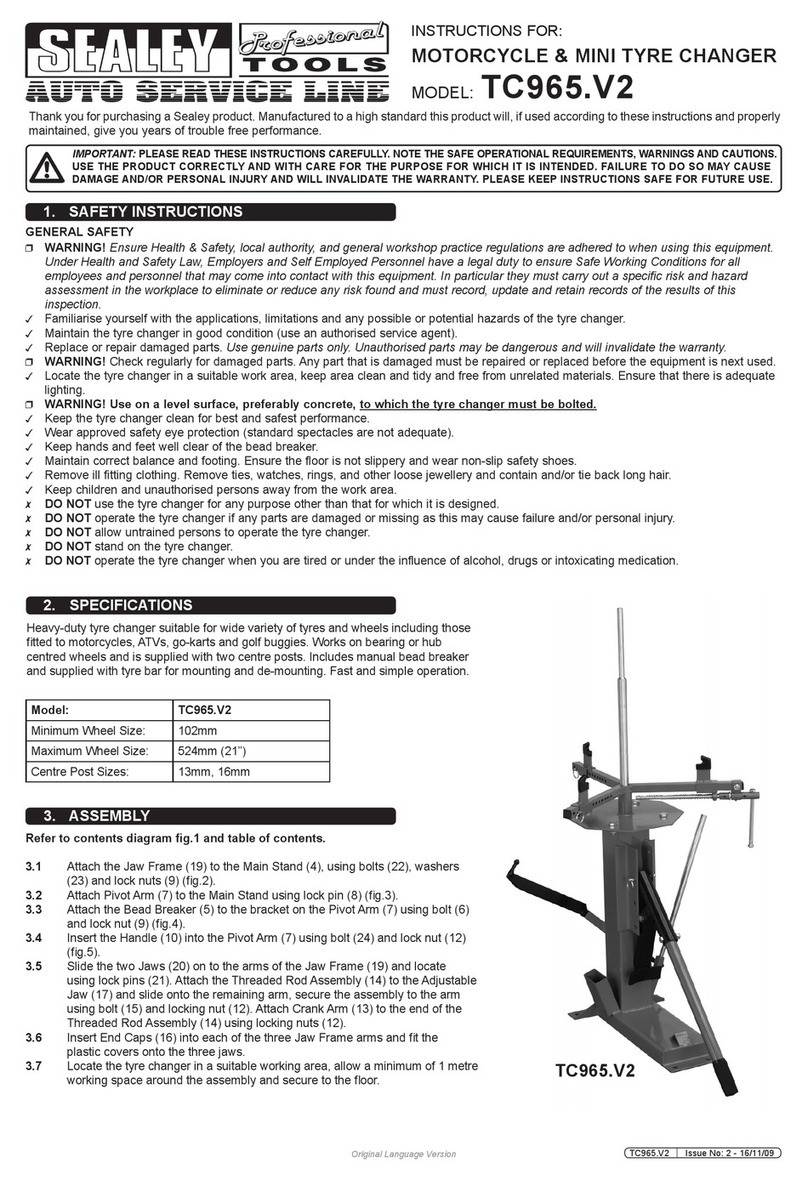

INSTRUCTIONS FOR:

