Smartgen HGM9530 User manual

HGM9530

Genset Parallel (With Genset) Unit

USER MANUAL

SMARTGEN (ZHENGZHOU) TECHNOLOGY CO.,LTD.

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 6 of 65

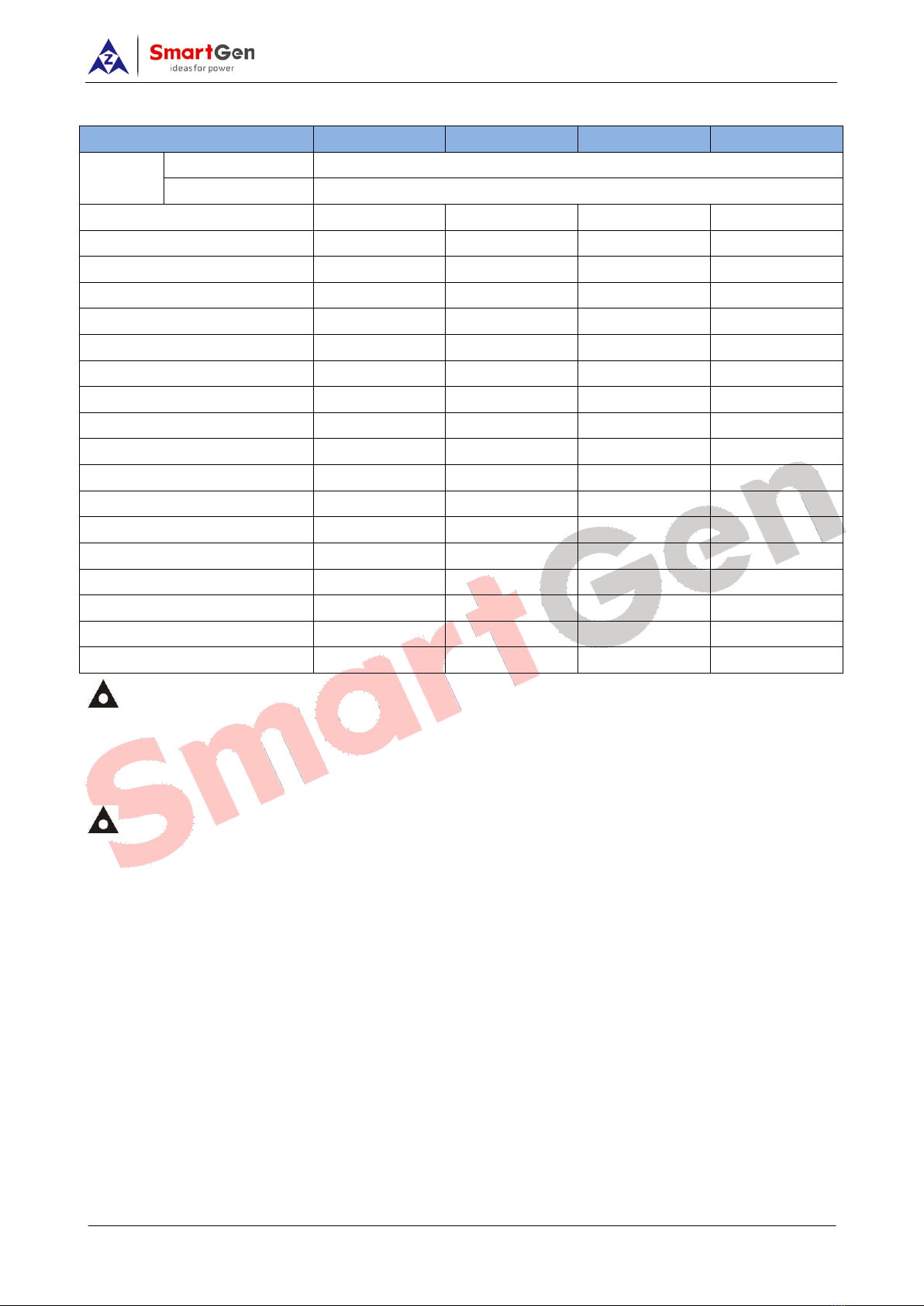

2 MODULES COMPARISON

Item HGM9510 HGM9520 HGM9530 HGM9540

LCD Dimension 4.3”

Pixel 480 x 272

AMF ●●

BUS Monitoring ●●

Parallel connection ●●●●

Digital input expansion ●●●●

Digital output expansion ●●●●

Analog input expansion ●●

Input Port 7 8 7 8

Output Port 8 8 8 8

Sensor Number 5 5 5 5

Neutral (Earth) current

Schedule function

●●●●

RS485 ●●●●

GSM

J1939 ●●●●

USB ●●●●

LINK

Real-time clock ●●●●

Event log ●●●●

NOTE:

(1) Two of the outputs are fixed: start output and fuel output.

