SMAR fy303 Manual

OPERATION, MAINTENANCE

A

ND INSTRUCTION MANUAL

Profibus PA Valve Positioner

JUL / 16

FY303ME

web: www.smar.com/contactus.asp

www.smar.com

Specifications and information are subject to change without notice.

Up-to-date address information is available on our website.

smar

Kpvtqfwevkqp"

KKK"

INTRODUCTION

The FY303 is a Profibus PA valve positioner for Single (spring return) or Double acting Linear

motion type control valves e. g. Globe, Gate, Diaphragm, Pinch or Clamp and Rotary motion type

control valves e. g. Ball, Butterfly or Plug with pneumatic type actuators e. g. Diaphragm, Piston,

Vane, or Bellows. It is based on a field-proven piezo flapper and non-contacting Hall-effect position

sensor that provides reliable operation and high performance. The digital technology used in the

FY303 enabled the choice of several types of flow characterizations, an easy interface between the

field and the control room and several interesting features that considerably reduce the installation,

operating and maintenance costs.

The FY303 is part of Smar's complete 303 line of Profibus PA devices.

Some of the advantages of bi-directional digital communications are known from existing smart

transmitter protocols: Higher accuracy, multi-variable access, remote configuration and diagnostics,

and multi-dropping of several devices on a single pair of wires.

The system controls variable sampling, algorithm execution and communication so as to optimize

the usage of the network, not loosing time. Thus, high closed loop performance is achieved.

Using Profibus technology, with its capability to interconnect several devices, very large control

schemes can be constructed. In order too be user friendly the function block concept was

introduced.

The need for implementation of Fieldbus in small as well as large systems was considered when

developing the entire 303 line of Profibus-PA devices. They have common features and can be

configured locally using a magnetic tool, eliminating the need for a configuration tool or console in

many basic applications.

Get the best result of the FY303 by carefully reading these instructions.

NOTE

In case of using Simatic PDM as the configuration and parameterization tool, Smar

recommends that the user does not apply the option "Download to Device". This function

can improperly configure the field device. Smar recommends that user make the use of

the option "Download to PG / PC" and then selecting the Device Menu, use the menus of

the transducer, function and display blocks acting specifically, according to each menu

and method for reading and writing.

WARNING

Throughout the operation of the positioner, including self-setup, do not touch the moving parts of

valve/actuator/positioner assembly as they may unexpectedly move automatically. Make sure to disconnect

supply air before touching any moving parts.

H[525"/"Qrgtcvkqp."Ockpvgpcpeg"cpf"Kpuvtwevkqpu"Ocpwcn"

KX"

NOTE

This manual is compatible with version 1XX, where 1 denotes software version and XX software release. The

indication 1.XX means that this manual is compatible with any release of software version 1.

Waiver of responsibility

The contents of this manual abides by the hardware and software used on the current equipment

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically reviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acquired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated in

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or present agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to the warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipment or othe

r

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety procedures,

legal provisions and regulations for the mounting and operation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safety, explosion proof, increased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of equipments run with pneumatic

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since thei

r

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approval

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessary

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibility to

know and apply the safety practices in his country.

Vcdng"qh"Eqpvgpvu"

X"

TABLE OF CONTENTS

UGEVKQP"3"/"KPUVCNNCVKQP"0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"303

GENERAL ...................................................................................................................................................... 1.1

MOUNTING .................................................................................................................................................... 1.1

ROTARY MOVEMENT................................................................................................................................... 1.1

PNEUMATIC CONNECTIONS....................................................................................................................... 1.2

ELECTRONIC HOUSING ROTATING ........................................................................................................... 1.6

ELECTRIC WIRING........................................................................................................................................ 1.6

TOPOLOGY AND NETWORK CONFIGURATION ........................................................................................ 1.7

INTRINSIC SAFETY BARRIER...................................................................................................................... 1.8

JUMPER CONFIGURATION.......................................................................................................................... 1.8

POWER SUPPLY........................................................................................................................................... 1.9

AIR SUPPLY REQUIREMENTS..................................................................................................................... 1.9