MOTORCYCLE & MINI TYRE CHANGER

MODEL: TC965

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

2. SPECIFICATIONS

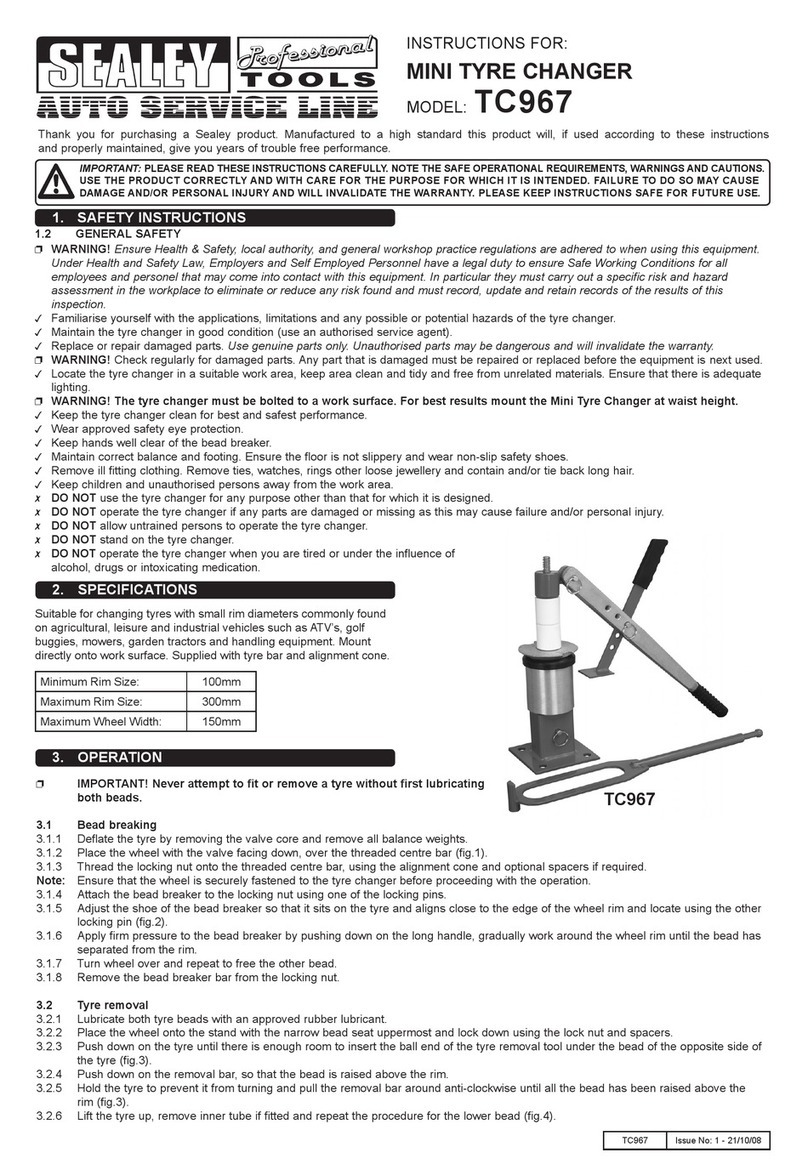

TC965

GENERAL SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

Under Health and Safety Law, Employers and Self Employed Personnel have a legal duty to ensure Safe Working Conditions for all

employees and personel that may come into contact with this equipment. In particular they must carry out a specific risk and hazard

assessment in the workplace to eliminate or reduce any risk found and must record, update and retain records of the results of this

inspection.

Familiarise yourself with the applications, limitations and any possible or potential hazards of the tyre changer.

Maintain the tyre changer in good condition (use an authorised service agent).

Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

WARNING! Check regularly for damaged parts. Any part that is damaged must be repaired or replaced before the equipment is next used.

Locate the tyre changer in a suitable work area, keep area clean and tidy and free from unrelated materials. Ensure that there is adequate

lighting.

WARNING! Use on a level surface, preferably concrete, to which the tyre changer must be bolted.

Keep the tyre changer clean for best and safest performance.

Wear approved safety eye protection (standard spectacles are not adequate).

Keep hands and feet well clear of the bead breaker.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip safety shoes.

Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery and contain and/or tie back long hair.

Keep children and unauthorised persons away from the work area.

DO NOT use the tyre changer for any purpose other than that for which it is designed.

DO NOT operate the tyre changer if any parts are damaged or missing as this may cause failure and/or personal injury.

DO NOT allow untrained persons to operate the tyre changer.

DO NOT stand on the tyre changer.

DO NOT operate the tyre changer when you are tired or under the influence of alcohol, drugs or intoxicating medication.

