Sly France BOSS Series User manual

BOSS DRILL

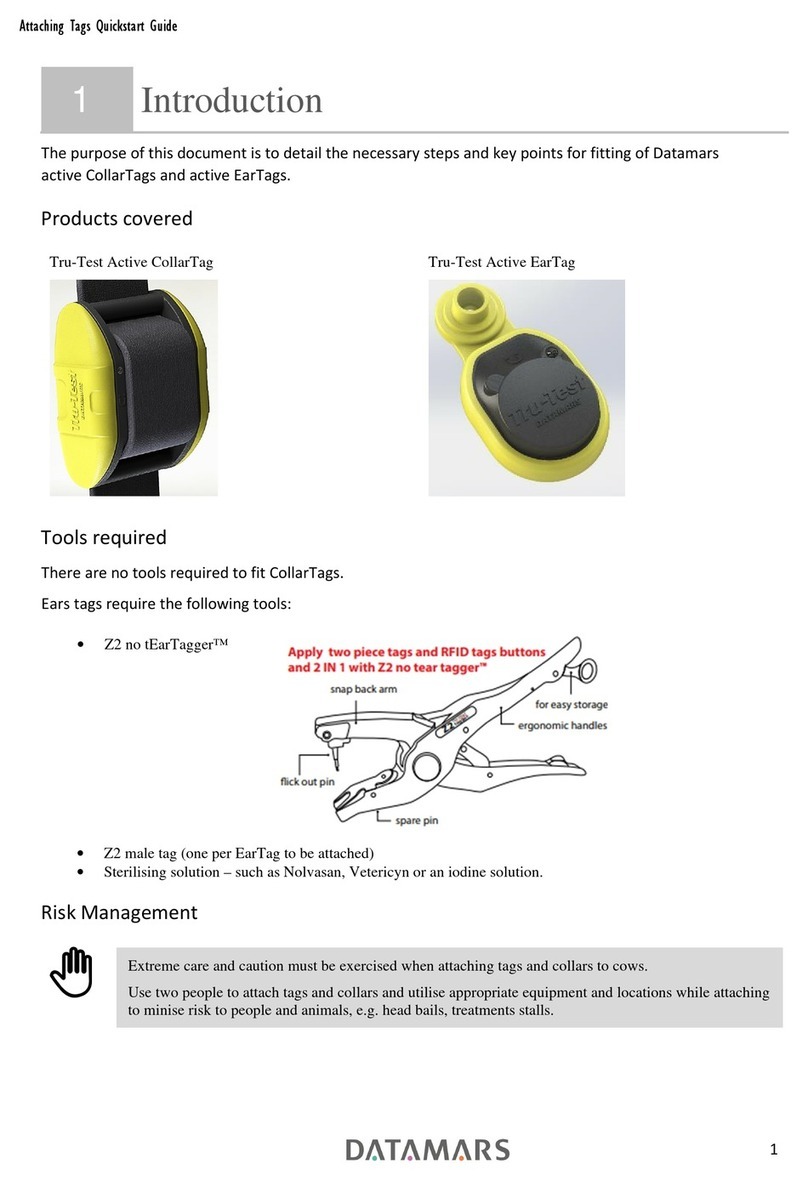

Internet : www.slyfrance.com

Tel: +33 (0)5 53 40 32 95

Fax: +33 (0)5 53 40 61 36

SLY France SAS

La Madeleine 47210 BOURNEL

OPERATING INSTRUCTIONS

2

Table of contents

1Introduction................................................................... 4

1.1 Foreword ............................................................ 4

1.2 Service ................................................................ 4

1.3 Damage .............................................................. 4

2Safety and responsibility............................................ 4

2.1 Intended use...................................................... 4

2.2 Spare parts ........................................................ 5

2.3 Operating Instructions..................................... 5

2.4 Qualification of personnel............................... 5

2.5 Groups of operators ......................................... 5

2.6 Children in danger............................................ 5

2.7 Personal protective outfit ............................... 6

2.8 Safety in traffic.................................................. 6

2.9 Safety in operation........................................... 6

2.9.1 Commissioning............................................. 6

2.9.2 Damage to the machine ............................. 6

2.9.3 Hitching and unhitching ............................. 7

2.9.4 Hydraulics...................................................... 7

2.9.5 Pressure accumulator................................. 7

2.9.6 Pneumatics ................................................... 7

2.9.7 Brake system................................................ 8

2.9.8 Overhead lines.............................................. 8

2.9.9 What to do in case of voltage flashover.. 8

2.9.10 Technical limiting values............................ 8

2.9.11 Use in the field............................................. 8

2.9.12 Changing wear items .................................. 9

2.9.13 Transport....................................................... 9

2.10 Fertiliser and dressed seed ............................ 9

2.11 Environmental protection................................ 9

2.12 Retrofits.............................................................. 9

2.13 Care and maintenance .................................. 10

2.14 Delivery............................................................. 10

2.15 Loading and unloading.................................. 10

2.16 Safety stickers................................................. 11

2.16.1 Meaning of the stickers:........................... 11

2.16.2 Position of safety stickers:....................... 12

3Technical Specifications........................................... 13

3.1 Technical data................................................. 13

3.2 Type plate ........................................................ 13

3.3 Dimensions...................................................... 14

3.4 Calculating the ballasting ............................. 16

4Operation..................................................................... 17

