RB-501-B02A

Contents

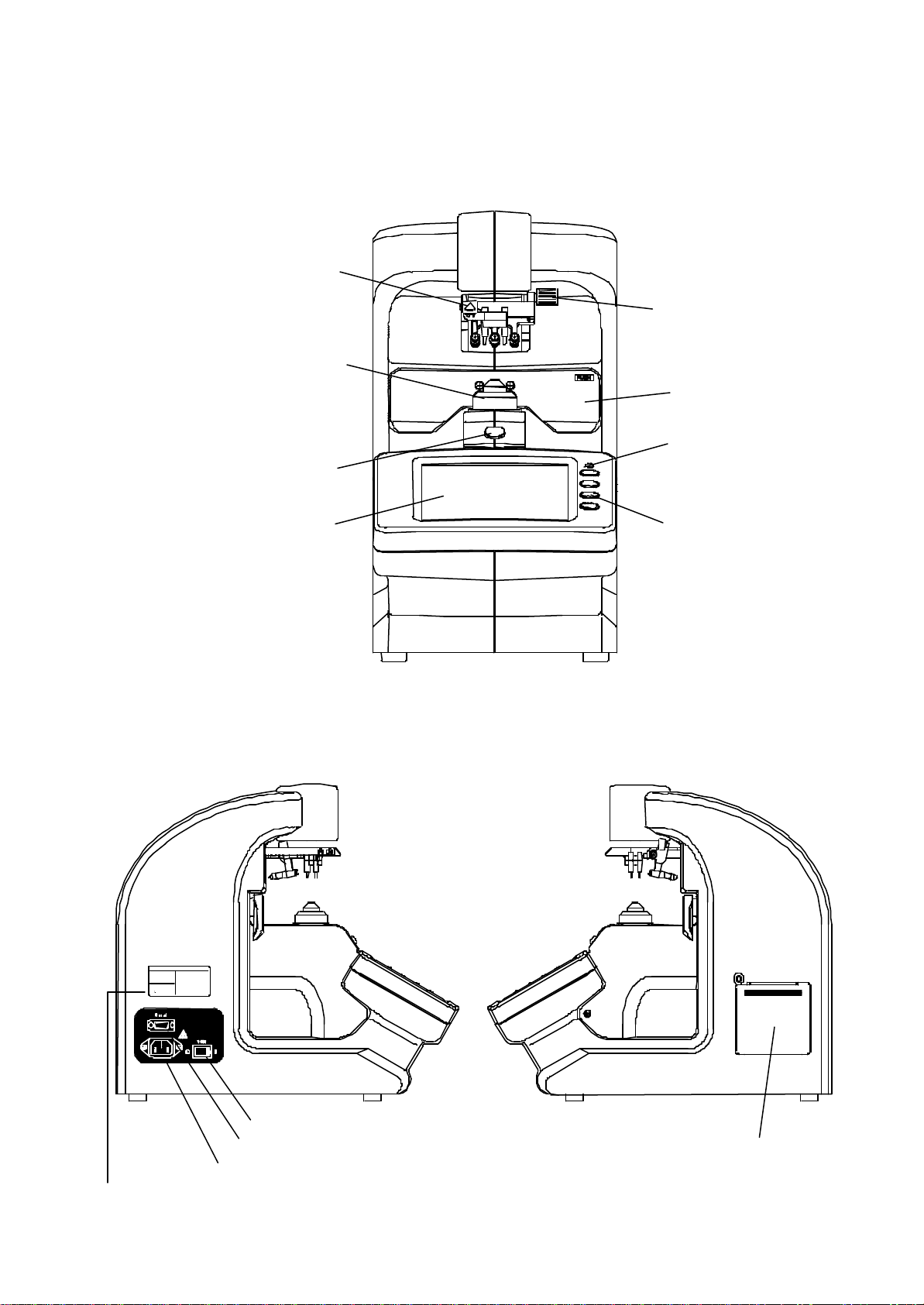

1. Parts Identification ...................................................................................................................1

1.1. Overview...........................................................................................................................1

1.2. Contents in a packing box.....................................................................................................2

