SLOPE INDICATOR 56804199 User manual

Copyright ©2006 Durham Geo Slope Indicator. All Rights Reserved.

This equipment should be installed, maintained, and operated by technically qualified personnel. Any errors

or omissions in data, or the interpretation of data, are not the responsibility of Slope Indicator Company. The

information herein is subject to change without notification.

This document contains information that is proprietary to Slope Indicator company and is subject to return

upon request. It is transmitted for the sole purpose of aiding the transaction of business between Slope Indi-

cator Company and the recipient. All information, data, designs, and drawings contained herein are propri-

etary to and the property of Slope Indicator Company, and may not be reproduced or copied in any form, by

photocopy or any other means, including disclosure to outside parties, directly or indirectly, without permis-

sion in writing from Slope Indicator Company.

SLOPE INDICATOR

12123 Harbour Reach Drive

Mukilteo, Washington, USA, 98275

Tel: 425-493-6200 Fax: 425-493-6250

E-mail: solutions@slope.com

Website: www.slopeindicator.com

EL In-Place

Inclinometer

56804199

EL In-Place Inclinometer, 2008/7/09

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . 1

Pre-Assembly . . . . . . . . . . . . . . . . . . . . . 5

Vertical Installation . . . . . . . . . . . . . . . . 6

Horizontal Installation . . . . . . . . . . . . .11

Manual Reading . . . . . . . . . . . . . . . . . . 14

Data Logging. . . . . . . . . . . . . . . . . . . . . .16

Data Reduction. . . . . . . . . . . . . . . . . . . .18

Removing Sensors. . . . . . . . . . . . . . . . .23

EL In-Place Inclinometer, 2008/7/09 1

Introduction

In-Place

Inclinometers

The in-place inclinometer system consists of

inclinometer casing and a string of linked

in-place inclinometer sensors.

The inclinometer casing provides access for sub-

surface measurements, controls the orientation of

the sensors, and moves with the surrounding

ground.

In vertical installations, the inclinometer casing is

installed in a borehole that passes through a sus-

pected zone of movement. One set of grooves is

aligned in the expected direction of movement

(downhill, for example).

In horizontal installations, inclinometer casing is

typically installed in a trench. One set of grooves

must be aligned to vertical, since the instrument is

expected to monitor vertical movements (settle-

ment or heave).

The string of linked sensors is positioned inside

the casing to span the zone of movement. When

the ground moves, the casing moves with it,

changing the inclination of the sensors inside the

casing.

Sensors for vertical installations measure inclination from vertical. Sen-

sors for horizontal installations measure inclination from horizontal.

Inclination measurements from the sensors are processed to provide

displacement readings in mm of displacement for the gauge length of

each sensor.

In most applications, sensors are connected to a data acquisition system

and data processing is completed by a computer program.

Casing

controls

orientation

of sensors

Fixed wheel

points at

direction of

movement

in vertical

installations

Sensor

gauge

length

Inclinometer casing controls the orientation of the sensor

Sensor gauge length

Fixed wheel points down

in horizontal installations

ExpectedDirection

ofMovement

In vertical installations, one

pair of casing grooves should

be aligned with the expected

direction of movement.

In horizontal installations, one

pair of casing grooves must be

aligned to vertical.

