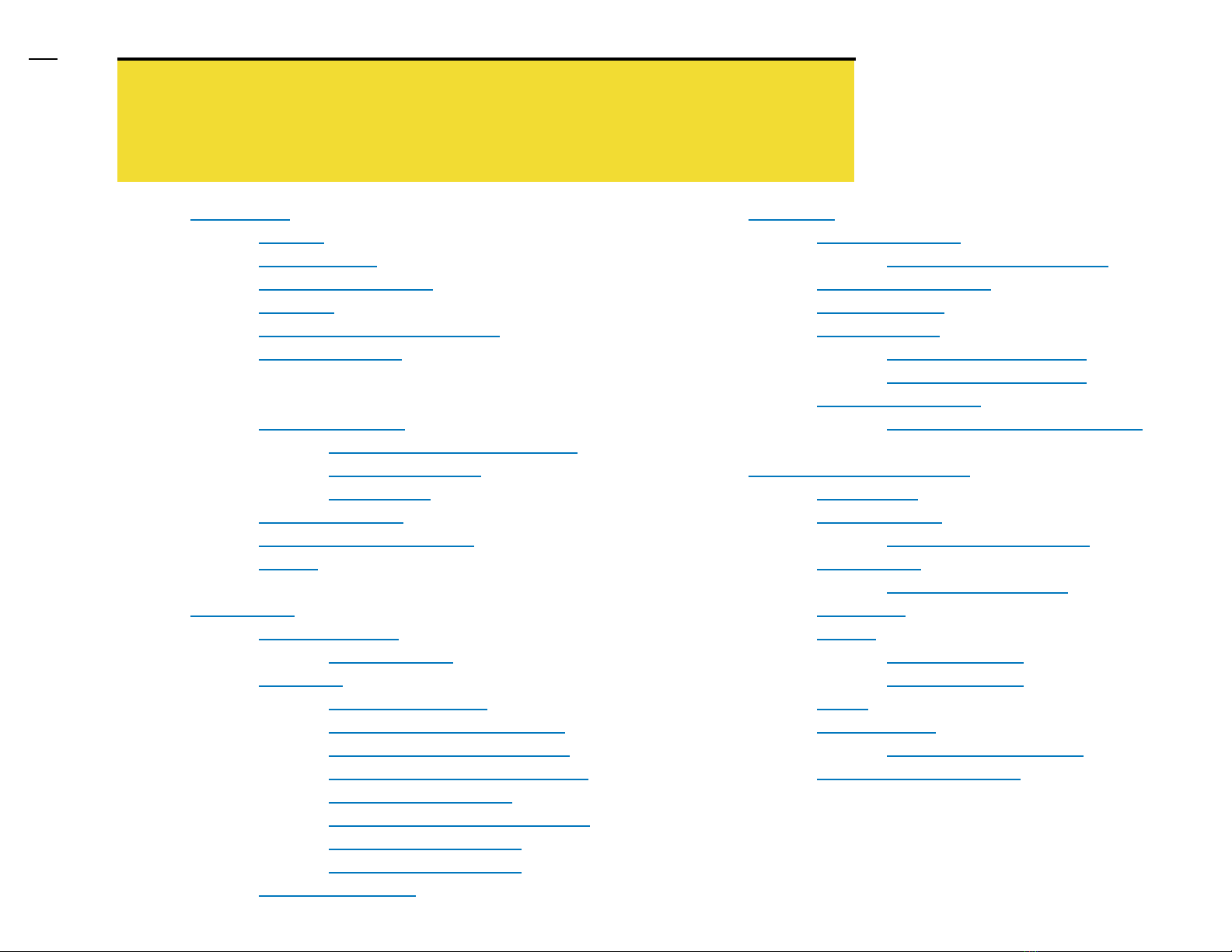

1.1 Warranty

PurePressure's trichome separators are built to last for many years with proper care. We want you to be satisfied with your equipment so

if there are ever any concerns, please do not hesitate to contact us. PurePressure guarantees the following warranty coverage for the Axis

Trichome Separator:

●2 year limited warranty against manufacturing defects for structural components (frame, sheet metal, and custom machined parts).

●1 year limited warranty against manufacturing defects for the entire trichome separator including electronic and pneumatic

components.

Warranty Replacements: In event of an approved warranty replacement or service, PurePressure will supply the necessary part(s) and special

tools, if needed. Shipping costs may be covered by PurePressure at its discretion.

Replacement Parts: Replacement parts for various components are available at reasonable prices for press owners directly from

PurePressure.

Exclusions: Warranty coverage eligibility will be determined by PurePressure and at PurePressure's sole discretion. PurePressure's

warranty obligations do not include (i) reasonable wear and tear; (ii) damage or corrosion caused by an electrical enclosure not being properly

closed/sealed; (iii) use of unapproved parts or unproved alterations to components; (iv) defects or damage caused by misuse, improper

electrical power supply, or compressed air inputs over 120 PSI (v) pneumatic components damaged from internal moisture or having been

pressurized with compressed air which is not clean or dry; (vi) vandalism, negligence, misuse or Force Majeure Events; or (vi) items expected to

be consumed or expended during the normal and routine operation and maintenance. This warranty is eligible for the original purchaser only

and is not transferable.

Disclaimer: Except as expressly set forth in this Limited Warranty and to the greatest extent allowed by law, PurePressure makes no other

representations, warranties or conditions, express or implied, including any implied representations, warranties or conditions of

merchantability, fitness for a particular purpose, non-infringement, and non-interference.

Warranty Procedures: If your automated washing machine is covered under the warranty period, please contact us with detailed information

regarding the issue you are experiencing so that we can get you operational as soon as possible. If you are experiencing a problem and are

outside of the warranty period, we will do everything in our power to get you affordable replacement component(s) in a timely manner. Please

send all warranty and replacement part related inquiries to support@gopurepressure.com. All returned parts must be accompanied by an RMA

number, which we will supply.

4