4.1 Connecting....................................................... 17

4.2 Hydraulic connection..................................... 17

4.3 Electrical connection ..................................... 17

5Getting Started........................................................... 18

5.1 Unfolding.......................................................... 18

........................................................................................... 18

5.2 Hoppers............................................................ 18

5.2.1 Access to hoppers ..................................... 18

........................................................................................... 18

5.2.2 Filling............................................................ 18

5.2.3 Draining the hopper .................................. 18

5.3 Small seed hopper.......................................... 19

5.4 Seed transportation ....................................... 19

5.5 Calibration of the metering unit................... 19

5.6 Disassembling the rotor................................ 20

5.7 Roller change................................................... 20

5.8 Folding.............................................................. 20

6Settings........................................................................ 20

6.1 Setting the sowing depth and the angle of the

pressing wheel ............................................................... 20

6.1.1 Quick adjustment system......................... 20

6.1.2 Quick adjustment system of the side

wheel (option) ............................................................ 21

6.2 Adjusting the hydraulic pressure................. 21

6.3 Adjusting the turbine ..................................... 22

6.4 Setting the row cleaners (option)................ 22

6.5 Setting the drill shoes.................................... 22

6.6 Adjustment of side wheels ........................... 22

6.7 Metal strapping of cleaning wheel.............. 23

6.8 Disk cleaning scraper .................................... 23

6.9 Adjustment of markers (option) .................. 24

7Brake system .............................................................. 24

7.1 Hydraulic brake............................................... 24

7.2 Pneumatic brake............................................. 25

7.3 Parking brake .................................................. 26

8Hydraulic...................................................................... 26

8.1 Suspension of the drawbar........................... 26

8.2 Hydraulic system folding / turbine.............. 27

3

8.3 Hydraulic system with CETOP..................... 28

8.4 Hydraulic system drill unit ............................ 29

9Operating instructions of the controller ................ 30

9.1 Operating instructions of RDS ISOCAN

ARTEMIS.......................................................................... 30

9.2 Operating instructions of SOFTIVERT touch

pad. 30

10 Maintenance ........................................................... 30

10.1 Disk and hub assembly ................................. 30

10.1.1 Disk 18’’....................................................... 30

10.2 Security reminder ........................................... 31

10.3 Cleaning............................................................ 31

10.4 Storage ............................................................. 31

10.5 Maintenance.................................................... 31

10.5.1 Daily maintenance..................................... 31

10.5.2 Annual maintenance ................................. 31

10.5.3 Lubrication points...................................... 32

11 Problem and troubleshooting .............................. 32

12 Appendix.................................................................. 34

12.1 Tightening torques ......................................... 34

12.2 Rotor selection table...................................... 35

4

1 Introduction

1.1 Foreword

Before putting the machine into operation, the

instructions in this operating manual must be carefully

read and followed. This prevents hazards, reduces

repair costs and downtime, and increases the reliability

and service life of your machine. Observe the safety

instructions!

SLY FRANCE declines all responsibility for damage and

malfunctions resulting from non-compliance with this

manual.

This manual is intended to make it easier for the user to

get to know his machine and to exploit the possibilities

of use in accordance with the intended use.

This operating manual must be read and applied by all

persons responsible for working on or with the machine,

e. g.:

-Operation (including preparation,

troubleshooting during work, maintenance)

-Maintenance (maintenance, inspection)

-Transport

The warranty period starts from the date of delivery.

Subject to changes in the illustrations and indications

concerning the technical characteristics and weights

indicated in this manual, aimed at improvement.

The illustrations in this user manual show different

versions of the mounted / coupled implement as well as

different equipment.

1.2 Service

SLY FRANCE wants you to be completely satisfied with

your machine and us.

In case of problems, contact the sales manager in your

area.

1.3 Damage

The machine has been carefully manufactured by SLY

FRANCE. Flow anomalies that can lead to a total

shutdown can, however, be caused, even in the event of

correct use, for example by:

-Damage due to external influences

-Wear of wear parts

-Missing or damaged work equipment

-Incorrect speeds of advancement

-Incorrect adjustment of the device (incorrect

assembly / coupling, non-compliance with the

adjustment instructions)

-Failure to follow the user manual

-Maintenance and maintenance not or poorly

executed

You must therefore check, before each use and during

the work of your machine, whether it is working properly

and whether the accuracy of the flow is sufficient.

Any claim for compensation for damages that have not

occurred directly on the machine is excluded. The

responsibility of the company cannot be held liable for

damages due to misbehavior and use.

2 Safety and

responsibility

The following danger and safety instructions apply to all

chapters of this manual.

The machine is built according to the current state of

the art and the recognized technical safety rules. Its use

may, however, present a danger of injury or death to the

user or third parties and / or result in damage to the

machine or other equipment.

Read and follow the safety instructions below

before using the machine!

2.1 Intended use

The machine is intended to be used for sowing and / or

normal cultivation according to the specific rules in the

agricultural field. Any other use or use beyond the

intended scope, such as use as a means of transport,

for example, is considered improper use and may result

in injury, if not death, to persons.

