10

The gearcase is not vented. The Relialube system

requires no relocation or installation of breather

vents for any approved mounting position, although

the oil fill quantity must be changed for mounting

positions other than the factory-standard K1/L1/S1

and grease fittings are required on output shaft up

and down versions. Reducers should be ordered for

the specific mounting position desired.

MAINTENANCE

The MASTER ComboGear reducer requires

little maintenance, but an occasional inspection to

check for hardware security, mounting integrity,

leakage and general overall condition is good

standard practice.

Seals are normal wear items and may require

periodic replacement.

LUBRICATION – GENERAL

The standard lubricant is Mobil SHC 634, which is

suitable for –10°F to +100°F ambient.

For low temperature operation, Mobil SHC 629 is

suitable for –30°F to +60°F ambient.

For those food processing installations requiring

USDA Class AA and H1 approvals, use Chevron

FM460X which is suitable for use from +15°F to

110°F.

Stock units are factory filled with Mobil SHC 634 for

the K1/L1/S1 mounting position unless specified at order.

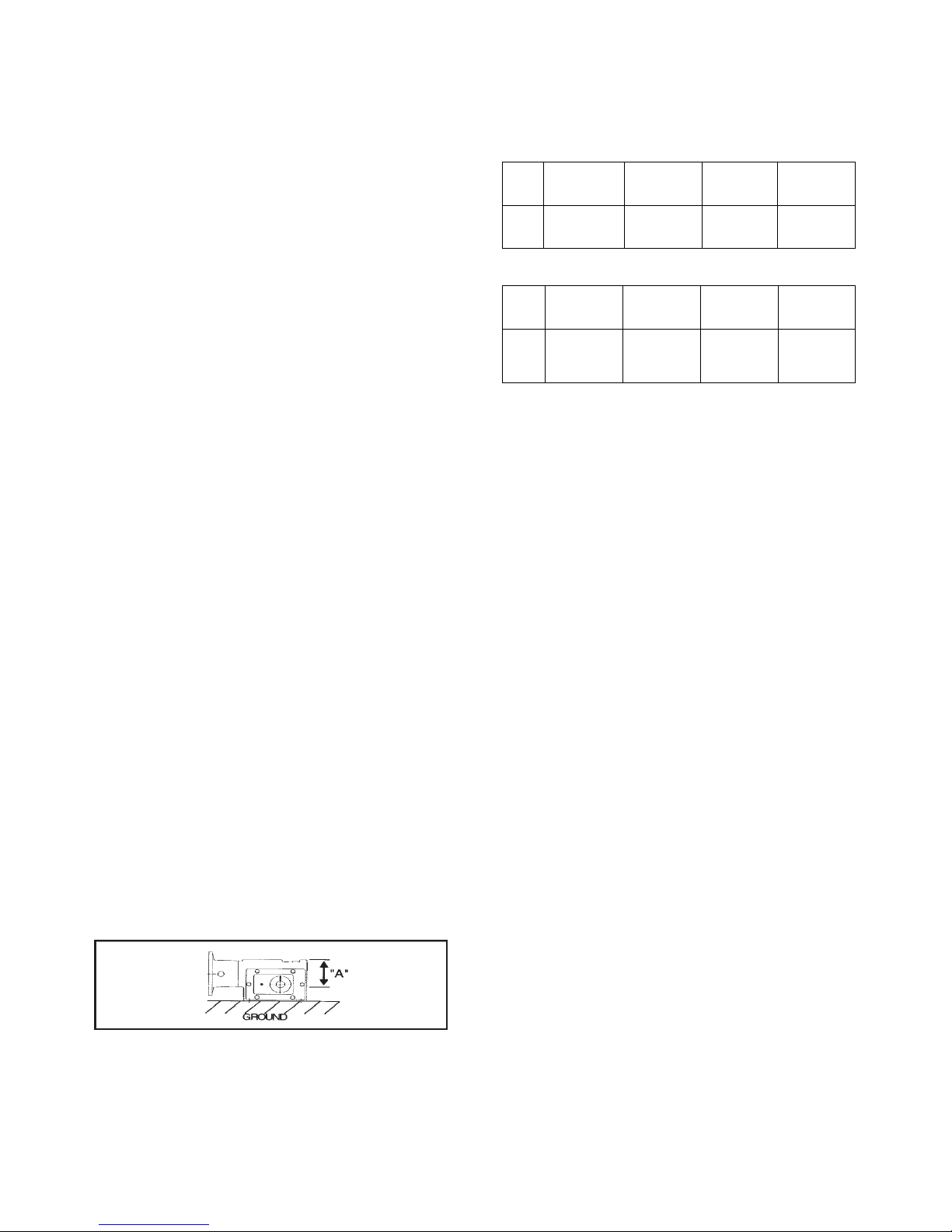

LUBRICATION – OIL FILL LEVELS

To change from one mounting position to another,

you MUST correct the oil quantity so the total oil in

the gearcase is as listed below. Failure to follow

these instructions will void warrantee. Oil is added to

the prescribed level with the gearcase sitting in the

K1/L1/S1 position, before the reducer is mounted in

the desired position.

NOTE: Vertical output shaft (up or down)

conversions require a new upper bearing housing

equipped with grease fittings. Consult Renewal

Parts.

