smaky UH-22MEC Manual

Meat Mincer UH-22MEC

Installation, Operation and Maintenance Instructions

SMAKY AB

Regulatorvägen 21, S-141 49 Huddinge, Sweden

Tel+ 46 8 657 9490

Fax+ 46 8 657 8980

http://www.smakymixers.com

e-mail: info@smaky.com

Specification………..…….……… 01

Before using the Mincer…….……. 02

Package and Transport…………… 03

Electrical Connect………..………. 03

Safety Tips………….……..……… 04

Particular Warnings……….……… 04

Thermal Overload Protection……. 05

Tool Installation………….…….…05

Controls……………………..……. 06

Correct use of Meat Mincer…....…07

Cleaning………………….………. 07

Maintenance...……………………. 08

Schematic Parts List……………… 09

(A) Pusher (B) Feed hopper

(C) Opening (D) Screw

(E) Outlet (F) Feed screw

(G) Blade (H) Extrusion plates

( I ) Ring Nut (J ) Tube

(K) Start button (L) Stop button

(M) Reverse button

The UH-22MEC is a professional meat mincer designed for mincing all types of lean meat (without

bone or fat) to obtain mincemeat, hamburger, meatballs and sausages. The intended use of mincer is the food

processing industry, which not including the pharmaceutical industry, chemical industry, printing, etc.

CONTENTS

1

INSTALLATION

The sound pressure level of the machine during cutting: 67.6dB.

Because of continual improvement, strict accuracy of description cannot be guaranteed.

BEFORE USING THE MINCER

1. Read this manual thoroughly before installation and operation; ensure that all users are familiar

with the correct operation of the machine. DO NOT proceed with installation and operation if you

have any questions or do not understand anything in the manual. Contact your local representative or

the factory first.

2. Owners should not permit anyone to touch this equipment unless they are over 18 years old, are

adequately trained and supervised, and have read and understood this manual. Owners should also

ensure that no customers, children, visitors or other unauthorized personnel come in contact with this

equipment.

3. In particular, care should be taken to ensure that all the accessories are correctly fitted in position prior

to starting the machine. The machine is supplied factory lubricated and ready to run. The work surface

which the mincer is positioned must be a height of between approximately 90and 120cm; ensure that

the work surface is free of objects of any kind that may interfere with operation of mincer.

Model

UH-22MEC

Motor capacity

1.5 HP (1200W)

Voltage/ Frequency

220V / 50 / 60 HZ/3PH

380V / 50 / 60 HZ/3PH

Max. Current

220V / 6A

380 V / 2.8A

Speeds

176 RPM

Average hourly

production

230-250KG

Standard equipment

Pusher, Feed hopper,

5mm Extrusion plates,

Blade, Tube

Dimensions(mm)

455 x 321 x 530

Packed ( L* W * H )

510 x 370 x 560

Weight

35 KG (N .W)

38 KG (G .W)

SPECIFICATION

2

INSTALLATION

PACKAGE AND TRANSPORT

1. Care is needed in removing the appliance from its packing. It is recommended that at least two persons

lift the device.

2. After removing the appliance from its packing check, in particular, to see whether any damage has been

caused in transit. If in doubt, do not use the appliance and contact a specialist.

3. The material used to pack the device should not be thrown away but kept for future transport.

WARNING: Keep all parts of the said material such as boxes, packets, plastic bags etc. out of the

reach of children as they may be dangerous.

ELECTRICAL CONNECTION

CAUTION: The user should install an over-current

protection device (e.g. fuse or NFB) in the machine incoming

site power lines to prevent a fault current risk.

CAUTION: The machine is designed for TN power system.

Before connecting this mincer to the electrical supply, check

that the details on the rating plate (located on the side of the

mincer) correspond to the details of your electrical connection.

If the style of mincer’s plug is unsuitable for the socket you plan

to use, the plug must be cut off and replaced with an appropriate

plug. The mincer should be plugged into a switched socket which

isolates all poles to facilitate servicing. (Max.2 meters of cable). The mincer must be incorporated into a

potential equalization system.

The leakage current for this appliance is no greater than 1 ma/kw. If the electrical supply cable to the

machine becomes damaged, it must be replaced by a qualified electrician using cable which is H05-RNF

(Europe-CE), G14*1.25(USA-UL) or higher and suitable for a 1.5HP (0.55KW) motor load.

NOTE: The ground wire is fixed to the machine and this connection must be kept intact.

NOTE: Particular attention should be paid when switching on devices with three-phase electric

motors. The direction of operation of the mincer must be Anticlockwise. If the mincer operates in a

clockwise direction switch off the device and use the reverse direction of R.S.T. wires

The minimum requirement for all electrical equipment is correct operation between air temperature of

+5°C and +40°C.

Electrical equipment is capable of operating correctly when the relative humidity does not exceeding

95% at a maximum temperature of +40°C.

Electrical equipment is capable of operating correctly at altitude up to 1000m.

Electrical equipment is designed to withstand to protected against the effects of transportation, and

storage temperature within a range of –25°C to +55°C and for short periods not exceeding 24h at up to

+70°C.