RECOMMENDATIONS FOR AN INSTRUMENT AIR SYSTEM..................................................................... 1.9

ROTARY AND LINEAR MAGNET................................................................................................................ 1.10

MAGNET CENTRALIZER DEVICE.............................................................................................................. 1.10

REMOTE HALL SENSOR ............................................................................................................................ 1.10

UGEVKQP"4"/"QRGTCVKQP"000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"403

FUNCTIONAL DESCRIPTION -OUTPUT MODULE..................................................................................... 2.1

FUNCTIONAL DESCRIPTION-ELECTRONICS ............................................................................................ 2.2

INTRODUCTION TO FIELDBUS APPLICATION........................................................................................... 2.4

FUNCTION BLOCKS...................................................................................................................................... 2.4

TRANSDUCER BLOCKS ............................................................................................................................... 2.4

PHYSICAL BLOCK......................................................................................................................................... 2.4

THE LOCAL INDICATOR ............................................................................................................................... 2.4

UGEVKQP"5"/"EQPHKIWTCVKQP"000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"503

TRANSDUCER BLOCK ................................................................................................................................. 3.1

HOW TO CONFIGURE ATRANSDUCER BLOCK ........................................................................................ 3.1

FUNCTIONAL DIAGRAM OF THE POSITIONER TRANSDUCER BLOCK................................................... 3.2

TRANSDUCER BLOCK STANDARD PARAMETER DESCRIPTIONS ......................................................... 3.3

TRANSDUCER BLOCK SPECIFIC PARAMETER DESCRIPTIONS............................................................. 3.5

TRANSDUCER BLOCK PARAMETER ATTRIBUTE TABLE......................................................................... 3.7

TRANSDUCER BLOCK VIEW OBJECT TABLE ............................................................................................ 3.9

FY303 CYCLICAL CONFIGURATION ......................................................................................................... 3.12

HOW TO CONFIGURE THE ANALOG OUTPUT BLOCK............................................................................ 3.17

POSITION CALIBRATION ........................................................................................................................... 3.20

TEMPERATURE CALIBRATION ................................................................................................................. 3.23

SELF-CALIBRATION ................................................................................................................................... 3.24

DIAGNOSIS.................................................................................................................................................. 3.25

TRANSDUCER DISPLAY -CONFIGURATION ........................................................................................... 3.26

DISPLAY TRANSDUCER BLOCK ............................................................................................................... 3.27

DEFINITION OF PARAMETERS AND VALUES .......................................................................................... 3.28

CALIBRATING USING LOCAL ADJUSTMENT ........................................................................................... 3.30

SELF-CALIBRATION USING LOCAL ADJUSTMENT ................................................................................. 3.34

HALL'S OFFSET COMPENSATION WITHOUT MAGNET PART................................................................ 3.34

TEMPERATURE COMPENSATION ............................................................................................................ 3.35

PRESSURE SENSORS VERSION (K1 OPTION)........................................................................................ 3.36

UGEVKQP"6"/"OCKPVGPCPEG"RTQEGFWTGU"0000000000000000000000000000000000000000000000000000000000000000000000000000000000000"603

GENERAL ...................................................................................................................................................... 4.1

DISASSEMBLY PROCEDURE ...................................................................................................................... 4.2

REASSEMBLY PROCEDURE ....................................................................................................................... 4.3

RESTRICTION CLEANING PROCEDURE.................................................................................................... 4.3

CHANGE OF THE FILTER ELEMENTS......................................................................................................... 4.4

H[525"/"Qrgtcvkqp."Ockpvgpcpeg"cpf"Kpuvtwevkqpu"Ocpwcn"

XK"

ELECTRONIC CIRCUIT................................................................................................................................. 4.4

INTERCHANGEABILITY................................................................................................................................ 4.5

PACKAGE CONTENT.................................................................................................................................... 4.5

EXPLODED VIEW.......................................................................................................................................... 4.6

SPARE PARTS LIST ...................................................................................................................................... 4.7

DETAILED CODE WHEN ORDERING OF SPARE PARTS........................................................................... 4.9

