Operating Manual BKS601C

2

Table of Contents

1Safety Instructions ....................................................................................4

1.1 Description Conditions 4

1.2 List of Safety Instructions 4

2Definitions..................................................................................................5

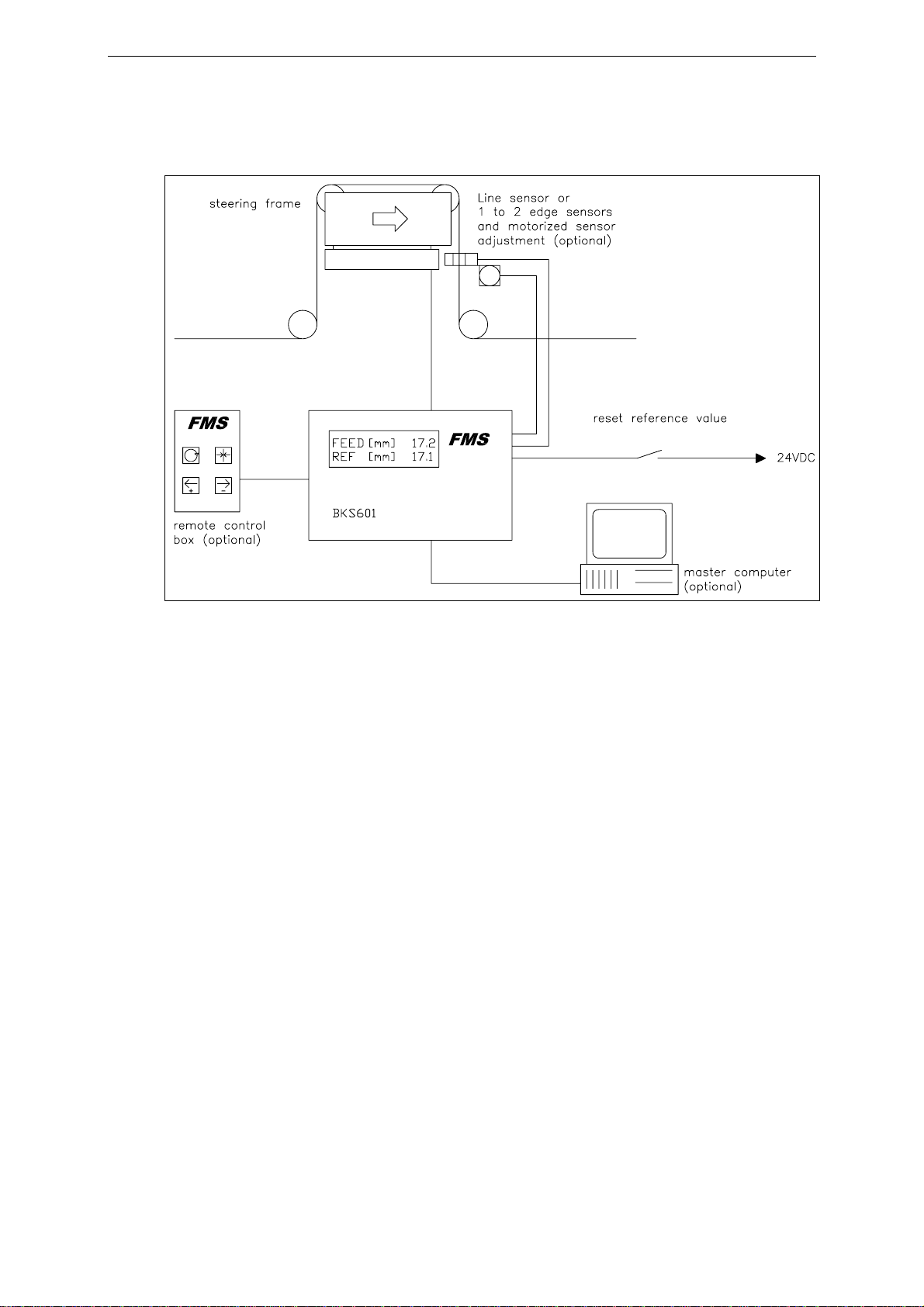

3System Components..................................................................................6

