Smartflow FasTie User manual

Form #154 (08.17)

4500 E. 142nd Street • Grandview, MO 64030 • Tel. (816) 878-6675 • www.smartflow-usa.com

General

FasTie Quick-Connect Ejector System “ties-in” the

mold ejector plate to the press ejection system. A

pneumatically-operated piston inside the coupler

releases the pull stud from the press ejection system

to reduce set-up and change-out times.

Fixed-length FasTie Knockout Bars may be used

with the couplers and pull studs. The FasTie air

manifold option distributes shop air to each coupler.

The aluminum manifold supplies air to up to four

couplers. Pneumatic fittings and tubing are included.

Maintenance

Use Ultra High Temperature Synthetic Anti-Seize grease regularly on

the couplers for smooth operation. Visually inspect coupler each

month or each tool change for the presence of grease. Generously

apply grease to pull stud end, connect the coupler to the pull stud,

then release and repeat.

Before Installation

Before clamping a mold to the injection molding machine, the

machine ejector plate must be completely retracted to the “home”

position.

Align ent

Per figure 2, maximum center line misalignment per coupler

outside diameter is as follows.

1" HS ±3.5mm (±0.138")

1-3/8" ±5mm (±0.197")

2" ±6mm (±0.236")

3" ±5mm (±0.197")

Multiple Knockout Bar Lengths

When using two or more knockout bars in an installation, knockout

bars must be the same length within .05mm (.002") to assure even

coupler operation.

