SMART-Workshop TIRE TRUER User manual

Operating Manual

Design and Manufacturer by SMART-Workshop

WWW.smart-workshop.net

T I R E T R U E R

Turning ideas into reality

www.smart-workshop.net

Page 1

Draft Copy.

SMART Workshop

T I R E T R U E R

Accessories and spare parts list:

1. Alignment Block x1

2 x1. Operating Manual

3. Service x1 Manual

4. Fuses

(Spare Parts)

5. Carrying bag x1

30A x1

3A x1

TIRE TRUER

Opera ting Ma nual

Design and Manufacturer by SMART-Workshop

WWW.smart-workshop.net

Laser Injure hand

Caution

TIRE TRUER

Design and Manufacturer by SMART-Workshop

WWW.smart-workshop.net

Laser Injure hand

Caution

Serv ice Man ual

Page 2

Draft Copy.

SMART Workshop

T I R E T R U E R

TIR E TRUER

TIR E TRUER

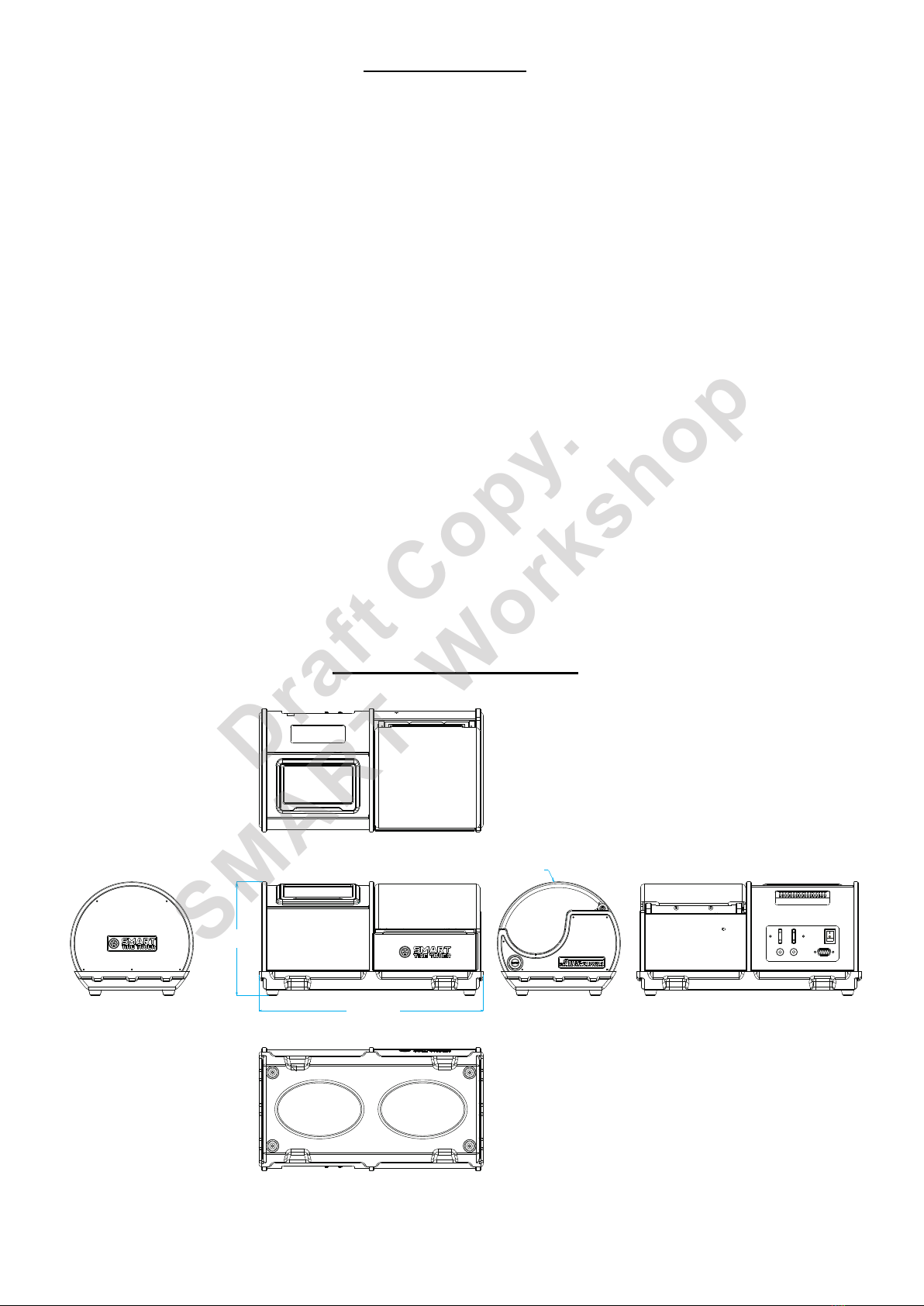

1.Operating by 4'3" color touch screen.

2.With 6 different programmable profiles. This provides the flexibility

to set the truing parameters independently for each to accommodate

for nearly any needed.

3.Fully automatic truing tire diameter and edging by one touch button.

4.Truing diameter (35-84mm), truing angle (0°-2.5°) and edging radius

(3-10mm).