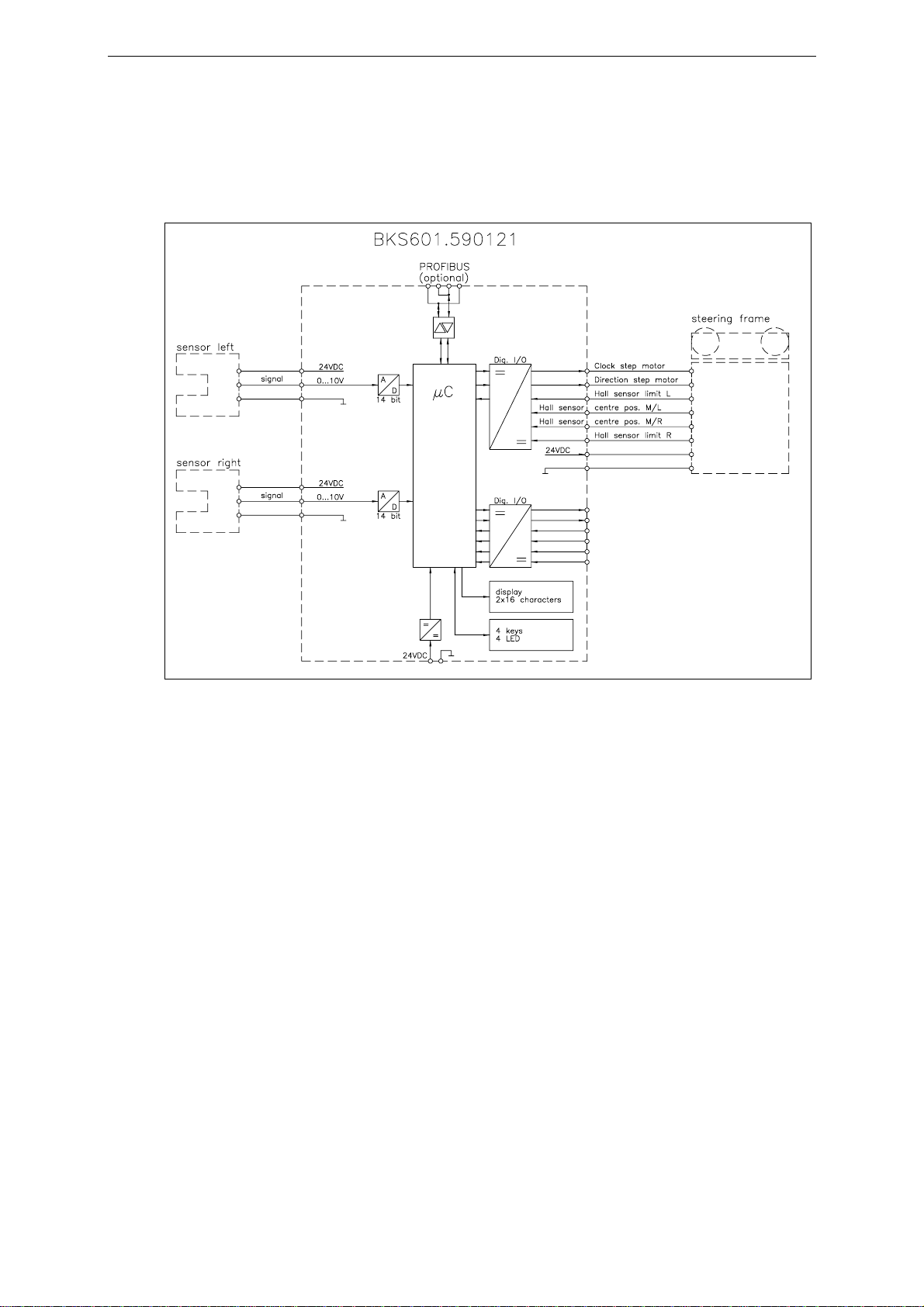

4System Description....................................................................................7

