Smartgen AIN16-M01 User manual

AIN16-M01

ANALOG INTEGRATED MODULE

USER MANUAL

AIN16-M01 Analog Integrated Module User Manual Page 2 of 13

Registered Trademark

No.28 Xuemei Street, Zhengzhou, Henan, China

Tel: +86-371-67988888/67981888/67992951

+86-371-67981000(overseas)

Fax: +86-371-67992952

Email: sales@smartgen.cn

Web: www.smartgen.com.cn

www.smartgen.cn

All rights reserved. No part of this publication may be reproduced in any material form (including

photocopying or storing in any medium by electronic means or other) without the written permission of

the copyright holder.

SmartGen Technology reserves the right to change the contents of this document without prior notice.

Table 1 - Software Version

Date

Version

Content

2014-10-10

1.0

Original release.

2017-03-17

1.1

Update the manual format.

2022-11-19

1.2

Update the information and logo of SmartGen.

AIN16-M01 Analog Integrated Module User Manual Page 3 of 13

This user manual only suits for AIN16-M01 Analog Integrated Module.

Table 2- Notation Clarification

Symbol

Instruction

NOTE

Highlights an essential element of a procedure to ensure correctness.

CAUTION

Indicates a procedure or practice, which, if not strictly observed, could result in

damage or destruction of equipment.

WARNING

Indicates a procedure or practice, which could result in injury to personnel or loss of

life if not followed correctly.

AIN16-M01 Analog Integrated Module User Manual Page 4 of 13

CONTENTS

1 OVERVIEW................................................................................................................................................. 5

2 PERFORMANCE AND CHARACTERISTICS.............................................................................................. 5

3 TECHNICAL PARAMETERS...................................................................................................................... 5

4 CONNECTION............................................................................................................................................ 6

5 PROTECTION ............................................................................................................................................ 8

5.1 WARNING .......................................................................................................................................... 8

5.2 SHUTDOWN ALARM......................................................................................................................... 9

5.3 PARAMETER CONFIGURATION ....................................................................................................... 9

5.4 PTIN1~PTIN8 AND CIN1 SETTINGS ............................................................................................. 10

5.5 MP1~MP3 SETTINGS..................................................................................................................... 11

5.6 AOUT1~ AOUT4 SETTINGS............................................................................................................ 11

6 ELECTRICAL CONNECTIONS................................................................................................................. 12

7 INSTALLATION ....................................................................................................................................... 12

8 TROUBLE SHOOTING ............................................................................................................................. 13

AIN16-M01 Analog Integrated Module User Manual Page 5 of 13

1OVERVIEW

AIN16-M01 analog integrated module contains 8 PT100 sensor input channels, 3 speed input

channels, 4 4~20mA output channels and one 4~20mA input channel. The data are transmitted to

the HMC9000 controller for processing via CANBUS port, then HMC9000 transfers 4~20mA data

back into AIN16-M01 module via CANBUS port and AIN16-M01 outputs corresponding 4~20mA

signals. Values can be set for each sensor via HMC9000 controller as demands.

2PERFORMANCE AND CHARACTERISTICS

32-bit ARM micro-processor with high integration of hardware and more reliable;

Must be used with HMC9000 together;

CANBUS communication baud rate can be set as 250kbps or 125kbps via dial switch;

Module address can be set as 1 or 2.

Widely power supply range DC(18~35)V, suitable to different starting battery voltage environment;

35mm rail mounting type;

Modular design, pluggable terminal, compact structure with easy installation.

3TECHNICAL PARAMETERS

Table 3- Technical Parameters

Item

Content

Working Voltage

DC18.0V~35.0V continuous power supply

Power Consumption

<0.5W

Case Dimension

161.6mm x 89.7mm x 60.7mm

Rail Dimension

35mm

Working Temp.

(-25~+70)°C

Working Humidity

(20~93)%RH

Storage Temp.

(-25~+70)°C

Weight

0.33kg

AIN16-M01 Analog Integrated Module User Manual Page 6 of 13

4CONNECTION

Fig.1- AIN16-M01 Front Panel

Table 4- Terminal Connection

No.

Function

Cable Size

Description

1

B-

1.0mm2

DC power supply negative input.

2

B+

1.0mm2

DC power supply positive input.

3

SCR

0.5mm2

CANBUS shielded wire, with single end earthed.