(2)HGM9530’s analog sensors are composed by 3 fixed sensors (temperature, pressure, level) and 2

configurable sensors.

NOTE: The features of HGM9210/HGM9220/HGM9310/HGM9320/HGM9410/

HGM9420/HGM9520/HGM9610/HGM9620 controllers mentioned in this document may change, please

check the corresponding user manual for accurate information.

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 10 of 65

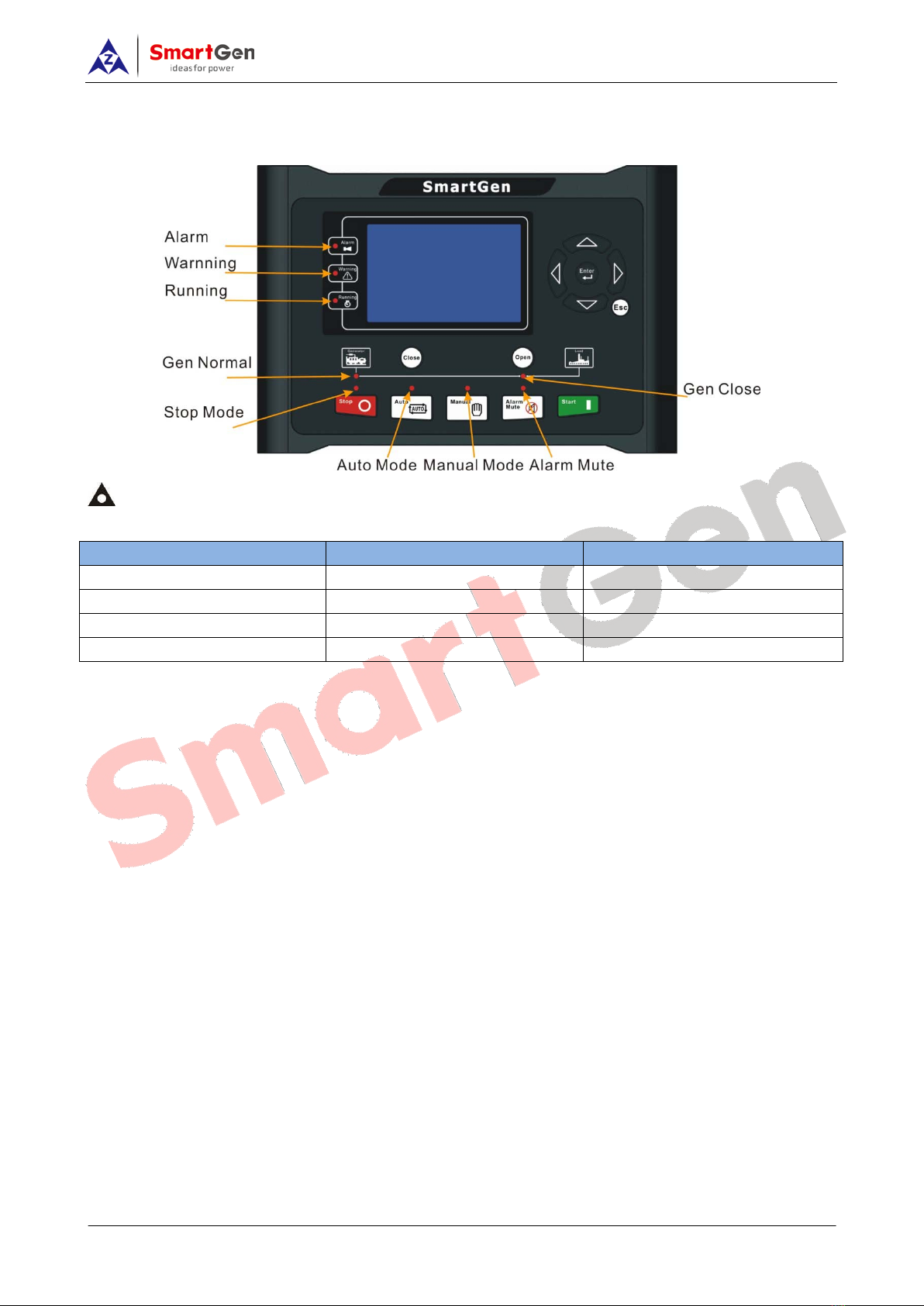

5 OPERATION

5.1 INDICATOR LIGHT

NOTE: Selected light indicators description:

Warning indicator and Alarm indicator:

Alarm Type Warning Indicator Alarm Indicator

Warning Slow flashing Slow flashing

Trip Alarm Slow flashing Slow flashing

Shutdown Alarm Off Fast flashing

Trip and Stop Alarm Off Fast flashing

Running indicator: illuminated from crank disconnect to ETS while off during other periods.

Genenerator normal light:It is light on when generator is normal; flashing when generator state is

abnormal; off when there is no generator power.

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 11 of 65

5.2 PUSHBUTTONS

Icons Keys Description

Stop

Stop running generator in Auto/Manual mode; Lamp test (press

at least 3 seconds); Reset alarm in stop mode; During stopping

process, press this button again to stop generator immediately.

Start Start genset in Manual mode.

Manual Mode Press this key and controller enters in Manual mode.

Auto Mode Press this key and controller enters in Auto mode.

Mute/Reset Alarm Alarming sound off; If trip alarm occurs, pressing the button at

least 3 seconds can reset this alarm.

Close Close breaker in manual mode.

Open Open breaker in manual mode.

Up/Increase 1) Screen scroll;

2) Up cursor and increase value in setting menu.

Down/Decrease 1) Screen scroll;

2) Down cursor and decrease value in setting menu.

Left 1) Screen scroll;

2) Left move cursor in setting menu.

Right 1) Screen scroll;

2) Right move cursor in setting menu.

Set/Confirm Select viewing area.

Exit 1)Return to main menu;

2) Return to previous menu in setting menu.

NOTE: Press and simultaneously in manual mode will force generator to crank.

Successful start will not be judged according to crank disconnect conditions, operator will have to crank