SLY FRANCE declines any responsibility for the damage

that may result. The user assumes full responsibility.

Adhere to the accident prevention regulations of the

Mutual Agricultural Insurance Funds and the other

generally recognized rules on safety, occupational

health and road safety.

Use the machine only in perfect technical condition

according to its destination and in full knowledge of the

risks!

5

Immediately remove any incidents that may affect

safety.

The machine must only be used, maintained and

repaired by persons familiar with it and informed of the

dangers.

2.2 Spare parts

The original SLY FRANCE spare parts and accessories

are specially designed for this machine.

Other spare parts or accessories are neither controlled

nor authorized by SLY FRANCE.

The assembly or use of parts that are not of the SLY

FRANCE brand may lead, in certain cases, to

unfavorable modifications to the characteristics of the

machine and thus to the safety of persons and the

machine.

The responsibility of the company SLY FRANCE cannot

be held liable for damages due to the use of parts and

accessories that are not original.

When safety stickers are affixed to the component to be

replaced, they must also be ordered and affixed to the

replacement component.

2.3 Operating Instructions

Proper use also implies compliance with the

instructions in the operating manual as well as the

manufacturer's instructions for use, care and

maintenance.

The user manual is a constituent part of the machine!

The machine is exclusively intended for use in

accordance with the user manual. Failure to observe the

operating manual may result in serious injury, if not

death, to persons.

Before work, read and observe the corresponding

chapters of the user manual.

Keep the operating manual handy.

Return the user manual to the following users. To put

back in the language of the country in case of resale in

a country where one speaks another language.

2.4 Qualification of personnel

Improper use of the machine can lead to serious injury,

if not death, of people. To avoid accidents, everyone

working on the machine must meet at least the

following general criteria:

She must be physically able to control the machine.

It is able to carry out work on the machine in compliance

with safety in the context of this manual.

She knows how the machine works as part of her job

and is aware of the hazards of the job. It can estimate

and avoid work-related hazards.

She understands the user manual and can apply the

information it contains.

She is familiar with the safe driving of vehicles.

For driving on the road, she is aware of the respective

rules of the highway code and has a driving license in

good standing.

An apprentice must always be supervised when working

with the machine.

The operator must:

-Regulate the scope of responsibilities,

competence and supervision of staff.

-Train and instruct the staff if necessary.

-Give the operator the possibility to have access

to the user manual.

-Make sure that the operator has read and

understood the user manual.

2.5 Groups of operators

People working with the machine must be trained

accordingly to perform the various tasks.

These persons must have been instructed in the tasks

to be performed by the operator or a sufficiently

qualified person. This concerns the following tasks:

-Road transport

-Use and adjustment

-Operation

-Interview

-Troubleshooting

2.6 Children in danger

Children are not able to assess hazards and behave

unpredictably. They are therefore particularly

threatened:

Keep children away.

6

Especially before starting and triggering the movements

of the machine, make sure that no children are in the

danger zone.

Before getting off, stop the tractor.

Children can trigger dangerous movements on

the machine. A machine parked insufficiently

secure and unattended is a danger for children

playing nearby!

2.7 Personal protective outfit

Missing or incomplete protective equipment increases

the risk of damage to health. Personal protective

equipment means, for example:

Well-fitting clothing / protective clothing, if necessary,

a fishnet for the hair

Safety shoes, protective gloves

Protective goggles to protect against dust or splashes

when handling fertilizers and liquid fertilizers (follow

fertilizer manufacturer's instructions)

Respirator mask and protective gloves when handling

disinfectants or disinfectant-treated seed (follow

disinfectant manufacturers' instructions)

Determine the personal protective equipment for the

respective task.

Keep available protective equipment that is effective

and in perfect condition.

Never wear a ring or other jewel.

2.8 Safety in traffic

It is forbidden to take passengers on the

machine!

Observe the permitted widths and heights of transport.

Take into account the transport height especially to

pass under bridges and low power lines.

The axle loads, tire load capacities and total permissible

weights must be adhered to, so that sufficient steering

and braking accuracy is maintained. The front axle must

always have a load of at least 20% of the unladen weight

of the tractor.

For road transport, the machine must be in the transport

position. The machine must be folded and locked.

Before folding, the folding areas must be free of soil.

This is to prevent damage to the mechanical system.

Mount the lights, signaling and protection devices and

check the operation.

Before driving on the road, clear the entire machine of

the soil that has clung to it.

Driving is influenced by mounted / hitched tools.

Particularly when cornering, take into account the large

overhang and the mass of inertia of the mounted /

hitched tool as well as the degree of filling.

Raised machinery (three-point hydraulic system):

Take into account the lack of stability and

manoeuvrability of the tractor.

For transportation on public roads, respect the

maximum speed allowed in the traffic permit!

Always adapt driving to road conditions to prevent

accidents and damage to the chassis and transport

wheels. Consider personal skills, road conditions,

traffic, vision and weather.

2.9 Safety in operation

2.9.1 Commissioning

Without proper commissioning of the machine, its

operational safety is not guaranteed. This can cause

accidents and serious injury, if not death, of people.

Use the machine only after having received the

necessary instructions from the authorized dealer,

factory representatives or employees of SLY FRANCE.