UGEVKQP"7"/"VGEJPKECN"EJCTCEVGTKUVKEU"0000000000000000000000000000000000000000000000000000000000000000000000000000000000"703

FUNCTIONAL SPECIFICATIONS.................................................................................................................. 5.1

PERFORMANCE SPECIFICATIONS............................................................................................................. 5.2

PHYSICAL SPECIFICATIONS....................................................................................................................... 5.2

ORDERING CODE......................................................................................................................................... 5.3

CRRGPFKZ"C"⁄"EGTVKHKECVKQPU"KPHQTOCVKQP"000000000000000000000000000000000000000000000000000000000000000000000000000000"C03

EUROPEAN DIRECTIVE INFORMATION .....................................................................................................A.1

HAZARDOUS LOCATIONS GENERAL INFORMATION...............................................................................A.1

HAZARDOUS LOCATIONS APPROVALS.....................................................................................................A.2

CSA (CANADIAN STANDARDS ASSOCIATION)......................................................................................................... A.2

FM APPROVALS (FACTORY MUTUAL)....................................................................................................................... A.2

NEMKO (NORGES ELEKTRISKE MATERIELKONTROLL) ......................................................................................... A.3

EXAM (BBG PRÜF -UND ZERTIFIZIER GMBH) .......................................................................................................... A.3

CEPEL (CENTRO DE PESQUISA DE ENERGIA ELÉTRICA) ...................................................................................... A.3

IDENTIFICATION PLATE...............................................................................................................................A.5

CONTROL DRAWING....................................................................................................................................A.7

CRRGPFKZ"D"⁄"UTH"⁄"UGTXKEG"TGSWGUV"HQTO"00000000000000000000000000000000000000000000000000000000000000000000000000000"D03

RETURNING MATERIALS.............................................................................................................................B.2

CRRGPFKZ"E"⁄"UOCT"YCTTCPV["EGTVKHKECVG"00000000000000000000000000000000000000000000000000000000000000000000000000000"E03

CRRGPFKZ"DH["00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"3

Kpuvcnncvkqp"Hnqyejctv"

XKK"

Kpuvcnncvkqp"Hnqyejctv"

H[525"/"Qrgtcvkqp."Ockpvgpcpeg"cpf"Kpuvtwevkqpu"Ocpwcn"

XKKK"

Section 1

1.1

INSTALLATION

General NOTE

The installation carried out in hazardous areas should follow the recommendations of the IEC60079-14 standard.

The overall accuracy of measurement and control depends on several variables. Although the

converter has an outstanding performance, proper installation is essential, in order to maximize its

performance.

Among all factors, which may affect converter accuracy environmental conditions are the most

difficult to control. There are, however, ways to reduce the effects of temperature, humidity and

vibration.

The FY303 has a built-in temperature sensor to compensate for temperature variations. At the field,

this feature minimizes the temperature variation effect.

Locating the positioner in areas protected from extreme environmental changes can minimize

temperature fluctuation effects.

In warm environments, the positioner should be installed to avoid, as much as possible, direct

exposure to the sun. Installation close to lines and vessels subjected to high temperatures should

also be avoided.

Use of sunshades or heat shields to protect the positioner from external heat sources should be

considered, if necessary.

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O-rings for the

electronics cover must be correctly placed. Removal of the electronics cover in the field should be

reduced to the minimum necessary, since each time it is removed; the circuits are exposed to

humidity. The electronic circuit is protected by a humidity proof coating, but frequent exposures to

humidity may affect the provided protection. It is also important to keep the covers tightened in

place. Every time they are removed, the threads are exposed to corrosion, since painting cannot

protect these parts. Code approved sealing methods on conduit entering the positioner should be

employed.

Although the positioner is virtually insensitive to vibration, installation close to pumps, turbines or

other vibrating equipment should be avoided.

Mounting

The mounting of positioner FY303 will depend on actuator type, single (spring return) action or

double action and on actuator movement, if it is linear or rotary. Two supports are required for

mounting, one for the magnet and the other for the positioner itself. Smar may supply them both

since they are specified in the order code.