the starter motor manually; when operator decides that the engine has fired, he/she should release the

button and start output will be deactivated, safety on delay will be initiated.

WARNING: Default password is 00318, user can change it in case of others change the advanced

parameters setting. Please clearly remember the password after changing. If you forget it, please

contact SmartGen services and send all information in the controller page of “ABOUT” to us.

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 12 of 65

5.3 LCD DISPLAY

5.3.1 MAIN DISPLAY

Main screen show pages; use to scroll the pages and to scroll the screen.

Main Screen, including as below,

Gen: voltage, frequency, current, active power, reactive power

Bus: voltage, frequency

Engine: speed, temperature, oil pressure

Some status

Status, including as below,

Status of genset and ATS

Engine, including as below,

Engine speed, engine temperature, engine oil pressure, fuel level, flexible sensor 1, flexible sensor 2,

battery voltage, charger voltage, engine accumulated run, accumulated start times.

NOTE: If connected with J1939 engine via CANBUS port, this page also includes: coolant pressure,

coolant level, fuel temperature, fuel pressure, inlet temperature, exhaust temperature, turbo pressure,

total fuel consumption and so on. (Different engine with different parameters)

Generator, including as below,

Phase voltage, line voltage, frequency, phase sequence, current, Active Power(positive and negative),

total active power (positive and negative), Reactive Power(positive and negative), total reactive power

(positive and negative), Apparent Power, total apparent power, Power Factor(positive and negative),

average power factor (positive and negative), accumulated energy (kWh, kVarh, kVAh), multi power,

earth current, negative sequence current.

NOTE: Power factor shows as following,

Remark:

P stands for active power

Q stands for inactive power

Power

factor Conditions Active

power Reactive power

Remark

COS>0L P>0,Q>0 Input Input Load is inductive resistance.

COS>0C P>0,Q<0 Input Output Load is capacitance resistance.

COS<0L P<0,Q>0 Output Input Load is equal to one under excitation generator.

