CONTENTS CONTINUED.

6.4 CONTROLLING THE SPEED OF THE FEEDER.

6.5 CONTROLLING THE SPEED OF THE MAGNET.

6.6 CONTROLLING THE SPEED OF THE DIRT CONVEYOR.

6.7 MACHINE SHUT-DOWN SEQUENCE.

SECTION 7.0: MAINTENANCE.

7.1 GENERAL MAINTENANCE INFORMATION.

7.2 DAILY MAINTENANCE.

7.3 VISUAL CHECKS DURING OPERATION.

7.4 WEEKLY MAINTENANCE.

7.5 LUBRICATION POINTS.

7.6 LUBRICATION SCHEDULE.

7.7 AUTOMATIC LUBRICATION

7.7.1 AUTOLUBE OVERVIEW.

7.7.2 AUTOLUBE MAINTENANCE.

7.7.3 CLEANING THE AUTOLUBE SYSTEM.

7.7.4 FILLING THE GREASE RESERVOIR.

7.7.5 TEST RUN / MANUAL LUBRICATION.

7.7.6 AUTOLUBE FAULT FINDING.

7.8 SERVICE SCHEDULE:

7.8.1 OIL & FLUID REPLACEMENT QUANTITIES:

7.8.2 RECOMMENDED LUBRICANTS

7.9 ENGINE MAINTENANCE.

7.9.1 ROUTINE DAILY ENGINE MAINTENANCE.

7.10 MANUAL CLUTCH MAINTENANCE.

7.10.1 MANUAL CLUTCH LUBRICATION.

7.11 HYDRAULIC CLUTCH MAINTENANCE.

7.12 TRACKS MAINTENANCE:

7.12.1 CHECKING THE TRACK TENSION:

7.12.2 INCREASING THE TRACK TENSION.

7.12.3 RELEASING THE TRACK TENSION.

7.12.4 TRACKS GEARBOX MAINTENANCE.

7.12.5 CHECKING AND FILLING THE GEARBOX OIL.

7.12.6 DRAINING THE GEARBOX OIL.

7.13 HYDRAULIC OIL SYSTEM MAINTENANCE.

7.13.1 CHECKING THE HYDRAULIC OIL LEVEL.

7.13.2 CHANGING THE HYDRAULIC OIL FILTERS.

7.13.3 HYDRAULIC OIL SERVICE.