Vertical

EL In-Place Inclinometer, 2008/7/09 2

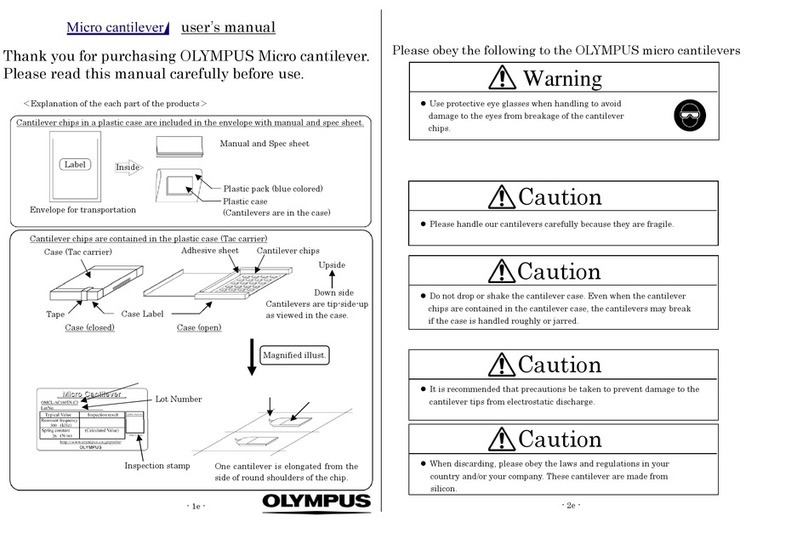

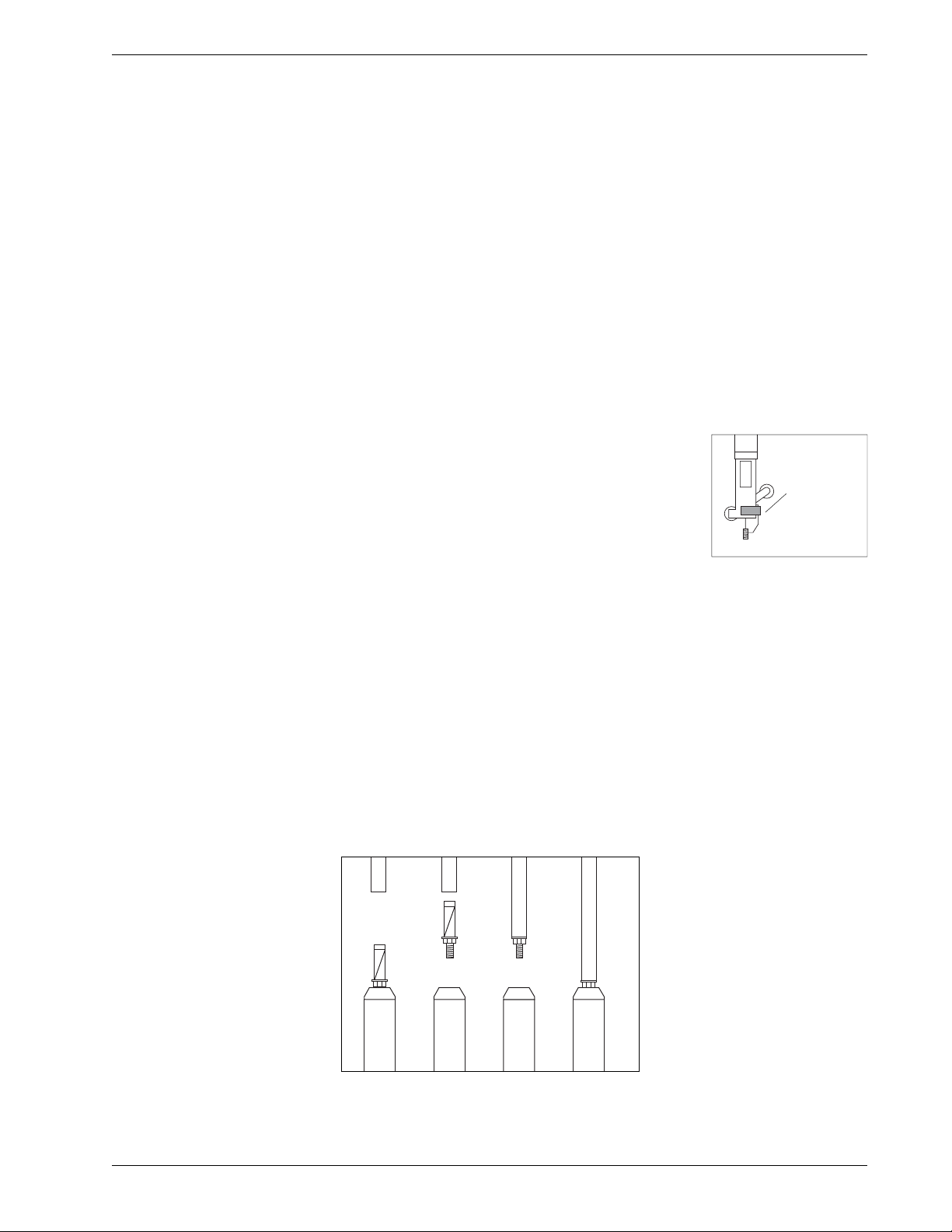

IPI Sensor

Components

IPI sensor with wheel

assembly and top and

bottom tubing clamps.

Each sensor has a serial

number and is sup-

plied with a specified

length of signal cable.

Tubing clamp connects

sensor to gauge tubing

Gauge tubing completes the

gauge length of the sensor

below. Typically longer than

shown here.

Tubing clamp connects the

sensor to the gauge tubing.

Bottom IPI sensor

includes a swivel clamp

to lock the bottom

wheel assembly.

Fixed wheel is

important at

installation

time.

Fixed wheel is

important at

installation

time.

EL In-Place Inclinometer, 2008/7/09 3

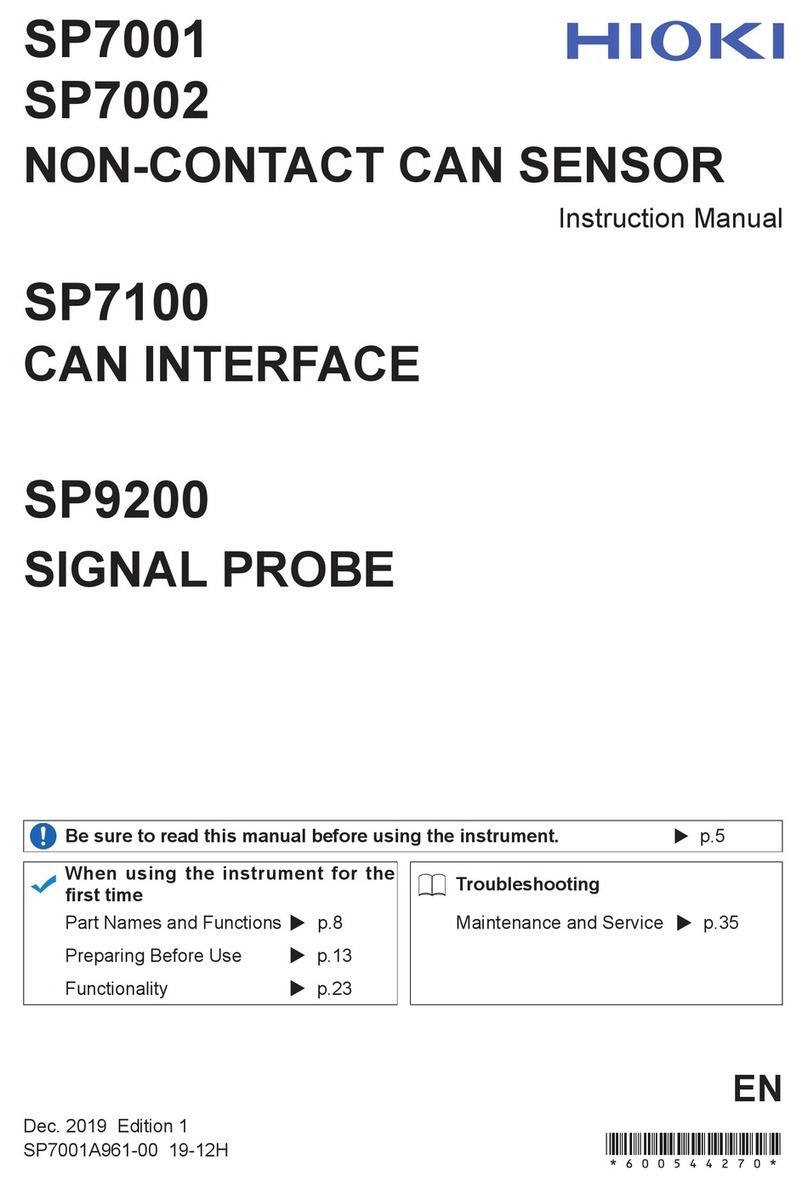

Other Components

Suspension Kit includes wheel

assembly and hardware to clamp

and adjust suspension cable.

