SLOPE INDICATOR Digitilt DataMate User manual

Copyright ©2006 Slope Indicator Company. All Rights Reserved.

This equipment should be installed, maintained, and operated by technically qualified personnel. Any errors

or omissions in data, or the interpretation of data, are not the responsibility of Slope Indicator Company. The

information herein is subject to change without notification.

This document contains information that is proprietary to Slope Indicator company and is subject to return

upon request. It is transmitted for the sole purpose of aiding the transaction of business between Slope Indi-

cator Company and the recipient. All information, data, designs, and drawings contained herein are propri-

etary to and the property of Slope Indicator Company, and may not be reproduced or copied in any form, by

photocopy or any other means, including disclosure to outside parties, directly or indirectly, without permis-

sion in writing from Slope Indicator Company.

SLOPE INDICATOR

12123 Harbour Reach Drive

Mukilteo, Washington, USA, 98275

Tel: 425-493-6200 Fax: 425-493-6250

E-mail: solutions@slope.com

Website: www.slopeindicator.com

Digitilt

DataMate

50310999

Digitilt DataMate, 2006/10/23

Contents

Digitilt DataMate . . . . . . . . . . . . . . . . . . .1

Setting Up Installations . . . . . . . . . . . . 4

Recording Surveys . . . . . . . . . . . . . . . . . 6

Retrieving Surveys . . . . . . . . . . . . . . . . 10

Validating Surveys . . . . . . . . . . . . . . . . 11

Comparing Surveys . . . . . . . . . . . . . . . 14

Inspection and Maintenance . . . . . . 16

Trouble-Shooting . . . . . . . . . . . . . . . . . 17

Digitilt DataMate, 2006/10/23 1

Digitilt DataMate

What is

the DataMate?

The Digitilt DataMate is a recording readout that is used with Digitilt inclinometer

probes (vertical or horizontal), Digitilt tiltmeters, and the spiral sensor. It works

with both metric and English unit versions of these sensors.

Readings stored in the DataMate are transferred to a PC using the DMM software

supplied with the DataMate. The use of DMM is discussed in a separate manual:

DMM for Windows.

DataMate

Controls

Power Switch When you switch power on, the DataMate displays a copyright notice for ten

seconds or until you press Enter. The copyright date serves as the version number

for the DataMate.

Connector Sockets Sensor: Socket for inclinometer control cable.

Power: Socket for battery charger or external power.

I/O: Socket for hand switch or computer interface cable.

Sockets are waterproof only when connectors are plugged in or when protective

caps are in place.

KeyPad Up: Moves cursor up. Also scrolls forward through the alphabet (a...z).

Down: Moves cursor down. Also scrolls backwards through the alphabet (z...a).

Left: Moves cursor to the left.

Right: Moves cursor to the right.

Esc: Cancels current process and returns to menu.

Enter: Chooses menu items. In record mode, records readings.

Digitilt DataMate, 2006/10/23 2

DataMate Menus 1. Use the arrow keys to select (highlight) a menu item.

2. Press Enter to choose the item or Esc to exit the item.

Main Menu The Main menu appears when you turn on the DataMate. The Main menu shows

the main functions of the DataMate.

Read Menu The Read menu lets you record inclinometer readings, edit inclinometer installa-

tion parameters, review and correct readings, and operate the readout in manual

mode, which displays readings but does not record them.

Surveys Menu The Surveys menu lets you list the surveys that are stored in memory, validate a

survey, check available memory, delete a survey, compare two surveys, and print a

survey to a communications program.

Comm Menu Comm puts the DataMate into communications mode for transferring data to and

from a computer. Communications requires the DMM program, the included

serial interface cable, and an RS232 serial port at the computer. If your computer

has only USB connectors, you must use a USB-to-serial adapter or a PCM serial

adaptor.

Utilities Menu The Utilities menu lets you set defaults, and check battery voltage and memory.

Read Surveys

Comm Utilities

Your screen may show

“Datasets” instead of “Surveys”

Record Installation

Correct Manual Read

Dir Validate Memory

Del Compare Print

Waiting for PC . . .