5.Heavy Duty Truing motor provides regulated speed for fully automatic

truing.

6.Dual fuse overload protection for truing motor and CPU controller.

7.Changeable adapter for all classes – 1/8, 1/10, 1/12.

8.Extra volume collecting container for ground rubber.

9.Transparent plexiglass protective cover.

10.Emergency Switch provides a safety feature.

11.Delivered in an exclusive carrying bag.

Specifications:

DC Input Voltage: 12V

Display: LCD; color touch panel

Dimensions: L315xW175xH160mm

Weight: 4.6Kg

Memory: 6 different profiles

Product Dimension

Main features

L=315.0mm

W=175.0mm

H=160.0mm

Page 3

Draft Copy.

SMART Workshop

Page 4

1.

following operation guide to fix it.

When there is locking on X or Y axial block, please refer to the

1.1 Turn off the machine and remove the carbon fibre plate on the right side.

1.3 Turning the X axial until the Y axial near the hole on the back panel.

Note: Once X and Y axial is free, the machine will back to home position automatically

once you power on the machine. Calibration needed after this.

1.4

counterclockwise moves to the back).

Use 2.5 hex screwdriver turn the Y axial (Clockwise moves to the front and

1.2

counterclockwise moves to the right).

Use 2.5 hex screwdriver turn the X axial (Clockwise moves to the left and

Draft Copy.

SMART Workshop

Clean the dust on the dust cover frequently

2.

in each cut, if over the limit the infrared sensors will have serious

damage.

During Manual operation, the truing distance can’t more than 2mm

3.

dust cover movement.

Clean the dust on the dust cover frequently, avoid obstructing the

4. How to adjust the sensors cleaning block.

2.5mm

0mm

4.1 Use 2.5mm hex screwdriver to loosen up the screw as shown below.

4.2

(Cleaning block too close to the sensors will damage the sensors

during auto cleaning).

Adjust the cleaning block close to the sensors within the 1-1.5mm gap.

Page 5

Draft Copy.

SMART Workshop

Lase r Inju re hand

Caution

Equipment guidelines

Page 6

www. sma rt-wo rksh op.or g

Des ign an d Man ufac ture r by SMA RT-Wo rks hop

MODE L TR-32 3

ID03 102019 0101

PROD UCT ID No .

Turning ideas into reality

TIRE TRUER

G

E

R

N

E

C

M

Y

E

ST OP

Touch Panel

Protective Cover

Spare Cutting Bit

Compartment

Sensors Cutting Bit Measuring Ruler

Sensors Cleaner

Locking Nut Wheel Adapter

Main Power Input 12V

Emergency Stop Switch

Container For Ground Rubber

CPU Board Fuses(3A)

Motor Fuses(30A)

Main Switch

RS 232

Draft Copy.

SMART Workshop

IMPORTANT - Don’t remove this stopper from the original position.

If accidentally moved, must be calibrated by alignment block.

Please refer to Service Manual for the calibration method.