Smartflow®

FasTie® Quick-Connect Ejector Tie-In Syste

1"HS, 1-3/8", 2" & 3" Components, Installation Instructions

US Patent No. 6,379,072

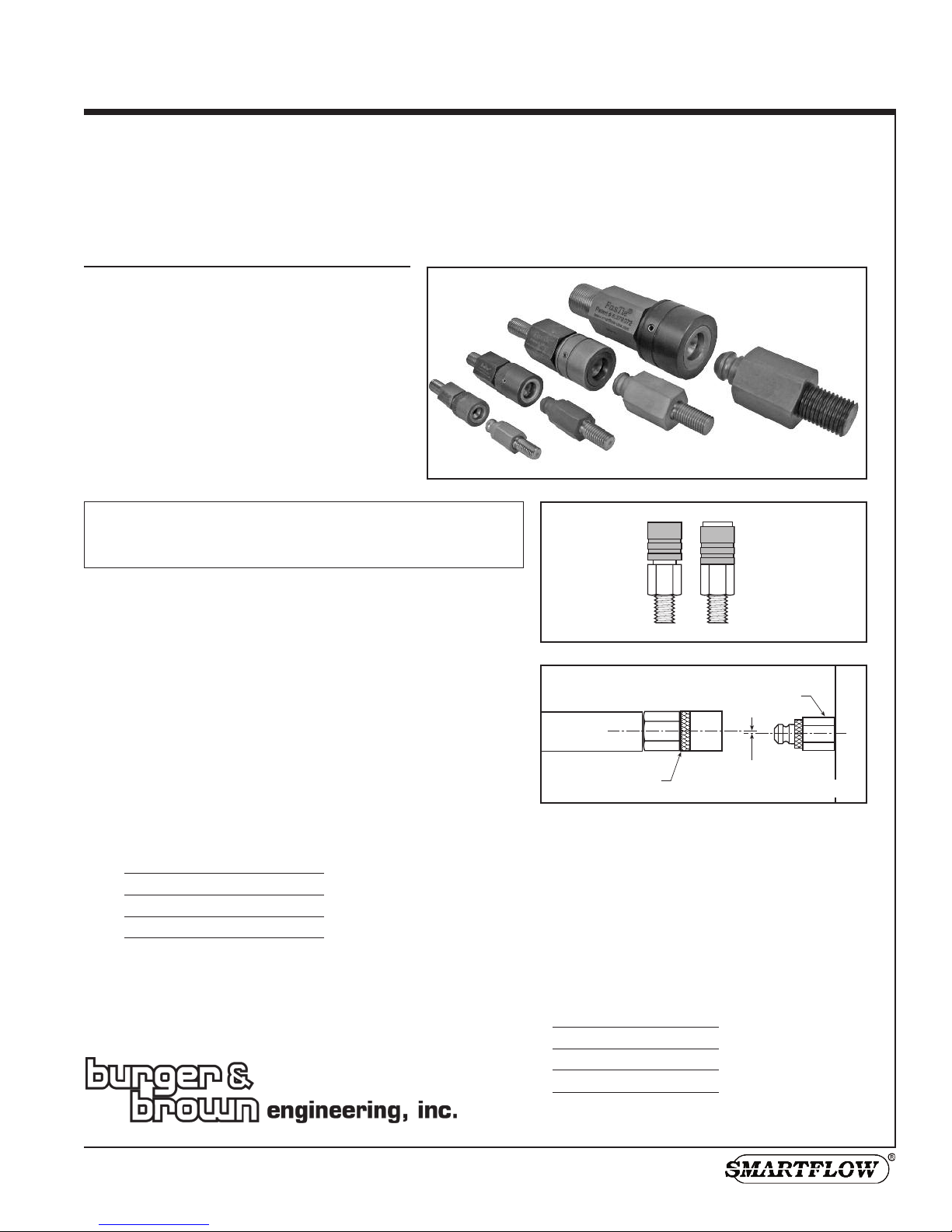

figure 1

Coupler

Open

(sleeve fo wa d)

Coupler

Closed

(sleeve back)

Couplers shown in open position

FasTie Coupler

Maximum Center Line

Misalignment

HS

Pull Stud

HS

figure 2

Caution: Couplers must be in the open position before

connecting with pull studs. See figure 1. Coupler

damage will result from improper set-up.

Ejector Bar Length Note:

Individual ejector bars should not exceed 24" in

length to prevent sagging and excessive

coupler/pull stud misalignment.

It may be necessary to use two ejector bars for

extra-long ejector bar applications, one for each

pull stud and coupler.

Mini u Clearance Needed to

Disengage Coupler and Pull Stud

1" HS 15mm (0.59")

1-3/8" 21mm (0.81")

2" 25mm (1.00")

3" 34mm (1.34")