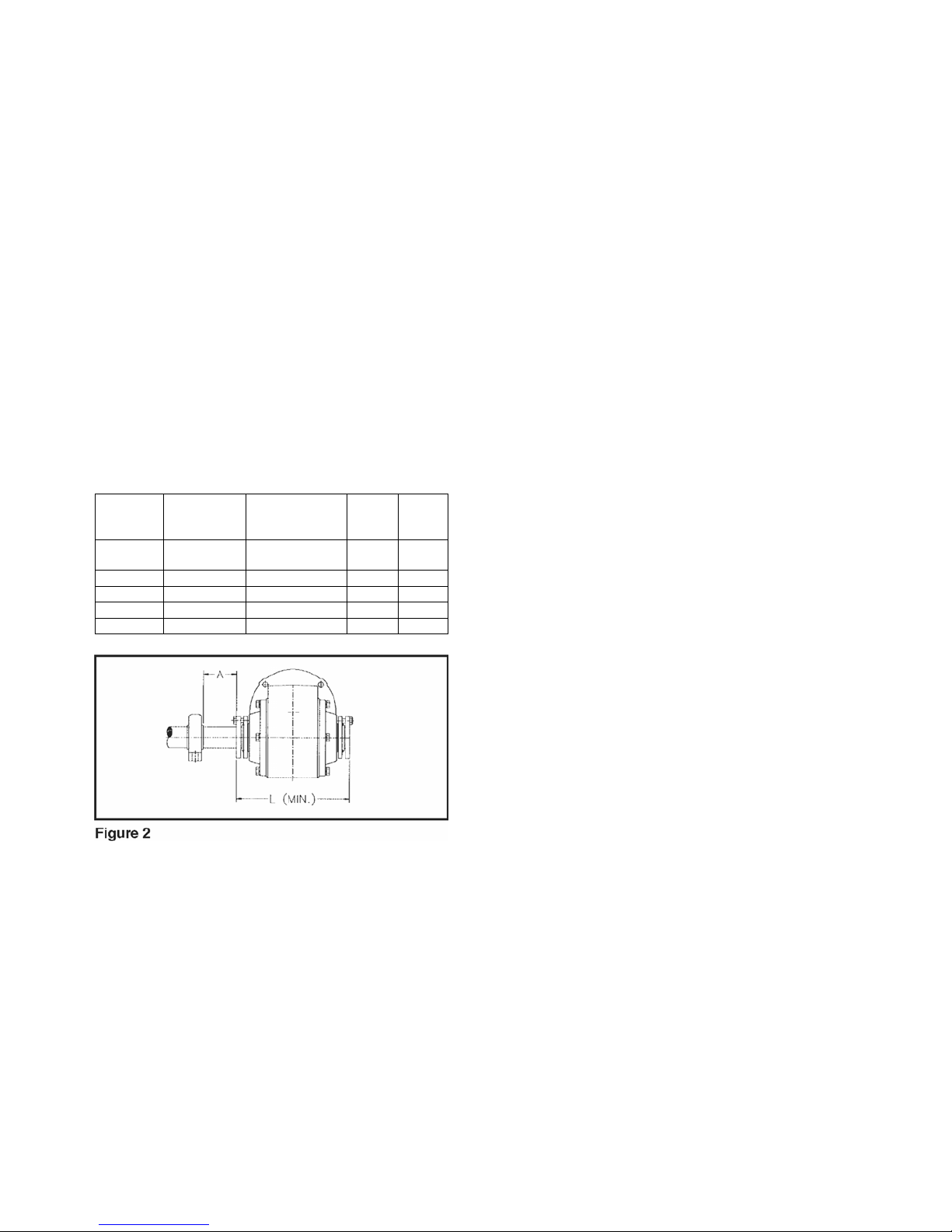

Dimension “A” is measured with a dipstick inserted

into the tapped fill hole from the machined top of the

gearcase to the oil level with the gearbox set level

on the ground.

Approximate oil volumes (fluid ounces) by case size

and assembly. Divide ounce quantities by 16 for

volumes in pints.

HOLLOW (TAPERED OR STRAIGHT BORE) OUTPUT SHAFT

Assm. S1 Dist. S2 S4 S5

H4 “A” H1 “A” H3 “A” H5 “A”

B2 (in.) B3 (in.) B1 (in.) B5 (in.)

Size

C150 24 oz. 2¾” 27 oz. 2¼" 27 oz. 2¼" 43 oz. 1½"

1

C200 40 oz. 3¾" 44 oz. 3¼" 44 oz. 3¼" 60 oz. 2 /8"

C262 64 oz. 5¾" 112 oz. 2¾" 112 oz. 2¾" 112 oz. 2¾"

C350 168 oz. 6" 235 oz. 4" 235 oz. 4" 256 oz. 3

3/ "

8

SOLID OUTPUT SHAFT

Assm. L1 L4 K4 L5

K1 Dist K2 L2 K5

B2 “A” B1 “A” B3 “A” B5 “A”

H4 (in.) H1 (in.) H3 (in.) H5 (in.)

Size

C150 27 oz. 2¾" 32 oz. 1¾" 52 oz. 3/4" 48 oz. 3/4"

C200 40 oz. 3¾" 44 oz. 3" 68 oz. 1½" 68 oz. 1½"

C262 83 oz. 5¼" 96 oz. 33/8” 128 oz. 1¾" 128 oz. 1¾"

C350 168 oz. 6" 235 oz. 4½" 312 oz. 1½" 256 oz. 4"

LUBRICATION – VERTICAL

OUTPUT SHAFT MOUNTINGS

Vertical output shaft assemblies such as

K2/L2/K4/L4/S2/ S4 require periodic lubrication of

the reducer bearings that are out of the oil splash.

These units are equipped with grease fittings on the

upper intermediate and output shaft bearings.

Lubrication frequency is 2 pumps from a hand

grease gun every 6 months or 2000 hours operation.

Do not overgrease. The recommended lubricant is

Shell Alvania #2.

NOTE: Units shipped from the factory for vertical

output shaft mounting positions have grease fittings

wired to plugs in the bearing housings. This prevents

oil leakage through the fittings. Plugs must be

replaced with grease fittings before use.