Suspension kit is used with vertical

inclinometers. Stainless cable is

required, but not shown.

Placement tubing is used

to push inclinometer into

position and then keep it

there. Generally supplied

in 10 ft. or 3 meter

length.

Coupling for placement

tubing.

Placement Kit includes

wheel assembly and top

clamp. Clamp rests on top of

casing and hold placement

tubing in center of casing.

Placement kit is typically

used with horizontal IPI

installations, but can also be

used for vertical installations.

EL In-Place Inclinometer, 2008/7/09 4

Gauge Tubing Gauge tubing is typically ordered with the sensors. If gauge tubing is

not supplied, check project specifications for required gauge length,

and then follow the instructions below:

1. Choose stainless tubing that can accept tubing clamps. The standard

tubing clamps have a minimum OD of 15.6 mm (0.615 inch) and

expand to a maximum OD of 17.4 mm (0.685 inch).

2. Measure and mark the gauge tubing for the proper length:

tubing length = total gauge length – 550 mm (21.625 inch).

For example, you would cut tubing lengths of 1450 mm for a total

gauge length of 2 meters.

3. Cut and deburr the gauge tubing. Check that tubing clamps fit inside.

Suspension Cable Suspension cable, if used, is typically ordered with the system. The sus-

pension kit contains hardware for 3/16 inch cable. The cable is 3/16

inch, 19 x 7, stainless steel aircraft cable.

Placement Tubing Placement tubing, if used, is typically ordered with the system. If place-

ment tubing is required, but not supplied, follow the instructions below.

1. Choose stainless tubing that can accept tubing clamps and couplings.

The standard tubing clamps have a minimum OD of 15.6 mm (0.615

inch) and expand to a maximum OD of 17.4 mm (0.685 inch).

2. Deburr the gauge tubing and check that tubing clamps fit inside.

3. Use the coupling shown on previous page to join lengths of place-

ment tubing.

4. Use in-line wheel assembly if placement tubing must be articulated.

Safety Cable In vertical installations, you may find it useful to connect a safety cable

to the bottom sensor to prevent accidental loss of the sensors.

EL In-Place Inclinometer, 2008/7/09 5

Pre-Assembly

Introduction This chapter tells how to connect gauge tubing to the sensors. We do

not recommend further pre-assembly. Sensors should be joined to

other sensors only as they are installed downhole.

Tools •Vice-grips to hold gauge tubing.

•Wrench to tighten tubing clamps.

Identify and

Check Sensors

•Test each sensor. See “Manual Readings” for instructions.

•Write down the serial number and intended installation depth of

each sensor.

•Check that wheels are firmly attached to sen-

sors. Also check that the swivel clamp is

attached to the wheel assembly of the bottom

(farthest) sensor.

•Check that cable lengths are correct and attach

sensor ID tags to ends of signal cables.

•Mark sensors for order of installation.

Attach Gauge Tubing

to Each Sensor

As you work, be careful not to bend or damage the wheel assembly as

you work.

1. Remove the tubing clamp from the top of the sensor body.

2. Insert clamp into gauge tubing

3. Hold tubing and tighten clamp well.

4. Screw gauge tubing onto sensor body until sensor body and gauge

tubing form a rigid unit.

Swivel

clamp on

bottom

sensor

1234

EL In-Place Inclinometer, 2008/7/09 6

Vertical Installation

Overview 1. Lay out sensors in order of installation.

2. Insert the first sensor in the preferred set of grooves. The fixed wheel

should point toward the expected direction of movement.

3. Lower the sensor into the casing. Keep the top of the gauge tube

accessible.

4. Align the next sensor with the preferred set of grooves as in step 2,

and connect it to the gauge tubing of the downhole sensor.

5. Lower the sensors into the casing. Repeat steps 4 and 5 until all sen-

sors have been installed.

6. Prepare the suspension kit or the placement kit.

7. Lower the sensors to their final location and terminate the top.

Required Tools •Safety cable attached to bottom sensor to prevent loss of sensors

down hole.

•Vice grips (clamping pliers) for holding gauge tubing while

connecting adjacent sensors.

•Thin 17 mm wrench for tightening tubing clamps.

•Tools for cable clamps or Allen wrench for securing top clamp.

•Vinyl tape for securing cable to gauge tubing.

Preparations 1. Note serial number and position of each sensor.

2. Lay out sensors in order of installation. We do not recommend pre-

assembly of the string of sensors. Add sensors to the string one by

one as you install them downhole.

3. Keep cables coiled until sensor is installed.

Removal If it is necessary to remove sensors, take the following precautions:

•Never try to remove the assembled string of sensors. The weight and

leverage of long gauge lengths make it very easy to damage the

wheels.

•Always disassemble the string, sensor by sensor. When removing

each sensor, always clamp the gauge tubing of the downhole sensor to

prevent it from twisting.