Rotary Movement

Install the magnet on the valve stem using the magnet support (See Figure 1.2).

Install the positioner support on the actuator. The actuator should be in accordance with standard

VDI/VDE 5845, all you have to do is tighten the four screws with the lock washers on the standard

support.

For special supports, refer to specify instructions. After installing the support on the actuator, it is

possible to mount the positioner FY303 on the support by means of the four screws with lock

washers.

Make sure that the arrow engraved on the magnet coincides with the arrow engraved on the

positioner when the valve is in mid travel.

If the installation of the positioner or magnet should be altered, or if there should be any other

modification, the positioner will require a recalibration.

As to the type of valve action, refer to paragraph "Pneumatic Connections".

FY303 - Operation, Maintenance and Instructions Manual

1.2

Linear Movement

Install the magnet on the valve stem using the magnet support (See Figure 1.3).

Install the positioner support on the actuator. The actuator support may be secured in place as per

standard NAMUR/IEC 536-4 or in accordance with user specified boring. Install the positioner on the

support and tighten the four screws in the threaded bores located on the side opposite to the

pressure gages (See Figure 1.3). Use lock washers in order to prevent screw slackening.

Make sure that the support is not obstructing the exhaustion outlets.

NOTE

Make sure that arrow engraved on the magnet coincides with the arrow engraved on the positioner when the

valve is in mid travel. The magnet mounting in relation to the hall sensor:

1. Must not have attrition between the internal magnet face and the hall sensor salience during the travel

(rotary or linear), through the magnet.

2. The magnet and the salience of hall sensor must not be distant.

A minimum distance of 2 mm and a maximum distance of 4 mm is recommended between the magnet external

face and the positioner face. For that, a centralizer device (linear or rotary) must be used. The centralizer

device is in the positioner packing.

If the installation of the positioner or magnet should be altered, or if there should be any other

modification, the positioner will require a recalibration.

Pneumatic Connections

Air supplied to the positioner FY303 shall be quality instrument air, i. e., dry, clean and non-

corrosive. Refer to the American National Standard. “Quality Standard for Instrument Air” (ANSI/ISA

S7.0.01 - 1996).

The FY303 is supplied with input and outputs air filters; but these filters do not substitute a

preliminary instrumentation air treatment. We recommend a periodic cleaning of such filters each 6

months or less, case the air instrument quality is not good.

Air supply pressure to the FY303 shall be between 1.4 bar (20 psi) and 7 bar (100 psi). In case such

requirements can not be fulfilled, the use of an air pressure regulator is acceptable.

Use sealant on threads. Sealants like PTFE (Teflon) tape shall be avoided because they may

fragment and eventually obstruct internal parts.

Positioner FY303 may be supplied with pressure gages. There are taps available for IN, OUT1 and

OUT2. Before connecting the pressure gages, make sure that all lines be completely purged.

Valve positioner FY303 has two pneumatic outputs. They work on opposite directions to open or

close the valve.

WARNING

The FY303 should fail, for example, because of a power failure. The output identified as OUT1 (output 1)

goes to nearly zero; while the output identified as OUT2 (output 2) goes to nearly the air supply pressure.

Pneumatic connections are identified as IN (input) for the air supply, and OUT1 and OUT2 for

Output 1 and Output 2 respectively. Use 1/4 NPT connections. Sealant may be used NPT threads.

Connect the air supply tubing to the connection identified as IN. Make sure that the air supply

pressure does not exceed the maximum rating accepted by the positioner or actuator. The tubing

used to connect the positioner FY303 to the actuator shall be as short as possible. The manometer

supply is optional.

NOTE

When ordering the positioner in stainless steel 316, combined with the local pressure gauges, the gauge

case is in SS 316. For wet parts and threads in SS 316, please, consult Smar.

ATTENTION

Make sure that sealant does not enter the positioner.

There are six exhaust outputs in the FY303, all of them fitted with filters. It is very important that

such outputs are neither blocked nor obstructed, because the air must circulate freely.