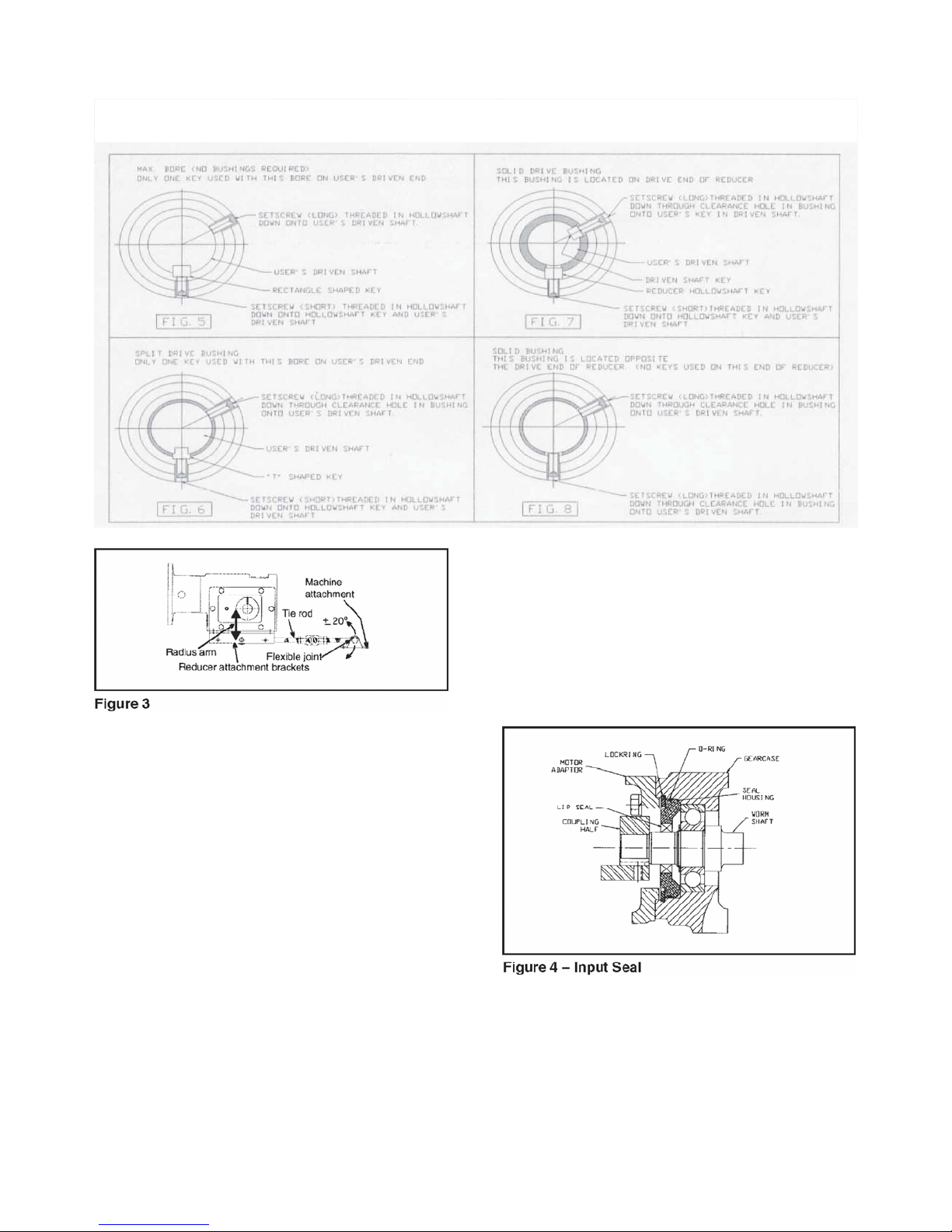

INPUT SEAL REPLACEMENT

The input seal on the all-position RELIALUBE

design is considered a normal wear item with a finite

life. If necessary, the input seal is easily replaced.

Refer to assembly drawings.

1. Stop and lock out the motor.

2. Remove four bolts attaching the motor to the motor

adapter. Remove the motor. The motor coupling half

will come off with the motor.

3. Remove four bolts attaching the motor adapter to

the reducer gearcase. Remove adapter. Do not

remove the reducer-side input coupling half yet.

Remove the large retaining ring from the bore of the

input of the reducer gearcase.

4. Use two prybars, spaced 180º, behind the input

coupling against the gearcase face and gently pry the

input shaft out of the gearcase. The input seal housing

will come out with it. It is not normally necessary to

completely remove the input shaft from the gearcase.