4.1 Functional Description 7

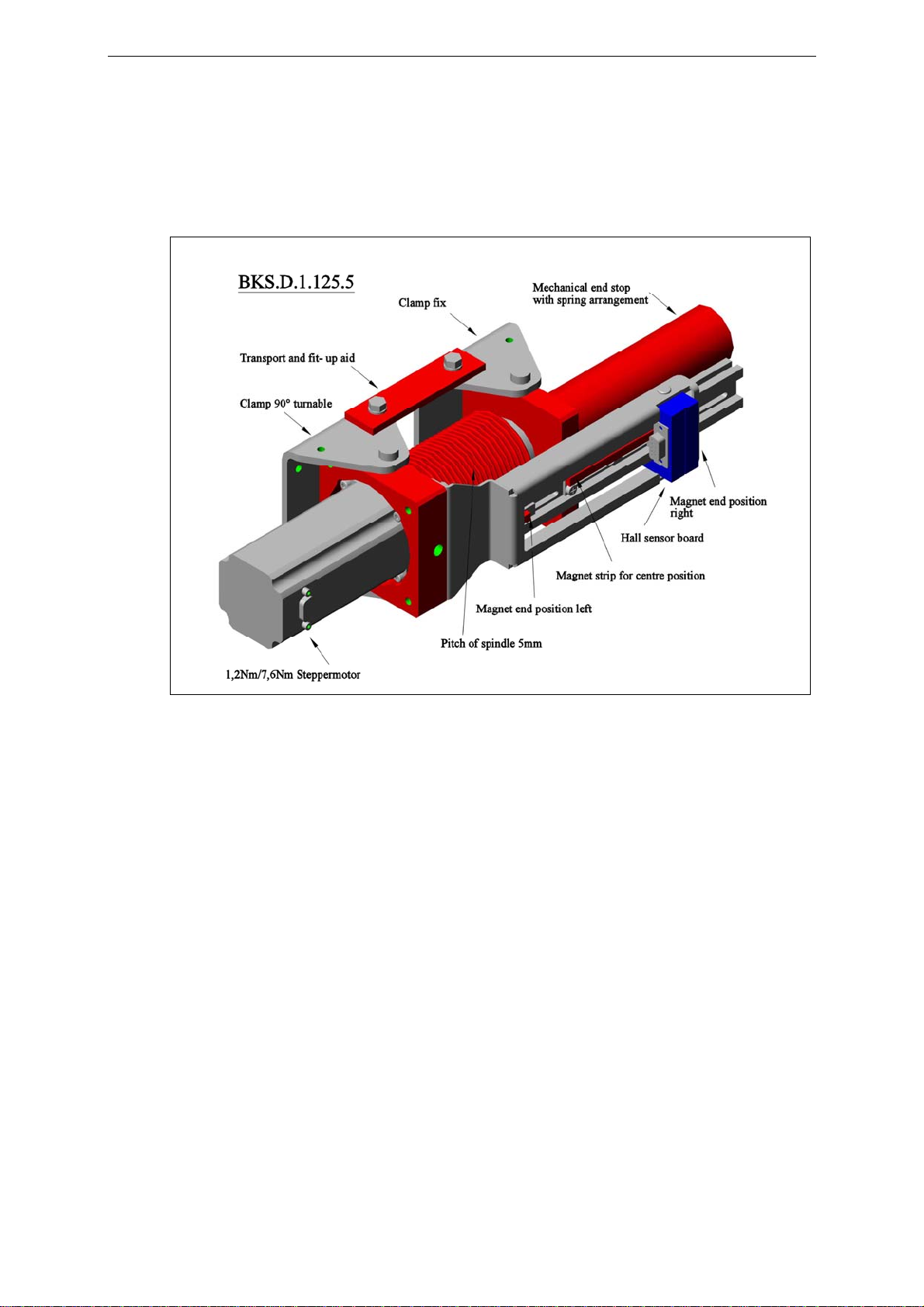

4.2 Steering Device 8

4.3 Electronic Control Unit 8

4.4 Sensors 9

4.5 Manual Sensor Adjustment 9

4.6 Linear Units 9

4.7 Remote Control Box 10

5Quick Installation Guide........................................................................10

6Dimensions...............................................................................................11

7Installation and Wiring ..........................................................................13

7.1 Mounting the Electronic Unit 13

7.2 Mounting BKS601C Wall Mounting Configuration 15

7.3 Wiring Diagrams 16

7.4 Mounting the Steering Device 19

7.5 Mounting of Manual Sensor Adjustment 19

7.6 Mounting of the Linear Units 20

7.7 Mounting of the Sensors 21

8Operation .................................................................................................22

8.1 View of the Operating Panel 22

8.2 Configuring the Electronic Unit 23

8.3 Main Operating Menu and Special Functions 24

8.4 Manual Operation 25

8.5 Operation without Linear Units 26

8.6 Operation with Linear Units 27

8.7 Measuring from a Reference Point on the Machine Frame 29

9ParametriSation ......................................................................................30

9.1 Flow Chart ParametriSation 30

9.2 List of the System Parameters 31

9.3 List of the Parameters BKS601C 31

9.4 Description of the System Parameters 32

9.5 Description of the Parameters BKS601C 33

9.6 Flow Chart Service Mode 37

9.7 List of the system service parameters BKS601C 38

9.8 List of the service parameters BKS601C 38

9.9 Description of System Service Parameters BKS601C 39

9.10 Description of the Service Parameters BKS601C 39

10 PROFIBUS Interface Description.........................................................43

10.1 Wiring the PROFIBUS Data Cable 43

10.2 Setting the PROFIBUS Address 44

10.3 GSD File 44

10.4 BKS601C.P DP Slave Functional Description 44