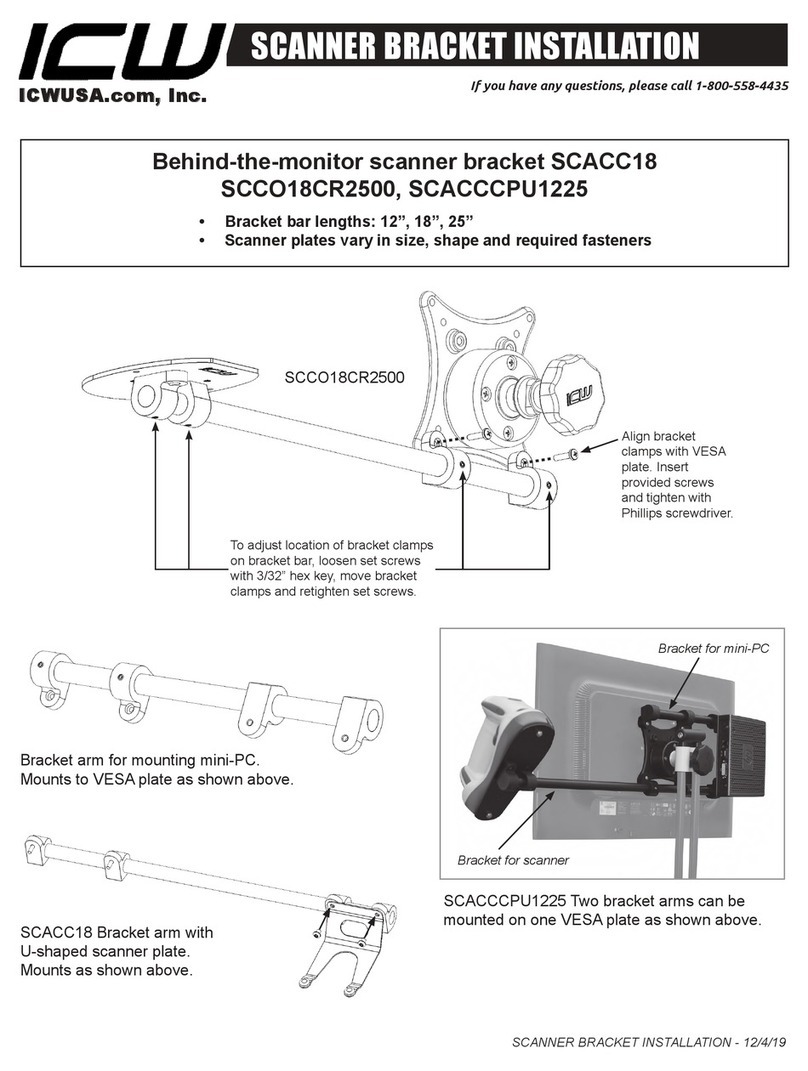

Installing to Solid Concrete or Cinder Block

1

Level wall plate (A

D) into holes and secure wall plate

(A) with six screws (C

C

A

D

SOLID CONCRETE

CINDER BLOCK

7 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

Drill holes and insert anchors (D).

concrete surface

1D

Place plate (A) over anchors (D). Secure with screws (C). Tighten screws.

A

D

C

2

anchors. Do not drill into mortar joints! Be sure to mount in a solid part of the block, gener-

ally 1" (25 mm) minimum from the side of the block. Cinder block must meet ASTM C-90

hole instead of a hammer drill to avoid breaking out the back of the hole when entering a

void or cavity.

directly to load-bearing concrete.