Batt Beep Light

Temp Date Contrast

Digitilt DataMate, 2006/10/23 3

Setting Defaults Date and Time: Choose Date from the Utilities menu. The DataMate displays the

current date and time. Press Enter to edit the date. Press Up or Down to change the

year, then press Right to move the cursor to month, etc. Press Enter when done.

Beeper: Choose Beep from the Utilities menu. Press Enter to toggle the beeper on

or off.

Backlight: Choose Light from the Utilities menu to switch backlight on. Choose

again to switch backlight off. Backlight increases battery drain by about 12 percent.

LCD Contrast: Choose Contrast from the Press Up or Down to adjust contrast for

easy viewing. Press Esc when done.

Checking

the Battery

Choose Batt from the Utilities menu. A new, fully charged battery shows approxi-

mately 6.2 volts with a full charge. If the main battery drops below 6 volts, it should

be recharged.

Recharging

the Battery

For best performance, you should recharge the battery after every use of the Data-

Mate. We recommend charging it over night.

Plug the charger into an AC mains socket. Plug the Lemo connector into the

DataMate’s Power socket. Use the Utilities - Batt function to verify that the battery

is charging. You should see the voltage reading increasing.

Checking Memory Choose Memory from the Surveys menu. The DataMate can hold readings from

2,500 depths and up to 40 Surveys.

Moisture

Management

When you return to the office, remove caps from the DataMate’s connectors and

allow connectors to air-dry for a number of hours.

Use desiccant to keep the inside of the readout dry. This is particularly important in

hot humid weather. Warm moist air trapped in the readout can condense when the

readout is brought into a cool air-conditioned office.

To check the moisture level in the DataMate, choose Temp from the Utilities menu.

The DataMate displays humidity and temperature. Humidity levels from 20 to 60%

are normal. If humidity exceeds 75%, replace the desiccant. See instructions in the

chapter on inspection and maintenance.

Digitilt DataMate, 2006/10/23 4

Setting Up Installations

Overview Setting up the DataMate involves entering a list of inclinometer installations into

the DataMate’s memory. You can do this with DMM software or with the

DataMate’s keypad.

Setting Up

with DMM Software

This method is convenient when you are in the office:

1. Use DMM to create a setup database on your PC.

2. Connect the DataMate to your PC.

3. Use DMM to transfer the setup to the DataMate.

Setting Up with

DataMate Keypad

This method is convenient when you are in the field.

1. Choose Read.

2. Choose Installation.

3. Press Down key to scroll past any previously entered installations. The cursor

stops on the word, “Create.” Press Enter.

4. Enter the required information (see next page). To make an entry:

Press the Right key to move the cursor into the editing zone.

Press the Up or Down key to change the character under the cursor.

Press the Right key to move to the next column.

Press Enter to move to the next field.

5. To correct a mistake, press the Up or Down key to display the line that you want

to correct. Then press the Right key to enter your correction.

Note 1: DataMates built before 5/2005 have a slightly different editing routine: The

the cursor is automatically placed into the editing zone. The Up or Down keys have

only one function: they change the character under the cursor. They cannot be

used to scroll the display or move from field to field.

Note 2: The DataMate can hold a maximum of 40 installation records. If there are

already 40 installation records in the DataMate, the Create command does not

appear, and you cannot enter an installation.

You cannot delete installations using the DataMate keypad, but you can still record

a survey, if necessary. At recording time, select any installation and change its

parameters as necessary.

Digitilt DataMate, 2006/10/23 5

Installation Fields Site & Install#: Every installation has a two-part identifier consisting of a “site” and

an “installation.” Enter up to 6 characters for each.

A0 dir: Enter up to 3 characters to identify the compass heading of the A grooves.

Not used for any calculation, so this field is optional.

Operator: Enter up to 3 characters to identify the operator. Optional.

Sensor#: Enter the serial number of the probe. Optional, but recommended.

Sens Type: Choose Digitilt for inclinometer probes or Spiral for spiral sensors.

Units: Choose Metric or English. If you don’t know, check the distance between the

upper and lower wheels of the probe: 0.5 m for metric systems; 2 feet for English-

unit systems.

Ins Constant: Use 25000 for metric-unit systems or 20000 for English-unit systems.

Start: Enter the starting depth for the survey. Surveys typically start at the bottom

of the casing. With English-systems, it is best to use an even number so that 2-foot

intervals coincide with cable markings.