FasTie® Quick-Connect Ejecto Tie-In System

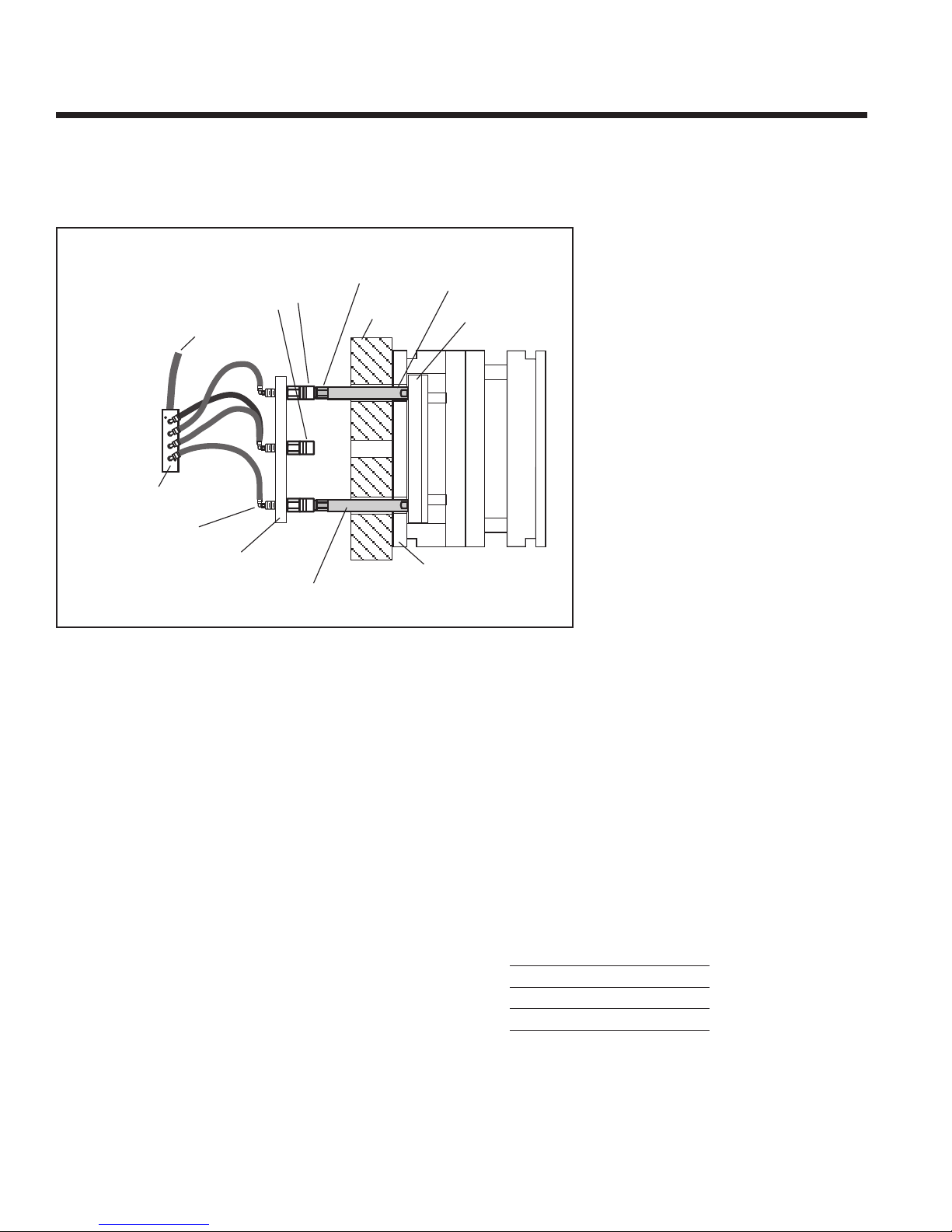

Couplers on Press Ejector Plate

fo multiple molds in the same machine with diffe ent ejecto

patte ns and diffe ent ejecto st okes

The following installation instructions are for reference only.

Installation may vary depending on the application and

customer preferences.

1. Install the coupler into the press ejector plate populating

for the required molding machine patterns (i.e. vertical,

horizonal and/or center knockout positions). Use thread-

locking compound to prevent movement during use.

2. Install pneumatic fitting to the coupler per figure 3.

3. If using the manifold accessory, mount the manifold and

tubing so they do not interfere with moving parts.

4. Connect shop air lines to the pneumatic fittings that feed

the FasTie couplers. Couplers must be in the open

position (see figure 1) before connection to pull studs,

otherwise coupler damage will occur.

5. Install the pull stud onto the end of the knockout bar.*

6. Insert the knockout bar assembly in the moving platen.

7. ower the mold into position and clamp the A side

(stationary side) making sure the mold is square to the

machine.

8. Position the moving platen, providing clearance between

the platen and the mold, for installation of the knockout

bar assembly into the mold ejector plate.

9. Slowly position the moving platen against the mold,

observing the coupler and pull stud. Proper center

alignment and engagement are critical at this time.

10. Clamp the B side (moving side) of the mold to the platen.

Open the mold to safe ejection position.

11. Check that air supply to the coupler is off. If press ejector

plate and FasTie system are not set at machine zero, set

Machine Ejector Back setting to match Mold Ejector Back

position. Move the press ejector plate forward to connect

the coupler and the pull stud.

12. Tighten nuts to the press ejector plate (if using) after the

FasTie components are coupled. This helps alignment of

the FasTie system.

13. Maximum allowable center-to-center misalignment of

coupler and pull stud is below: (see figure 2)

1" HS ±3.5mm (±0.138")

1-3/8" ±5mm (±0.197")

2" ±6mm (±0.236")

3" ±5mm (±0.197")

14. Follow “Test Installation” procedure on page 6.

* 1” HS FasTie only: For installation using SpeedBar®

Adjustable ength Knockout bars, insert bars at step 5,

taking care to insure all bars are exactly the same length.