EL In-Place Inclinometer, 2008/7/09 7

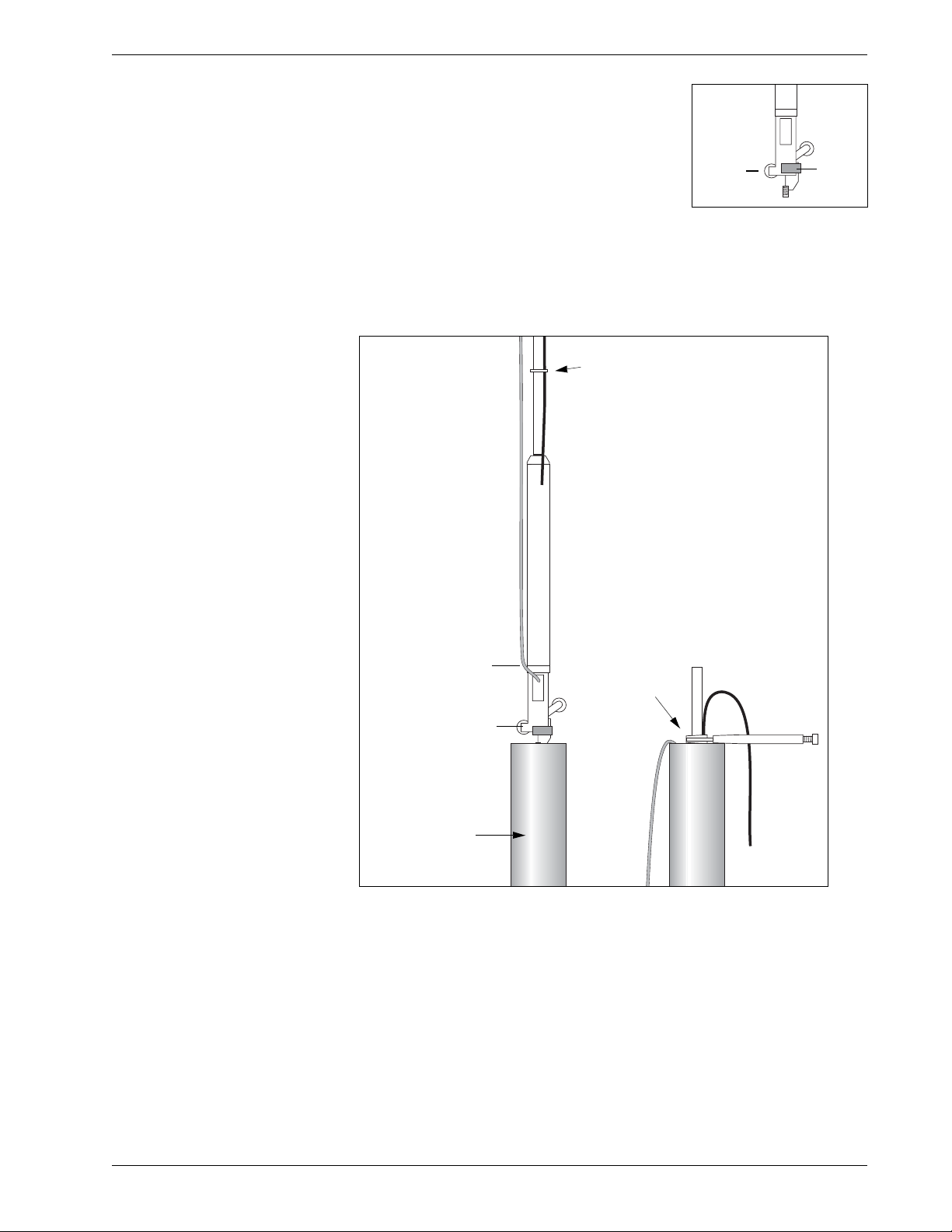

Install the

Bottom Sensor

1. Attach safety line (nylon or wire rope) to

bottom sensor. Secure the safety line.

2. Insert first (bottom) sensor in preferred set

of grooves. The fixed wheel should point to

the expected direction of movement. Check

that the wheel has a swivel clamp.

3. Lower sensor into casing. Tape signal cable to gauge tubing.

Use vice grips to clamp top of gauge tubing. Now the next sensor can

be installed.

Fixed

Wheel

Swivel

Clamp

Clamp gauge

tubing with

vice grip.

Tie a safety line (nylon

or wire rope) to the

bottom sensor.

Tape signal cable to gauge tubing.

Inclinometer

Casing

Fixed wheel should

point to expected

direction of move-

ment.

EL In-Place Inclinometer, 2008/7/09 8

Install Next Sensor Connect next sensor to the gauge tubing of the sensor below, as shown

in the drawing. Continue adding sensors until the sensor string is com-

plete. Keep the following points in mind:

•Do not allow the installed sensor to twist in the casing when you

tighten the connection. Twisting can damage the wheels or pop them

out of the grooves.

•When you lower the sensor into the casing, check that the fixed

wheel is aligned in the proper direction.

•Tape cables neatly, so that they do not cross each other.

Hold gauge

tubing firmly

so that it does

not twist.

Check that fixed

wheel is aligned with

proper groove.

Tighten tubing

clamp well.

Tape cables

neatly for

easier

installation.