WARNING

CUTAWAY VIEW

INCORRECT

CORRECT

drywall

wall plate

wall plate

concrete

concrete

drywall

WARNING

8 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

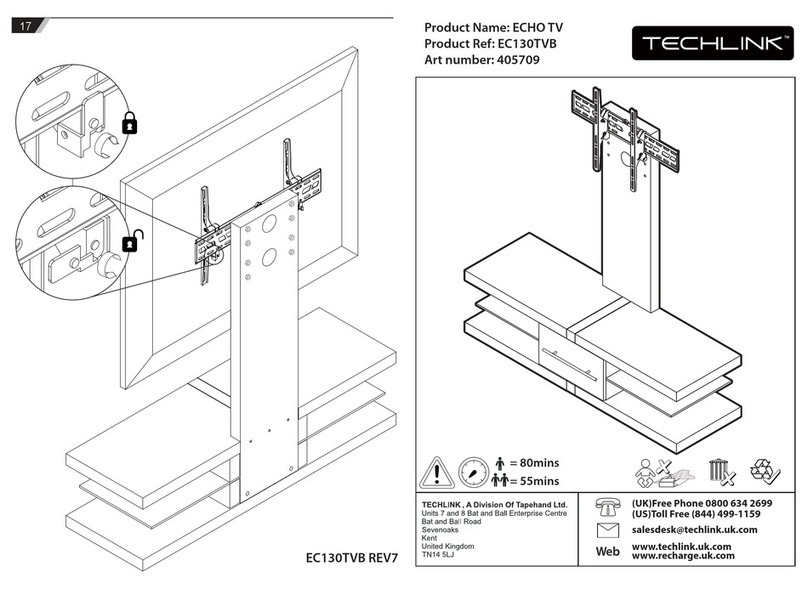

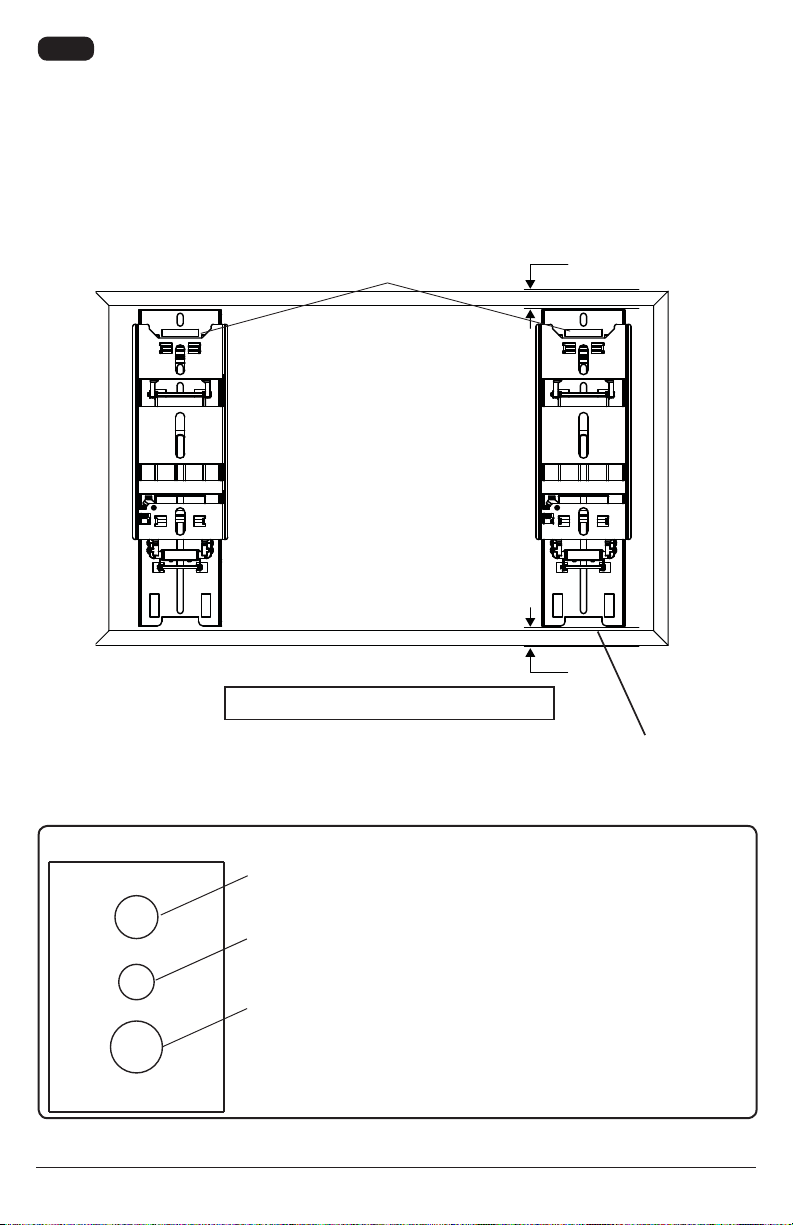

Installing Tilt Brackets

If screen has obstructions on the back, remove them to allow the tilt brackets to be attached. Fully extend

tilt brackets (B) and place tilt brackets on back of screen. Align to holes, and center vertically on back of

screen as shown below. Attach the tilt brackets to the back of the screen using the appropriate combination of

screws, washers, and spacers as required

shown in steps 2-1 or 2-2.