4

CAN(H)

A CANBUS port which communicate with

HMC9000 controller.

5

CAN(L)

6

120Ω Terminal Resistor

Short out 5 and 6 terminals if 120Ω terminal

resistor is needed.

7

MP1

-

0.5mm2

Connect with speed sensor(shielded wire is

recommended). Speed sensor input (-), B- has been

connected in the controller.

8

+

9

MP2

-

0.5mm2

10

+

11

MP3

-

0.5mm2

12

+

13

AOUT1

COM1

0.5mm2

4~20mA output common port

14

mAOUTPUT1

4~20mA output port

15

AOUT2

COM2

0.5mm2

4~20mA output common port

16

mAOUTPUT2

4~20mA output port

17

AOUT3

COM3

0.5mm2

4~20mA output common port

18

mAOUTPUT3

4~20mA output port

19

AOUT4

COM4

0.5mm2

4~20mA output common port

20

mAOUTPUT4

Sensor terminal

21

CIN1

COM(B+)

0.5mm2

4~20mA analog input.

B+ input (supply power for pressure transmitter)

22

mA

AIN16-M01 Analog Integrated Module User Manual Page 7 of 13

No.

Function

Cable Size

Description

23

PTIN1

C

0.5mm2

PT100 sensors are three-wire system terminals,

and C terminal stands for common port.

A and B terminals are amphenol connectors.

24

B

25

A

26

PTIN2

C

0.5mm2

27

B

28

A

29

PTIN3

C

0.5mm2

30

B

31

A

32

PTIN4

C

0.5mm2

33

B

34

A

35

PTIN5

C

0.5mm2

36

B

37

A

38

PTIN6

C

0.5mm2

39

B

40

A

41

PTIN7

C

0.5mm2

42

B

43

A

44

PTIN8

C

0.5mm2

45

B

46

A

47

SWITCH

HMC9000 can connect to two AIN16-M01 modules at the same

time.

Address selection :It is module 1 when the switch 1 is

connected to terminal 12 while module 2 when connect to ON

terminal.

Baud rate selection: It is 250kbps when the switch 2 is

connected to terminal 12 while 125kbps when connect to ON

terminal.

POWER

Power supply indicator and communication status indicator; It is

flashing when the communication is abnormal.

AIN16-M01 Analog Integrated Module User Manual Page 8 of 13

5PROTECTION

All data can be protected via HMC9000 controller. HMC9000 can connect to two AIN16-M01 modules

at the same time and users can select module address via dial switch. Following parameters can be

set via HMC9000:

1) AIN16-M01 module enable: HMC9000 can communicate with the module and collect the data;

2) Each of sensor’s alarm threshold and alarm are enabled;

AIN16-M01 can collect data only and all alarms are initiated by HMC9000 controller. HMC9000 will

initiate alarm when the sensor value is abnormal. There are two kinds of alarm: warning alarm and

shutdown alarm. All alarms are handled by HMC9000 controller only.

5.1 WARNING

Table 5 - Warning Types

No.

Items

Range

Description

1

PTIN1~ PTIN8

High

From “Waiting for load”

delay to “Cooling” delay

When the controller detects the sensor warning

signals, it will initiate a warning alarm and the

corresponding alarm information will be displayed

on HMC9000 LCD.

2

MP1~MP3

High

Always active.

3

CIN1 High

From “Waiting for load”

delay to “Cooling” delay

4

PTIN1~ PTIN8

Low

From “Waiting for load”

delay to “Cooling” delay

5

CIN1 Low

From “Waiting for load”

delay to “Cooling” delay

6

PTIN1~ PTIN8

Open Circuit

Always active.

7

CIN1 Open

Circuit

Always active.

AIN16-M01 Analog Integrated Module User Manual Page 9 of 13

5.2 SHUTDOWN ALARM

Table 6 - Shutdown Types

No.

Items

DET Range

Description

1

PTIN1~ PTIN8

High

From “Waiting for load”

delay to “Cooling” delay

When the controller detects the sensor shutdown

alarms, it will initiate a shutdown alarm and the

corresponding alarm information will be displayed

on HMC9000 LCD.