EL In-Place Inclinometer, 2008/7/09 9

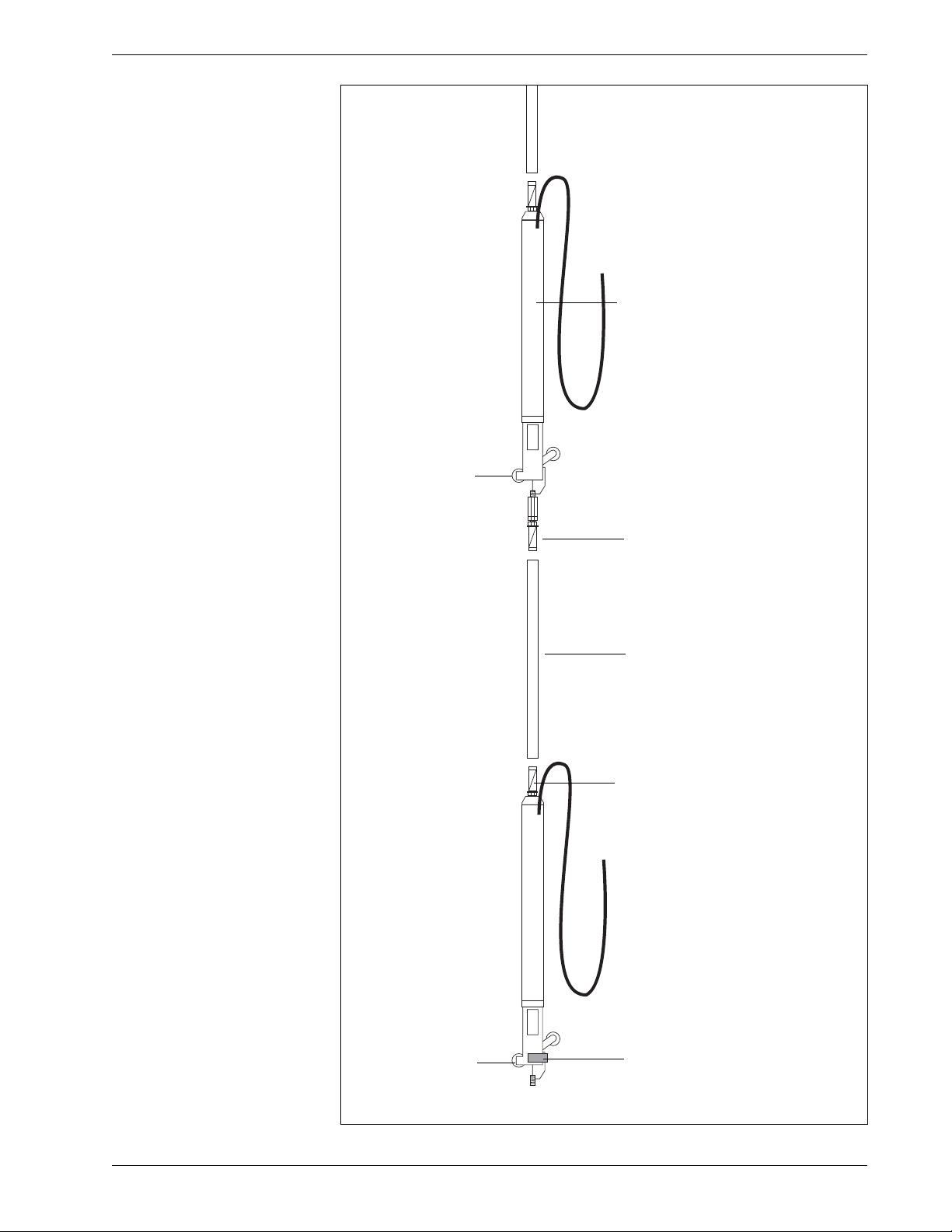

Install Top Wheel Attach top wheel from suspension kit or placement kit.

•Suspension kit: Wheel supplied in suspension kit has an eyelet for

suspension cable. Connect suspension cable as shown in drawing.

•Placement kit: Wheel supplied in placement kit has tubing clamp.

Attach placement tubing as shown in the drawing.

Check alignment of

fixed wheel and do

not twist gauge tube

when tightening nuts.

Suspension

Cable

Placement

Tubing

EL In-Place Inclinometer, 2008/7/09 10

Terminate

with Suspension Kit

The suspension kit is used with vertical

installations. It consists of a top wheel

assembly, shown on the previous page,

cable thimbles, cable clamps, and a

hook for the top of the casing.

1. Cut the suspension cable to the

appro-priate length.

2. Attach the cable to the top wheel

assembly using the thimble and

clamps.

3. Attach the other end of the cable to

the chain, as shown in the drawing.

4. Use the chain is used to adjust the

final depth of the sensors.

Terminate with

Placement Kit

The placement kit is sometimes used

with vertical installations. It consists of

a top wheel assembly, shown on the

previous page, and a “top” clamp for

placement tube.

The top clamp holds either placement

tubing - when the sensors are deeper in

the casing - or the gauge tube of the

nearest sensor.

The top clamp has a split collar. Loosen

the screws, slide the collar over the

placement tubing or gauge tubing, and

then tighten the screws.

Cable

thimble

EL In-Place Inclinometer, 2008/7/09 11

Horizontal Installation

Overview 1. Lay out sensors in order of installation.

2. Align the first sensor with the vertical grooves of the casing. Insert

the sensor with its fixed wheel pointing downwards.

3. Push the sensor into the casing. Keep the top end of its gauge tubing

accessible.

4. Connect the next sensor to the gauge tubing of the downhole sensor.

Then push it into the casing.

5. Continue connecting sensors until the string is complete.

6. Connect the final wheel assembly.

7. Prepare the placement kit and placement tubing.

8. Push push sensors to final location and terminate.

Required Tools •Safety cable may be useful if sensors are to be retrieved or if casing

actually slopes downwards.

•Vice grips (clamping pliers) for holding gauge tubing while

connecting adjacent sensors.

•Thin 17 mm wrench for tightening tubing clamps.

•Allen wrench for securing top clamp.

•Vinyl tape for securing cable to gauge tubing.

Preparations 1. Attach gauge tubing to each sensor, as explained previously. We do

not recommend joining sensors together now. Add sensors one by

one to the string.

2. Lay out sensors in order of installation. Note the serial number and

position of each sensor.

3. Keep cables coiled until sensor is installed.

Removal If it is necessary to remove sensors, take the following precautions:

•Never try to remove the assembled string of sensors. The weight and

leverage of long gauge lengths make it very easy to damage the

wheels.

4. Always disassemble the string, sensor by sensor. When removing

each sensor, always clamp the gauge tubing of the downhole sensor

to prevent it from twisting.