NOTE: Top and bottom holes must always be used.

Verify that tilt brackets are properly aligned and then tighten screws using phillips screwdriver.

2

X

X

B

CENTER

BRACKETS

VERTICALLY

ON BACK OF

SCREEN

NOTE: "X" dimensions should be equal.

NOTE: Cut outs indicate

bottom of tilt brackets (B)

Notes:

depending upon the type of screen.

used, depending upon the type of screen.

washer that matches your screw size.

MEDIUM HOLE

FOR M5 SCREWS

SMALL HOLE

FOR M4 SCREWS

LARGE HOLE

FOR M6 SCREWS

MULTI-WASHER

9 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

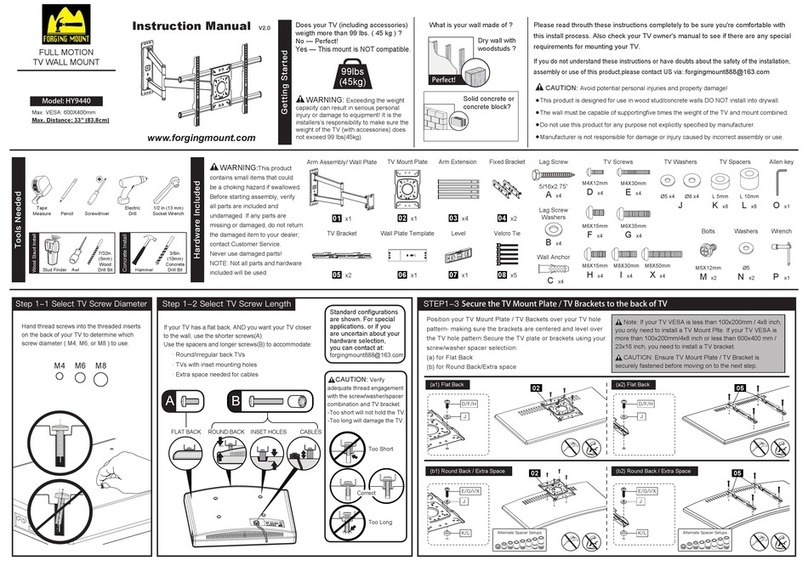

For Flat Back Screens

For Bump-Out or Recessed Back Screens

Begin with the shortest length screw, hand thread through multi-washer, tilt bracket and

spacer, if required, into screen as shown below. If screw cannot make three full turns into the

Repeat for remaining mounting holes, level brackets and tighten screws.

NOTE: Spacers may not be used depending on the type of screen.

NOTE: If screen manufacturer's requirements state that more than 0.68" of ventilation is

required, spacers may be used to add an additional 0.5" (spacer P) or 0.75" (spacer Q) of

space between the wall and the screen as shown below.

Begin with the shortest length screw, hand thread through multi-washer , tilt bracket and

spacer as required into screen as below. If screw cannot make three full turns into the screen

for remaining mounting holes, level brackets and tighten screws.

If you have any questions, please call Peerless customer care at 1-800-865-2112

2-1

2-2

If you have any questions, please call Peerless customer care at 1-800-865-2112

SCREEN

SPACER

MULTI-WASHER

SCREW

TILT BRACKET (B)TILT BRACKET (B)

SCREEN

MULTI-WASHER

SCREW

SCREEN

SPACER

SCREW

TILT BRACKET (B)

bracket is still not tightly secured, damage may occur to screen or product may fail.