End: Enter the ending depth for the survey, typically 0.5 for metric-unit systems or

2 for English-unit systems.

Interval: Enter 0.5 for metric-unit systems and 2 for English unit systems.

Check

the Installations

Verify that the DataMate now holds your installation list:

1. Choose Read from the main menu.

2. Choose Installation.

3. Scroll through the list of installations.

Digitilt DataMate, 2006/10/23 6

Recording Surveys

Good Practices 1. Use the same probe and control cable for each survey, if possible.

2. Use a pulley assembly, if possible. It protects the control cable and provides a

good reference.

3. Use a consistent top reference. The goal is repeatable placement of the probe

within 5 mm or 1/4 inch. If one technician uses a pulley and another technician

does not, probe positioning will be inconsistent, and data will be unusable.

4. Power up the probe before you insert it into the casing. Powered-up sensors

resist shock better than unpowered sensors. Compress the wheels with your

hand to allow smooth insertion of the probe into the casing.

5. Always wait 10 minutes for the probe to adjust to the temperature of the bore-

hole. This helps prevent bias-shift (offset) errors.

6. Always pull the probe upward to the reading depth. If you accidentally pull the

probe past the intended depth, lower it to the previous depth, then pull it back up

to the intended depth. This ensures consistent placement.

7. Wait for displayed readings to stabilize. The DataMate displays 3 diamonds when

readings have stabilized within two units. If the reading does not stabilize, watch

the display and try to record an average reading.

8. When you remove the probe from the casing, use your hand to compress the

wheels so that they don’t spring free or force the body of the probe to strike the

side of the casing. This helps prevent bias-shift errors.

9. Check your readings on site using the DataMate’s Validate command. If neces-

sary, reposition the probe at the required depth and using the Correct command

to obtain a new reading for that depth.

Digitilt DataMate, 2006/10/23 7

Recording

a Survey

1. Connect the control cable to the probe. Do not over tighten. Plug the other end

of the control cable into the Sensor socket on the DataMate.

2. Switch on the DataMate. Press Enter to display the main menu.

3. Choose Read, then Choose Record.

4. Choose the appropriate installation from the list.

5. Press Enter to step through the installation parameters without making changes.

Normally, no editing is required.

6. Finally the DataMate displays the Start depth (bottom depth).

7. Insert the probe into the casing with upper wheels in the A0 direction.

Lower the probe to slightly below the start depth.

8. Wait ten minutes for the probe to adjust to the temperature at the bottom. This

step is important for consistent readings.

9. Begin the survey. Raise the probe to the start depth, then watch for a stable

reading. Normally, you will see three diamonds, as shown below. Press Enter to

record the reading.

Read Surveys

Comm Utilities

Your DataMate may display

Datasets rather than Surveys.

Record Installation

Correct Manual Read

Select Installation

SR18 IN1

Edit Installation

Site :SR18 IN1 Press Enter to step through

these parameters

50.♦204 48

Depth A0 B0

Start depth

50.♦206♦52♦

Depth A0 B0

Three diamonds ♦♦♦

indicate stable reading.

Press Enter to record.

Digitilt DataMate, 2006/10/23 8

Recording a Survey

continued

10.The DataMate beeps and scrolls up to the next depth. The reading just recorded

is now on the bottom line. Raise the probe to the next depth (shown in the top

line of the display) and wait for the numbers to stabilize. Press Enter to record

the reading.

11. Repeat this process until you have recorded a reading at the top of the casing.

The DataMate displays a menu. Choose Continue.

12.The DataMate now displays the starting depth for the second pass. Remove the

probe from the casing and rotate it 180 degrees so that the upper wheels point to

the A180 direction. Insert the probe and lower to the bottom of the casing, or

slightly below the start depth.

13.Raise the probe to the start depth, and wait for the numbers to stabilize. Press

Enter to record.

14.Repeat these steps until the probe is at the top of the casing and you have

recorded the last reading. Choose Done from the menu, and remove the probe

from the casing.

15.You may want to validate the survey using the DataMate’s validate command.

See Appendix 1 for instructions.

48.♦210 55

50.* 206* 52* Recorded readings are

marked with a *

After you record the

reading, pull the probe

up to the next depth.

