1

Features

• 5 Digit Scaling Factor

• Display Rate, Batch Size and

(Batch Total or Grand Total)

• Second B Relay Programmable for Output at

Prewarn or selected Batch/Grand Total

• Pulse Input - 10 kHz Max.

• Security Lockout

• RS422/RS232 Serial Communication

• NEMA 4X / IP65 Front Panel

• 30mV Magnetic Pickup Inputs

• 4-20mA or 0-20mA Analog Output

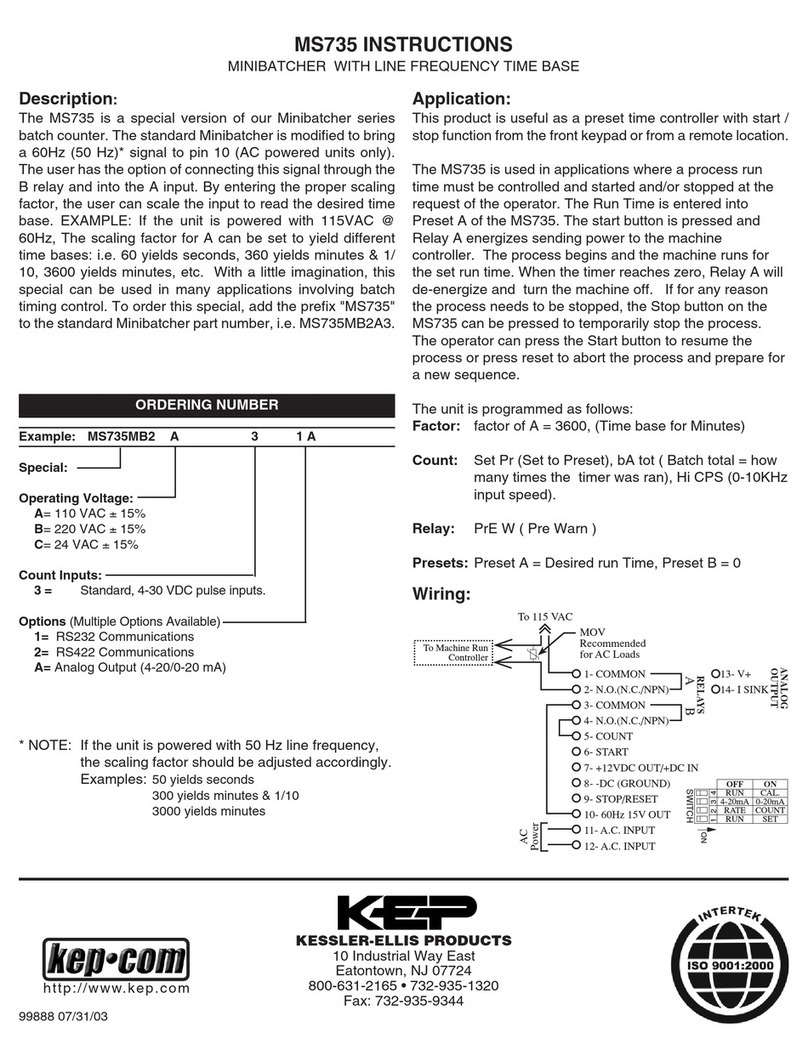

Application:

This miniature batcher is ideal for all batching applications. The

display will show Batch Amount, Rate and Batch/Grand Total at the

push of a button. The Start and Stop buttons make batching simple.

Description:

The MINI-Batcher is a 6 digit totalizer and 4.5 digit ratemeter with two

relay outputs. One output is dedicated to the batch amount (Preset

A), the other can be activated for Prewarn or Batch/Grand Total. The

unit can count up to the preset (reset to 0) or down from the preset

(set to preset). Start, Stop and Reset functions can be activated from

the front panel or remote inputs.

An analog output (assignable for Rate or Batch Amount) is available

for data logging.

Up to 99 units can communicate to a host computer on a single

RS232 or RS422 loop.