2

MP1~MP3

High

Always active

3

CIN1 High

From “Waiting for load”

delay to “Cooling” delay

4

PTIN1~ PTIN8

Low

From “Waiting for load”

delay to “Cooling” delay

5

CIN1 Low

From “Waiting for load”

delay to “Cooling” delay

5.3 PARAMETER CONFIGURATION

AIN16-M-01 parameters can be set via HMC9000 controller or HMC9000 PC software; more

details please refer to specific instruction of HMC9000.

Table 7 - Parameter Configuration List

Parameter

Contents

Default

Module Enable

0:Enable

1:Disable

Disable

PTIN1~ PTIN8 and

CIN1 Set

Sensor types/ Alarm Speed /Range/ High Shutdown

Enable / High Shutdown Value / High Shutdown

Delay / Low Shutdown Enable / Low Shutdown Value

/ Low Shutdown Delay / High Warn Enable / High

Warn Value / High Return Value / High Warn Delay/

Low Warn Enable / Low Warn Value / Low Return

Value / Low Warn Delay

For more details please refer to the following chapter

MP1~MP3 Set

Sensor Enable/Teeth Number Set/ High Shutdown

Enable / High Shutdown Value / High Shutdown

Delay/ High Warn Enable / High Warn Value / High

Return Value / High Warn Delay

4~20mA Output Set

Output can be configured as relevant to the sensor

AIN16-M01 Analog Integrated Module User Manual Page 10 of 13

5.4 PTIN1~PTIN8 AND CIN1 SETTINGS

Table 8 –PTIN1~ PTIN8 and CIN1 Settings

No.

Items

Contents

Remarks

1

Sensor types

0:Not Used

1:Oil Pressure Sensor

2:Temperature Sensor

2

Sensor Curve

0:PT100

1:4~20mA

3

Alarm Speed

(0-200)%

4

Range (current type)

(0-6000)kpa

5

High Shutdown Enable

0:Enable

1:Disable

6

High Shutdown Value

(0-6000)

7

High Shutdown Delay

(0-3600)s

8

Low Shutdown Enable

0:Enable

1:Disable

9

Low Shutdown Value

(0-6000)

10

Low Shutdown Delay

(0-3600)s

11

High Warn Enable

0:Enable

1:Disable

12

High Warn Value

(0-6000)

13

High Return Value

(0-6000)

14

High Warn Delay

(0-3600)s

15

Low Warn Enable

0:Enable

1:Disable

16

Low Warn Value

(0-6000)

17

Low Return Value

(0-6000)

18

Low Warn Delay

(0-3600)s

19

User-defined string

User can reset the sensors’ names which are displayed on

HMC9000 LCD. e.g. rename sensor 1 as Temperature Exhaust

sensor. User-defined string can be edited via HMC9000 PC

software only.

AIN16-M01 Analog Integrated Module User Manual Page 11 of 13

5.5 MP1~MP3 SETTINGS

Table 9 –MP1~MP3 Settings

No.

Items

Contents

Remarks

1.

Sensor Enable

0:Disable

1:Enable

2.

Teeth Number

(1-300)

3.

High Shutdown Enable

0:Enable

1:Disable

4.

High Shutdown Value

(0-6000)

5.

High Shutdown Delay

(0-3600)s

6.

High Warn Enable

0:Enable

1:Disable

7.

High Warn Value

(0-6000)

8.

High Warn Delay

(0-3600)s

5.6 AOUT1~ AOUT4 SETTINGS

Table 10 –AOUT1~AOUT4 Settings

No.

Items

Description

Remark

0

HMC9000 Speed

After analog output

selected

corresponding sensor,

HMC9000 transfers

data to related

4~20mA output port of

the AIN16-M01 module

via CANBU.

1~8

HMC9000 Sensor1~ Sensor 8

9~11

AIN16-C Module1 Speed 1~3

12~27

AIN16-C Module1 Sensor 1~16

28~30

AIN16-C Module2 Speed 1~3

31~46

AIN16-C Module2 Sensor 1~16

47~62

AIN16-PT Module1 Sensor 1~16

63~78

AIN16-PT Module2 Sensor 1~16

79~81

AIN16-M01 Module1 Speed 1~3

82~89

AIN16-M01 Module1 PT00 Sensor 1~8

90

AIN16-M01 Module1, 4~20mA Sensor 1

91~93

AIN16-M01 Module2 Speed 1~3

94~101

AIN16-M01 Module2 PT00 Sensor 1~8

102

AIN16-M01 Module2, 4~20mA Sensor 1

102~149

Reserved

AIN16-M01 Analog Integrated Module User Manual Page 12 of 13

6ELECTRICAL CONNECTIONS

Fig.2- AIN16-M01 Electrical Connection Diagram

Fig.3- HMC9000 with two AIN16-M01 modules connection diagram

7INSTALLATION

Fig.4- Overall Dimensions

AIN16-M01 Analog Integrated Module User Manual Page 13 of 13

8

TROUBLE SHOOTING

Table 11 –Trouble Shooting

Problem

Possible Solution

Controller no response with power.