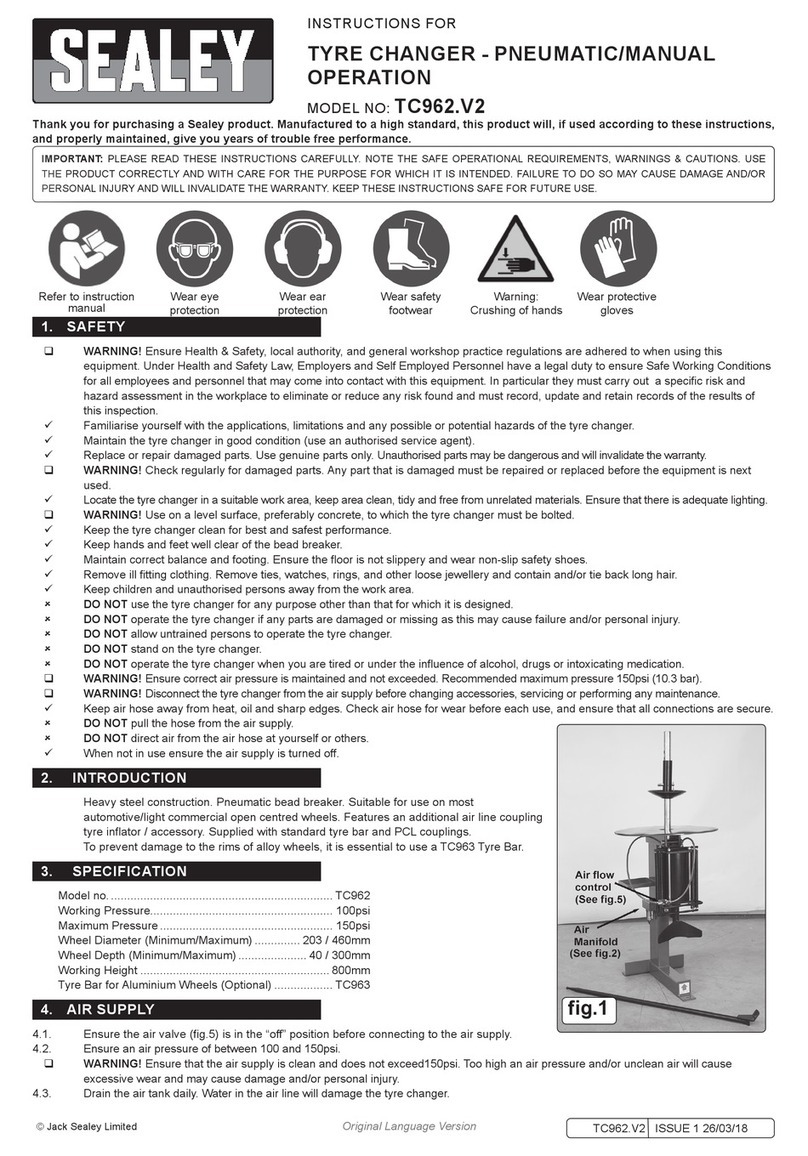

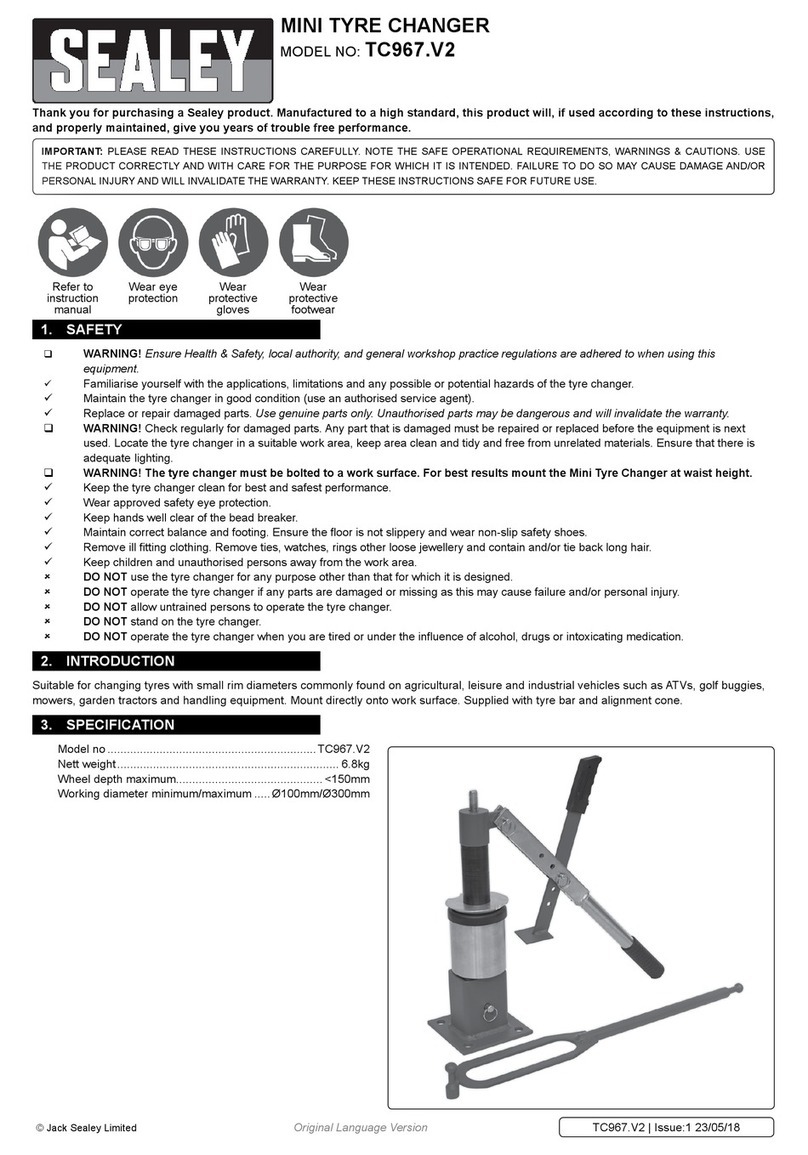

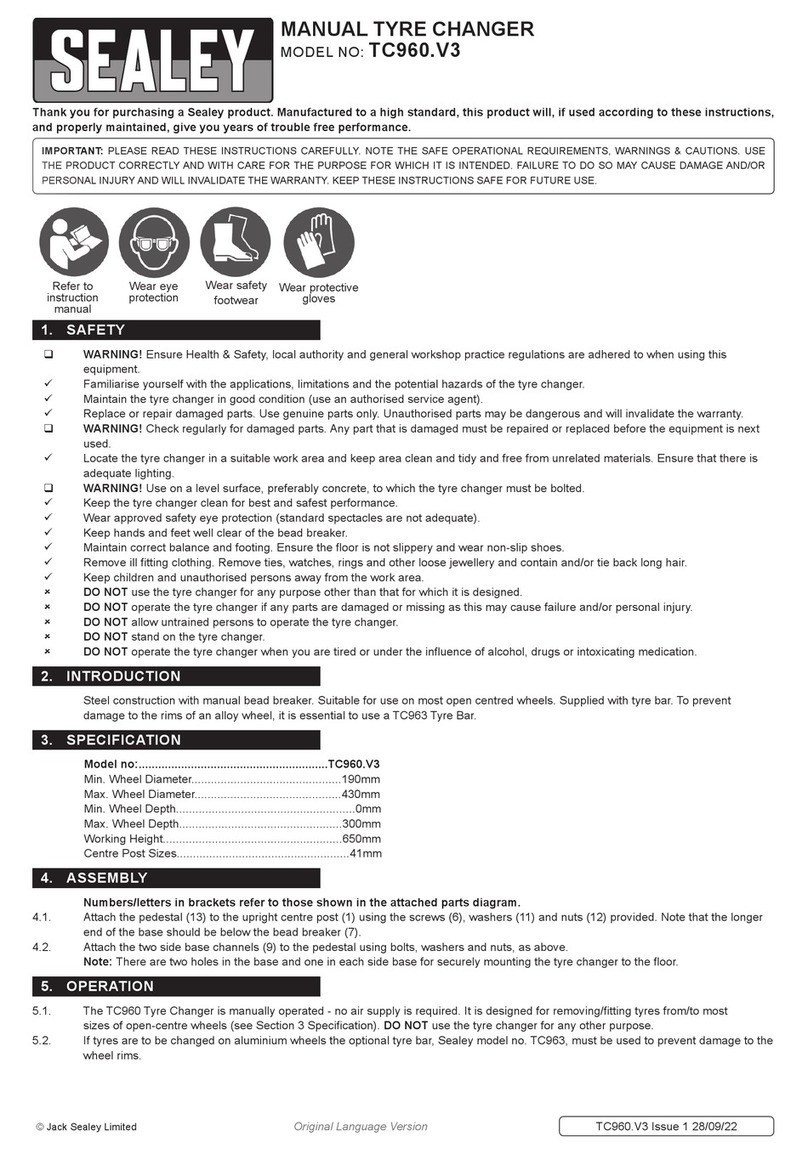

Heavy-duty tyre changer suitable for wide variety of tyres and wheels including those

tted to motorcycles, ATVs, go-karts and golf buggies. Works on bearing or hub

centred wheels and is supplied with two centre posts. Includes manual bead breaker

and supplied with tyre bar for mounting and de-mounting. Fast and simple operation.