Specifications:

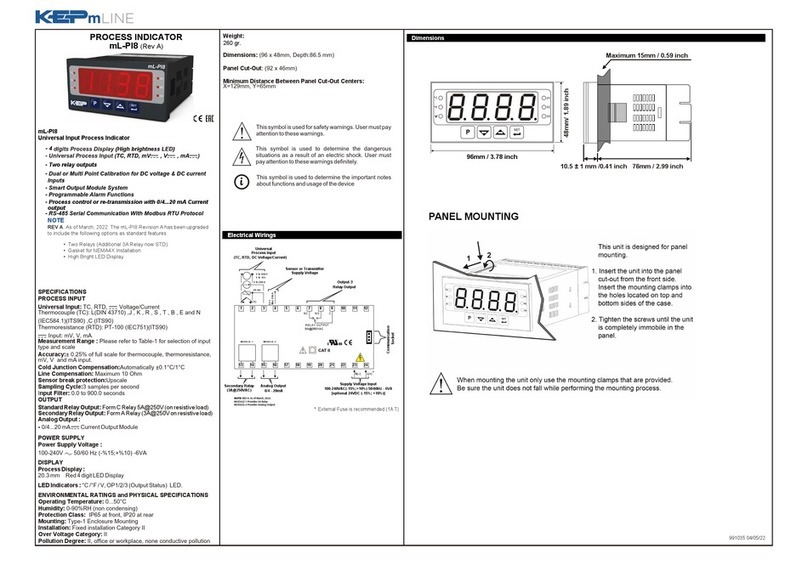

Display: 6 digit, 0.55" High LED

Input Power:

110 VAC ± 15% or 12 to 15 VDC

220 VAC ± 15% or 12 to 15 VDC

24 VAC ± 15% or 12 to 15 VDC

Current: 250 mA DC max. or 6.5 VA AC

Output Power: (AC powered units only)

+12 VDC @ 50 mA, unregulated -10 + 50%

Temperature:

Operating:

+32°F (0°C) to +130°F (+54°C)

Storage:

-40°F (-40°C) to +200°F (93°C)

Humidity: 0-90% Noncondensing

Memory: EEPROM stores data for 10 years if power is lost.

Inputs:

3: High Impedance DC pulse input 4-30 VDC (high), Open or 0-

1 VDC (low), 10 ký imp. 10 kHz max. speed.

3M: Mag. Input, accepts 30mV input (50 V max.) signals 10 Ký

imp. 5 kHz max.

Stop / Reset:

Front Panel:

STOP/RST button stops batch if batch is running, Resets dis-

played value and control output if batch is stopped.

Remote:

4-30 VDC, positive edge: stops batch if batch is running, Resets

batch amount if batch is stopped.

NOTE: Hold either front or remote reset active to inhibit any start

inputs.

Start:

Front Panel:

START button Starts batch by energizing Relay A (and Relay B if

Prewarn selected).

Remote:

4-30 VDC, positive edge: Starts batch by energizing Relay A (and

Relay B if Prewarn selected).

Scaling Factor (K-Factor): A user programmable K-Factor is used

to convert the input pulses to engineer ing units. The 5 digit K-

Factor divider, with decimal k eyed into an y position, allo ws easy

direct entry of any K-Factor from 0.0001 to 99999.

Presets: Two control outputs are provided. A 5 digit value can be

entered for both presets. The decimal point location is the same as

the counter (No decimal in Batch Total counter).

PRESET A:

The preset A output is dedicated to the batch amount. When

START is activated, Relay A will energiz e and remain on until

the batch is complete or the batch is stopped.

PRESET B:

The preset B output can be progr ammed to activ ate as a

Prewarn (for two stage batch control) or activate on Batch Total

or Grand Total (selectable).

When set for PREWARN, Relay B will energize when START is

activated and drop out at Prewarn number before preset.

When set for Batch Total or Grand Total, Relay B will activ ate

when the batch total or gr and total counts up to preset B

amount. The output ON time can be set for a duration (0.01 to

99.99 sec.) or latched (0.00 setting). If a value other than 0.00

is set for the duration, the batch total or g rand total will auto-

reset at preset B.

Control Outputs:

Relays:

2 each N.O. Relay; 10 Amps 120/240 VAC or 28 VDC. (N.C.

relay contacts and NPN transistor output available with solder

jumpers. Transistor output is internally pulled up to 10 VDC

through relay coil, sinks from 10 VDC to 0.5 V @ 100 mA)

Analog Output:

An optional 4-20mA (0-20mA) output is available for the Mini-

Batch series. The output can be programmed to track rate or

batch amount. Connections are via a 2 terminal pluggable

screw connector. Programming is accomplished by using the

front panel in conjunction with rear dip switches. Accuracy:

±.25% FS worst case. Compliance Voltage: 3 to 30 VDC non

inductive.

SPECIFICATIONS