Continue 0

Done Del

50.♦-210 -60

Depth A180 B180

48♦-215 -75

50.π∗ -210π-60π

Recorded readings

for the second pass

are marked with

the Pi symbol.

Continue 0

Done Del

Digitilt DataMate, 2006/10/23 9

Making Corrections If you make a mistake during the survey, you can easily correct it.

1. Use the Down key to return to the depth where the mistake was made. The depth

should appear on the top line of the display.

2. Lower the probe below that depth, then pull it up to the exact depth.

3. Press Enter to make the top line active. A diamond appears next to the depth.

4. Wait for the readings to stabilize, then press Enter to record.

5. Continue recording as in a normal survey.

Cancelling a Survey 1. Press Esc. If you press Esc by mistake, press Continue.

2. Choose Del to delete the survey that you cancelled.

3. The DataMate prompts for confirmation. Press Up to confirm.

Deleting a Survey If you want to record a survey, but the DataMate prompts “no room in memory” or

“too many surveys,” you must free some memory by deleting a survey.

1. Choose Surveys from the main menu.

2. Choose Del.

3. Select a survey to delete and press Enter. (Surveys marked with the ^ symbol

have been retrieved by a PC, so it might be safe to delete one of them.)

4. Press Up to confirm the deletion or Esc to cancel. The DataMate deletes the

survey. To avoid possible loss of data, do not switch the DataMate off during this

process.

Deleting

an Installation

The DataMate itself provides no way to delete installations. DMM is required for

deleting installations. However, if you need to survey an installation that is not in

your DataMate, you can “borrow” another installation temporarily and fix it later

with DMM.

1. Go to Read - Record - and choose an installation (remember its name for later).

2. As you step through the installation parameters, change the start depth, stop

depth and any other parameters.

3. Record the survey.

4. When you return to the office, upload the survey as usual. Then use DMM to

create a new installation and move the survey to that installation. The How-To

notes in the DMM manual show how to do this.

Digitilt DataMate, 2006/10/23 10

Retrieving Surveys

Overview To retrieve surveys, connect your DataMate to your PC and run the DMM

program. This is the normal and most efficient way to retrieve data.

Using DMM Detailed instructions are provided in the DMM manual. The basic steps are:

1. Connect the DataMate to your PC. Choose Comm on the DataMate.

2. Start DMM and choose Retrieve Surveys.

3. Drag and drop the retrieved surveys into your project database (or export sur-

veys to a text file).

Using a

Terminal Program

You can also “print” surveys, one by one, to the DataMate I/O port and run a termi-

nal program on your PC to receive it. This is for special purposes only.

1. Connect the DataMate to the PC.

2. Start your terminal program. Set it for 8-bit, no parity at 9600 bps.

3. Set the terminal program to “capture” or “log” the data sent from the DataMate.

Specify a file name for the captured data.

4. Choose Print from the DataMate’s. Set the baud rate for 9600 and press Enter.

Then select the survey and press Enter to “print” it.

5. Your terminal program will usually display the readings as they are sent from the

DataMate.

6. Close the file with your terminal program.

Digitilt DataMate, 2006/10/23 11

Validating Surveys

About Checksums A checksum is the sum of 0 and 180 degree readings at the same depth. Ideally, the

sum should be zero since the readings have opposite signs. In practice, checksums

are rarely zero.

In general, you should look for consistency in checksums. A checksum that is sig-

nificantly different from checksums above and below it may indicate that the probe

wasn’t positioned correctly or the reading was not stable when recorded. A large

checksum may also be caused by debris in the groove, an out-of-round casing sec-

tion, a separated casing section, or a wheel falling in the joint of a telescoping cas-

ing section.

A graph of checksums shows very clearly whether checksums are consistent or not.

Alternatively, scanning through a column of checksums gives you an idea of con-

sistency. Unfortunately, the DataMate provides neither graphs nor columns of

checksums. However, the DataMate does provide the standard deviation of check-

sums, which can be used as a measure of reading quality, as explained below.

Standard Deviation

of Checksums

The standard deviation of checksums can be used as a way to confirm that the cur-

rent survey is comparable to other surveys for the same borehole.