Coupler

Unused Coupler in

Open Position

Shop Air

Pull Stud

Moving

Platen

Knockout Bar

Mold

Ejector Plate

Mold

Ejector

Housing

Press

Ejector Plate

Manifold

Accessory

Pneumatic

Fitting

Knockout Bar

(SpeedBar or Fixed Length)

figure 3

2burger & brown engineering tel. 800-764-3518

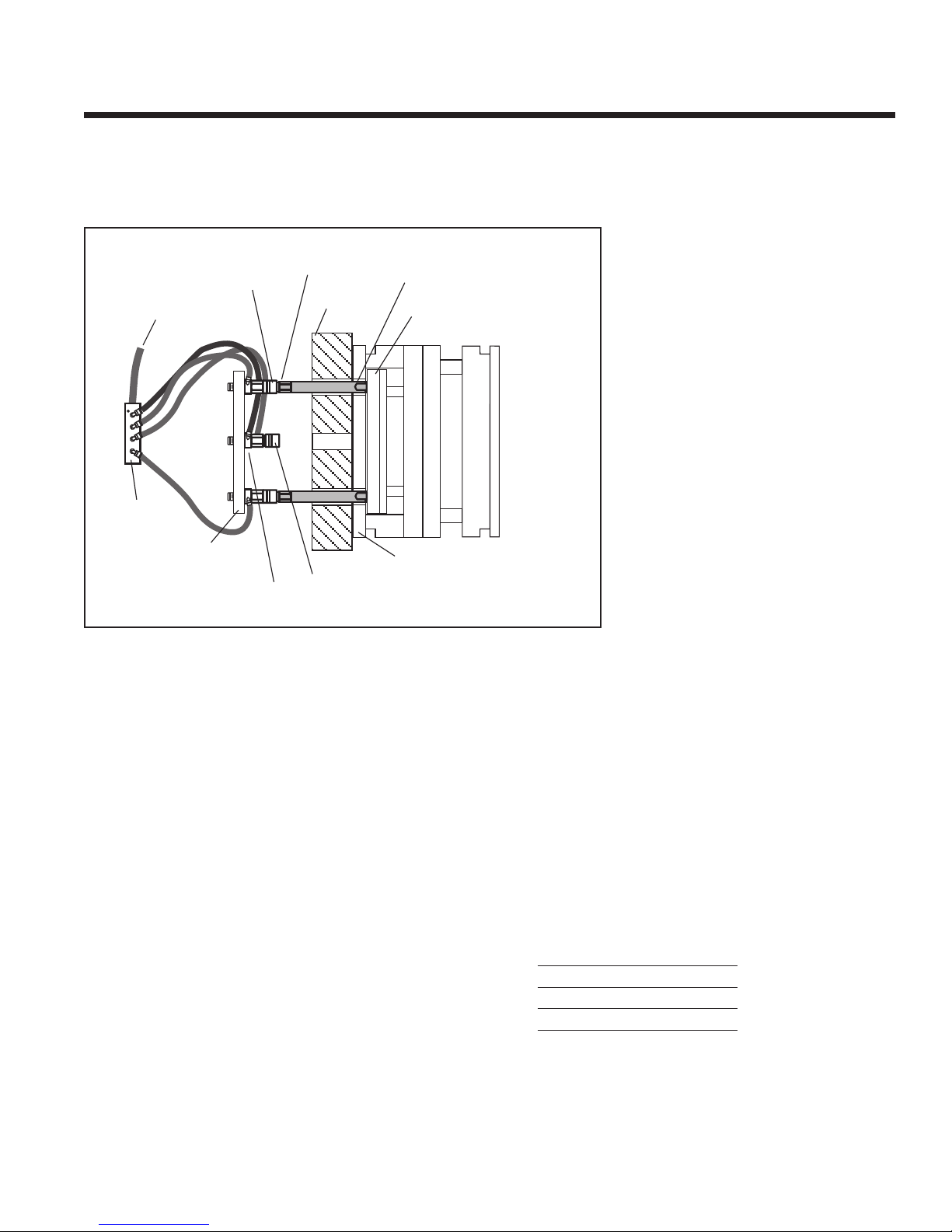

Couplers and Center Adapters on Press Ejector Plate

fo p esses with limited access to the back of the P ess Ejecto Plate.

Custom molde s using smalle p esses will benefit f om this installation.

Shop Air

Coupler

Pull Stud

Moving

Platen

Knockout Bar

(SpeedBar or Fixed Length)

Mold Ejector Housing

Press

Ejector Plate

Manifold

Accessory

Mold Ejector

Plate

Center Adapter

with Pneumatic Fitting

Unused Coupler

in Open Position

figure 4

The following installation instructions are for reference only.

Installation may vary depending on the application and

customer preferences.