COS<0C P<0,Q<0 Output Output Load is equal to one over excitation generator.

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 51 of 65

12 TYPICAL APPLICATION

HGM9530 typical application diagram

Note: Fuse F1:min. 2A; max. 20A. Fuse F2:max. 32A. Users should select suitable fuse

depend on practical application. 3 Phase 3 Wire

2 Phase 3 Wire

Single Phase 2 Wire

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 52 of 65

HGM9530 Multi-genset Parallel Application

HGM9530 Single-genset Parallel Application

Note: Mains parallel function for HGM9530 controller can be selected via configurable input port.

In mains parallel mode, generator will run in parallel with mains and it will only be able to output a

fixed amount of power. (Set load mode as Gen control mode).

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 53 of 65

HGM9530 Expansion Module Connection Diagram

Note: HGM9530 can be connected with multiple expansion modules via ECU CANBUS port and it

can expand 4 expansion modules most: 1 DOUT16 module, 1 DIN16 module, 2 AIN24 modules.

DOUT16 is digital output module concluding 16# auxiliary relay output.

DIN16 is digital input module concluding 16# auxiliary digital input.

AIN24 is analog input module concluding 14# K-type thermocouple input, 5# PT100 resistance input and

5# 4-20mA current input.

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 54 of 65

13 POWER MANAGEMENT MODE

Power management mode can be selected via configurable input ports.