WARNING

MULTI-WASHER

10 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

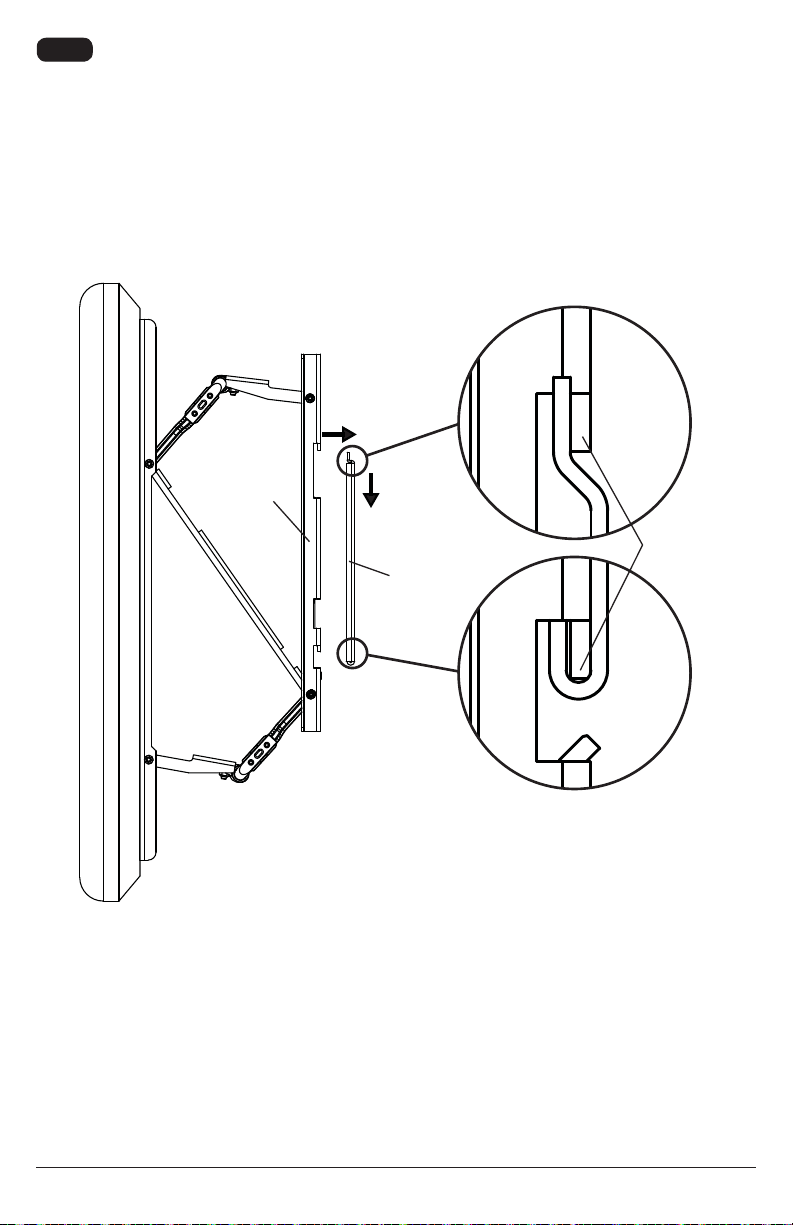

Mounting the Flat Panel Screen

3

Fully extend tilt brackets (B) and move tilt brackets toward wall plate (A

-

DETAIL 1

FLANGES

B

B

B

A

11 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

Tighten safety screws using allen wrench (T) to lock down safety latches securing tilt

brackets to wall plate as shown in detail 2. Reverse steps 3 and 4 to remove screen.

DETAIL 2

SAFETY

LATCH

WALL

PLATE

SAFETY

SCREW

B

4

Failure to lock brackets (B) with safety

screws can cause sceen to come off mount

if hit accidentally.