The completed acknowledgment of receipt must be

returned to SLY FRANCE.

The machine should only be used if all safety devices

and devices related to safety, e.g. removable guards

(shims, etc.) are in place and working well.

Regularly check the tightness of the nuts and bolts,

especially those of the wheels and work tools, and

tighten them if necessary.

Regularly check the tire pressure.

2.9.2 Damage to the machine

7

Damage to the machine can adversely affect the

operating safety of the machine and cause accidents.

This can lead to serious injury, if not death, of people.

The following elements of the machine are particularly

important for safety:

-Hydraulic system

-Brakes (if applicable)

-Connecting devices

-Protective devices

-Lighting

If in doubt as to the safe state of the machine, for

example when disposing of consumables, visible

damage or behavior unexpectedly changed: stop the

machine immediately and secure it.

If possible, determine the damage using this instruction

manual and dispose of it.

Eliminate possible causes of damage (e.g. coarse dirt or

loosened screws).

Faire réparer le dommage par un atelier spécialisé

qualifiéquand il peut nuire àla sécuritéet quand vous

ne pouvez pas y remédier vous-même.

2.9.3 Hitching and unhitching

Presence of a single operator, the driver hitch and

detects his own machine. Use the external lift controls.

Make sure that no one can stand between the tractor

and the machine or in an environment close to the

machine when coupling or unhitching.

Before getting off the tractor, to hitch or unhitch, set the

parking brake, stop the engine and remove the ignition

key from the tractor.

Before hitching up your machine, make sure that the

hitch pins, hitching lugs or ball joints do not show signs

of wear, breakage or incompatibility with your tractor.

Depressurize your hydraulic system before connecting

or disconnecting the hydraulic connections.

Connect or disconnect the electrical connections.

Lower the machine completely to the ground before

unhitching. Check that the surface is flat and

sufficiently firm to ensure perfect machine stability

during storage.

When your machine is parked, make sure that it is stable

so that it does not cause bodily injury or property

damage.

2.9.4 Hydraulics

The hydraulic system is under high pressure.

Spray may penetrate under the skin and cause

serious injury. In case of injury, consult a doctor

immediately.

The hydraulic system of the machine has several

functions that can cause personal injury and property

damage if mishandled.

Do not connect the hydraulic hoses to the tractor until

the system is depressurized on the tractor side and the

machine side.

The hydraulic system is under high pressure. Regularly

check for leaks and visible damage from outside on all

lines, hoses and connections!

Use only appropriate means to check for leaks.

Immediately correct the damage! Oil splashes can

cause injuries and fires!

To prevent handling errors, mark the plugs and plugs of

the hydraulic connections.

In case of injury, consult a doctor immediately!

Secure or lock tractor valves when not in use!

Replace the hydraulic hoses at the latest after six years.

2.9.5 Pressure accumulator

In the hydraulic system, there are possibly pressure

accumulators.

Do not open pressure accumulators or work on

them (welding, drilling). Even after emptying,

the tanks are still under gas pressure.

Before carrying out any maintenance work, the

hydraulic system must be depressurized!

2.9.6 Pneumatics

Observe the installation order of the pneumatic

connections.

Before connecting the pneumatic circuit, clean the

tractor and machine connections, and check that there

is zero pressure on the tractor side and the machine

side.

Replace damaged or worn pneumatic hoses and

observe dimensional features.

8

For all interventions on the pneumatic system, place the

machine on the ground, depressurize the pneumatic

circuit.

2.9.7 Brake system

Depending on the equipment, the machines may be

equipped with a pneumatic or hydraulic service brake

system.

The braking system must always be connected and

function properly when driving on the road.

After hitching the machine and before transporting,

always check the condition and function of the braking

system first.

Check the setting on the brake force regulator.

Always first release the parking brake before traveling.

Before unhitching, always stop the machine against

rolling and apply the parking brake.

2.9.8 Overhead lines

When the side sections are unfolded and folded, the

machine can reach the height of overhead lines. The

voltage can then be discharged on the machine and

cause a fatal electric shock or fire.

When the side sections are folded and when unfolding

and folding, be sure to maintain a sufficient distance

from the high voltage power lines.

Never unfold or fold side sections near electrical

pylons and overhead lines.

Never climb on or under the overhead lines to

avoid the risk of electric shock due to voltage

surges.

2.9.9 What to do in case of voltage

flashover

Voltage discharges cause high voltages outside the

machine. Significant voltage differences appear on the

floor around the machine. Taking big strides, lying on

the floor or leaning on them with your hands can lead to

deadly electric currents (step voltage).

Do not leave the cabin.

Do not touch metal objects.

Do not make a conductive connection with the earth.

Notify people: DO NOT approach the machine. Electrical

voltages on the ground can cause strong electric

shocks.

Wait for the help of professional lifeguards. The airline

must be cut.

If people must leave the cabin despite voltage

discharges, for example when there is danger of

immediate death from fire:

-Jump from the machine. Make sure to jump

while maintaining stability. Do not touch the

outside of the machine.

-Move away from the machine.

2.9.10 Technical limiting values

When the machine's technical limit values are not

observed, this may be damaged. This can cause

accidents and serious injury, if not death, of people.