You must first establish a “typical SD” for each axis. Obtain the “typical SD” from

your initial survey. (It is good practice to make several surveys of the casing ini-

tially, compare them, and select one to be the official” initial.) Since the initial sur-

vey represents good readings, the standard deviation of checksums for that survey

can be used as “typical SD” for that installation. Note that the “typical” is likely to be

different for every installation.

When you obtain a new survey, run the DataMate’s validation routine. Compare its

SD to those of the initial survey. If the standard deviation is 3 to 5 units of typical,

the data is probably good. For example, if the typical standard deviation is 4, then

acceptable standard deviations for subsequent surveys could range as high as 7 or 9.

Narrower limits may be appropriate for deeper installations and critical measure-

ments. Wider limits may be appropriate for shallower installations or for poorly-

installed casing.

Digitilt DataMate, 2006/10/23 12

Validating

a survey

Here is a typical validation procedure:

1. Check the standard deviation of checksums. Is it typical for this casing? If so, the

survey is probably good and needs no further validation. You can quit the valida-

tion routine.

2. If the standard deviation is not typical, check the standard deviation for the

different zones. If any group shows an obvious problem, examine the individual

checksums in that group. Also look for drifting mean checksums. A drifting

mean may indicate a problem with the electronics inside the probe.

3. If you find a checksum that is too large, examine the readings at that depth to

determine whether the bad reading was recorded in the 0 or the 180 orientation.

Afterwards, you can correct the data by taking another reading for that depth.

4. The steps below explain this in detail.

Check the Standard

Deviation

1. Choose Validate from the Surveys menu.

2. Choose a survey to validate.

3. After a short delay, you will see a display that shows both the mean (MN) check-

sum and the standard deviation (SD) of checksums:

4. Compare the standard deviation with the “typical” SD that you have established

for the installation. If the standard deviation is acceptable, press Esc to quit.

Otherwise, look at the SD for each zone.

Check Zone Statistics 1. Press Enter to view the zone with the largest SD. You will see a display that looks

something like this:

2. To view the mean checksum for this zone, press the Left arrow. Press Right to

redisplay the SD.

3. Press Up or Down to display other zones. Again, the Left and Right keys toggle

between mean and standard deviation.

4. If you decide the survey is acceptable, press Esc to quit. Otherwise, note the

zones (depths) that you want to inspect and continue.

MN A=51.337 B=45.674

SD A=4.1781 B=5.7170

25. - 20. S.D.

A=3.2264 B=10.3388

Zone statistics include 10 readings. In

this case, there are 10 half-meter read-

ings in the zone from 25m to 20m.

Digitilt DataMate, 2006/10/23 13

View Individual

Checksums

Follow the steps below to find depths with large checksums:

1. After viewing the checksum statistics, press Enter to view checksums. The Data-

Mate first displays the largest checksum in the survey. In this case, the 89 in the B

axis is largest.

2. Use the Up and Down keys to view checksums at other depths. When you are

finished viewing checksums, press Esc.

Isolating the Bad

Reading

A large checksum may indicate a bad reading, but does not indicate which reading

was bad (the 0 or the 180 reading?). To isolate the bad reading, you must view read-

ings above and below the suspect reading. .

1. Choose Read from the main menu.

2. Choose Correct, then choose a survey (If necessary, press Right to see dates).

3. Press the Enter key to skip through parameters.

4. Choose 0 (orientation). Scroll through readings to the suspect depth. Check

readings above and below the depth. A bad reading does not fit with the readings

above and below it.

5. To view 180 readings at the same depth, press the Right arrow. Press again to dis-

play the 0 readings.

6. Note the depth and orientation of the bad reading. Then press Esc.

Correcting a Reading 1. Choose Correct from the Read menu.

2. Choose 0 or 180, and scroll the DataMate to the required depth. The depth

should be displayed on the top line.

3. Lower the probe to the required depth. Wait for the probe to adjust to the tem-

perature in the borehole (5 to 10 minutes if the probe has been in open air)

4. Press Enter to activate the reading. Press Enter again to record the reading.

25. 20 89

25.5 25 34

Depths A B

Digitilt DataMate, 2006/10/23 14

Comparing Surveys

Overview The DataMate can calculate a single value for cumulative deviation or cumulative

displacement.