WARNING

12 of 52 ISSUED: 11-30-09 SHEET #: 202-9417-1

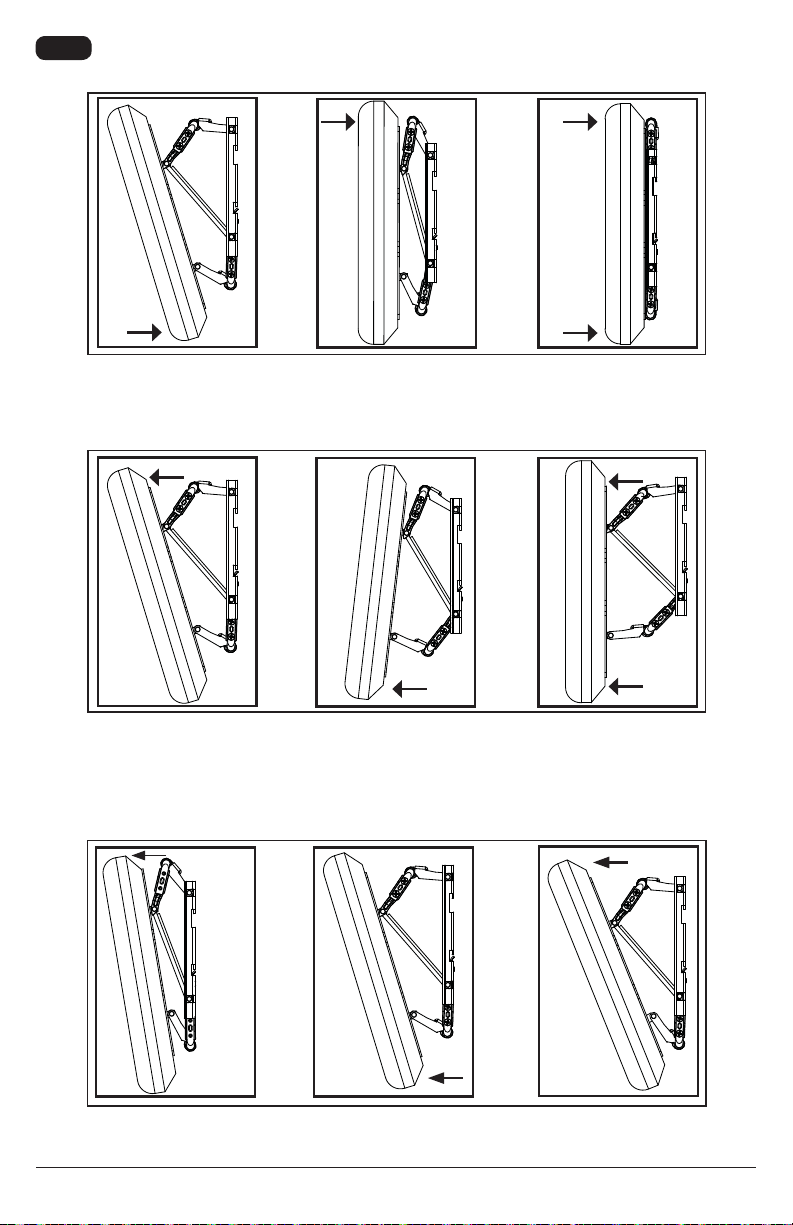

5To collapse adapter plate, grasp top and bottom of screen, push bottom of screen toward

wall then push top of screen toward wall.

132

12 3

13

2

Tilt option: From the collapsed position, pull from top to achieve up to 15° of forward tilt. For

more tilt adjustment, slightly pull out bottom and pull from top to desire tilt angle.

To extend adapter plate and access back of screen, grasp top and bottom of screen, pull

top of screen away from wall then pull bottom of screen away from wall.

PUBLICADO: 11-30-09 HOJA #: 202-9417-1

Modelo: SLTLU

Guía para la instalación

Soporte inclinación Slimline Ultra-Thin

para pantallas planas LCD de 37" à 60"

Máxima capacidad (UL) de carga: 100 lb (45.4kg)

©

UL

USC

Este producto está diseñado para ser instalado en paredes con montantes de madera y en paredes

de concreto macizo (de una densidad mínima de 2,000 psi) o de bloques de hormigón. Antes de

Máxima (UL) de Carga. Este producto está diseñado para uso en interiores solamente. Utilizar este

producto en exteriores podría causar fallas del producto o lesiones a individuos. La profundidad de

la pantalla tiene que ser menos de 2". Este soporte está diseñado para sostener la pantalla a 0.68"

de la pared. Por favor, repase las recomendaciones del manual de instalación del fabricante con

respecto a la distancia necesaria de la pared para evitar el riesgo de sufrir lesiones o causar daños a

la propiedad. Si necesita ayuda, por favor, llame a Servicio al Cliente de Peerless al 1-800-865-2112.

ADVERTENCIA

14 de 52 PUBLICADO: 11-30-09 HOJA #: 202-9417-1

Español

Herramientas necesarias para el ensamblaje

recomienda uno de "borde a borde")

montantes de madera

o de bloques de hormigón de escorias

A (1)

B (2)

15 de 52 PUBLICADO: 11-30-09 HOJA #: 202-9417-1

Español

C(6)

E(6)

M4 x 12 mm

D(6)

F(4)

M4 x 25 mm G(4)

M5 x 12 mm

H(4)

M5 x 25 mm

I(4)

M6 x 12 mm J(4)

M6 x 20 mm K(4)

M6 x 25 mm L(4)

M6 x 30 mm

M(6)

M8 x 16 mm

N(4)

M8 x 25 mm O(4)

M8 x 40 mm

T(1)

P(4)

ID .219" (5.56 mm)

Q(4)

ID .344" (8.74 mm)

R(6)

S(1)

16 de 52 PUBLICADO: 11-30-09 HOJA #: 202-9417-1

Español

A

C

Instalar en una pared con dos montantes de madera

1

Utilice la placa de pared (A) como plantilla, asegúrese de que esté nivelada y marque cautro

agujeros de montaje a lo largo de las líneas que pasan por el centro de los montantes de madera.

de pared (A) y fíjela a la pared con cautro tornillos de madera (C) en el centro del montante.Se

No apriete los tornillos en exceso.