1. Install the coupler with the center adapter into the press

ejector plate populating for the required molding machine

patterns (i.e. vertical, horizonal and/or center knockout

positions). Use thread-locking compound to prevent

movement during use.

2. Install pneumatic fitting to the center adapter per figure 4.

3. If using the manifold accessory, mount the manifold and

tubing so they do not interfere with moving parts.

4. Connect shop air lines to the pneumatic fittings that feed

the FasTie couplers. Couplers must be in the open

position (see figure 1) before connection to pull studs,

otherwise coupler damage will occur.

5. Install the pull stud onto the end of the knockout bar.*

6. Insert the knockout bar assembly in the moving platen.

7. ower the mold into position and clamp the A side

(stationary side) making sure the mold is square to the

machine.

8. Position the moving platen, providing clearance between

the platen and the mold, for installation of the knockout

bar assembly into the mold ejector plate.

9. Slowly position the moving platen against the mold,

observing the coupler and pull stud. Proper center

alignment and engagement are critical at this time.

10. Clamp the B side (moving side) of the mold to the platen.

Open the mold to safe ejection position.

11. Check that air supply to the coupler is off. If press ejector

plate and FasTie system are not set at machine zero, set

Machine Ejector Back setting to match Mold Ejector Back

position. Move the press ejector plate forward to connect

the coupler and the pull stud.

12. Tighten nuts to the press ejector plate (if using) after the

FasTie components are coupled. This helps alignment of

the FasTie system.

13. Maximum allowable center-to-center misalignment of

coupler and pull stud is below: (see figure 2)

1" HS ±3.5mm (±0.138")

1-3/8" ±5mm (±0.197")

2" ±6mm (±0.236")

3" ±5mm (±0.197")

14. Follow “Test Installation” procedure on page 6.

* 1” HS FasTie only: For installation using SpeedBar®

Adjustable ength Knockout bars, insert bars at step 5,

taking care to insure all bars are exactly the same length.