Page 7

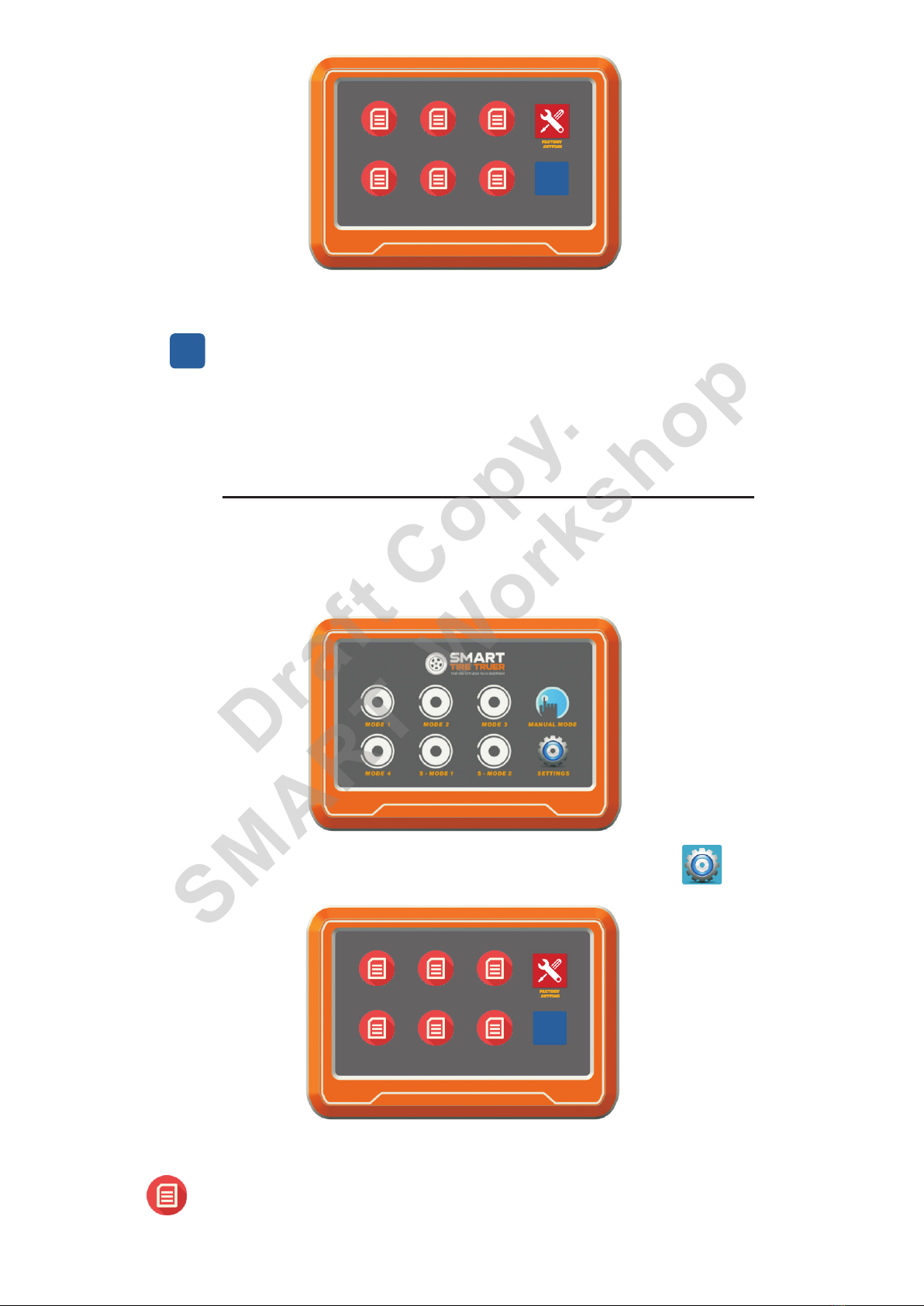

Main Menu

Parameter Setting Menu

Operating Menu

B. Mode 2

B. Setting Mode 2

B. Tire Original Diameter

B. Tire Original Diameter

A. Mode 1

A. Setting Mode 1

A. Setting Mode

*

*

A. Memory

C. Mode 3

C. Setting Mode 3

C. Tire Finish Diameter

D. Mode 4

D. Setting Mode 4

D. Camber

D. Tire Length

E. Round Edging

E. Camber

F. Round Edging

E. Special Mode 1

E. Special Mode 1

F. Tire Length

G. Speed

F. Special Mode 2

F. Special Mode 2

G. Speed 1

H. Traveling

G. Manual Mode

G. Factory Setting

H. Speed 2

I . Start

H. Setting

H. Exit

I . Exit

J

. Stop

K

. Exit

D E F H

A B C G

EXIT

MO DE 1 MODE 2 M OD E 3

MO DE 4 MO DE 2 MO DE 1

SE TTING S ET TING SE TT ING

SE TTING S PE CIA LSP ECIAL

SE TT ING

MO DE 1

EXIT

Ti re O ri ginal

mm

Tire Finish

mm

Ca mb er

Ro un d Ed ging

mm

mm

Sp eed 1

Sp eed 2

Tire Length

82.0

62.0 58.0

1.5 5

1

6.0

Memory 1

EXIT

Tire Finish

Tire Length

Tire Origin al

mmmm

82.0

62.0

0.0mm

mm

Ro und Edging

mm

Tr aveling

mm

Speed

Ca mber

1.5

6.0

9

0.0

Memory Setting Menu

Draft Copy.