The following technical limit values are particularly

important for safety:

• total weight allowed

• maximum axle loads

• maximum load transfer

• Maximum speed

Also observe the maximum loads of the tractor.

2.9.11 Use in the field

It is forbidden to take passengers on the

machine!

Before start-up and commissioning, make sure that

nobody is near the machine (children). Ensure that

visibility is sufficient.

Ensure sufficient stability of the machine in case of

longitudinal and transverse inclination on uneven

ground. Observe the permissible limit values for the

tractor.

None of the protective devices prescribed and delivered

shall be dismantled.

Make sure that nobody is in the pivot area of

hydraulically operated machine parts.

Do not move the machine in reverse when it is lowered.

The components are dimensioned only for forward

movement in the field and may be damaged in the event

of reverse.

9

2.9.12 Changing wear items

Stall the machine so that it does not move

unexpectedly!

The raised sections of the chassis under which you are

located must be securely locked with suitable supports!

Projecting parts (plowshares, etc.) can

represent a risk of injury!

Never climb rotating parts to mount on the machine.

These could turn and you could be seriously injured by

falling.

2.9.13 Transport

The use of the machines must always be done in

accordance with the directives and rules in force,

concerning accident prevention, road safety and

occupational health.

Before moving, check the tightness of the wheel studs

and tandem mounting bolts (if so equipped). Check the

pressure and condition of the tires.

Do not drive with too low pressures or damaged tires or

rims.

When transporting, use all the lighting and signaling

devices required by the law in force in the country of

use. If necessary, they can be removed during field work

so as not to be damaged.

The user is responsible for compliance with current

regulations and monitoring changes.

Regularly check the condition and fixing of the hitch

pins, do not hesitate to change them in case of wear.

The hitch joints of the tractor may also show signs of

wear, do not hesitate to replace them with new hinges.

Ride at a reasonable speed and comply with the

legislation so as always to keep control of the coupled

assembly.

Pay special attention in rough terrain or hills. Before

approaching a descent, engage a lower gear.

The tractor used to move the machine on the road must

have the same weight and power as that used for field

work.

Never maneuver when a person is near the machine or

tractor.

For machines equipped with a folding for transport,

make sure that no person or obstacle is in the sweeping

area when the elements fold down.

Observe all the rules of caution when driving, especially

when cornering and when the road is narrow.

Take all precautions before leaving the tractor.

Apply the parking brake, stop the engine, remove the

ignition key.

When traveling on the road, do not allow anyone to ride

on the machine or between the machine and the tractor.

2.10 Fertiliser and dressed seed

Improper handling of fertilizers and seeds treated with

disinfectants can lead to poisoning and death.

Follow the indications in the product manufacturer's

safety data sheet. If necessary, request the safety data

sheet from the dealer.

Determine the personal protective equipment according

to the manufacturer's instructions and make them

available.

2.11 Environmental protection

Consumables such as hydraulic oil, lubricants, etc., can

harm the environment and people's health.

Do not allow consumables to pollute the environment.

Absorb spilled consumables with absorbent material or

sand, collect them in a liquid-tight container and mark

and dispose of in accordance with statutory regulations.

2.12 Retrofits

Construction modifications and expansions may affect

the proper operation and operational safety of the

machine. This can lead to serious injury, if not death, of

people.

Do not make any construction modifications or

extensions that are not authorized by SLY FRANCE.

Only have the machine converted or extended by a

specialized workshop or by an operator trained for this

purpose by SLY FRANCE.

Observe national regulations for weights, weight

distribution and dimensions.

or equipment affecting weight or weight distribution, the

requirements for the coupling device, the load report

and the axle load shall be checked and observed.

With machines without brakes, a braking system may

have to be fitted later if the weight limits are exceeded.

10

For all changes to the nameplate data, a new nameplate

with the current data must be installed.

For changes concerning the indications of the

authorization of circulation, this one must be renewed.

2.13 Care and maintenance

Improper maintenance and servicing threaten

the operational safety of the machine. This can

cause accidents and serious injury, if not death, of

people.

Observe the intervals prescribed for periodic

inspections and inspections.

Maintain the machine according to the maintenance

plan, cf. chapter "Care and maintenance".

Only perform the work described in this user manual.

Carry out maintenance and service work after placing

the machine flat on a stable floor and after stalling to

prevent it from moving.

Depressurize the hydraulic system and lower the work

tool or support it with appropriate means.

Before proceeding with work on the electrical

installation, disconnect it from the power supply.

Before performing welding work on the machine,

disconnect the cables from computers and other

electronic components. Mount the grounding terminal

as close as possible to the weld.

Before cleaning the machine with a pressure washer,

cover all openings where it should not enter water,

steam or cleaning agent for safety and functional

reasons. Do not direct the water jet directly at electrical

or electronic components, bearings or blower. For high-

pressure or steam cleaning, always keep 50 cm from the

parts of the machine.

After cleaning, check all hydraulic lines for loose leaks

and connections.

Examine the wear due to friction and deterioration.

Immediately remedy the defects found!

Tighten all loose screw connections during

maintenance and maintenance work.

Do not wash new machines with a steam jet or high-

pressure cleaner. The paint did not harden until after

about 3 months and could be damaged before.