burger & brown engineering tel. 800-764-3518 3

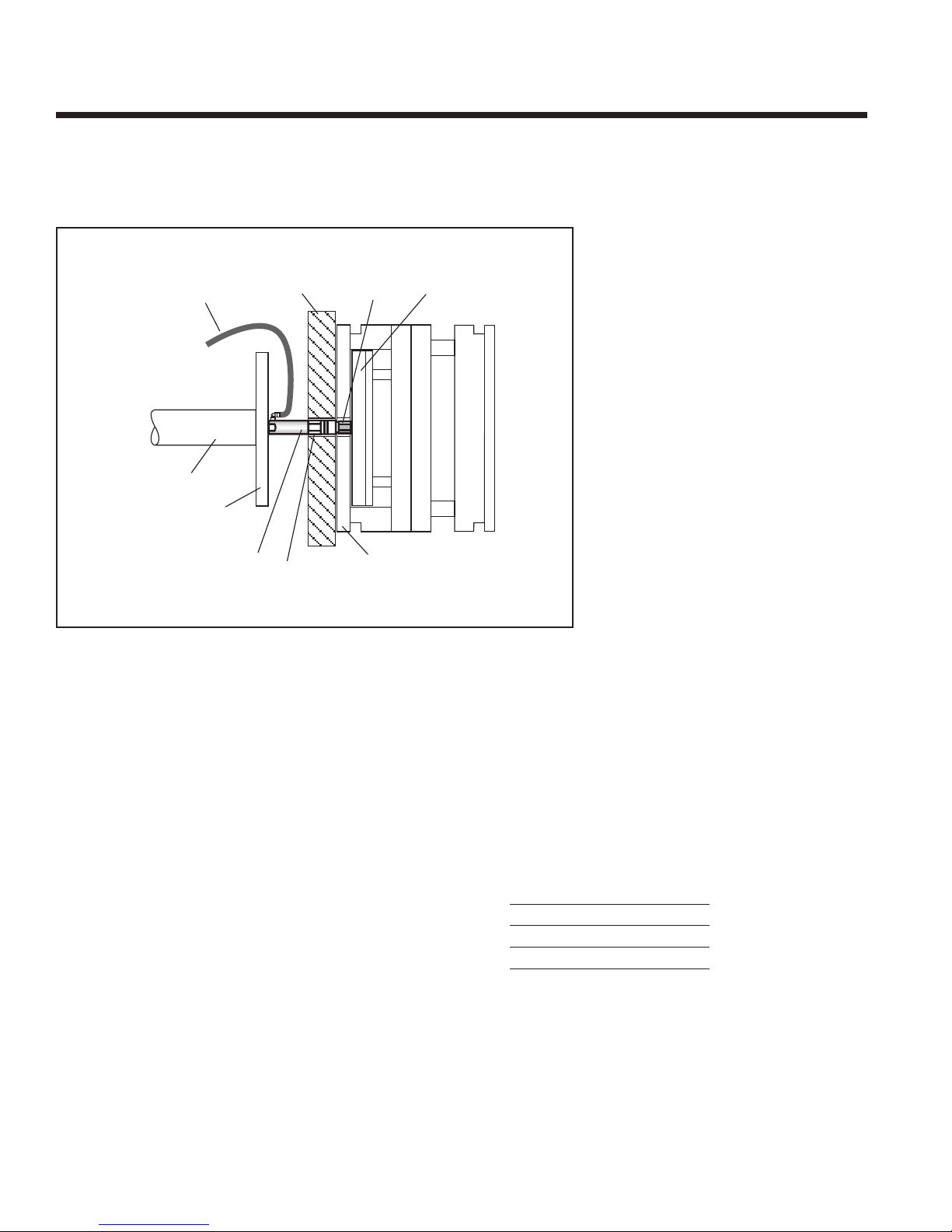

Coupler in Center Ejector Position

fo p esses with a cente ejecto , eplace the cylinde bolt with a

Cente Ejecto Ba o Cente Adapte and FasTie Couple .

The following installation instructions are for reference only.

Installation may vary depending on the application and

customer preferences.

1. Install the pull stud into the mold ejector plate per figure

5. Use thread-locking compound to prevent movement

during use.

2. Remove the Cylinder Bolt (if present) from the press.

3. Install the Center Ejector Bar or Adapter and FasTie

Coupler Assembly through the platen and tighten into the

cylinder.

4. ower the mold into position and clamp the A side

(stationary side) making sure the mold is square to the

machine.

5. Connect shop air lines to the pneumatic fitting for the

coupler. Coupler must be in the open position (see

figure 1) before connection to the pull stud, otherwise

coupler damage will occur.

6. Install the pull stud into the mold ejector plate.

7. Slowly position moving platen against the mold,

observing the coupler and pull stud. Proper center

alignment and engagement are critical at this time.

8. Clamp the B side (moving side) of the mold to the platen.

Open the mold to safe ejection position.

9. Check that air supply to the coupler is off. If press ejector

plate and FasTie system are not set at machine zero, set

Machine Ejector Back setting to match Mold Ejector Back

position. Move the press ejector plate forward to connect

the coupler and the pull stud.

10. Maximum allowable center-to-center misalignment of

coupler and pull stud is below: (see figure 2)

1" HS ±3.5mm (±0.138")

1-3/8" ±5mm (±0.197")

2" ±6mm (±0.236")

3" ±5mm (±0.197")

11. Follow “Test Installation” procedure on page 6.

Shop Air

Moving

Platen Pull

Stud Mold

Ejector Plate

Mold

Ejector

Housing

Coupler

Center Knockout Bar

or Center Adapter

with Pneumatic Fitting

Press

Ejector Plate

Cylinder

figure 5

4burger & brown engineering tel. 800-764-3518

burger & brown engineering tel. 800-764-3518 5

Couplers at the end of Ejector Bars

fo multiple molds in the same machine with the same ejecto

patte n and ejecto st okes

The following installation instructions are for reference only.

Installation may vary depending on the application and

customer preferences.

1. Install the coupler and the knockout bar assembly into the

press ejector plate populating for the required molding

machine patterns (i.e. vertical, horizonal and/or center

knockout positions). Use thread-locking compound to

prevent movement during use.*

2. Install washer, nut and pneumatic fitting per figure 6. Do

not tighten completely at this time.

3. If using the manifold accessory, mount the manifold and

tubing so they do not interfere with moving parts.

4. Connect shop air lines to the pneumatic fittings that feed

the FasTie couplers. Couplers must be in the open

position (see figure 1) before connection to pull studs,

otherwise coupler damage will occur.