EL In-Place Inclinometer, 2008/7/09 12

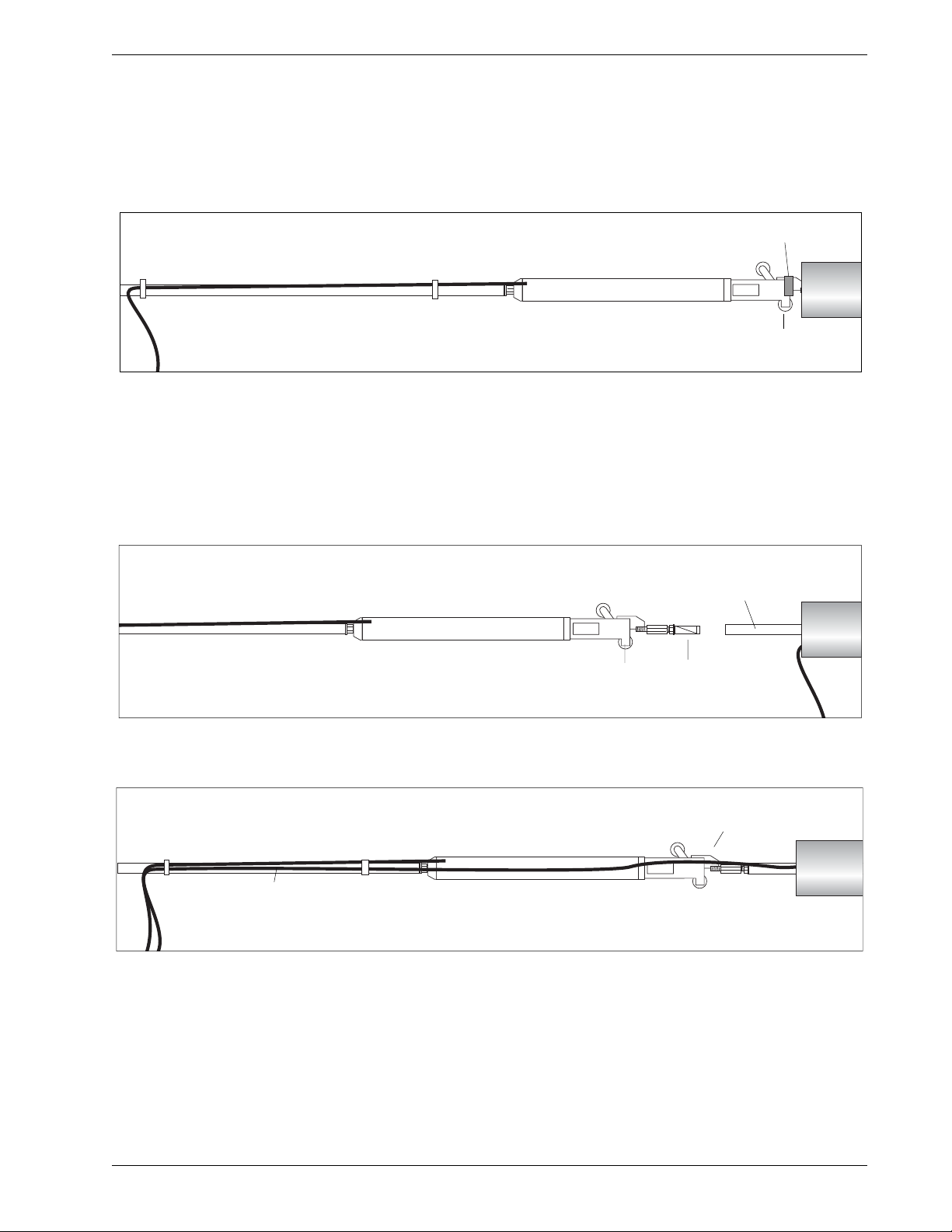

Install the

First Sensor

1. Check that the first sensor has a swivel clamp on its wheel assembly.

2. Tape signal cable to the gauge tubing.

3. Align the fixed wheel with the bottom groove and push the sensor

into the casing.

Install More Sensors 1. Prepare to connect the next sensor. Align the fixed wheel with the

bottom groove.

2. Push the tubing clamp into the gauge tubing of the sensor that is

already in the casing. Do not twist the gauge tubing when you tighten

the tubing clamp nuts.

3. Continue adding sensors until the sensor string is complete.:

•Do not twist the installed sensor when you tighten tubing clamps.

Twisting can damage the wheels or pop them out of the grooves.

•Always verify that the fixed wheel is in the bottom groove.

•Tie cables neatly, so that they do not cross each other.

Swivel Clamp

Fixed Wheel

Fixed

Wheel

Tubing

Clamp

Do not twist gauge tubing.

Keep cable away from wheels.

Allow some slack at the swivel.

Arrange cables neatly so that they

do not cross. Ideally, cables should

not touch casing.