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 55 of 65

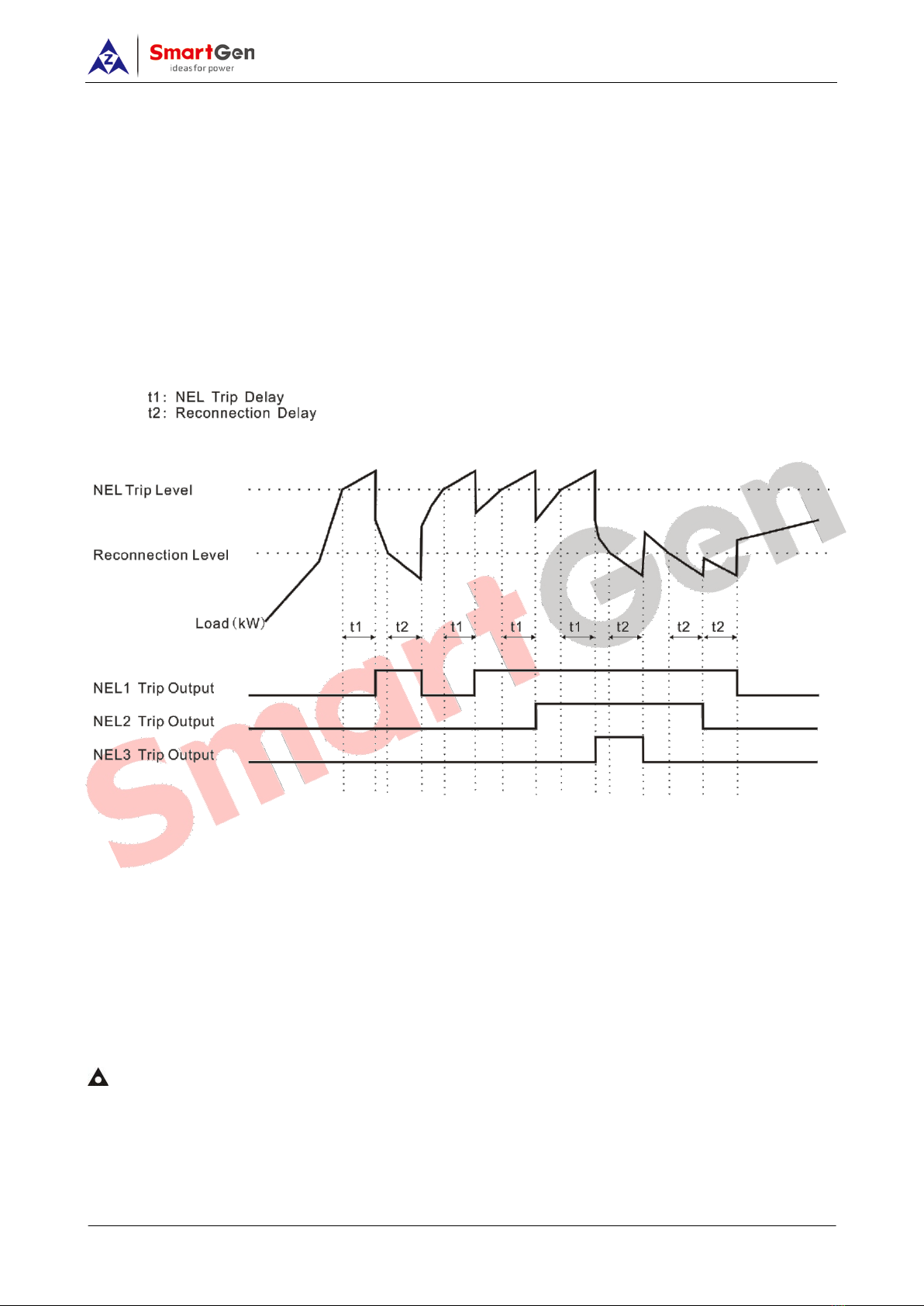

14 LOAD SHEDDING

Non-essential load ---- NEL for short.

The controller can control the NEL1, NEL2 and NEL3 to trip separately. The order of the essentiality is:

NEL3 > NEL2 > NEL1

Auto trip:

When NEL auto trip is enabled:

If the genset power has exceed the NEL trip value, after the trip delay, NEL1 will trip the earliest, and

then is NEL2,NEL3;

When NEL auto reconnection is enabled:

If the genset power has fallen below the auto reconnection set value, after the auto reconnection delay,

NEL3 will reconnection the earliest, and then is NEL2,NEL1;

Manual Trip

If NEL manual trip input is active (earthed failing edge is active), NEL1 will trip without delay; If NEL

manual trip input is active again, NEL2 will trip; If NEL manual trip input is active the third time, NEL3 will

trip. During this process, the controller do not detect if the genset power has exceed the NEL trip value or

not.

If NEL manual reconnection input is active (earthed failing edge is active), NEL3 will reconnect without

delay; If NEL manual reconnection input is active again, NEL2 will reconnect; If NEL manual

reconnection input is active the third time, NEL1 will reconnect. During this process, the controller

detects the genset power: if the genset power has fallen below the NEL reconnection value, then the

input is active; if it doesn’t, the input is deactivated.

Note: When auto trip and auto reconnection are enabled, manual trip is still active.