5. Install the pull stud into the mold ejector plate.

6. ower the mold into position and clamp the A side

(stationary side) making sure the mold is square to the

machine.

7. Position the moving platen, providing clearance between

the platen and the mold.

8. Slowly position the moving platen against the mold,

observing the coupler and pull stud. Proper center

alignment and engagement are critical at this time.

9. Clamp the B side (moving side) of the mold to the platen.

Open the mold to safe ejection position.

10. Check that air supply to the coupler is off. If press ejector

plate and FasTie system are not set at machine zero, set

Machine Ejector Back setting to match Mold Ejector Back

position. Move the press ejector plate forward to connect

the coupler and the pull stud.

11. Tighten nuts to the press ejector plate after the FasTie

components are coupled. This helps alignment of the

FasTie system.

12. Maximum allowable center-to-center misalignment of

coupler and pull stud is below: (see figure 2)

1" HS ±3.5mm (±0.138")

1-3/8" ±5mm (±0.197")

2" ±6mm (±0.236")

3" ±5mm (±0.197")

13. Follow “Test Installation” procedure on page 6.

* 1” HS FasTie only: For installation using SpeedBar®

Adjustable ength Knockout bars, insert bars at step 1,

taking care to insure all bars are exactly the same length.

Press

Ejector

Plate

Knockout Bar

(SpeedBar or Fixed Length)

Coupler

Pull Stud

Ejector

Housing

Manifold

Accessory

Shop Air

Moving

Platen

Mold Ejector Plate

Nut and

Washer

figure 6

Test Installation

Verify Connection

1. Open the mold.

2. Activate the ejector system.

3. Observe the ejector pins. They should move forward and

return. Visually inspect the FasTie couplers to verify that

they are connected to the pull studs.

Verify Release

1. Apply air to the FasTie couplers.

2. Activate the ejector system.

3. Observe the ejector pins. They should move forward, but

not return.

Reconnect Couplers

1. Ensure that the FasTie couplers are in the open position

and the air pressure is off. See figure 1.

2. Move the ejector system forward

3. Return the ejector system.

4. Observe the ejector pins. They should be retracted

If the system is not connected properly, open the platen,

disconnect the couplers and pull studs, reconnect each ejector

position and re-test the installation.

Troubleshooting

Symptom

Ejector pins don’t move back when retracting ejector system;

FasTie does not connect

Corrective Action

• Confirm shop air is off during connection.

• Check coupler operation.

• Check pull stud and coupler alignment.

• Pneumatic valve or selector switch must allow residual air

pressure to dissipate when valve is “off”. Air pressure

when “off” is zero.

FasTie uncouples during ejector cycle • Check mold position in the machine. Mold must be

squarely installed and the FasTie coupler must not contact

the platen.

FasTie doesn’t uncouple • Check Knockout Bar length.

• Check that the mold is clamped squarely to the machine.

• Air pressure supply to the couplers should be 80 to 100 psi.

Check air lines and fittings for leaks or breaks.

• Ensure that couplers are not under tension when

disconnecting.

• Apply grease to couplers per “Maintenance” on Page 1.

Li ited Warranty

Seller warrants that this product supplied will conform to the description herein stated and that the product will be of standard

quality. This is the sole warranty made by Seller with respect to this product. Seller expressly disclaims any other express or

implied warranties, including, but not limited to, the implied warranty of merchantability and the implied warranty of fitness for

a particular purpose.

Seller shall not be liable for any cost or damages, whether direct, incidental or consequential, including, but not limited to, any

injury, loss or damage resulting from the use of this product, regardless of whether any claim for such cost or damages is based

on warranty, contract, negligence, tort or strict liability. The sole liability of Seller is limited to repairing or replacing this

product.

This warranty shall not apply to any products that have been repaired or altered by anyone other than Seller. The warranty shall

not apply to any products subject to misuse due to common negligence or accident, nor to any products manufactured by Seller

which are not installed or operated in accordance with the printed instructions of Seller or which have been operated beyond the

rated capacity of the goods. Seller states that the product’s useful safe life is 5 years. Actual life may vary widely depending on

operating environment such as temperature, pressure, and chemical exposure.

If corrective action fails to correct the problem,

please contact the factory.

6burger & brown engineering tel. 800-764-3518

Table of contents