SMART Workshop

A

A

A

D

B

B

C

B

D

E

H

E

F

G

H

J

C

G

I

K

G

D

C

E

F

F

I

H

C. Tire Finish Diameter

B. Mode 2

EXIT

MO DE 1

MO DE 1

MO DE 2 MODE 3

MO DE 4 MO DE 2 MO DE 1

SE TTING

SE TT ING

SE TTING S ET TIN G

SE TTING S PE CIA LSP ECIAL

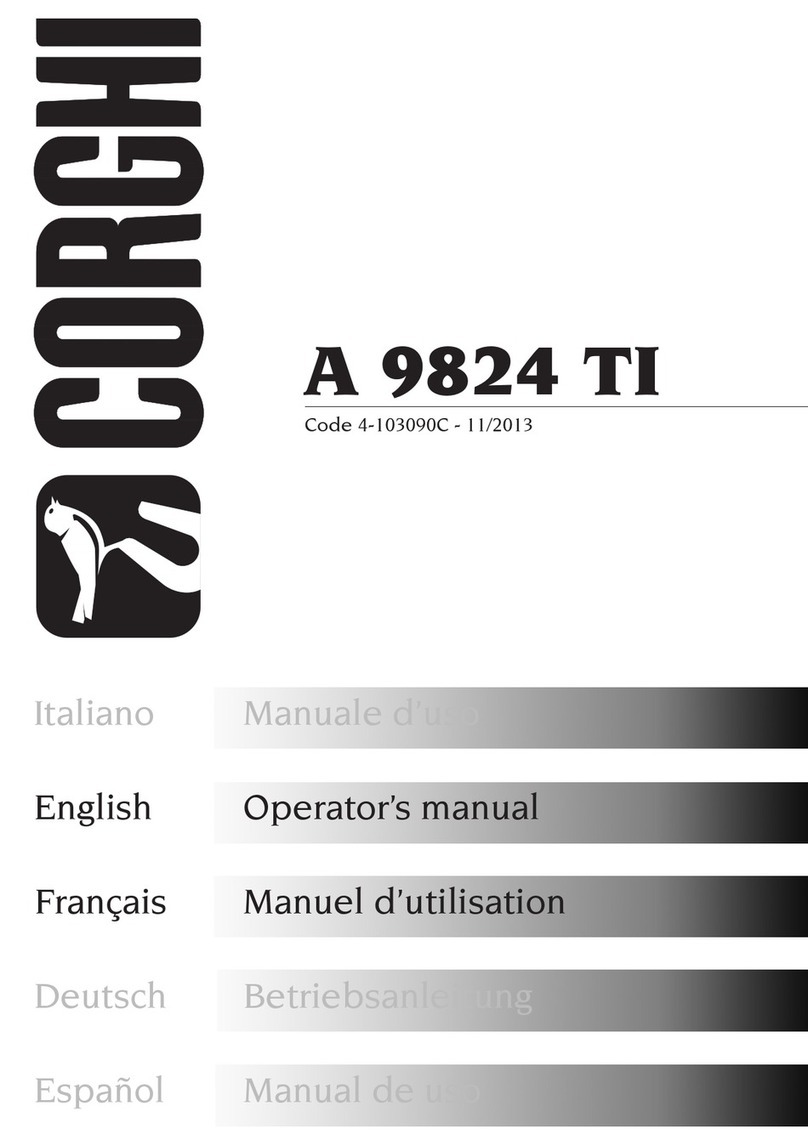

1 Press “Setting icon” enters Memory setting menu..

Mode 1 to 4 is designed for fully automatic feature, you only need to

measure the original outside diameter of the tire and key in all the para-

meters you prefer to use on the track. The measuring of tire original

diameter accuracy required is not high +/-1mm is acceptable (Low

accuracy will affect sensor detection).

We are not recommended to use Mode1-4 for those used tire or tire with

more than 3mm round edges. The large round edge radius will affect

sensors detection and accuracy of tire width measurement. But you can

use our Special Mode1-2 to fulfil this job (Please refer to Special Mode

setting instructions).

2 Press “Setting Mode Icon” enters to Parameter Setting Menu..

Mode1-4 Setting Instructions

SETTI NGS

SE TT ING

MO DE 1

EXIT

Ti re O ri ginal

mm

Tire Finish

mm

Ca mb er

Ro un d Ed ging

mm

mm

Sp eed 1

Sp eed 2

Tire Length

82.0

62.0 58.0

1.5 5

1

6.0

Page 8

Draft Copy.

SMART Workshop

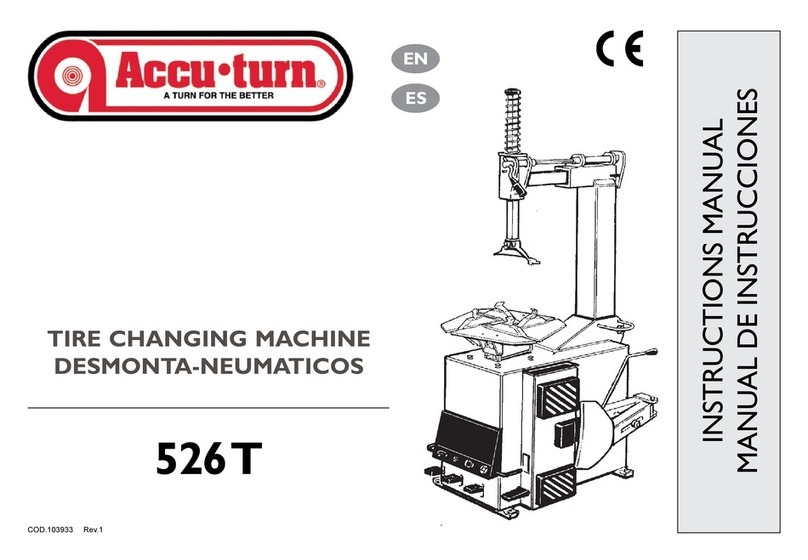

*

Remark:

We provide two types of the key in methods to key in the tire original diameter.

1. “Manual Key In” Direct key in the number of tire original diameter from

screen.

2. “Manual Detection” Detect the tire original diameter by cutting bit under

manual operating. Only one method requested.

2.1.1 Press “Manual key in Icon” enters to D1 manual key in menu.

2.1.2 Press “Manual Detection Icon” enters to D1 manual detection menu.

2. .1 1.1 Press “D1 flash cursor Icon”.

2. .1

position.

1.2 Press “Home Icon” wait for the truer cutting bit block return to home

2. .3 1.2 Press “Exit Icon” back to the Parameter Setting Menu.

2. .2

surface and complete with “Enter Icon”.

1.2 Use “Direction Arrow Icon” to move the truer cutting bit near to tire

2. .3 1.1 Press “Exit Icon” back to the Parameter Setting Menu.

Move the Cutting bit near to tire surface Move Cutting bit close to the surface of the tire

2. .2

and complete with “Enter Icon”.