Check batteries;

Check controller connection wirings;

Check DC fuse.

CANBUS communication failure

Check if CANBUS wires are connected in the opposite way.

Table of contents

Other Smartgen Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

BlastPro

BlastPro BP-505 Machine manual

Daikin

Daikin EWWD 340 Installation, operation and maintenance manual

CIMLINE

CIMLINE ME3 Owner's and operator's manual

IPG Photonics

IPG Photonics LC 340.01-A.3.5/6 operating manual

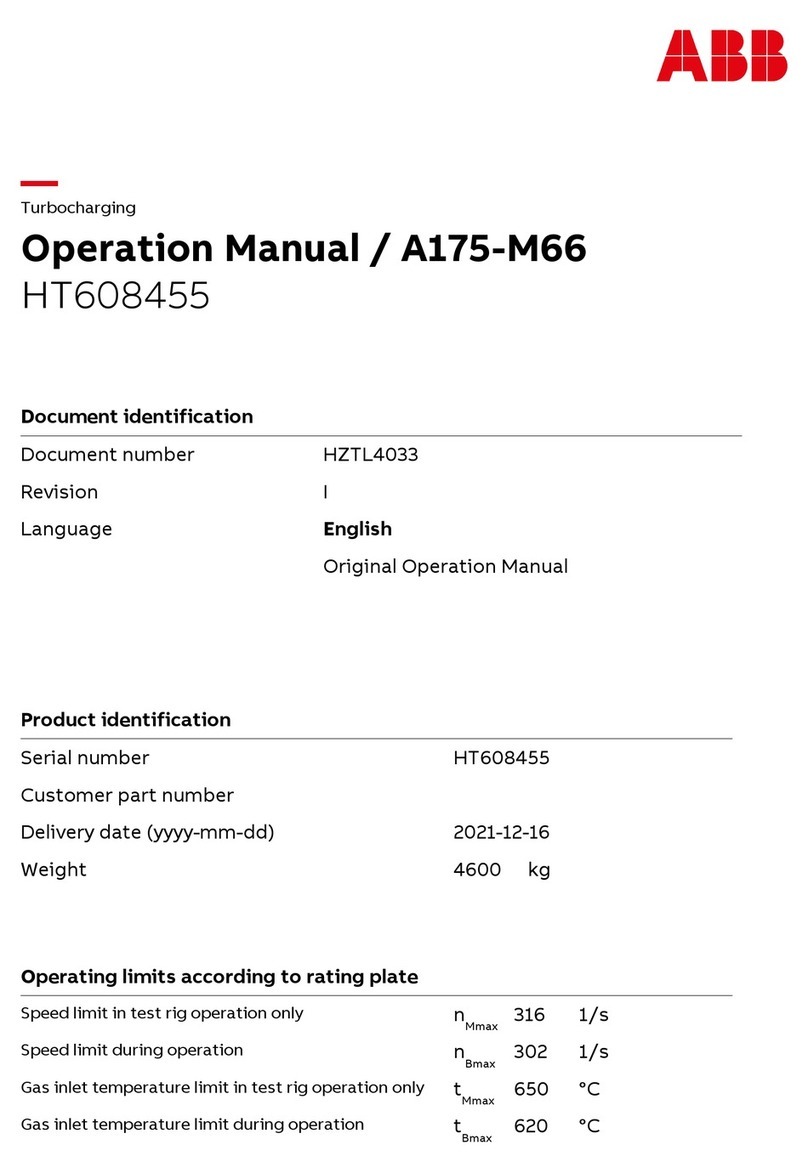

ABB

ABB HT608455 Operation manual

Emerson

Emerson CAD 581 Series RE-ASSEMBLY INSTRUCTIONS