2.14 Delivery

As a general rule, the machine and tools are delivered

fully mounted on a low loader truck. If parts or

subassemblies have been dismantled for transport, they

will be reassembled on site by our dealer or by our

assemblers.

Depending on the model of the low loader used, the

machine can be lowered by pulling it behind a tractor or

must be unloaded with suitable lifting equipment (lift or

crane).

Only use lifting gear and tools with sufficient load

capacity and approval!

2.15 Loading and unloading

Load and unload with a tractor.

Hitch or unhitch the machine to the tractor to load it

onto a truck or to unload it from the truck.

An assistant is needed to guide maneuvers.

Attach or remove the transport locks.

11

2.16 Safety stickers

Be careful not to damage the safety stickers when washing the machine. Make changes to damaged

or missing stickers.

2.16.1 Meaning of the stickers:

Sticker

Description

Sticker

Description

380135

Stay away when folding.

Stay clear of moving parts when

unfolding.

305021

Stop the engine and remove the

key.

Stop the engine and remove the

ignition key before any maintenance

or repair work.

305016

Foot crush zone

Stay well away from moving parts.

355001

Read the user manual.

Read the operating manual and

safety tips before start-up and take

them into account during operation.

355054

Crush risk zone.

Never operate in an area where

there is a risk of crushing as long

as parts can move.

355063

Stay well away from power lines.

Stay well away from high voltage

power lines.

355049

Locking device.

Set up the locking device before

any intervention.

305064

Hydraulic leak.

Follow the instructions in the user

manual for maintenance

operations.

355062

Transport on the machine.

Never carry passengers on the

machine.

355048

Scan area.

Stay away from the sweeping area.

355035

Rotating parts.

Never put your hands in the

rotating area of the moving screw.

380299

Moving parts.

Never ride on rotating parts. Only

use devices intended for mounting.

12

Sticker

Description

002

Clamping the wheels.

Check the tightness of the wheels after 8 hours of use.

2.16.2 Position of safety stickers:

The safety stickers with the "x 2" supplement are located on both sides of the machine.

355048

355016

355049

355062

380299

002

380135

355063

355054

305035

355001

355021

355064

355062

355065

x 2

x 2

x 2

x 2

13

3 Technical Specifications

3.1 Technical data

Working width (m)

3

4

4,5

6

7

Transport width (m)

2,99

Transport height (m)

3,23

3,29

3,97

4,45

Length (m)

7,18 –7,80 (triple hoppers)

Weight (kg)

4 850

5 310

6 240

6 650

7 200

Simple hopper capacity (l)

1200 or 2000

Double hopper capacity (l)

2400 or 4000

Triple hopper capacity (l)

3600 or 6000

Hopper opening dimension (m)

0,77 x 0,91

Hopper filling height (m)

2,63 (hopper 1200L) or 3,12 (hopper 2000L)

Number of sowing coulters

12 - 16 - 18

16 - 20 - 22

- 24

24

24 - 30 - 32

- 36

28

Row spacing (cm)

16,7 - 18,75

- 20 - 25

16,7 - 18,75

- 20 - 25

18,75

16,7 - 18,75

- 20 - 25

25

Tire size

500/60R-22.5

Tire size (option)

710/50R-26.5

Work speed (km/h)

6 - 15

Max speed transport (km/h)

25

NOTE:

Subject to modifications as a result of technical improvements.

The weight of the coupled implement depends on the equipment; indication with minimal equipment.

The heights and widths of transport permitted on public roads may vary from country to country.

Comply with national registration requirements.

3.2 Type plate

The type plate with the CE marking is located on the frame of the machine.

14

3.3 Dimensions

BOSS drill 3m :

BOSS drill 4.5m :

15

BOSS drill 6m :

BOSS drill 7m :

16

3.4 Calculating the ballasting

The mounting or coupling of tools must not lead to exceeding the total permissible laden weight, the axle load

and the characteristics of the tractor tires.

PV Unladen weight of the tractor.

CAV Load on the front axle of the empty tractor.

CAR Load on the rear axle of the empty tractor.

MAV Front weight (if present).

RAR Load report of the coupled machine.

a Distance between the centre of gravity of the front tool and the centre of the front axle.

b Wheelbase of the tractor.

c Distance between the centre of the rear axle and the centre of the coupling point of the rear lower

arms.

All weight data are in (kg). All measurement data are in (m).

Calculation of the minimum ballast at the front:

Calculation of the actual load on the front axle:

Calculation of the total real weight:

Calculation of the actual load on the rear axle:

Calculated values must not exceed the allowable values.

Actual value obtained

by calculation

Authorized value

according to user

manual

Value x 2 of the tire load

Minimum

ballast before

MAV (min)=

Total weight

P(total)=

≥

Front axle load

CAV (total)=

≥

≥

Rear axle load

CAR (total)=

≥

≥

MAV

RAR

CAV

CAR

17

4 Operation

4.1 Connecting

Before hitching up the machine, make sure that the

machine is properly secured.

1. Check the wear and the cleanliness of the couplings

of the machine and the tractor.