All filters shall be inspected to make sure they will not obstruct the outputs (Refer to Section 4 -

Maintenance Procedures).

Installation

1.3

Double Action - Air to Open (Fail Close)

Connect Output 1 (OUT1) of the positioner to the input identified as OPEN in the actuator, and

connect Output 2 (OUT2) of the positioner to the input CLOSE in the actuator.

Double Action - Air to Close (Fail Open)

Connect Output 2 (OUT2) of the positioner to the input identified as OPEN in the actuator, and

connect Output 1 (OUT 1) of the positioner to the input CLOSE of the actuator.

Single Action

Connect Output 1 (OUT1) of the positioner to the input of the actuator. Use a plug to block Output 2

(OUT2).

69

21

24

50

(1.97)

(0.954)

(0.83)

(2.72)

6,5

MOUNTING HOLES FOR M6x1

SCREWS (2 PLACES)

(0.25)

22 13

39

(0.87) (0.51)

ROTARY MAGNET

VALVE POSITIONER

All dimensions are in mm

(1.54)

(

in

)

THREADS FOR SCREWS

M6x1 (4 PLACES)

INPUT

PRESSURE

1/8-27 NPT

OUTPUT

PRESSURE 2

1/8-27 NPT

OUTPUT

PRESSURE 1

1/8-27 NPT

TERMINAL

WIRING

OUTPUT 2

1/4-18 NPT

Leave, at least, a 150mm (5.8 in) space,

for zero and span adjustments with the

magnetic tool.

INPUT

1/4-18 NPT

OUTPUT 1

1/4-18 NPT

EXHAUST

ORIFICES

ELECTRICAL

CONNECTION

SOCKET SET

PLUG

(3.27)

(10.24)

(1.77)(1.77)(1.77)

(1.53)

(2.17) (1.83) (2.42) (0.94)

(2.10) (0.94) (0.94)

(4.45)

(

1

.

9

5

)(

2

.

1

7

)

(0.35)

LINEAR MAGNET

TRAVEL DIMENSION A

(

in

)

Note: Dimensions in mm

*ONLY FOR 50 AND 100 mm TRAVELS.

UP TO 100 mm (3.94)

UP TO 50 mm (1.97)

UP TO 30 mm (1.18) 105 mm (4.13)

181 mm (7.12)

67 mm (2.64)

UP TO 15 mm (0.59) 43 mm (1.7)

64.5

(2.54)

(0.71)

18

(0.89)

22.5

(1.30)

33 (0.59)

15

A

(2 PLACES)

15 *

(0.59)

HOLE 6.3 (0.25)Ø

FY303 - Operation, Maintenance and Instructions Manual

REMOTE HALL SENSOR

1.4

Figure 1.1 - FY303 Dimensional Drawing

LOCK

ROTATY

MAGNET

VALVE STEM POSITIONE

R

ROTATY

MAGNETY

BRACKET

POSITIONER

BRACKET

M6x1 SCREWS

(4 PLACES)

Figure 1.2 - Positioner on Rotary Actuator

NOTE

Included in the package content the centralizer device of rotary magnet. See figure 1.13.

Installation

1.5

OUT2OUT1

IN

POSITIONER

M6x1 SCREWS

(4 PLACES)

LINEAR MAGNET

VALVE YOKE

VALVE STEM

CENTRALIZER DEVICE

LINEAR MAGNET

BRACKET

POSITIONER

BRACKET

Figure 1.3 - Positioner on Linear Actuator

NOTE

Included in the package content the centralizer device of linear magnet. See figure 1.12.

FY303 - Operation, Maintenance and Instructions Manual

1.6

Electronic Housing Rotating

The electronic housing can be rotated in order to have a better position of the digital display. To

rotate it, use the Housing Rotation Set Screw. (See Figure 1.4).

The local indicator itself can also be rotated. (See Figure 2.4).

Electric Wiring

Reach the wiring block by removing the Electrical Connection Cover. This cover can be locked by

the cover locking screw. To release the cover, rotate the locking screw clockwise.

The wiring block has screws on which fork or ring-type terminals can be fastened.