Cumulative

Deviation

1. At the Main Menu, select “Surveys.” Then select “Compare.”

2. The DataMate prompts for the current survey. Press Enter to select the suggested

survey or scroll to find a different survey.

3. The DataMate prompts for a “previous” survey. Press Esc since you do not want

to calculate displacement.

4. The DataMate asks you to confirm a conversion value of 1. Press Enter. This will

display metric data in meters and English data in feet.

5. The DataMate then calculates the cumulative deviation for the survey and dis-

plays it.

6. Press Esc to return to the Surveys menu.

Note The DataMate calculates cumulative deviation by summing incremental

deviations from the bottom of the casing to the top.

If you are interested in borehole drift, you probably want the top of the borehole to

be used as reference. The DataMate does not offer this as a choice, but when sum-

ming from the top, the deviation at the bottom of the borehole will be the same

value except in the opposite direction.

Cumulative

Displacement

To calculate displacement, the DataMate must contain two surveys for the same

installation.

1. Choose Surveys from the main menu, then choose Compare.

2. The DataMate prompts for the current survey. Press Enter to select the sug-

gested survey or scroll to find a different survey. Then the DataMate prompts for

a “previous” survey. Scroll to find the initial set, then press Enter.

3. The DataMate prompts for a conversion value. Enter 1000 for a displacement in

millimeters (with metric data). Enter 12 for a displacement in inches (with

English unit data).

4. The DataMate then calculates the cumulative displacement for the survey and

displays it. Press Esc when done.

Digitilt DataMate, 2006/10/23 15

Inspection and Maintenance

Inspection

Maintenance

Part What to check for Remedy

Desiccant Check humidity under

utilities menu.

If humidity exceeds 75%, replace or recharge

desiccant.

Batteries Check main battery and

lithium battery under

utilities menu.

Main battery can be recharged. If battery does not hold

charge, battery can be replaced. Lithium backup battery

is good for 7 to 10 years if main battery keeps charge.

Return for servicing if Lithium battery is bad.

Connectors Dirt, bent pins, o-ring Clean with alcohol moistened swab. Note that connec-

tors are “water proof” only when capped or when con-

nector is plugged in.

Self Test Error 0 or 1 Bad signal input. Return for servicing.

Error 2 or 3 ±12V sensor power. Disconnect control cable and probe.

Try again. If error goes away, problem could be in probe

or cable. Connect cable only. If no error, then probe is the

problem. This error could also be caused by discharged

battery. So try recharging battery first. If error persists,

some component must be returned for servicing.

Error 4 Main battery is low. Try recharging. If error persists,

replace battery

Error 5 Memory keep alive power is bad. Retrieve any data

before switching off. Then return for service.

Error 6 Operating temperature range exceeded. Either below -20

or above 60C.

Error 7 Humidity above 80%. Replace desiccant.

Battery Recharge battery after every use. Charge at least two hours for

every hour of use. Charging overnight is common practice. Do

not change longer than 72 hours. Longer charge time may

damage the battery. A new, recharged battery will show 6.2V

or higher.

The DataMate displays a low battery warning when voltage

drops to 5.5 volts. Turn off the DataMate when the warning

appears and then recharge as soon as possible. Deep dis-

charge of the main battery can reduce its performance and

shorten its life.

Desiccant Check humidity under utilities menu. If humidity exceeds

75%, replace desiccant.

Connector sockets If it is necessary to clean the connector, use a small brush or a

slim cotton swab. Do not use spray lubricants or electric con-

tact cleaners. Solvents contained in such products will attack

the neoprene inserts in the connectors.

Digitilt DataMate, 2006/10/23 16

Replacing

Desiccant

You must open the DataMate to change the desiccant. You should ground yourself

to prevent a static discharge that could damage the DataMate’s electronics.

Remove the two screws from the bottom of the case. Hold the top panel and pull off

the case. Look for the desiccant pack between the battery and the panel connectors.

Replace the desiccant pack with a new one. You may be able to renew the desiccant

in an oven at 250 °F (121 °C) for 16 hours. Do not use a microwave oven to renew

the desiccant. You may damage your microwave oven.

Before you replace the case, apply a light coat of silicone grease to the gasket. Also

lubricate the O-rings on the screws. Then slip the DataMate back into its case,

checking that the gasket is seated properly. Replace the screws and tighten to draw

the top panel squarely against the case. Do not over-tighten the screws

Wiring Diagram

for Interface Cable

Below is the wiring diagram for the connectors on the control cable.