Pernos largos en el

centro del montante

C

A

dañar.

ADVERTENCIA ADVERTENCIA

VISTA SUPERIOR EN CORTE

MONTANTE

17 de 52 PUBLICADO: 11-30-09 HOJA #: 202-9417-1

Español

1

Utilice la placa de pared (A) como plantilla, asegúrese de que esté nivelada y marque seis agujeros

de montaje a lo largo de las líneas que pasan por el centro de los montantes de madera. Taladre seis

A) y

fíjela a la pared con seis tornillos de madera (C) en el centro del montante. Se recomienda utilizar un

en exceso.

Instalar en una pared con tres montantes de madera

C

A

Pernos largos en el

centro del montante

C

A

dañar.

ADVERTENCIA ADVERTENCIA

VISTA SUPERIOR EN CORTE

MONTANTE

18 de 52 PUBLICADO: 11-30-09 HOJA #: 202-9417-1

Español

1Instalar en una pared de concreto

Nivele la placa de pared (A) y úsela como plantilla para marcar cautro agujeros de montaje. Taladre

anclajes (DA) a la pared con seis pernos largos (C). Apriete

C

A

D

CONCRETO MACIZO

BLOQUE DE HORMIGÓN

DE ESCORIAS

19 de 52 PUBLICADO: 11-30-09 HOJA #: 202-9417-1

Español

Perfore los agujeros y después inserte los anclajes (D).

concreto macizo

1D

Coloque la placa (A) sobre los anclajes (D), fíjela con los tornillos (C). Apriete

los tornillos.

A

D

C

2

-

(35 mm) en el agujero, que pueda usar para los anclajes para concreto. ¡No taladre en

juntas de argamasa! Asegúrese de hacer la instalación en la parte sólida del bloque, por lo

general, a un mínimo de 1" (25 mm) del extremo del bloque. Los bloques de hormigón de

taladro eléctrico convencional a baja velocidad para hacer el agujero en vez de un taladro

percutor para no perforar el fondo del agujero al entrar en un vacío o una cavidad.

ADVERTENCIA

INCORRECTO

CORRECTO

placa de

pared

concreto

concreto

ADVERTENCIA

VISTA EN CORTE

de yeso-cartón

de yeso-cartón

placa de

pared

20 de 52 PUBLICADO: 11-30-09 HOJA #: 202-9417-1

Español

Instalación de los soportes inclinables

-

clinables. Extienda los soportes inclinables (B) completamente y colóquelos en la parte trasera de

la pantalla. Centralícelos verticalmente con los agujeros en la parte trasera de la pantalla, como se

muestra abajo. Fije los soportes inclinables en la parte trasera de la pantalla utilizando la combi-

nación adecuada de tornillos, arandelas y espaciadores necesarios, como se muestra en el paso 2-1

o en el paso 2-2.

NOTA: Siempre se tienen que usar los agujeros superiores y los inferiores.

usando un destornillador phillips.

2

X

X

B

CENTRE LOS

SOPORTES

VERTICALMENTE

EN LA PARTE

TRASERA DE LA

PANTALLA

NOTA: Las dimensiones "X" deben ser iguales.

NOTA: Los extremos recorta-

dos indican la parte inferior de

los soportes inclinables (B).

Notas:

según el tipo de pantalla.

arandelas múltiples y los espaciadores,

dependiendo del tipo de pantalla.

arandela múltiple que coincida con el tamaño

de su tornillo.

AGUJERO

MEDIANO PARA

TORNILLOS M5

AGUJERO PEQUEÑO

PARATORNILLOS M4

AGUJERO GRANDE

PARA TORNILLOS M6

ARANDELA MÚLTIPLE

Table of contents

Languages:

Other SlimLine TV Mount manuals