1.1 Key in the number of tire original diameter from screen keypad

Memory 1 Tire Origin al

Tire Origin al

mm

mm

Tire Origin al R

mm

EXIT

EXIT

SAVE

HOME

HO ME

SE TTING

MO DE 1

2.1 Press “D1 icon” enters to original diameter setting menu.

SE TTING

MO DE 1

Manual

Key In

Manual

Key In

Manual

Detection

Manual

Detection

EXIT

Page 9

X movement

Y movement

Draft Copy.

SMART Workshop

Page 10

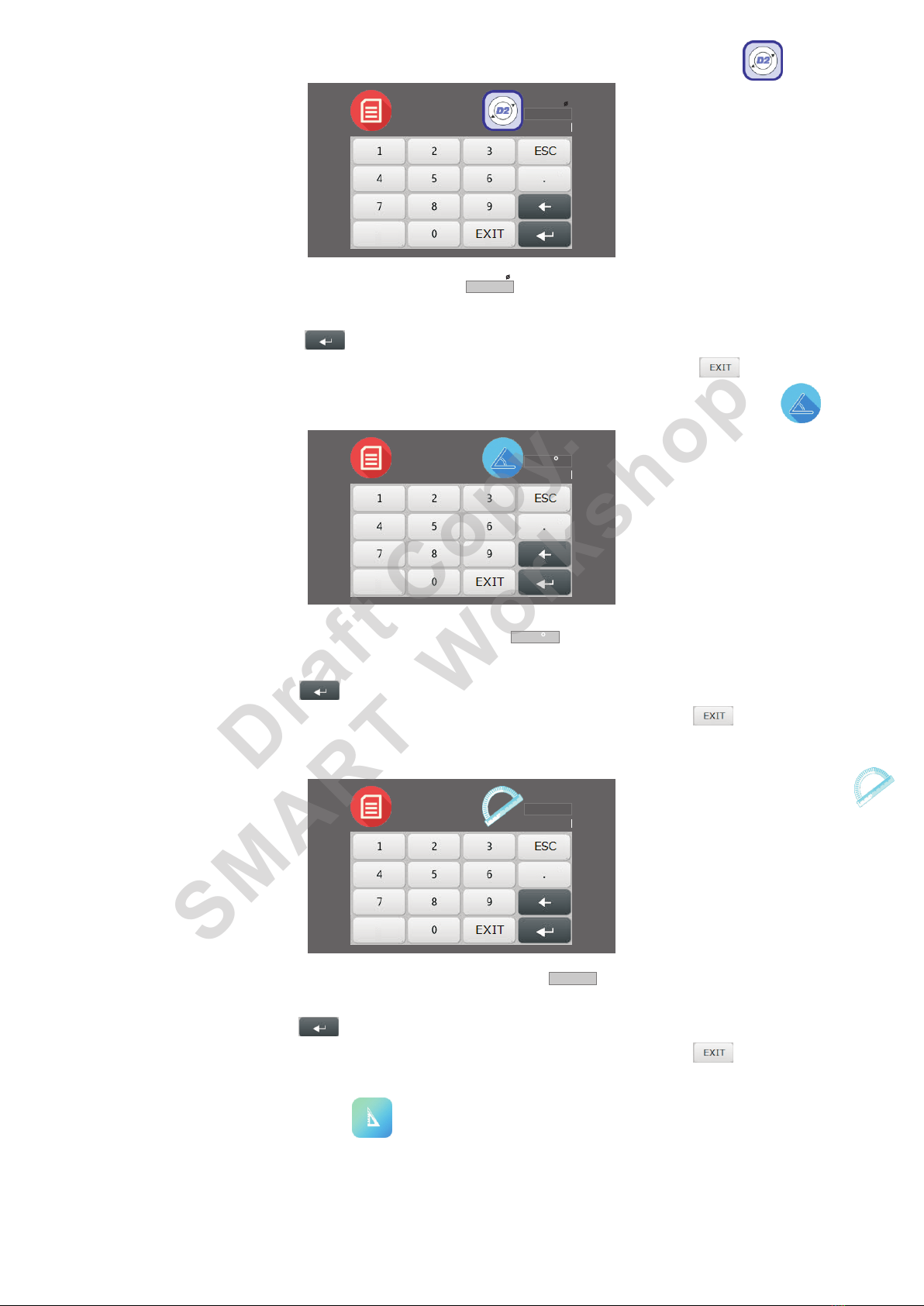

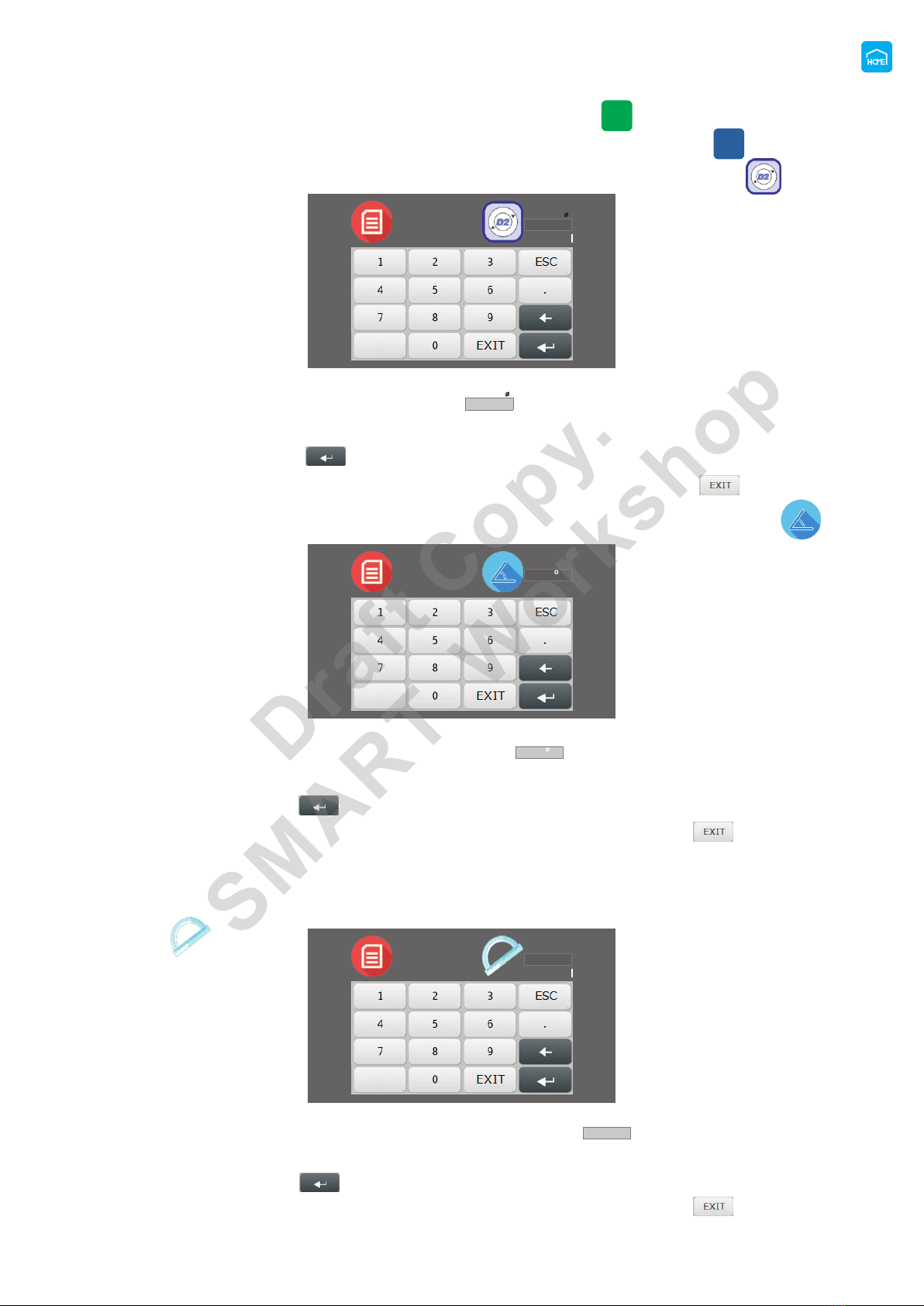

2 2 Press “D2 Icon” enters to truing diameter setting menu. .

2 3 Press “Camber Icon” enters to camber angle setting menu..

2 4 Press “Round Edging Icon” enters to Round edge radius setting menu..

2 5 “Tire Length” setting will auto detected by machine, no parameter .

needed for Mode1-4.

2 2.1 Press “D2 flashing cursor Icon”..

2 3.1 Press “Camber cursor Icon”.. flashing

2 4.1 Press “Round Edging flash cursor Icon”..

2 3.2 Key in the number of camber angle from screen keypad and complete

with “Enter Icon”.

.

2 4.2 Key in the number of round edge radius from screen keypad and complete