HGM9530 GENSET PARALLEL UNIT USER MANUAL

HGM9530 Genset Parallel Unit 2016-11-03 Version 1.4Page 56 of 65

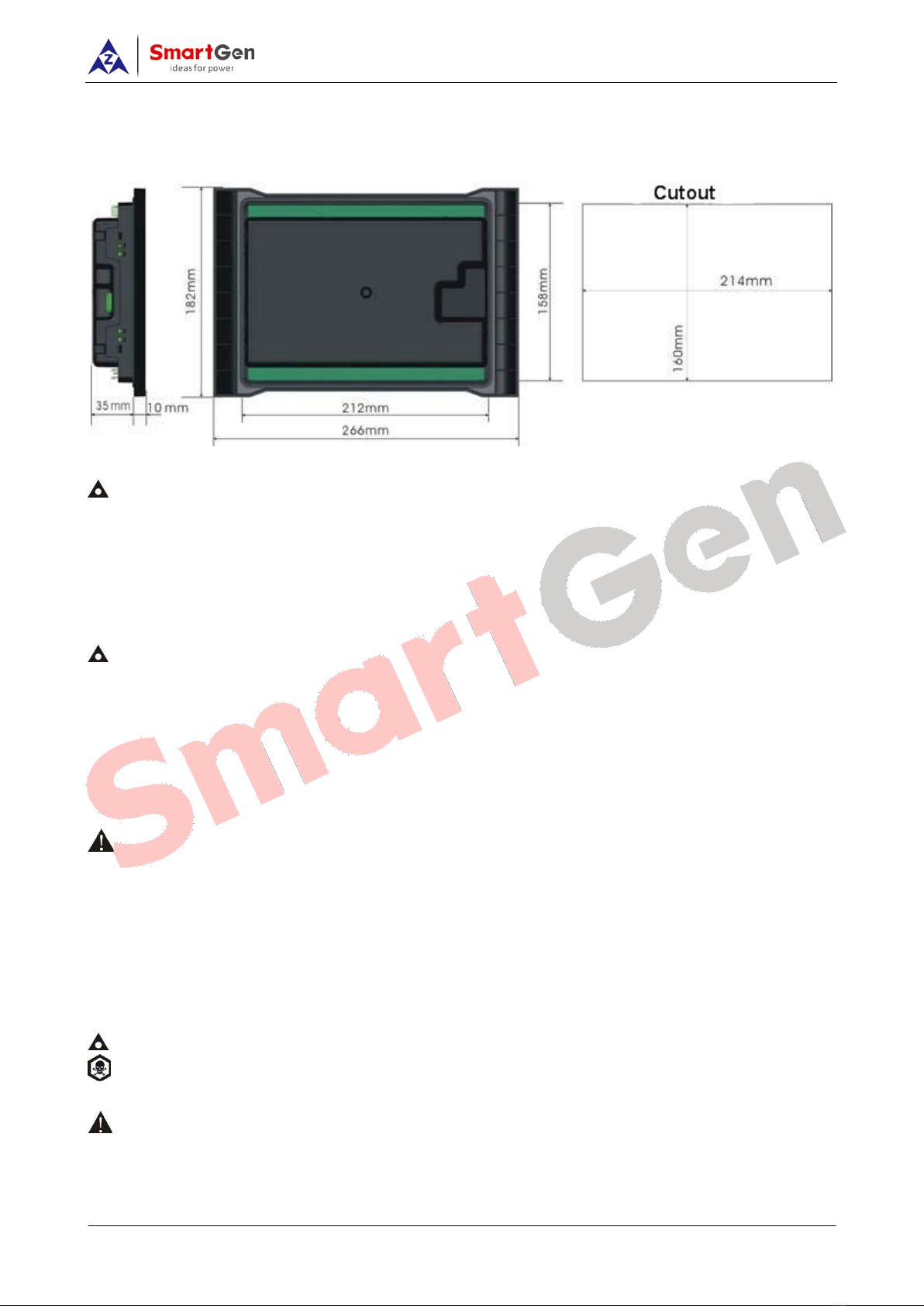

15 INSTALLATION

Controller is panel built-in design; it is fixed by clips when installed. The controller’s overall dimensions

and cutout dimensions for panel, please refers to as following,

1) Battery Voltage Input

NOTE: HGM9530 controller can suit for widely range of battery voltage (8~35) VDC. Negative of

battery must be connected with the shell of starter stable. The wire’s diameter must be over 2.5mm2 and

which is connected to B+ and B- of controller power. If floating charge configured, please firstly connect

output wires of charger to battery’s positive and negative directly, then, connect wires from battery’s

positive and negative to controller’s positive and negative input ports in order to prevent charge

disturbing the controller’s normal working.

2) Speed Sensor Input

NOTE: Speed sensor is the magnetic equipment which be installed in starter and for detecting teeth

of flywheel. Its connection wires to controller should apply for 2 cores shielding line. The shielding layer

should connect to No. 16 terminal in controller while another side is hanging in air. The else two signal

wires are connected to No.17 and No.18 terminals in controller. The output voltage of speed sensor

should be within AC(1~24)V (effective value) during the full speed. AC12V is recommended (in rated

speed). When install the speed sensor, let the sensor is spun to contacting flywheel first, then, port out

1/3 lap, and lock the nuts of sensor at last.

3) Output And Expand Relays

CAUTION: All outputs of controller are relay contact output type. If need to expand the relays, please

add freewheel diode to both ends of expand relay’s coils (when coils of relay has DC current) or,

increase resistance-capacitance return circuit (when coils of relay has AC current), in order to prevent

disturbance to controller or others equipment.

4) AC Input

Current input of controller must be connected to outside current transformer. And the current

transformer’s secondary side current must be 5A. At the same time, the phases of current transformer

and input voltage must correct. Otherwise, the current of collecting and active power maybe not correct.

NOTE: ICOM port must be connected to negative pole of battery.

WARNING! When there is load current, transformer’s secondary side prohibit open circuit.

5) Withstand Voltage Test

CAUTION! When controller had been installed in control panel, if need the high voltage test, please

disconnect controller’s all terminal connections, in order to prevent high voltage into controller and

damage it.

Table of contents

Other Smartgen Industrial Equipment manuals