Model: TC965

Minimum Wheel Size: 102mm

Maximum Wheel Size: 420mm

Centre Post Sizes: 13mm, 16mm & 19mm

3. ASSEMBLY

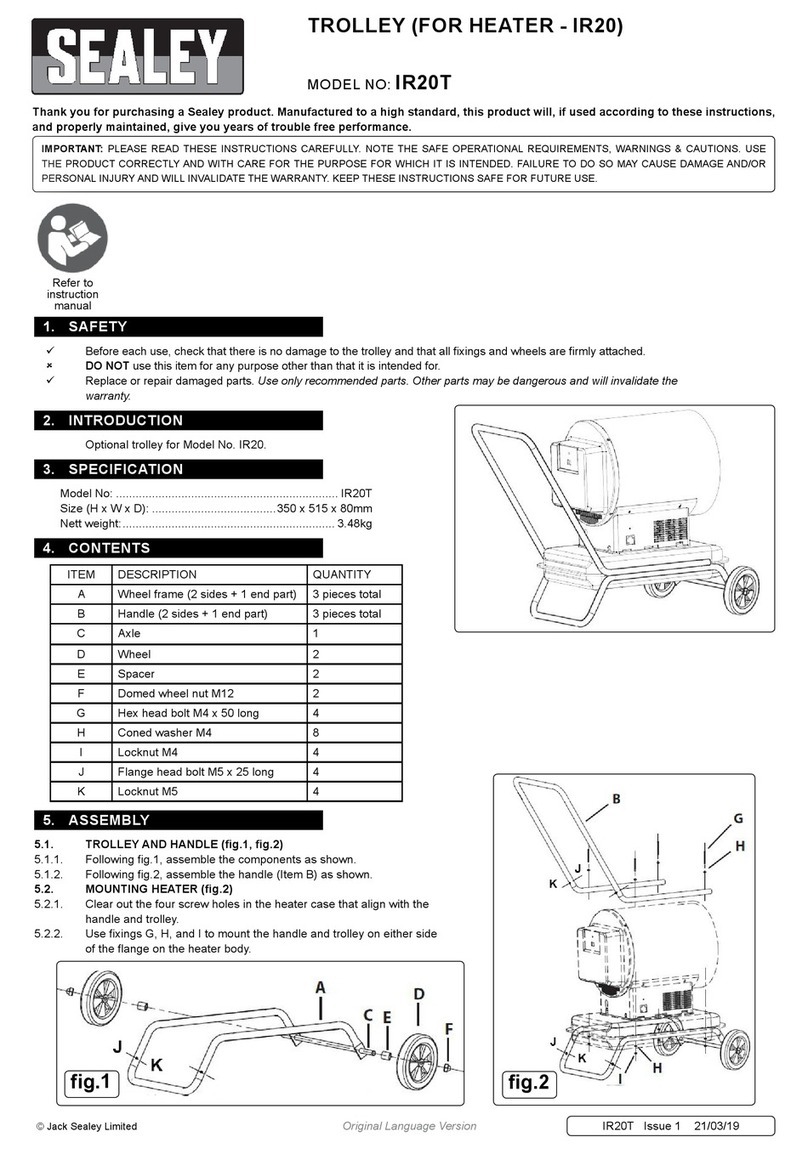

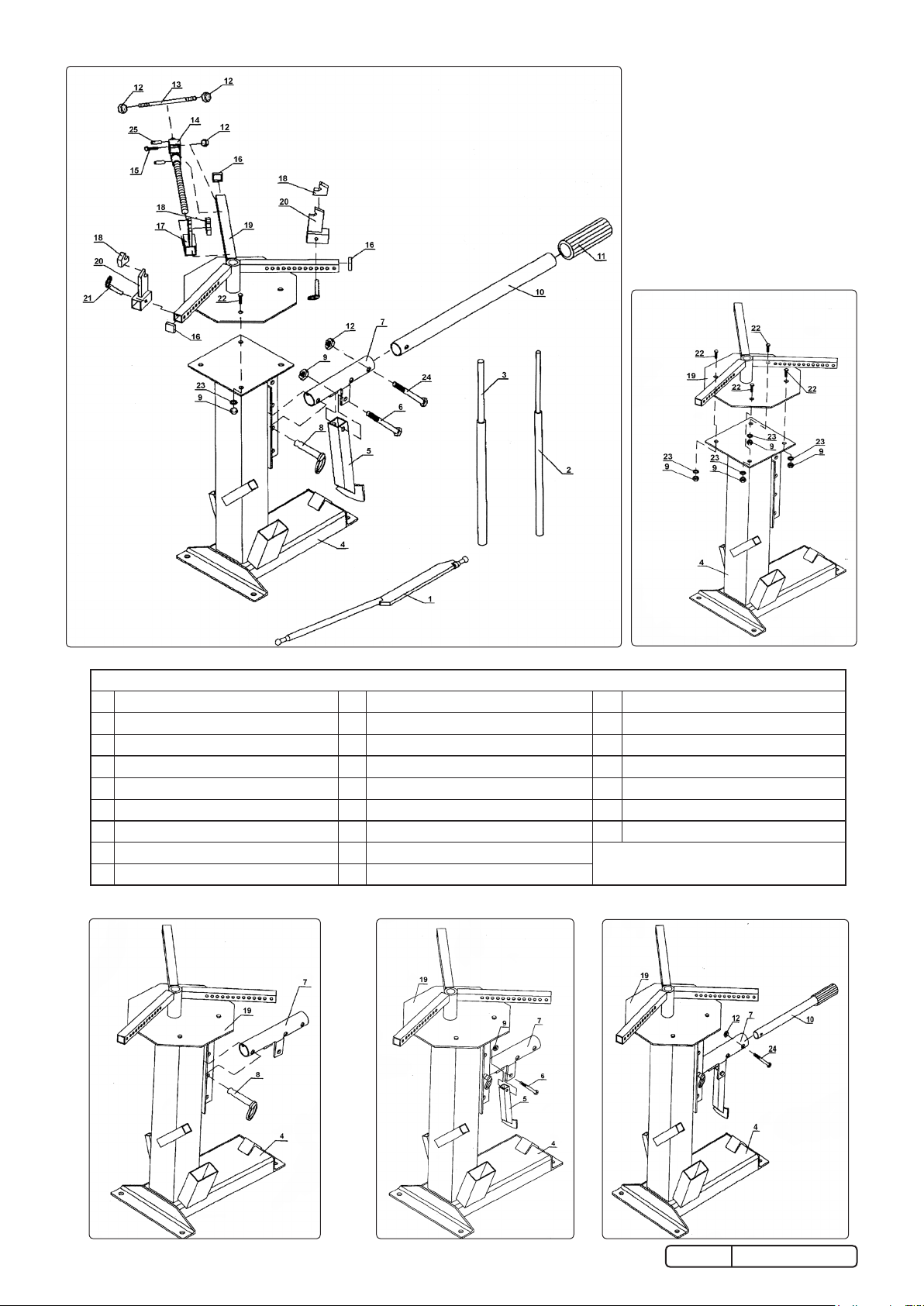

Refer to contents diagram g.1 and table of contents.

3.1 Attach the Jaw Frame (19) to the Main Stand (4), using bolts (22), washers

(23) and lock nuts (9) (g.2).

3.2 Attach Pivot Arm (7) to the Main Stand using lock pin (8) (g.3).

3.3 Attach the Bead Breaker (5) to the bracket on the Pivot Arm (7) using bolt (6)

and lock nut (9) (g.4).

3.4 Insert the Handle (10) into the Pivot Arm (7) using bolt (24) and lock nut (12)

(g.5).

3.5 Slide the two Jaws (20) on to the arms of the Jaw Frame (19) and locate

using lock pins (21). Attach the Threaded Rod Assembly (14) to the Adjustable

Jaw (17) and slide onto the remaining arm, secure the assembly to the arm

using bolt (15) and locking nut (12). Attach Crank Arm (13) to the end of the

Threaded Rod Assembly (14) using locking nuts (12).

3.6 Insert End Caps (16) into each of the three Jaw Frame arms and t the

plastic covers onto the three jaws.

3.7 Locate the tyre changer in a suitable working area, allow a minimum of 1 metre

working space around the assembly and secure to the oor.

TC965 Issue No: 1 - 24/10/08