EL In-Place Inclinometer, 2008/7/09 13

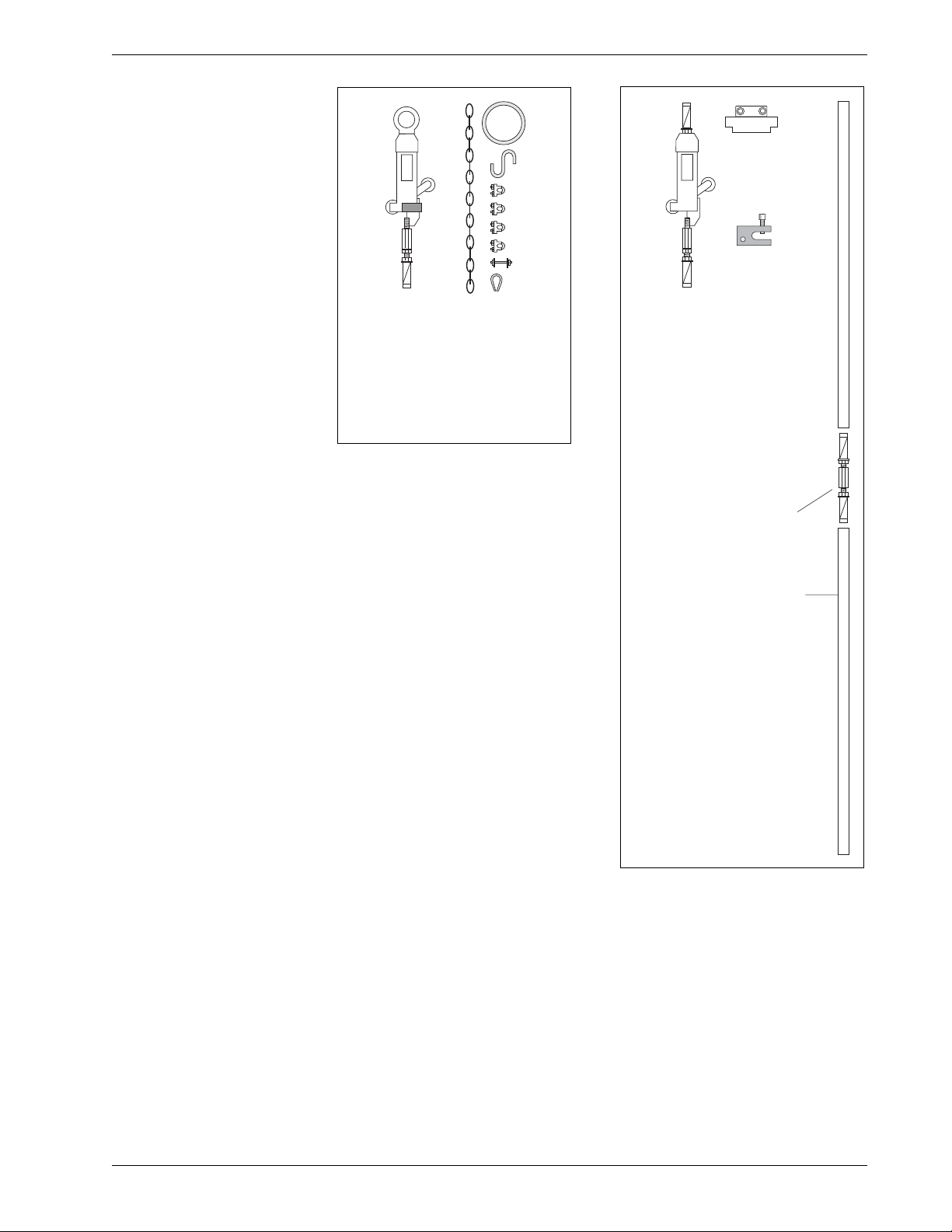

Terminating the

Installation

The placement kit supplies most of the components used to terminate

horizontal installations. The placement kit includes a top wheel assem-

bly and a top clamp. A top clamp retainer is also available.

Install Top Wheel The top wheel com-

pletes the gauge length

of the nearest sensor.

Align the fixed wheel

with the bottom

groove.

The top wheel is not required if the gauge length of the top sensor is ter-

minated with the top clamp.

Install

Placement Tubing

Placement tubing is used to position the sensors deeper into the casing.

Placement tubing is normally longer than shown in the illustration. A

coupling is used to join two placement tubes.

Install

Top Clamp

The top clamp holds placement tubing or the gauge tube of the nearest

sensor.

1. The top clamp has a split collar.

Loosen the screws, slide the collar over

the placement tubing or gauge tubing,

and then tighten the screw.

2. (Optional) Use the top clamp retainer

to hold the top clamp to the casing.

3. In horizontal installations, the sensors normally must be pushed into

the casing. This puts the mechanical linkage of the sensors into com-

pression. If possible, put the linkage into tension, but pushing the

sensors deeper into the casing and then pulling them back into

position.

Do not twist the sensors when

you tighten the tubing clamp.

Do not twist the sensors when you

tighten the tubing clamp.

Top

clamp

Top

clamp

retainer

EL In-Place Inclinometer, 2008/7/09 14

Manual Readings

Introduction Manual readings are useful for testing the system before the data acqui-

sition system is set up. This manual covers connections to IPI sensors

that have a 2.5v signal conditioner. Previous signal conditioners used a

250 mV signal conditioner with different wiring.

EL Data Recorder 1. Connect sensor to readout as shown in the table below.

2. Switch on. Choose uniaxial or biaxial sensor.

3. Tilt is displayed in volts. Temperature is displayed in degrees C.

Testing with

a Voltmeter

The voltmeter should be capable of displaying values in the low milli-

volt dc range. You must also have a power source must supply between

5.5 and 15 Vdc. An alkaline 9-volt battery is suitable

1. Connect green wire to the + terminal of the power source. Connect

the violet wire and black wire to the - terminal of the power source.

2. To read the A-axis sensor, connect the voltmeter to the orange wire

(signal) and yellow wire (reference).

3. To read the B-axis sensor, connect the voltmeter to the blue wire (sig-

nal) and yellow wire (reference).

4. To read the thermistor, connect the voltmeter to the red and yellow

wires.

Data Recorder Terminal Signal Cable Wire

1TiltA Orange

2TiltB Blue

3Temp Red

4 Sig Common Yellow

5Sense Violet

6 Power + Green

7Power- Black

8 Shield Drain Wire

EL In-Place Inclinometer, 2008/7/09 15

Test Readings 1. When the sensor body is vertical, you should see a reading of about

0.0 Vdc.

2. The A-axis sensor measures tilt in the plane of the wheels. Tilt the top

of the sensor in the direction of the fixed wheel. The reading should

be about 2.2 to 2.3 V as the tilt nears 10 degrees. Tilt the top of the

sensor in the direction of the sprung wheel. The reading should be

about -2.2 to -2.3 V as the tilt nears 10 degrees.

3. The B-axis sensor (available with biaxial sensors only) is rotated 90

degrees from the A-axis sensor. Tilting the sensor to 10 degrees

should provide a reading of ±2.2 to 2.3 Volts.

4. See the next section, data reduction, to learn how to convert the

reading in volts to deviation in mm.

5. At 25 degrees C, the thermistor reading should be about 1 Vdc.

EL In-Place Inclinometer, 2008/7/09 16

DataLogging

Data Logging

with CR10X

These instructions provide information needed for reading uniaxial

and biaxial IPIs with the Campbell Scientific CR10X datalogger system.

Sample Program: A sample CR10X monitoring program is available at

Slope Indicator’s website. Go to www.slopeindicator.com - support -

tech notes. Look at the data logger technotes. You’ll see a link for sam-

ple programs.