Figure 1.4 - Cover Locking and Housing Rotation Set Screw

For convenience there are two ground terminals: one inside the cover and one external, located

close to the conduit entries. (See Figure 1.5).

Figure 1.5 - Wiring Block

The FY303 uses the 31.25 kbit/s voltage mode option for the physical signaling. All other devices on

the same bus must use the same signaling. All devices are connected in parallel along the same

pair of wires.

Various types of Profibus devices may be connected on the same bus.

Installation

1.7

The FY303 is powered via the bus. The limit for such devices is according to the DP/PA coupler

limitations for one bus for non-intrinsically safe requirement. In hazardous area, the number of

devices may be limited by intrinsically safe restrictions, according to the coupler DP/PA and barriers

limitations.

WARNING

HAZARDOUS AREAS

In hazardous areas with explosion proof requirements, the covers must be tightened with at least 8 turns. In

order to avoid the penetration moisture or corrosive gases, tighten the O’ring until feeling the O'ring touching

the housing. Then, tighten more 1/3 turn (120°) to guarantee the sealing. Lock the covers using the locking

screw.

In hazardous zones with intrinsically safe or non-incentive requirements, the circuit entity parameters and

applicable installation procedures must be observed.

Cable access to wiring connections is obtained by the two conduit outlets. Conduit threads should be sealed

by means of code-approved sealing methods. The unused outlet connection should be plugged and sealed

accordingly.

Should other certifications be necessary, refer to the certification or specific standard for installation

limitations.

The Figure 1.6 - Conduit Installation Diagram shows the correct installation of the conduit, in order

to avoid penetration of water, or other substance, which may cause malfunctioning of the

equipment.

WIRES

CORRECT INCORRECT

Figure 1.6 - Conduit Installation Diagram

The FY303 is protected against reverse polarity, and can withstand ±35 Vdc without damage, but it

will not operate when in reverse polarity.

Topology and Network Configuration

Bus topology (See Figure 1.7) and tree topology (See Figure 1.8) are supported. Both types have a

trunk cable with two terminations. The devices are connected to the trunk via spurs. The spurs may

be integrated in the device giving zero spur length. A spur may connect more than one device,

depending on the length. Active couplers may be used to extend spur length.

Active repeaters may be used to extend the trunk length.

The total cable length, including spurs, between any two devices in the Fieldbus should not exceed

1900m.

The connection of couplers should be kept less than 15 per 250m. In following figures the

DP/PA link depends on the application needs.

FY303 - Operation, Maintenance and Instructions Manual

1.8

Spur

Terminato

r

Spur

S

pur

Shield

Junction

Box

++

+

+

-

Analog

Ground

+

-

Figure 1.7 - Bus Topology

Analog

Ground

+

-+

-

Coupler

++

+

+

Terminato

r

Enabled

Junction

Box

Figure 1.8 - Tree Topology

Intrinsic Safety Barrier

When the Fieldbus is in an area requiring intrinsic safety, a barrier must be inserted on the trunk

between the power supply and the DP/PA coupler, when it is Non-Ex type.

Use of SB302 is recommended.

Jumper Configuration

In order to work properly, the jumpers J1 and W1 located in the FY303 main board must be correctly

configured.

J1 This jumper enables the simulation mode parameter in the AO block.

W1 This jumper enables the local adjustment programming tree.

Installation

1.9

Power Supply

The FY303 receives power from the bus via the signal wiring. The power supply may come from a

separate unit or from another device such as a controller or DCS.

The voltage should be between 9 to 32 Vdc for non-intrinsic safe applications.

A special requirement applies to the power supply used in an intrinsically safe bus and depends on

the type of barrier used.

Use of PS302 is recommended as power supply.

Air Supply Requirements

Before the air supply is connected to the positioner, we recommend the hose is opened freely for 2

to 3 minutes to allow any contamination to be blown out. Direct the air jet into a large paper bag to

trap any water, oil, or other foreign materials. If this indicates that the air system is contaminated, it

should be properly cleaned.