(A)Rating Plate (B) Individual Plug

3

OPERATION

SAFETY TIPS

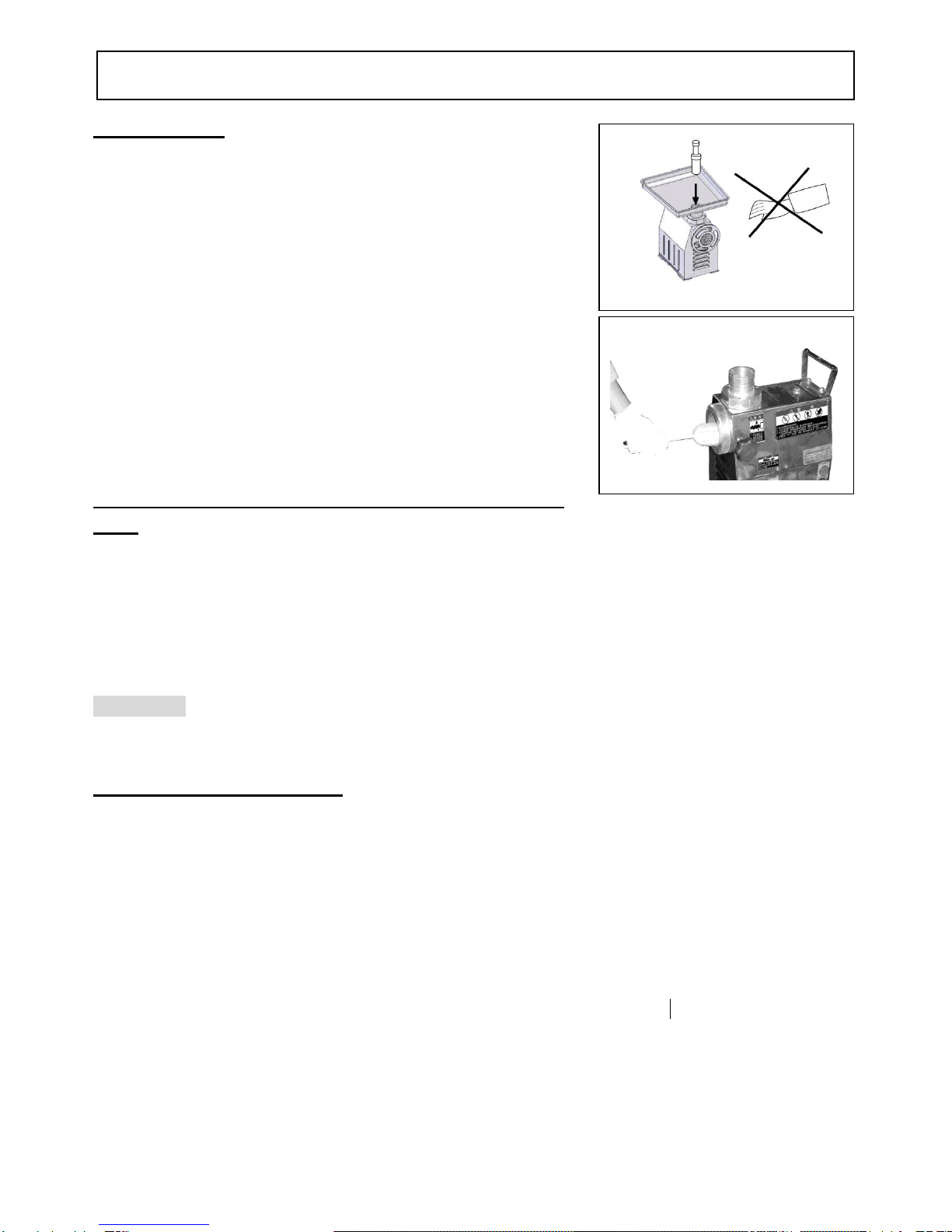

NEVER place your hand, tie, clothes, long hair or any kitchen

utensil in the outlet when the mincer is in operation. Isolate the

machine from the electrical supply by removing the plug from the

socket before cleaning or dismantling. A notice advising operator of

the safe use of this mincer is attached to the machine.

Please wearing apron for cleaning.

Please wear a glove to clean/remove blade.

No-frozen meat product is used.

The extrusion plate cannot be ground thinner the than 5mm

thickness

The mincer should be cleaned at the end of each work cycle.

For reasons of hygiene particular attention should be paid to

those parts which come into constant with the meat.

OFFICE, SHOPS AND RAILWAY PREMISES ACT,

1963

The above Act requires that this machine and attachments shall be operated only by a properly

instructed person or by an employee who is under the supervision of a properly instructed person. The

instruction shall include indication of the possible dangers arising and the precautions to be observed. The

act also requires that no person under the age of 18 shall clean a machine if this exposes him to risk of injury

from a moving part of that machine or any adjacent machine

WARNING: Do not allow children, unqualified persons who have not read this manual and are not

familiar with this mincer to use the appliance.

PARTICULAR WARNINGS

(1) This appliance must be used only for those purposes for which they were specifically designed. Any

other use is improper and therefore dangerous. The company cannot be considered responsible for any

damage resulting from improper wrong or unreasonable use.

(2) Do not allow children, unqualified persons who have not read this manual to use the appliance.

(3) Do not touch the moving parts when in operating. Be careful with hands, hair, tie, and clothing.

(4) Turn off the appliance and always unplug it before connecting the attachments and before cleaning.

(5) Before doing any cleaning, maintenance, replacing or when the device is not to be used in the long or

short term, please disconnecting the device from the mains electricity supply.

(6) Do not expose the machine to atmospheric agents such as rain, sunlight or any other agent which may

damage the internal parts in the long term, thus seriously reducing the degree of efficiency and safety.

(7) It is extremely important to avoid bringing the device into contact with water, solvents and harmful or

corrosive substances, for preventing the electrical shock. Never touch the machine with wet or damp

hands unless the device has been unplugged from the mains beforehand for preventing the electrical

Table of contents