with “Enter Icon”.

.

2 3.3 Press “Exit Icon” back to the Parameter Setting Menu..

2 4.3 Press “Exit Icon” back to the Parameter Setting Menu..

2 2.2 Key in the number of truing diameter from screen keypad and complete

with “Enter Icon”.

.

2 2.3 Press “Exit Icon” back to the Parameter Setting Menu..

Memory 1 Tire Finis h

Tire Finis h

mm

mm

Memory 1 Ca mber

Ca mber

Memory 1 Ro und E dging

Ro und E dging

mm

mm

Tire Length

Draft Copy.

SMART Workshop

2 6.1 Press “Speed 1 cursor Icon”.. flashing

2 7.1 Press “Speed 2 cursor Icon”.. flashing

2 7.3 Press “Exit Icon” back to Parameter Setting Menu..

2 7.2 Key in the number of traveling Speed from screen keypad and

complete with “Enter Icon”.

.

2 6.2 Key in the number of traveling Speed level from screen keypad and

complete with “Enter Icon”.

.

2 6.3 Press “Exit Icon” back to Parameter Setting Menu..

2 6 Press “Speed 1 Icon” enters to surface truing traveling speed level

setting menu.

.

2 7 Press “Speed 2 Icon” enters to round edge truing traveling speed

level setting menu.