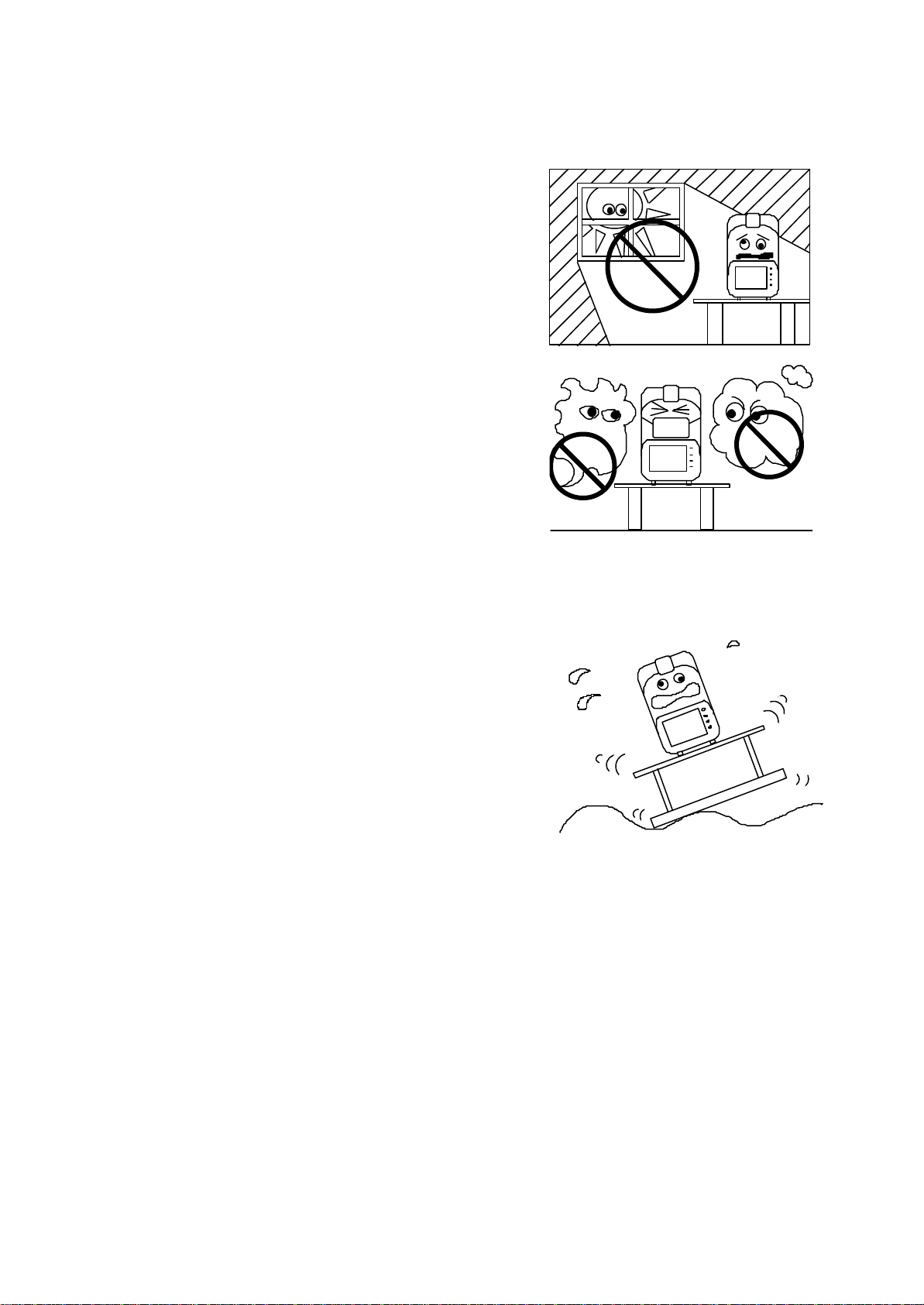

2. Installation Environment...........................................................................................................3

3. Safeguard Summary.................................................................................................................4

4. Measurement Screen.................................................................................................................5

4.1. Switch Function..................................................................................................................5

4.2. Each Setting .......................................................................................................................6

4.2.1. Set up Screen...............................................................................................................6

4.2.2. ID Screen....................................................................................................................7

4.2.3. RS 232C Screen...........................................................................................................8

4.2.4. Date/Time Screen.........................................................................................................9

5. How to operate the lensmeter...................................................................................................10

5.1. Lens holder......................................................................................................................10

5.2. Lens plate........................................................................................................................10

5.3. Marking lever ................................................................................................................... 11

5.3.1. How to operate..........................................................................................................11

5.3.2. Replacement of marking pen.......................................................................................11

5.4. Printer..............................................................................................................................12

5.4.1. How to operate...........................................................................................................12

5.4.2. Type of print out........................................................................................................12

5.4.3. Setting and replacement of printer paper .......................................................................13

6. Measurement.........................................................................................................................14

6.1. Check before Measurement................................................................................................14

6.2. Lens without frames..........................................................................................................15

6.3. Framed Lens.....................................................................................................................17

6.4. Multifocal Lens.................................................................................................................18

6.5. Progressive Lens ...............................................................................................................19

6.6. Contact lens......................................................................................................................22

6.6.1. Preparation ................................................................................................................22

6.6.2. How to measure.........................................................................................................22

7. Marking................................................................................................................................23

7.1. Lens without Astigmatism..................................................................................................23

7.2. Lens with Astigmatism.......................................................................................................23

7.3. Marking of prism Lens.......................................................................................................24

8. Error Messages......................................................................................................................25

8.1. Descriptions .....................................................................................................................25

8.2. Measures taken for the errors..............................................................................................25

9. Specification .........................................................................................................................26

10. Applicable Laws and Standards ...............................................................................................26