As soon as the positioner is connected and started, internal air leakage will provide protection

against corrosion and prevent the ingress of moisture. For this reason, the air supply pressure

should always be kept on.

Recommendations for an Instrument Air System

Instrument air quality shall be superior to that of industrial compressed air. Humidity, airborne

particles and oil may impair the instrument operation, either temporarily or permanently in case of

internal parts wearing.

As per standard ANSI/ISA S7.0.01 – 1996 - Quality Standard for Instrument Air, instrument air shall

have the following characteristics:

Dew point 10°C below minimum instrument temperature

Size of particles (airborne) 40 µm (maximum)

Oil content 1 ppm w/w (maximum)

Contaminants free from corrosive flammable gases

This standard recommends that the compressor intake be located in an area free from process spills

and fitted with and adequate filter. It also recommends the use of non-lubricated type compressors,

in order to prevent air contamination by lubricating oil. Where lubricated type compressors are

adopted, there shall be used means to make the air oil free.

The figures 1.9 and 1.10 show a typical system for air supply and air quality conditioning.

COMPRESSOR

INTAKE

CO

MPRE

SSO

R

AFTERCOOLER CONDENSATE

SEPARATOR

WITH DRAIN AIR RECEIVER

WITH DRAIN

Figure 1.9 - Air Supply System

FY303 - Operation, Maintenance and Instructions Manual

1.10

OILAND WATER

MIST PREFILTER

WITH DRAIN AIR

DRYER DRY AIR

AFTERFILTER

Figure 1.10 - Air Quality Conditioning System

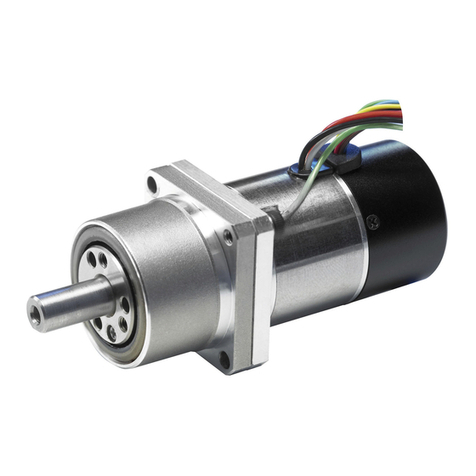

Rotary and Linear Magnet

Magnet models are linear and rotary, for utilization on linear and rotary actuators.

Figure 1.11 – Linear and Rotary Magnet Models

Magnet Centralizer Device

NOTE

Centralizer device of linear magnet is used for all type of

linear bracket.

NOTE

Centralizer device of linear magnet is used only for

universal rotary bracket.

Figure 1.12 – Centralizer device of linear magnet Figure 1.13 - Centralizer device of rotary magnet

Remote Hall Sensor

The remote Hall magnetic sensor is an accessory recommended for high temperature and extreme

vibration applications. It prevents excessive wear of the equipment and, consequently, the reduction

of its useful time.

Installation

1.11

Figure 1.14 - Remote Hall Sensor

The electric signals on the remote sensor’s connection to que equipment are of low intensity.

Therefore, when installing the cable inside the conduit (maximum limit 20 meters length) keep it

away from possible sources of induction and/or magnetic interference. The cable supplied by Smar

is shielded for excellent protection against electromagnetic interference, but despite this protection

avoid the cable sharing the same conduit with other cables.

The connector for remote Hall sensor is easy handling and simple installation.

See the installation procedure:

Figure 1.15 - Connecting the Cable to the

Remote Hall Sensor Figure 1.16 - Connecting the Cable to the

Positioner

FY303 - Operation, Maintenance and Instructions Manual

1.12

Table of contents

Other SMAR Controllers manuals

Popular Controllers manuals by other brands

Icom

Icom IP1000C instruction manual

digitalview

digitalview SVX-1920-PRO instructions

Signature Control Systems

Signature Control Systems SoloRain 8014 DuraLife instructions

Harmonic Drive

Harmonic Drive RSF B mini Series manual

CHERUBINI

CHERUBINI A510078 instructions

Siemens

Siemens siprotec 7SA6 user manual