.

Sp eed

Sp eed 1

Sp eed 2

Speed 1

Speed 1

Memory 1

Sp eed

Speed 2

Speed 2

Memory 1

Page 11

SE TT ING

MO DE 1

EXIT

Ti re O ri ginal

mm

Tire Finish

mm

Ca mb er

Ro un d Ed ging

mm

mm

Sp eed 1

Sp eed 2

Tire Length

82.0

62.0 58.0

1.5 5

1

6.0

2 8 Press “EXIT Icon” on Parameter Setting Menu, the parameter's entire

.

saved and return to Memory Setting Menu. EXIT

Draft Copy.

SMART Workshop

Page 12

*

2 9 Press “EXIT Icon” on the Memory Setting Menu and return to Main

.

Special mode is designed for those tire round edge is too large, it will

affect the sensors detection. Because of this, we add a manual detection

function for the width of the tire.

Menu.

EXIT

EXIT

MO DE 1 MODE 2 M OD E 3

MO DE 4 MO DE 2 MO DE 1

SE TTING S ET TING SE TT ING

SE TTING S PE CIA LSP ECIAL

Special Mode1-2 Setting Instructions

EXIT

MO DE 1 MODE 2 M OD E 3

MO DE 4 MO DE 2 MO DE 1

SE TTING S ET TING SE TT ING

SE TTING S PE CIA LSP ECIAL

MO DE 1

SP EC IA L

1 Press “Setting Icon” enters to Memory setting menu..

2 Press “Setting SPECIAL Mode Icon” enters to Parameter Setting .

Menu.

SETTI NGS

Draft Copy.

SMART Workshop

SP EC IAL

MO DE 1

EXIT

Ti re O ri ginal

mm

Tire Finish

mm

Ca mb er

Ro un d Ed ging

mm

mm

Sp eed 1

Sp eed 2

Tire Length

82.0

62.0 58.0

1.5 5

1

6.0

Remark:

We provide two types of the key in methods to key in the tire original diameter.

1. “Manual Key In” Direct key in the number of tire original diameter from

screen.

2. “Manual Detection” Detect the tire original diameter by cutting bit under

manual operating. Only one method requested.

2.1.1 Press “Manual key in Icon” enters to D1 manual key in menu.

2.1.2 Press “Manual Detection Icon” enters to D1 manual detection

2. .1 flashing 1.1 Press “D1 cursor Icon”.

2. .3 1.1 Press “Exit Icon” back to the Parameter Setting Menu.

2. .2

and complete with “Enter Icon”.

1.1 Key in the number of tire original diameter from screen keypad

2.1 Press “D1 Icon” enters to original diameter setting menu.

Manual

Key In

SP ECIAL

MO DE 1

Manual

Key In

Manual

Detection

EXIT

SPECIAL

MODE 1

SPECIAL

MODE 1

Tire Origin al

Tire Origin al

mm

mm

Manual

Detection

Tire Origin al R

mm

EXIT SAVE

HOME

SP ECIAL

MO DE 1

Menu.

Page 13

Draft Copy.

SMART Workshop

2. .1 1.2 Press “Home Icon” the cutting bit block will return to home position.

2. .3 1.2 Press “Exit Icon” back to the Parameter Setting Menu.

2. .2

tire surface and complete with “Save Icon”.

1.2 Press “Direction Arrow Icon” move the truer cutting bit near to

2 2 Press “D2 Icon” enters to truing diameter setting menu. .

2 3 Press “Camber Icon” enters to camber angle setting menu..

2 2.1 Press “D2 cursor Icon”.. flashing

2 3.1 Press “Camber cursor Icon”.. flashing

2 3.2 Key in the number of camber angle from screen keypad and complete

with “Enter Icon”.

.

2 3.3 Press “Exit Icon” back to the Parameter Setting Menu..

2 2.2 Key in the number of truing diameter from screen keypad and complete

with “Enter Icon”.

.

2 2.3 Press “Exit Icon” back to the Parameter Setting Menu..

2 4 Press “Round Edging Icon” enters to Round edge radius setting.

2 4.1 Press “Round Edging cursor Icon”.. flashing

2 4.2 Key in the number of round edge radius from screen keypad and complete

with “Enter Icon”.

.

2 4.3 Press “Exit Icon” back to the Parameter Setting Menu..

Tire Finis h

Tire Finis h

mm

mm

SPECIAL

MODE 1

Ca mber

Ca mber

SPECIAL

MODE 1

Ro und E dging

Ro und E dging

mm

mm

SPECIAL

MODE 1

Menu.

Page 14

HO ME

SAVE

EXIT

Draft Copy.

SMART Workshop

Page 15

2 5 Press “Tire Length Icon” enters to Tire Length setting menu..

Tire Length

Tire Length

EXIT

EXIT

ORIGI N

OR IGI N

mm mm

Start E nd

2 5.1 Press “Home Icon” wait for the cutting bit block return to the home

position.

.

Starting point

Ending point

2 5.3 Use “Direction Arrow Icon” to move the left sides of the cutting bits

to the right edge of the tire to get the ending point and complete with

“Save Icon”.

.

2 5.4 Press “Exit icon” back to the parameter setting menu..