2. Approach the tractor to the machine

3. Hitch the machine.

a) Machines with hitch on the lift arms:

➢Hitch the machine

➢Block the catch-up hooks

➢Tighten the stabilizers to avoid lateral

movements

➢Make sure to adjust the lift level so that the

machine frame is in a horizontal position

➢Connect the hydraulic brake plug

b) Machines with coupling ring:

➢Adjust the height of the drawbar so that the

machine can be hitched.

➢Hitch the machine.

➢Insert the bolt and lock it.

➢Connect the hydraulic brake plug

c) Machines with ball hitch:

➢Lower the drawbar or the cap on the ball and

raise the machine slightly.

➢Position the blank holder.

➢Check and adjust the size of the gap between

the blank holder and the cap

4. Fold up the crutches and lock them thanks to the

dowel provided for this purpose.

4.2 Hydraulic connection

The operation of the drill requires:

-1 double acting hydraulic distributor for

unfolding and folding the wings of the machine

-1 double acting hydraulic distributor to raise

and lower the sowing elements in the field

-1 double hydraulic distributor for the use of

tracers (optional)

-1 single effect for feeding the hydraulic turbine

-1 free return (male in ¾) to the hydraulic oil

tank of the tractor for the oil return of the

turbine.

Never operate the valve controlling the turbine

without properly connecting the free return,

otherwise the motor can be damaged.

When using a tractor with variable displacement pump

and integrated regulators (closed circuit), use the

tractor controller to adjust the speed of the turbine

The oil flow required for a rotation speed of the turbine

of about 4500 rpm is 45 l / min.

➢Clean the hydraulic connections before

connecting

➢Connect to a double acting distributor, the

hydraulic hoses feeding the folding.

➢Connect on a double-acting distributor the

hydraulic hoses for the markers.

➢Connect the free return of the turbine (photo)

➢Connect to a single-acting distributor the

power supply of the turbine

4.3 Electrical connection

1. Connect the electrical signaling socket.

2. Connect the power plug of the regulator (photo)

3. Connect the cigarette lighter power plug of the touch

pad.

18

5 Getting Started

5.1 Unfolding

1. Remove the wing locking safety pins

Do not position yourself under the wing of the

drill to remove the axes.

2. Actuate the corresponding hydraulic distributor until

the wings are completely unfolded

Warning before unfolding the wings, check that

the sowing units are in the up position.

5.2 Hoppers

Whether the machine is in single configuration, double

or triple hoppers, these are strictly identical and

designed to receive all types of seed and solid fertilizer.

The choice in the allocation of the hoppers is up to the

user depending on the convenience of use.

5.2.1 Access to hoppers

Before accessing the hoppers make sure that the

seeder is perfectly immobilized and that the wings are

unfolded.

1. Remove the pin and the bearing pin from the left rear

row.

2. To open the hoppers activate the locking levers.

Be careful the hoppers are pressurized, do not

proceed to open the hoppers when the hydraulic

turbine is running.

5.2.2 Filling

Before filling the hoppers, we recommend closing the

hopper bottom hatches.

When closing the hoppers make sure that no grain or

foreign matter remains trapped between the lid gasket

and the hopper

After each opening of the hoppers and after prolonged

shutdowns, check the tightness while the blower is

operating. Start the blower and look for air exhaust from

the lid with your hand or at the ear.

In case of leaks, replace seals or tighten hinges and

closures. Sealing defects with air losses cause dosing

errors.

IMPORTANT SAFETY NOTES

- Take care never to go under a suspended load.

- Ensure that no one passes through the changing area

of the material handling equipment used for loading.

- When the load approaches the hopper, make sure that

no one is standing on the bridge.

- Mount on the bag only when the load is stabilized

above the hopper opening.

- When loading, avoid contact with the treated seed and

wear gloves and a dust mask.

- The intervention on a big bag is done only when the

bag is stabilized.

5.2.3 Draining the hopper

1. Put the seeder in the transport position.

2. Position a big bag or container under the machine.

19

3. Open the drain hatch on the side of the hopper.

4. If necessary, operate the metering device in forced

operation to completely empty the bottom of the hopper.

5.3 Small seed hopper

As an option, it is possible to equip the BOSS single,

double or triple seed drill with an additional 280L hopper

for small seeds.

➢Unlock to open (A) and turn counterclockwise.

➢Turn clockwise to close and lock (A).

5.4 Seed transportation

The metering unit are made of stainless steel and

plastic as well as rotors.

Each metering unit is equipped with a valve allowing the

cut of half-drill (1 row on 2).

To send the contents of the hopper into the seed drill,

the lever must be in the middle position. To choose only

one of the two rows, position the lever on the

corresponding row. Repeat this action on all the

metering unit.

5.5 Calibration of the metering

unit

1. Fit the appropriate dosing device according to the

quantity and type of seed (see table and dosing

instructions).

2. Turn on the seed drill control pad and go to the

calibration setup menu (see using the tablet).

3. Fill the hopper.

4. Open the guillotine hatch to release the seed or

fertilizer.

5. Open the hatch under the dispenser, actuate the

valve to orient the flow of the selected side for

calibration.

6. Insert the receptacle for this purpose (photo).

7. Proceed to the "flow test" phase (see the use of the

tablet).

8. Remember to close the hatch once calibration is

complete.