7.13.4 GENERAL HYDRAULIC SYSTEM MAINTENANCE.

7.14 PRODUCT CONVEYOR GEARBOX MAINTENANCE.

7.14.1 CHANGING THE OIL IN THE GEARBOX.

7.15 CRUSHER DRIVE BELT MAINTENANCE.

7.15.1 DRIVE BELT TENSIONING.

7.16 CONVEYORS MAINTENANCE.

7.17 FEEDER MAINTENANCE (Mogenson).

7.17.1 FEEDER MAINTENANCE (McKenna).

7.17.11 CHECKING THE OIL BATH LUBRICANT LEVEL.

7.17.12 CHANGING THE OIL BATH LUBRICANT.

7.17.13 FITTING ADDITIONAL WEIGHTS TO THE PRIMARY FEEDER.

7.18 CRUSHER UNIT MAINTENANCE.

7.18.1 CHECK FOR SEPERATION OF THE TOGGLE.

7.18.2 CHECK FOR WEAR ON THE TOGGLE AND TOGGLE SEATS.

7.18.3 CHECKING THE WEAR LIMITS.

7.18.4 REPLACING THE FIXED JAW PLATE.

7.18.5 REPLACING THE SWING JAW PLATE.

7.18.6 REPLACING THE SIDE WEAR PLATES.

7.18.7 REPLACING THE TOGGLE.

7.18.8 ACCUMULATOR MAINTENANCE.

7.19 HYDRAULIC SYSTEM LAYOUT.

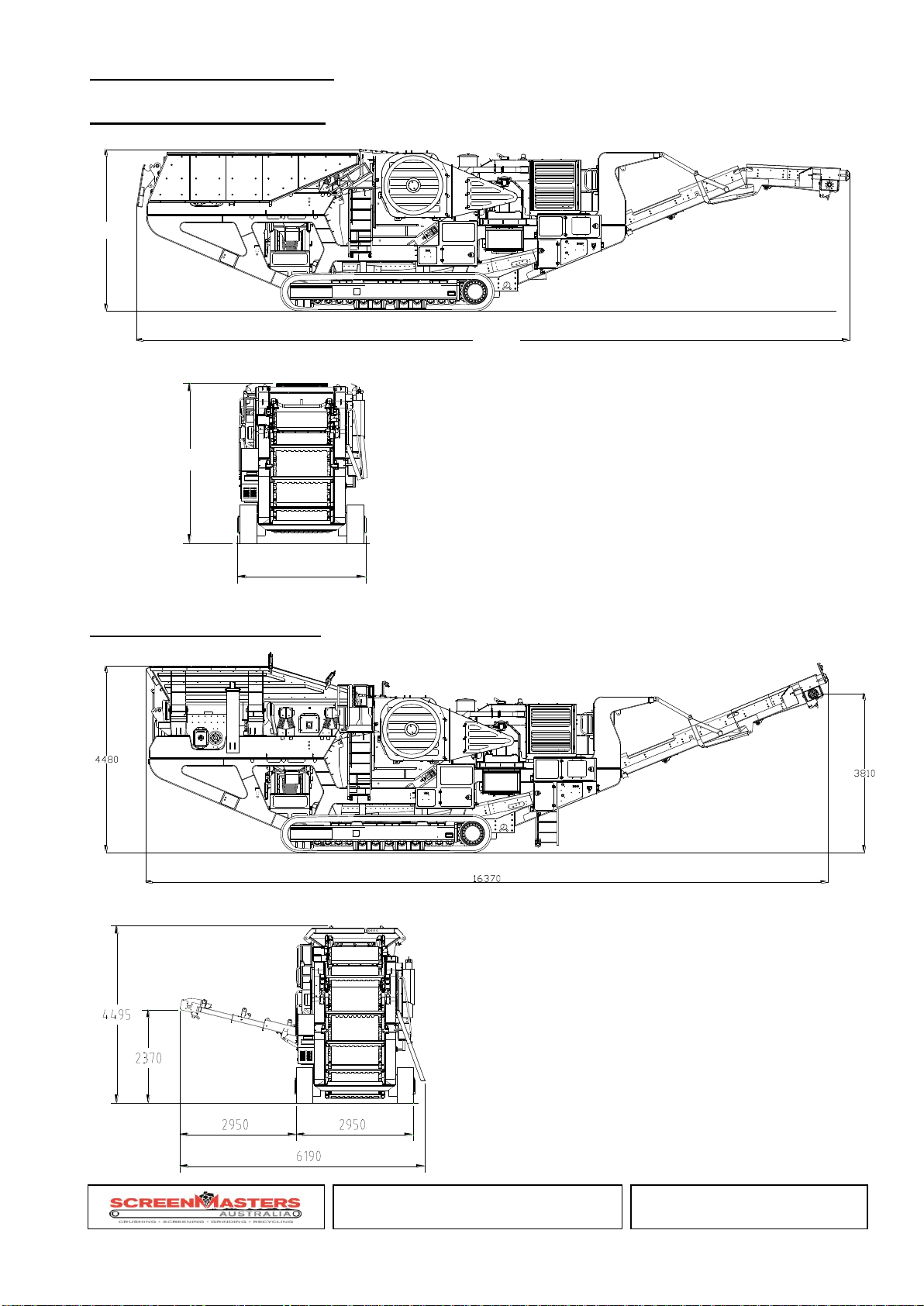

SECTION 8.0: TRANSPORTATION:

8.1 TRANSPORTATION OVERVIEW.

8.2 PREPARING FOR TRANSPORT SEQUENCE.

8.2.1 STEP 1: CLEAR THE MACHINE OF ALL MATERIAL.

8.2.2 STEP 2: RAISE THE PRODUCT CONVEYOR BOTTOM END.

8.2.3 STEP 3: FOLD UP THE DIRT CONVEYOR.

8.2.4 STEP 4: REMOVE THE FEED IN CHUTE GRID FRAME.

8.2.5 STEP 5: LOWER THE CRIBS.

8.2.6 STEP 6: REMOVE THE PRE-CLEANER AND WORKING LIGHTS.

8.2.7 STEP 7: RASIE THE JACKING LEGS.