2 5.2 Use “Direction Arrow Icon” to move the right sides of the cutting bits

to the left edge of the tire to get the starting point and complete with

“Save Icon”.

.

2 6.1 Press “Speed 1 cursor Icon”.. flashing

2 6 Press “Speed 1 Icon” enters to surface truing traveling speed level

setting menu.

.

Sp eed

Sp eed 1

Speed 1

Speed 1

SPECIAL

MODE 1

Draft Copy.

SMART Workshop

Page 16

SP EC IAL

MO DE 1

EXIT

Ti re O ri ginal

mm

Tire Finish

mm

Ca mb er

Ro un d Ed ging

mm

mm

Sp eed 1

Sp eed 2

Tire Length

82.0

62.0 58.0

1.5 5

1

6.0

2 8 Press “EXIT Icon”on Parameter Setting Menu, the parameters entire

.

saved and return to Memory Setting Menu. EXIT

2 9 Press “EXIT Icon” on the Memory Setting Menu and return to Main

.

Menu.

EXIT

EXIT

MO DE 1 MODE 2 M OD E 3

MO DE 4 MO DE 2 MO DE 1

SE TTING S ET TING SE TT ING

SE TTING S PE CIA LSP ECIAL

2 7.1 Press “Speed 2 cursor Icon”.. flashing

2 7.3 Press “Exit Icon” back to the Parameter Setting Menu..

2 7.2 Key in the number of traveling Speed from screen keypad and

complete with “Enter Icon”.

.

2 7 Press “Speed 2 Icon” enters round edge truing traveling speed

setting menu.

. to

Sp eed 2

Sp eed

Speed 2

Speed 2

SPECIAL

MODE 1

2 6.2 Key in the number of traveling Speed level from screen keypad and

complete with “Enter Icon”.

.

2 6.3 Press “Exit Icon” back to the Parameter Setting Menu..

Draft Copy.

SMART Workshop

Page 17

Memory 1

EXIT

Tire Finis h

Tire Length

Tire Origin al

mmmm

82.0

62.0

0.0mm

mm

Ro und Edging

mm

Tr aveling

mm

Speed

Ca mber

1.5

6.0

9

0.0

2 Press “Mode Icon” which you need to use enters to Operating Menu..

3 Press “Tire Length Icon” enters to auto tire length detection..

(This step is just for checking the tire length, you can skip this step

if you’re confident with your tires ).

4 Press “Start Icon” to start truing tire..

3 1 The sensors will move to detect tire length and detected length will show

on screen once completed.

.

4 1 Sensors will detect the tire length automatically and show on the screen. .

4 2 Truing motor will turn on automatically..

4 3 Truing the tire diameter and camber automatically..

4 4 Truing the left and right round edge automatically..

4 5 The cutting bit block will go back to the home position after the truing

process completed.

.

4 6 Remove the tire from wheel adapter..

4 7 Press “Start Icon” to redo tire truing with the same program..

4 8 Press “EXIT Icon” back to Main Menu. .

During truing operating you can “Press Stop Icon” to stop the machine or

press the Emergency button cut off the power.

Please check all the setting parameter is correct and make sure the tire

installed properly before you proceed to start. The length of the tire will

show once the detection completed.

1 Press “Mode Icon” enters to Operating Menu.

.

Auto Mode Operation Instructions

MODE 1

Draft Copy.

SMART Workshop

Manual Mode Operation Instructions

1 Press “Manual Mode Icon” enters to Manual Operating Menu.

.

2 Press “Home Icon” machine will back to home position automatically.

.

3 Press “Speed Icon” enters to Speed Setting Menu.

.

4 Press “Direction Arrow Icon” to move the truer cutting bit as you like.

.

MA NUAL MO DE

EXIT

EXIT

X:

X:

mm

mm

mm

mm

Y:

Y:

ON

ON

Sp ee d

Sp eed

Sp eed

MA NU AL MODE

MANUA L MODE

HO ME

HOME

HO ME

0.0

0.0

8

8

35.0

35.0

3 1 Key in the number of speed levels from screen keypad and complete with

“Enter Icon”.

.

3 2 Press “EXIT Icon” return to Manual Operating Menu..

MANUA L MODE

Speed

Speed

Page 18

Draft Copy.

SMART Workshop

Table of contents

Popular Tyre Changer manuals by other brands

Corghi

Corghi A 9824 TI Operator's manual

Weber

Weber Expert Series manual

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES Coats Rim Clamp X-Model Series instructions

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES Coats CHD-4730-4730W Operating and maintenance instructions

Hofmann

Hofmann monty 3550 Operation instructions, Spare parts list

Corghi

Corghi A 222 Operator's manual

ATLAS PLATINUM

ATLAS PLATINUM PTC 300 Use and maintenance instruction manual

Mondolfo Ferro

Mondolfo Ferro Startline S 524 Operator's manual

Accu-Turn

Accu-Turn 526T instruction manual

Glomstad Motor

Glomstad Motor GM-U221 PRO Use and maintenance manual

Fasep

Fasep BALATRON 331.G3 user manual

ATH-Heinl

ATH-Heinl 7226 operating instructions