Wiring Diagrams: The wiring g diagrams on the following pages show

how to connect uniaxial and biaxial IPIs to the Campbell Scientific

CR10X datalogger system.

Wiring Diagram 1 Connecting a uniaxial sensor directly to the CR10X

Wiring Diagram 2 Connecting a biaxial sensor directly to CR10X

EL In-Place Inclinometer, 2008/7/09 17

Wiring Diagram 3 Connecting uniaxial sensors to an AM416 multiplexer

Wiring Diagram 4 Connecting biaxial sensors to an AM416 multiplexer

EL In-Place Inclinometer, 2008/7/09 18

Data Reduction

Introduction Data reduction is usually automated because it involves a large number

of readings and a large number of calculations.

Here, we explain how to use the sensor calibration record and provide

an example of converting a single reading from voltage to mm of devia-

tion and mm of displacement.

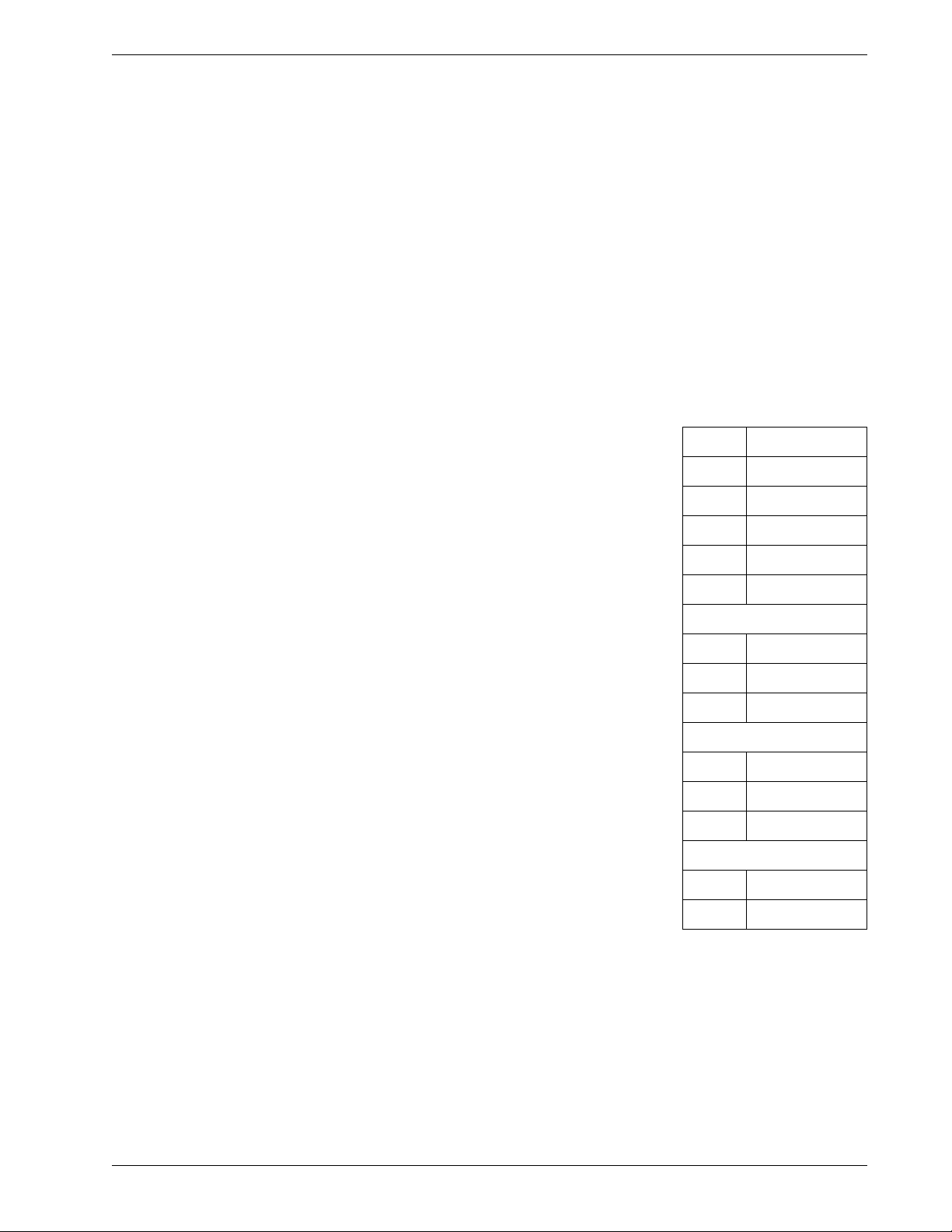

Calibration Record A calibration record is provided with each EL IPI sensor. Note that cali-

brations are unique for each sensor, so use sensor serial numbers to

match sensors with their calibrations.

The sensor calibration record lists three sets

of factors for each axis of the sensor and

one factor for the temperature sensor. The

table at right shows factors for sensor serial

number 10001. Your sensors will have dif-

ferent factors.

C0 to C5: Use these factors to convert a

reading in volts to mm per meter of gauge

length.

S0 to S2: Use these factors if it is necessary

to adjust the mm/m value above for tem-

perature-related changes in sensor sensitiv-

ity.

F0 to F2: Use these factors if it is necessary

to adjust the mm/meter value for tempera-

ture-related changes in the offset of the sen-

sor.

Toffset: Use this factor in the equation to

convert a thermistor reading in volts to

degrees C.

Tnom: Tnom is normally 12 degrees C.

However, the value shown on the sensor calibration record may be

higher or lower if your sensors were calibrated over a custom range of

temperatures.

C0 -7.0311

C1 73.878

C2 -0.22265

C3 -0.33079

C4 0.019426

C5 0.020221

S0 1

S1 0.00059828

S2 0.0000068117

F0 00012125

F1 0.016273

F2 0.00096919

Toffset 0.19

Tnom 12

Table of contents

Other SLOPE INDICATOR Measuring Instrument manuals