IMPORTANT:

At each change of product, variety or

metering

unit

roll a new calibration is required. A change of dose

without changing the product does not require a new

calibration.

A

20

5.6 Disassembling the rotor

Regularly check the rotors to avoid any clogging and

dosing errors.

Unscrew both handles on each side of the rotor.

Then remove the rotor from its housing.

5.7 Roller change

Remove the circlip holding the different rotors on the

hexagonal axis using a hammer and a flush pin.

Then place the rotors corresponding to the type of seed

and the chosen dose (see adjustment table).

Each rotor has a specific volume, adapt the choice of

rotors to the desired volume.

From left to right the volumes are: 3 cm3, 67.7 cm3,

203.3 cm3

Be sure to complete with full rotors before replacing the

circlip.

Be sure to replace the metering unit rotation sensor

correctly.

5.8 Folding

IMPORTANT SAFETY NOTES

Make sure no one is on the seed drill or hopper access

ramps.

Move people away from the danger zone.

1. Ensure that the sowing units are in the up position,

fully folded before reloading the machine.

2. Remove the locking pins.

3. Actuate the hydraulic distributor corresponding to the

folding of the drill.

4. Lock the wings with the locking pins.

6 Settings

6.1 Setting the sowing depth

and the angle of the

pressing wheel

Before adjusting the depth, check the horizontal plumb

of the machine. Make sure the elements are in the up

position and do not touch the ground.

6.1.1 Quick adjustment system

6.1.1.1 Depth adjustment

Pull the handle and position it on the desired notch

thanks to the graduated adjustment plate.

This manual suits for next models

5

Table of contents

Popular Farm Equipment manuals by other brands

Euro Systems

Euro Systems P130 Translation of the original

TKS

TKS Kuhn FeedMixer Operator's manual

Krone

Krone MX 310 GL Original operating instructions

Kemper

Kemper 300F Operator's manual

SpeedEPart

SpeedEPart Agri-Fab 45-0175 owner's manual

ANTTI

ANTTI Agrosec Optivol M11 Installation and operating instructions

AGI

AGI GRAINMAXX 6300 Series Assembly manual

LELY

LELY Hibiscus 725 CD Classic Operator's manual

Ag Leader Technology

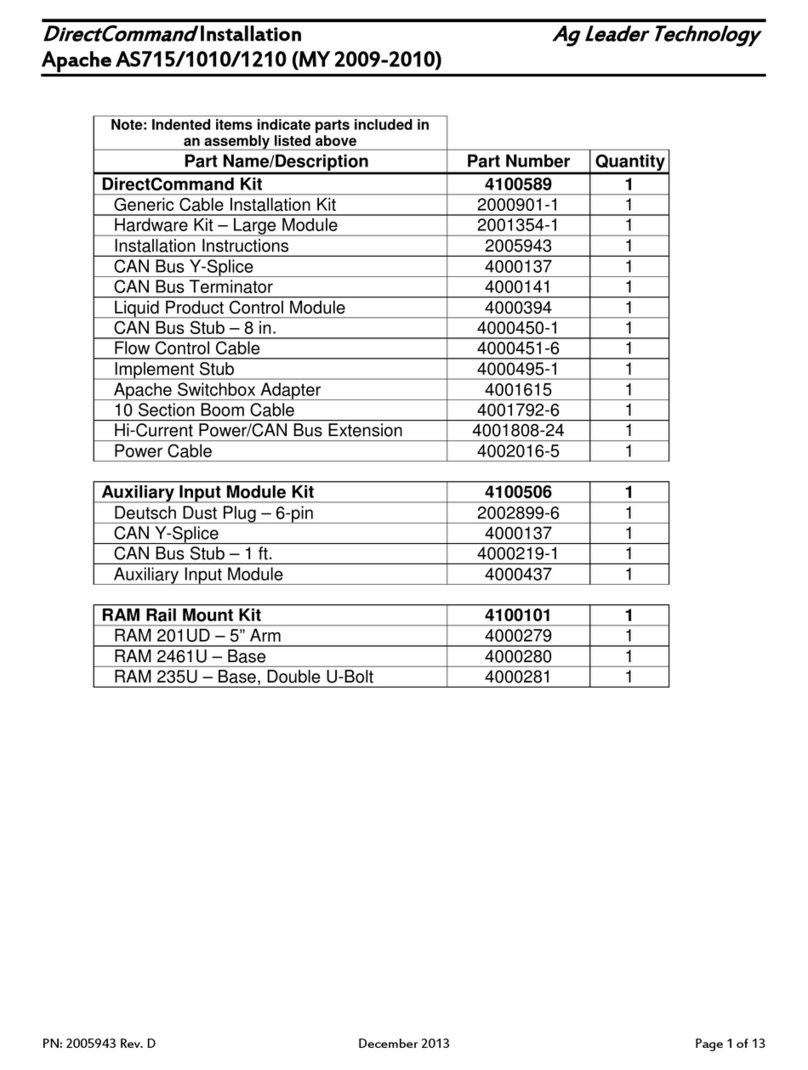

Ag Leader Technology DirectCommand installation instructions

Frontier

Frontier DC1000 Operator's manual

Datamars

Datamars Active CollarTag quick start guide

Brinly

Brinly SAT2-40BH1-P owner's manual