Wiring Diagram

for Hand Switch

Below is the wiring diagram for the hand switch.

Digitilt DataMate, 2006/10/23 17

Trouble-Shooting

Tech Notes on

slopeIndicator.com

Many questions can be answered by a visit to the Tech Notes section of

www.slopeindicator.com. Go to Support - TechNotes. The scroll down the page to

find the inclinometer tech notes. Take a look at the Digitilt DataMate Q & A page.

Readings Not Stable The DataMate's "ready" signal is displayed when readings in both axes are stable

within 2 digits. If this happens occasionally, but readings vary within 3 or 4 digits,

you can record the readings with no significant loss of accuracy.

•If this problem always occurs at a single installation and at a just a few depths, it

is possible that the backfill around the casing has washed away or was simply

incomplete.

•In some situations, such as when there is no water in the inclinometer casing,

control cable can go into a slow oscillation, shaking the probe, and preventing

full stabilization of readings. The same may occur at sites where heavy

construction machines are active. In this case, look for the average reading.

•Reading instability can also be caused by a low battery, so always check battery

voltage before you leave the office.

•If readings always take a long time to stabilize, and this happens at all installa-

tions, contact Slope Indicator.

Strange Readings A & B readings are midrange or higher (e.g. +6000 or -6000): Mid-range readings

like this point to a cable problem. It is likely that one of the power wires is bad. The

problem may be in a a broken or corroded wire in the connector.

Readings are very high, for example 12,000: If your DataMate shows a full scale

reading, such as 10,000 or 12,500, when the probe is near vertical, there is probably

water in the connector or in the cable.

Reading of +1786 (English) or 3125 (Metric): Typically, many readings will have this

same number. This indicates an input line problem. The problem is probably in the

cable or a connector. If you disconnect the signal cable, you will see the same num-

ber.

Reading of 60 or some other low number: If you see a low number that stays con-

stant in one axis, the problem is mostly likely in the probe. The accelerometer for

that axis is not working and the op amp is trying to compensate, resulting in a con-

stant value.

Table of contents

Other SLOPE INDICATOR Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

MADDALENA

MADDALENA ElecTo Bulk Instructions for installation, use and maintenance

VOLTCRAFT

VOLTCRAFT FM-300 operating instructions

Spinner

Spinner BN 53 70 84 Handling & Cleaning Instructions

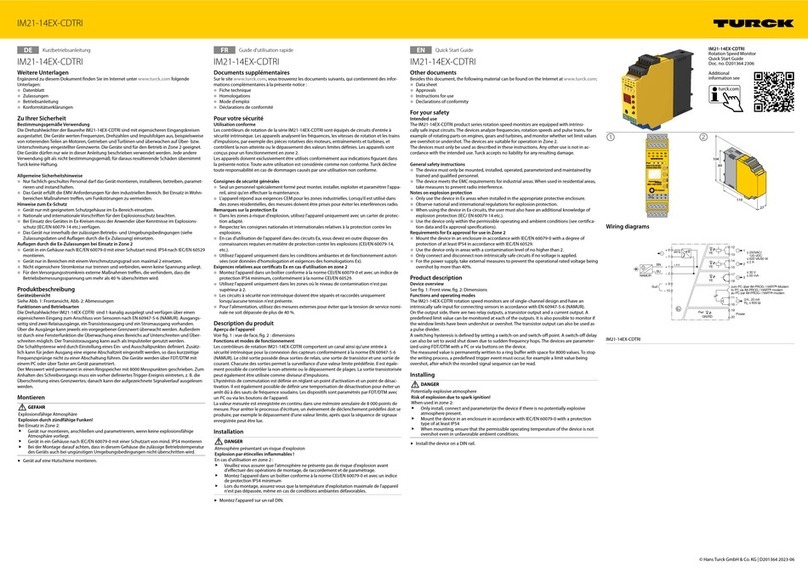

turck

turck IM21-14Ex-CDTRi quick start guide

Levenhuk

Levenhuk LX700 user manual

RKI Instruments

RKI Instruments GP-03 Operator's manual